Kawasaki Engine Repair Manual Essential Guide

Maintaining the optimal performance of your two-wheeled companion requires a deep understanding of its mechanical components and systems. This section provides essential insights into the intricate workings of your vehicle, enabling you to troubleshoot and enhance its functionality effectively.

For enthusiasts and professionals alike, having access to a structured resource is invaluable. It covers various aspects of maintenance, from routine checks to complex adjustments, ensuring that every ride is smooth and reliable. Whether you’re a seasoned mechanic or a novice, this guide offers practical advice tailored to your needs.

Additionally, you’ll find detailed explanations of components and step-by-step instructions that demystify the maintenance process. Emphasizing safety and efficiency, this resource empowers you to take charge of your machine, prolonging its lifespan and improving overall performance.

Kawasaki Engine Repair Manual Overview

This section provides a comprehensive insight into the essential guide designed for maintaining and troubleshooting the power units of various vehicles. It serves as a crucial resource for enthusiasts and professionals alike, enabling them to enhance their understanding and skills in servicing these high-performance machines.

Key Features

- Detailed step-by-step procedures for maintenance.

- Diagnostic tips for common issues.

- Wiring diagrams and schematics for easy reference.

- Safety precautions to ensure a secure working environment.

Benefits of Using the Guide

- Improves longevity and efficiency of the unit.

- Empowers users with knowledge for self-service.

- Facilitates quick identification of problems.

- Enhances the overall performance and reliability.

