Comprehensive Guide to Automotive Air Conditioning Repair

The intricate systems within modern vehicles are crucial for maintaining comfort and safety. Understanding these components is essential for ensuring optimal performance and longevity. This section will delve into the various aspects of climate control, emphasizing the importance of regular maintenance and troubleshooting techniques.

Whether dealing with issues such as insufficient cooling, unusual noises, or system failures, a thorough grasp of the underlying mechanisms can empower vehicle owners and technicians alike. By exploring practical solutions and preventive measures, readers will gain valuable insights into maintaining their vehicle’s comfort systems effectively.

In addition to addressing common problems, this guide will outline essential tools and techniques that can facilitate effective interventions. With a focus on fostering knowledge and confidence, it aims to enhance the reader’s ability to tackle climate control challenges head-on, ensuring a comfortable driving experience.

Understanding Automotive Air Conditioning Systems

In today’s vehicles, maintaining a comfortable environment is essential for both driver and passengers. The cooling mechanism plays a vital role in ensuring optimal temperatures within the cabin, especially during warm weather. This section explores the fundamental principles and components that contribute to effective climate control in vehicles.

Key Components of Air Conditioning Systems

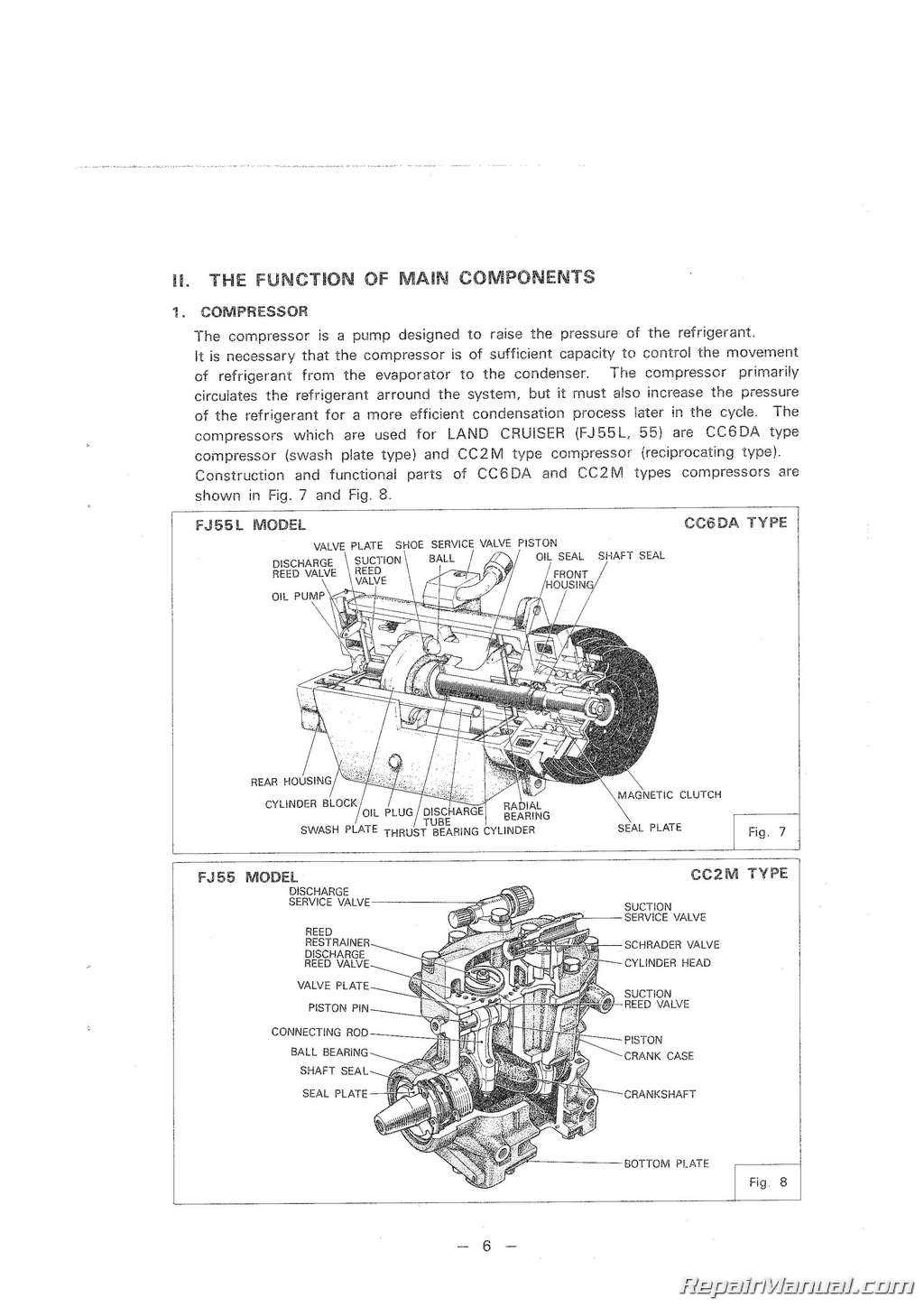

The cooling system comprises several critical parts, each working in unison to provide efficient operation. The primary elements include the compressor, condenser, evaporator, and expansion valve. The compressor pressurizes the refrigerant, enabling it to circulate through the system. Next, the refrigerant travels to the condenser, where it dissipates heat and transforms into a liquid state. Once cooled, it moves to the evaporator, where it absorbs heat from the cabin, providing the desired cooling effect.

How the System Functions

The functioning of the cooling mechanism relies on the principles of thermodynamics. As the refrigerant circulates, it undergoes various phase changes that allow it to absorb and release heat effectively. When the refrigerant evaporates in the evaporator, it extracts warmth from the air inside the vehicle, resulting in a cool atmosphere. This cycle continues, maintaining a comfortable climate regardless of external temperatures. Understanding these processes is crucial for anyone looking to troubleshoot or enhance the performance of vehicle climate systems.

Common AC Problems in Vehicles

Air conditioning systems in vehicles can encounter a variety of issues that affect their performance and efficiency. Recognizing these common problems is essential for maintaining a comfortable driving experience. This section explores some frequent challenges faced by vehicle AC systems and their potential causes.

