Comprehensive Guide to Fmx Transmission Repair

This section focuses on the essential aspects of understanding and maintaining automatic gear systems commonly found in various vehicles. Proper knowledge and techniques can significantly enhance the longevity and performance of these intricate components. Whether you’re a seasoned mechanic or an enthusiastic DIYer, having a comprehensive understanding of these systems is crucial for successful operation and troubleshooting.

It covers the intricacies involved in diagnosing issues, performing routine upkeep, and addressing common malfunctions. By familiarizing yourself with the various parts and their functions, you can ensure smooth operation and optimal efficiency. The information provided aims to equip you with the skills and knowledge needed to handle typical challenges encountered in this area.

Through detailed instructions and practical insights, this guide empowers you to approach maintenance tasks with confidence. Gaining a thorough understanding of the operational principles will enable you to implement effective solutions and make informed decisions regarding the upkeep of automatic gear systems. Embracing these practices can lead to a more reliable driving experience and enhance the overall performance of your vehicle.

Undertaking maintenance on complex machinery necessitates the right equipment to ensure effective and safe procedures. Proper tools enhance efficiency, allowing for precise work and minimizing the risk of damage during the process.

Here is a list of essential instruments that will facilitate your work:

- Socket Set: A comprehensive set is vital for loosening and tightening various fasteners.

- Wrench Set: Different sizes are necessary to accommodate various nuts and bolts.

- Torque Wrench: Ensures fasteners are tightened to the manufacturer’s specifications.

- Seal Installer: Used for correctly fitting seals to prevent leaks.

- Fluid Pump: Essential for transferring oils and fluids without spills.

- Gasket Scraper: Helps remove old gaskets efficiently, ensuring a clean surface for new gaskets.

- Inspection Mirror: Allows for visual checks in hard-to-reach areas.

- Magnetic Pick-Up Tool: Useful for retrieving dropped metal components.

- Diagnostic Scanner: Assists in identifying electronic issues and performance problems.

- Work Light: Ensures visibility in dimly lit areas for safer and more effective work.

Equipping yourself with these tools will enhance your ability to conduct thorough evaluations and effectively service the machinery, leading to improved performance and longevity.

Step-by-Step Repair Process Overview

This section outlines a systematic approach to addressing issues in complex mechanical systems. By following a structured procedure, technicians can effectively diagnose problems, perform necessary adjustments, and ensure optimal functionality. Each step is designed to facilitate a thorough understanding and execution of tasks, ultimately leading to enhanced performance and reliability.

1. Initial Assessment

The first stage involves a comprehensive evaluation of the unit in question. This includes gathering information on the symptoms observed, conducting visual inspections, and performing diagnostic tests. Establishing a clear understanding of the underlying issues is crucial for effective intervention.

2. Disassembly and Component Inspection

Following the initial assessment, the next phase requires careful disassembly of the assembly. During this process, each component should be inspected for wear, damage, or irregularities. Identifying problematic parts is essential for determining the appropriate course of action, whether it involves replacement, refurbishment, or further examination.

By adhering to these steps, technicians can ensure a methodical and efficient approach to resolving issues, thereby enhancing the longevity and functionality of the system.

Diagnostic Techniques for Transmission Problems

Identifying issues within the gear-shifting system requires a systematic approach. Employing effective diagnostic methods can significantly enhance the troubleshooting process, leading to timely and accurate resolutions. Utilizing both visual inspections and advanced tools is essential in pinpointing the underlying causes of irregularities.

Visual Inspection

A comprehensive visual examination can reveal numerous indicators of malfunction. Consider the following steps:

- Check for leaks under the vehicle.

- Inspect hoses and connections for wear or damage.

- Examine the fluid condition, looking for discoloration or particles.

- Listen for unusual noises during operation.

Diagnostic Tools

Incorporating specialized instruments can facilitate a more in-depth analysis. Recommended tools include:

- Scan Tool: Utilize this device to read error codes from the onboard computer.

- Pressure Gauge: Measure the hydraulic pressure to ensure it meets the manufacturer’s specifications.

- Fluid Tester: Assess the quality and level of the working fluid.

Preventive Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the durability and performance of automotive systems. Implementing a series of preventive measures can significantly extend the lifespan of these components. By following best practices, vehicle owners can avoid costly breakdowns and enhance overall efficiency.

Routine Inspections

Conducting periodic checks is vital. Inspect fluid levels, hoses, and connections to identify any signs of wear or leakage. Addressing minor issues early can prevent them from escalating into major problems.

Fluid Changes

Regularly changing fluids is crucial for maintaining optimal function. Ensure that all lubricants and coolants are replaced according to the manufacturer’s recommendations. This practice not only helps in preventing overheating but also minimizes friction, enhancing performance.