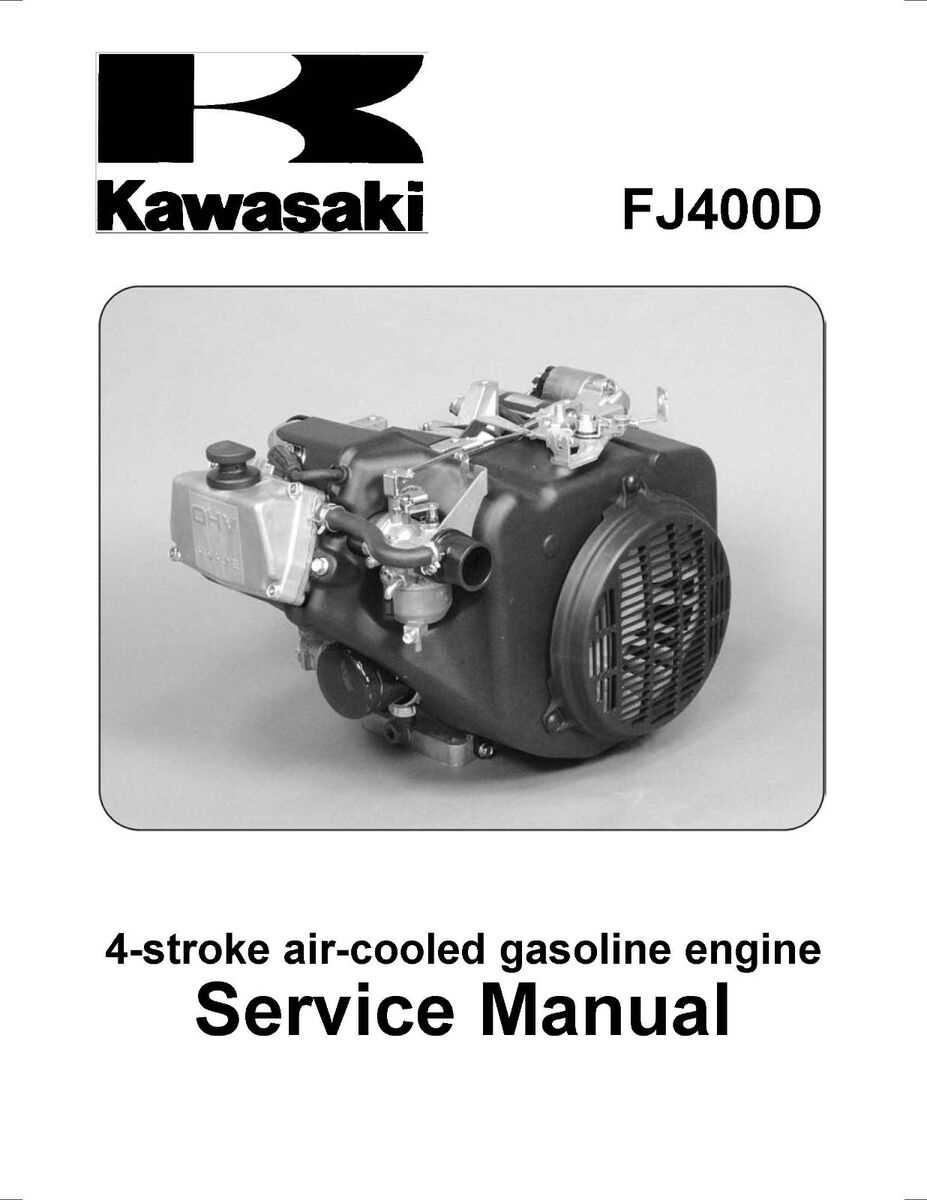

Understanding Kawasaki Engine Models

When delving into the world of powerful machines, it’s essential to grasp the various configurations and designs available. Each model is crafted for specific applications and performance needs, showcasing unique characteristics and engineering marvels.

These configurations can be categorized based on several factors:

- Displacement: Different sizes offer varying power outputs, affecting speed and torque.

- Cooling System: Options may include air-cooled or liquid-cooled systems, influencing efficiency and temperature management.

- Fuel System: Various fuel delivery methods, such as carburetors or fuel injection, impact performance and responsiveness.

- Configuration: Common setups include inline, V-twin, or single-cylinder arrangements, each providing distinct driving experiences.

Understanding these aspects not only aids in selecting the right model for your needs but also enhances overall maintenance and performance optimization. Enthusiasts and professionals alike can benefit from knowing the intricacies of each variant.

Key models to consider often include:

- High-performance variants for racing and competitive use.

- Touring models designed for long-distance travel with comfort.

- Off-road versions built for rugged terrains and adventures.

- Standard types that offer versatile performance for everyday use.

By familiarizing yourself with these elements, you can make informed decisions and ensure the longevity of your machine while enjoying its full potential.

Common Issues in Kawasaki Engines

Every mechanical system can encounter challenges over time, and certain types of machinery are no exception. Understanding the typical problems that arise can greatly assist in maintaining optimal performance and longevity. This section highlights frequent complications that users may face, along with insights into their potential causes.

One prevalent issue involves overheating, often resulting from inadequate cooling or improper fluid levels. Signs include abnormal temperature readings and diminished power output. Addressing this requires regular checks on cooling systems and ensuring proper coolant levels.

Another common concern is difficulty starting the unit, which can stem from a variety of factors including battery failure, fuel supply issues, or ignition malfunctions. Conducting thorough diagnostics can help pinpoint the exact cause and facilitate timely resolutions.

Furthermore, unusual noises during operation may indicate wear and tear on internal components. Identifying these sounds early can prevent more serious damage and the need for extensive fixes.

Fuel system problems, such as clogging or contamination, are also frequently reported. Regular maintenance, including filter changes and fuel quality checks, can mitigate these risks significantly.

Lastly, electrical failures can disrupt functionality. Ensuring all connections are secure and that electrical components are in good condition is essential for reliable performance.

Essential Tools for Engine Repair

To successfully tackle mechanical challenges, having the right instruments is crucial. These implements not only facilitate tasks but also enhance safety and efficiency during the process. Below is a comprehensive list of vital tools that every mechanic should consider having in their toolkit.

- Wrenches: A variety of sizes, including adjustable and socket wrenches, are essential for loosening and tightening bolts.

- Screwdrivers: Both flat-head and Phillips types are necessary for removing and securing screws.