| Problem | Symptoms | Possible Causes |

|---|---|---|

| Insufficient Cooling | Air feels warm or less cool than expected | Low refrigerant levels, faulty compressor, blocked condenser |

| Strange Noises | Unusual sounds when AC is in use | Worn-out compressor, loose components, debris in the system |

| Odors | Unpleasant smells when AC is running | Mold or mildew in the system, clogged air filter |

| AC Does Not Turn On | System fails to activate | Electrical issues, blown fuse, faulty thermostat |

| Frequent Cycling | Compressor turns on and off rapidly | Low refrigerant, malfunctioning pressure switch, overheating |

Diagnostic Tools for AC Repair

In the realm of air conditioning systems, effective troubleshooting relies heavily on a variety of diagnostic instruments. These tools enable technicians to assess the performance of cooling systems, pinpoint issues, and ensure optimal functionality. Understanding how to utilize these devices is crucial for anyone looking to maintain or enhance the efficiency of their climate control systems.

Common Diagnostic Instruments

Several essential tools are commonly employed during the evaluation process. Among these, manifold gauges stand out as invaluable for measuring pressure levels in both high and low sides of the system. Thermometers and vacuum pumps also play critical roles, allowing technicians to gauge temperature differences and remove moisture from the system, respectively. Together, these instruments provide a comprehensive view of the system’s health.

Advanced Diagnostic Equipment

For more in-depth analysis, advanced devices such as electronic leak detectors and scan tools have become increasingly popular. These sophisticated instruments not only identify refrigerant leaks but also access vehicle data to highlight potential issues within the system. Utilizing such technology can lead to more accurate diagnostics and efficient resolutions.

Step-by-Step AC Troubleshooting Guide

This guide aims to provide a systematic approach to diagnosing issues with air conditioning systems. By following these steps, you can identify common problems and implement effective solutions to restore optimal performance.

Identifying the Problem

The first step in troubleshooting is to recognize the signs of malfunction. Common indicators include:

- No cool air – If the system fails to produce cold air, it may be a sign of low refrigerant levels or a malfunctioning compressor.

- Unusual noises – Sounds such as hissing or grinding can indicate issues with internal components.

- Weak airflow – Insufficient airflow could result from a clogged filter or ductwork problems.

Conducting the Diagnosis

Once you’ve identified potential issues, proceed with the following checks:

- Check the thermostat settings – Ensure the thermostat is set to a lower temperature than the current room temperature.

- Inspect the air filter – A dirty or blocked filter can restrict airflow, so replace or clean it as necessary.