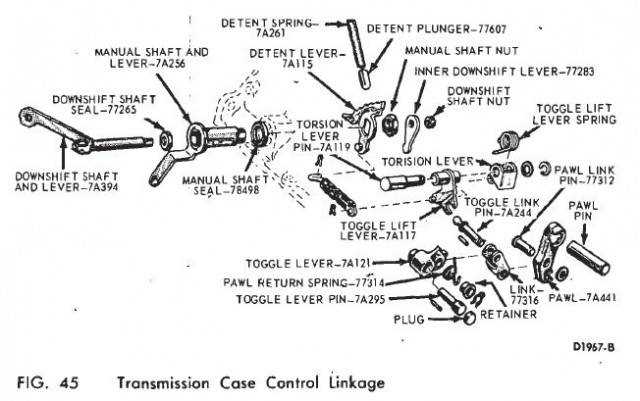

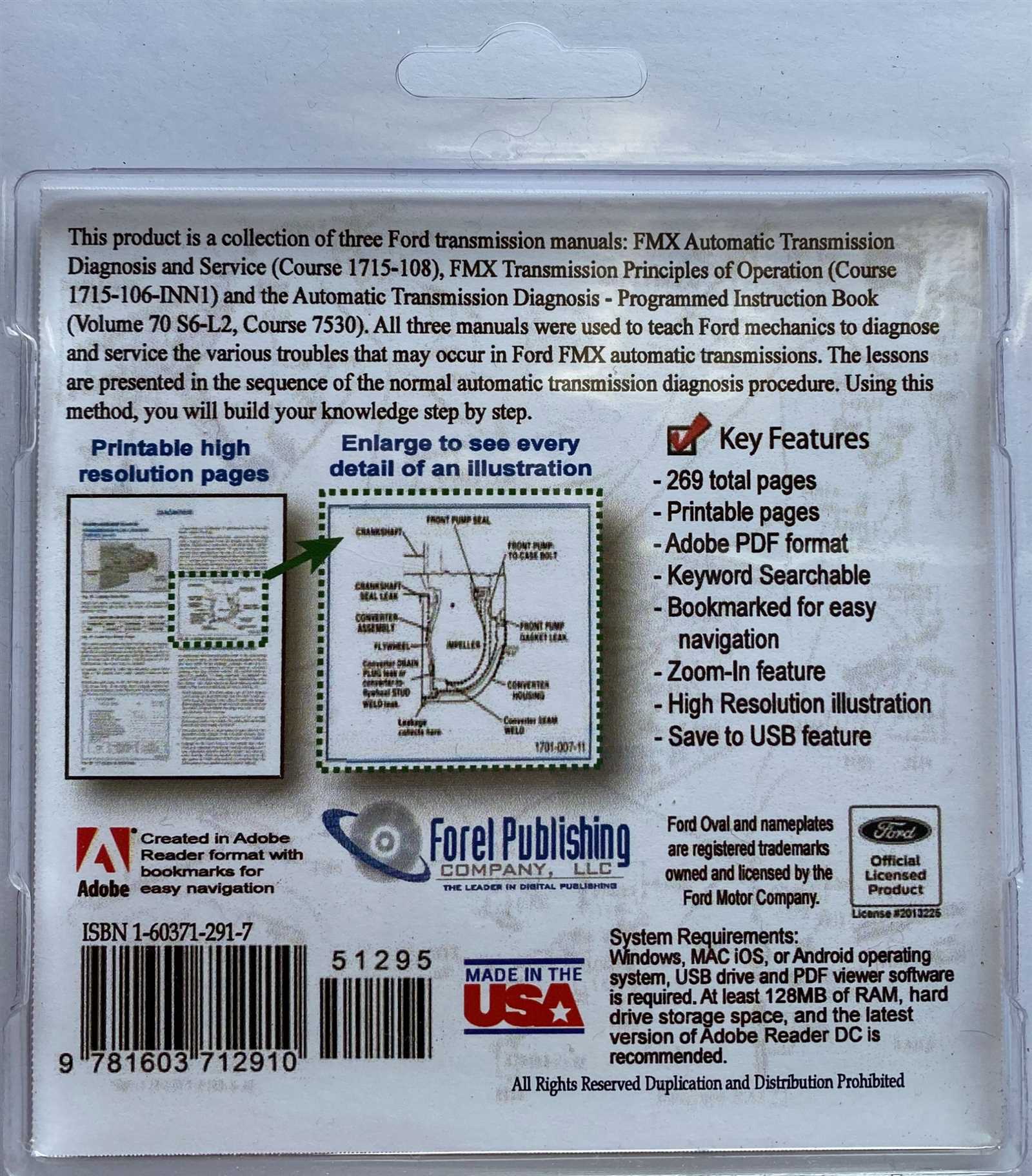

FMX Transmission Parts and Components

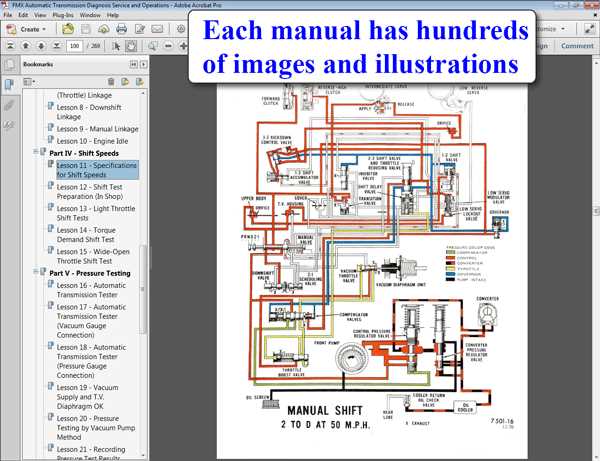

This section delves into the essential elements and mechanisms that comprise a specific type of power transfer system. Understanding these components is crucial for ensuring optimal performance and longevity. Each part plays a vital role in the overall functionality, contributing to the smooth operation and efficiency of the vehicle.

Key Elements

The main components include the gear sets, valve bodies, and clutch assemblies. Gear sets are responsible for changing the torque and speed of the output, while valve bodies manage fluid flow to engage and disengage various functions. Clutch assemblies are essential for the seamless shifting between different operating modes, ensuring power is transmitted effectively.

Additional Components

Other noteworthy parts include the input and output shafts, which facilitate the connection to the engine and drive wheels, respectively. Additionally, filters and fluid pumps are crucial for maintaining cleanliness and proper lubrication within the system. Each component must be carefully inspected and maintained to prevent potential failures and ensure reliable performance.

Identifying Wear and Damage

Recognizing signs of deterioration and impairment is crucial for maintaining optimal performance in any mechanical system. Observing components for irregularities can help prevent significant failures and extend the lifespan of the equipment.

Visual Inspection: Start with a thorough visual assessment of the parts. Look for cracks, discoloration, or unusual wear patterns that may indicate stress or excessive use. Pay close attention to surfaces that experience friction or are subjected to high loads.

Functional Testing: Conduct tests to evaluate functionality. Listen for unusual noises or vibrations that could signify internal issues. Perform operational checks to ensure all systems respond as expected under load.

Measurement Techniques: Utilize measuring tools to assess clearances and tolerances. Comparing current measurements to specified standards can highlight any deviations that suggest wear or damage.

Fluid Analysis: Analyzing lubricants can provide insights into the condition of internal components. Contaminants or metal particles in the fluid may indicate wear and necessitate further investigation.