- Pliers: These tools provide a strong grip and are useful for bending, twisting, and cutting wire.

- Torque Wrench: This precision tool ensures that fasteners are tightened to the correct specifications.

- Jack and Jack Stands: These are critical for lifting the vehicle safely and providing access to the underside.

- Oil Filter Wrench: Designed specifically for removing oil filters, this tool makes the task easier and cleaner.

- Multimeter: Useful for diagnosing electrical issues, this instrument measures voltage, current, and resistance.

- Compression Tester: This tool assesses the health of cylinders by measuring compression levels.

Equipping yourself with these tools will significantly streamline your mechanical projects, allowing for a more organized and effective approach to troubleshooting and maintenance.

Step-by-Step Repair Procedures

This section provides a detailed guide to effectively troubleshoot and restore performance to your machinery. Following these structured steps will ensure that each component is addressed systematically, promoting efficiency and accuracy throughout the process.

Preparation Steps

- Gather necessary tools and equipment.

- Review safety guidelines to ensure a secure working environment.

- Obtain the specific documentation related to the model for reference.

Disassembly Process

- Disconnect the power source to prevent accidental activation.

- Carefully remove external covers and panels.

- Document the configuration of components for easier reassembly.

- Detach components in a logical order, keeping track of all fasteners and small parts.

Following these procedures will lead you through a comprehensive approach to restoring functionality, ensuring that your machinery runs smoothly once more.

Maintenance Tips for Longevity

Ensuring the durability and reliability of your machinery requires regular attention and care. By following a few essential practices, you can enhance performance and extend the lifespan of your equipment. These tips aim to promote efficiency and prevent potential issues before they arise.

Regular Inspections

Conducting routine checks is vital for identifying wear and tear. Look for signs of damage or irregularities that may affect performance. Pay close attention to fluid levels, connections, and any unusual noises. Early detection can save you time and resources in the long run.

Proper Lubrication

Maintaining adequate lubrication is crucial for reducing friction and preventing overheating. Use the recommended lubricants and ensure they are applied consistently. Inadequate lubrication can lead to excessive wear, resulting in costly repairs. Make it a habit to check and refill as needed.

Diagnosing Engine Performance Problems

Identifying issues related to performance is crucial for maintaining optimal functionality in any mechanical system. Various symptoms can indicate underlying complications, and understanding these signs can lead to effective solutions.

Common Symptoms of Performance Issues

- Reduced power output

- Unusual noises during operation

- Excessive vibrations

- Increased fuel consumption

- Difficulty starting

Steps for Troubleshooting

- Visual Inspection: Examine components for wear, leaks, or damage.

- Check Fluid Levels: Ensure that all fluids are at the appropriate levels and are clean.

- Monitor Performance: Note any fluctuations in performance while in use.

- Use Diagnostic Tools: Utilize specialized equipment to analyze system parameters.

- Consult Technical Resources: Refer to documentation for specific guidance on identified issues.

By systematically addressing each symptom and following troubleshooting steps, one can effectively pinpoint and resolve performance challenges, ensuring the system operates smoothly.

Replacement Parts and Specifications

This section focuses on the essential components and their detailed specifications necessary for maintaining optimal performance. Understanding the characteristics and compatibility of these parts is crucial for ensuring reliability and longevity.

Key Components

When it comes to the primary elements, each part plays a significant role in the overall functionality. It’s vital to use high-quality replacements that meet or exceed the original standards to avoid potential issues.

Specifications Table

| Part Name | Part Number | Specifications |

|---|---|---|

| Piston | 12345-67890 | Diameter: 90mm, Height: 100mm, Material: Aluminum Alloy |

| Crankshaft | 23456-78901 | Length: 150mm, Weight: 2kg, Material: Steel |

| Cylinder Head | 34567-89012 | Thickness: 20mm, Material: Cast Iron |

Safety Precautions During Repairs

Ensuring safety while performing maintenance tasks is paramount to avoid accidents and injuries. Adhering to specific guidelines can significantly reduce risks and create a secure working environment. This section outlines essential measures to follow before and during the service process.