- Examine the outdoor unit – Ensure the unit is free of debris and that the fan is operational.

By systematically following these steps, you can efficiently troubleshoot and resolve air conditioning issues, ensuring a comfortable environment.

Refrigerant Types and Their Uses

Understanding the various categories of refrigerants is essential for maintaining and optimizing cooling systems. Different substances serve unique functions, impacting efficiency, environmental safety, and compatibility with equipment. This section explores the distinct types of refrigerants commonly employed in various applications.

1. Hydrofluorocarbons (HFCs): These are among the most widely used refrigerants due to their effective heat transfer properties and relatively low toxicity. HFCs, such as R-134a and R-410A, are favored for their stability and efficiency in both residential and commercial cooling units.

2. Hydrocarbons (HCs): Natural refrigerants like propane (R-290) and isobutane (R-600a) are gaining popularity due to their minimal environmental impact. These substances offer high energy efficiency but require careful handling due to their flammability.

3. Carbon Dioxide (CO2): Known as R-744, this refrigerant is an environmentally friendly alternative with a low global warming potential. CO2 systems operate efficiently under high pressure, making them suitable for various commercial refrigeration applications.

4. Ammonia (NH3): Ammonia is a traditional refrigerant widely utilized in industrial settings. Its excellent thermodynamic properties and low environmental impact make it an attractive choice, though it is toxic and requires safety precautions during use.

5. Blends: Refrigerant mixtures, such as R-407C and R-404A, combine different refrigerants to achieve desired performance characteristics. These blends can provide benefits like improved efficiency and reduced environmental impact compared to single-component refrigerants.

Each type of refrigerant presents distinct advantages and challenges, emphasizing the importance of selecting the appropriate substance for specific cooling needs.

How to Recharge Your AC System

Maintaining an efficient cooling system is essential for a comfortable driving experience. Over time, refrigerant levels can deplete, leading to reduced cooling performance. This section outlines the steps to restore the refrigerant levels, ensuring your air conditioning system operates effectively.

Gather Necessary Tools

Before beginning the recharging process, make sure you have the following tools on hand: a refrigerant canister, a pressure gauge, and a set of safety goggles. These items are crucial for accurately measuring pressure and ensuring safety during the procedure.

Recharging Process

Start by locating the service ports on your system, typically found near the compressor. Attach the pressure gauge to the low-pressure port and check the current refrigerant level. If it’s below the recommended range, proceed to connect the refrigerant canister. Follow the manufacturer’s instructions for introducing the refrigerant into the system, monitoring the pressure gauge to avoid overcharging. Once the desired pressure is reached, disconnect the canister and check for any leaks before closing the ports securely.

Replacing AC Components Safely

Ensuring a secure and effective replacement of cooling system elements is essential for maintaining optimal functionality and safety. Proper precautions and procedures not only protect the individual performing the work but also contribute to the longevity and efficiency of the system.

Preparation and Precautions

Before beginning any work, gather the necessary tools and protective equipment. This includes safety goggles, gloves, and a suitable workspace. Familiarize yourself with the specific components being replaced and consult the guidelines for discharging refrigerants safely. Always work in a well-ventilated area to minimize exposure to harmful substances.

Steps for Safe Component Replacement

Begin by disconnecting the power source to prevent accidental activation. Carefully remove the old component, ensuring to take note of the connections for reassembly. Handle refrigerants with care, using appropriate recovery equipment to avoid releasing them into the atmosphere. When installing the new component, ensure all seals are intact and connections are secure. Finally, recharge the system as needed and check for any leaks or issues.

By following these guidelines, you can effectively replace cooling system components while prioritizing safety and performance.

Importance of Regular Maintenance

Routine upkeep is essential for ensuring optimal performance and longevity of any vehicle. By following a consistent maintenance schedule, owners can prevent potential issues before they escalate into costly repairs.

Regular servicing offers several benefits, including:

- Enhanced Safety: Routine checks can identify potential hazards, ensuring the vehicle operates safely.

- Improved Efficiency: Keeping components in good condition can lead to better fuel efficiency and lower operating costs.

- Increased Resale Value: A well-maintained vehicle is often more attractive to buyers, enhancing its market value.

- Extended Lifespan: Regular maintenance can prolong the life of key components, reducing the need for premature replacements.

To maximize these benefits, it is important to adhere to a maintenance schedule that includes:

- Checking and changing fluids regularly.

- Inspecting tires for wear and proper inflation.