By systematically evaluating these aspects, one can effectively identify and address issues before they escalate, ensuring the longevity and reliability of the system.

Cost Estimates for Repairs

When addressing mechanical issues in vehicles, understanding the financial implications is crucial for effective budgeting. Various factors influence the overall expenses involved, including the complexity of the task, the quality of parts needed, and the labor rates charged by service providers. By estimating these costs in advance, vehicle owners can make informed decisions about the necessary work.

Parts costs often vary significantly based on the brand and model of the vehicle. Genuine components may come at a premium price compared to aftermarket alternatives. Therefore, it is wise to compare different suppliers and consider warranties offered on parts. This can save money in the long run while ensuring quality performance.

Another important factor is labor charges. Rates can differ based on geographic location and the shop’s expertise. Some facilities might offer a flat rate for specific services, while others charge hourly. It’s advisable to obtain quotes from multiple shops to gauge the average costs in the area.

In conclusion, a comprehensive understanding of potential costs associated with mechanical work allows for better planning and can help avoid unexpected financial strain. Gathering estimates on both parts and labor will ensure that vehicle owners are well-prepared for any upcoming services.

When to Seek Professional Help

Understanding when to consult an expert can save you time and prevent further complications. Certain situations may arise where self-diagnosis or basic troubleshooting does not yield results. Recognizing these moments is crucial for maintaining the longevity and efficiency of your vehicle’s system.

Signs of Serious Issues

If you notice persistent unusual noises, fluid leaks, or erratic behavior, it is advisable to seek assistance. Ignoring these warning signs can lead to more significant problems down the line. Consulting a specialist can help identify underlying issues before they escalate.

Complex Problems Beyond DIY Solutions

Some situations require advanced knowledge and specialized tools that the average vehicle owner may not possess. If you’re faced with intricate issues that demand technical expertise, do not hesitate to reach out for professional guidance. Investing in expert help ensures that your vehicle receives the appropriate care it needs.