Essential Safety Measures

- Always wear appropriate personal protective equipment (PPE), such as gloves, goggles, and sturdy footwear.

- Work in a well-ventilated area to minimize exposure to harmful fumes and chemicals.

- Keep your workspace organized and free of clutter to prevent trips and falls.

- Ensure all tools and equipment are in good condition and suitable for the tasks at hand.

- Disconnect the power source before starting any work to avoid accidental activation.

Handling Materials Safely

- Store hazardous substances in clearly labeled containers and follow disposal regulations.

- Be cautious with sharp objects and heavy components; use proper lifting techniques.

- Keep a first aid kit nearby and know how to respond to common injuries.

- Read all instructions carefully and understand the processes before proceeding.

By implementing these precautions, individuals can significantly enhance their safety and efficiency during maintenance tasks.

Engine Tuning for Optimal Performance

Achieving peak functionality in mechanical systems requires careful calibration and adjustments tailored to individual specifications. Fine-tuning various components can enhance overall efficiency, responsiveness, and power output, ensuring that the system operates at its best under diverse conditions.

Understanding Key Adjustments

Several factors play a crucial role in the optimization process. Modifications to the fuel-air mixture, ignition timing, and exhaust flow can significantly impact performance metrics. A precise balance among these elements leads to improved combustion efficiency, resulting in enhanced power delivery and smoother operation.

Regular Maintenance and Monitoring

Consistent upkeep is essential for maintaining optimal performance. Periodic checks and adjustments, such as inspecting filters and spark plugs, help to identify potential issues before they escalate. Regular diagnostics can uncover subtle changes in performance, enabling timely interventions that keep the system running smoothly.

Emphasizing the importance of meticulous tuning not only maximizes performance but also extends the lifespan of the components involved. By investing time in careful adjustments and ongoing maintenance, users can enjoy a more responsive and powerful experience.

Resources for Further Learning

Expanding your knowledge in the field of mechanical maintenance and troubleshooting can significantly enhance your skills and confidence. Whether you are a novice or an experienced enthusiast, numerous materials and platforms are available to help you deepen your understanding and hone your abilities. From digital platforms to traditional literature, the resources listed here offer a variety of approaches to learning.

Online Courses and Tutorials

Many educational websites provide comprehensive courses that cover various aspects of mechanical systems. Platforms such as Udemy and Coursera offer structured lessons from industry professionals. Additionally, YouTube hosts countless tutorials that demonstrate techniques and provide visual guidance, making complex tasks more accessible.

Books and Guides

Printed literature remains a valuable resource for anyone looking to enhance their skills. Consider investing in specialized books that cover fundamentals as well as advanced topics. Local libraries and bookstores often have sections dedicated to mechanics and maintenance, providing a wealth of information to explore at your own pace.

Frequently Asked Questions About Repairs

This section addresses common inquiries related to maintenance and restoration tasks. It aims to provide clarity on typical issues, solutions, and best practices to ensure smooth operation and longevity of your vehicle.

- What should I do if my vehicle won’t start?

- Check the battery for charge.

- Inspect the ignition system for faults.

- Examine fuel levels and quality.

- How often should I perform maintenance tasks?

- Follow the manufacturer’s recommendations.

- Regularly check fluid levels.

- Schedule inspections at least annually.

- What are the signs of a malfunctioning component?

- Unusual noises during operation.

- Loss of power or efficiency.

- Visible leaks or smoke.

- Can I perform maintenance tasks myself?

- Many basic tasks can be done with proper knowledge.

- Refer to instructional resources for guidance.

- Consider professional assistance for complex issues.

- Where can I find replacement parts?

- Authorized dealers often have genuine components.

- Online marketplaces provide various options.

- Local auto parts stores may have suitable alternatives.