- Replacing filters as needed.

- Reviewing brake systems periodically.

In conclusion, maintaining a consistent upkeep routine not only enhances vehicle performance but also promotes safety and reliability on the road.

Signs You Need Professional Help

Recognizing when to seek expert assistance can prevent minor issues from escalating into major problems. Certain indicators suggest that a trained technician should handle the situation to ensure safety and effectiveness.

- Unusual Noises: If you hear grinding, clunking, or whining sounds, it may indicate underlying issues that require immediate attention.

- Warning Lights: Dashboard warning lights, such as the check engine light, are signs that something is wrong. Ignoring them can lead to further complications.

- Fluid Leaks: Puddles or spots beneath your vehicle may signal leaks from crucial systems, which should be investigated by a professional.

- Changes in Performance: A noticeable decline in acceleration, braking, or handling may indicate that your vehicle needs expert evaluation.

- Frequent Breakdowns: Regular mechanical failures or the need for constant adjustments often suggest that a thorough inspection by a specialist is necessary.

- Unfamiliar Smells: Strange odors, such as burning or fuel smells, can be warning signs of serious issues that require immediate professional assessment.

Addressing these signs promptly can save you time and money while ensuring your vehicle remains safe and reliable.

Cost Factors in AC Repairs

The expense associated with restoring air conditioning systems can vary significantly based on multiple elements. Understanding these factors is essential for budgeting and making informed decisions when issues arise.

Labor Costs

Labor costs typically represent a substantial portion of the overall expenses. Rates can differ based on geographic location, the complexity of the job, and the technician’s expertise. Hiring a skilled professional may incur higher fees but can lead to better long-term outcomes.

Parts and Components

The price of parts plays a critical role in determining total expenses. Different systems may require specific components, some of which can be costly. It’s also worth noting that the availability of parts can influence their price; rare or discontinued items may command premium rates.

Additionally, unexpected issues discovered during the evaluation may lead to additional expenses. It’s wise to consider all these elements when planning for air conditioning system maintenance.

Upgrading Your Vehicle’s AC System

Enhancing the cooling system in your vehicle can significantly improve comfort, efficiency, and overall performance. Whether you’re looking to replace outdated components or integrate advanced technology, upgrading your cooling setup can be a rewarding endeavor. This section provides insight into the benefits of modernization and the various options available for enhancing your system.

When considering an upgrade, it’s important to evaluate the existing components and determine the most effective replacements or enhancements. Here are some common upgrades to consider:

| Upgrade Option | Description | Benefits |

|---|---|---|

| High-Efficiency Compressors | Replace standard compressors with high-efficiency models that consume less power. | Improved fuel economy and enhanced cooling performance. |

| Enhanced Condensers | Upgrade to larger or more efficient condensers to increase heat dissipation. | Better cooling capacity, especially in hot climates. |

| Upgraded Blower Fans | Install higher-capacity blower fans for improved airflow. | Faster cooling and more consistent cabin temperature. |

| Climate Control Systems | Integrate advanced climate control technologies for customizable comfort settings. | Increased convenience and enhanced user experience. |

Upgrading the cooling system not only elevates comfort but also contributes to the longevity of the vehicle. Regular maintenance combined with strategic enhancements can lead to a more enjoyable driving experience, making it worthwhile for any owner looking to invest in their vehicle’s future.

Environmental Impact of AC Repairs

Addressing issues in climate control systems is essential not only for vehicle performance but also for minimizing ecological footprints. The processes involved in servicing these systems can have significant environmental repercussions if not managed responsibly.

One of the primary concerns is the release of refrigerants. These substances, often containing greenhouse gases, can contribute to global warming when they escape into the atmosphere. Therefore, proper handling and disposal are crucial to mitigate their impact.

Key aspects to consider include:

- Refrigerant Management: Utilizing recovery systems to capture refrigerants prevents their release and ensures compliance with environmental regulations.

- Waste Disposal: Properly disposing of components such as compressors, condensers, and hoses is vital. Many of these parts can contain harmful materials that require specialized handling.

- Energy Consumption: The energy used during maintenance procedures can contribute to a larger carbon footprint. Employing energy-efficient practices and tools can help reduce this effect.

- Regulatory Compliance: Following local and international environmental laws ensures that all practices adhere to standards designed to protect the ecosystem.

By being aware of these factors, individuals and businesses can take proactive steps to minimize their environmental impact while maintaining effective climate control systems.