Comprehensive Guide to Yanmar Diesel Engine Repair

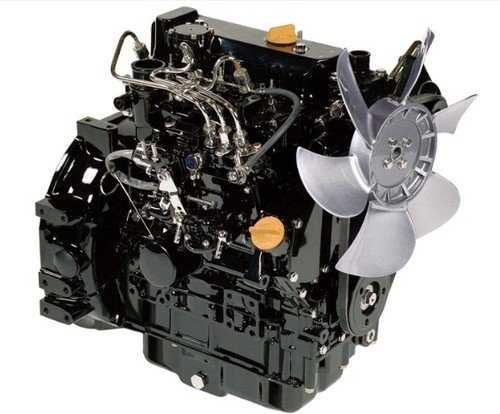

This section provides an in-depth overview of maintaining and troubleshooting a specific type of machinery often utilized in various industrial and agricultural applications. Understanding the intricate workings of this machinery is essential for ensuring optimal performance and longevity.

Regular upkeep and informed adjustments can significantly enhance the operational efficiency of these machines. By adhering to best practices and familiarizing oneself with common challenges, users can mitigate potential issues before they escalate, thus safeguarding their investment.

In the following segments, detailed insights into various aspects of upkeep will be shared. From basic preventive measures to advanced diagnostic techniques, this guide aims to empower operators and technicians alike, enabling them to achieve peak functionality and reliability in their equipment.

This section aims to provide an overview of specific power units commonly used in various applications. Understanding their design, functionality, and common issues is essential for effective maintenance and optimization of performance.

Fundamentals of Power Units

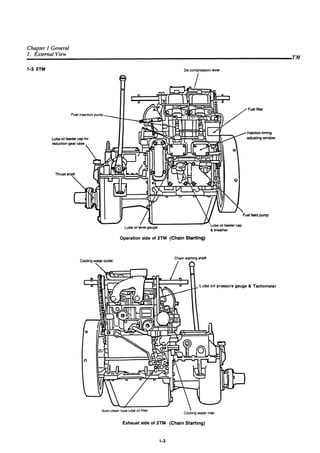

These machines operate on principles of combustion and mechanical efficiency. Familiarity with their core components, such as the combustion chamber, fuel delivery system, and cooling mechanisms, is crucial for ensuring longevity and reliability.

Common Issues and Solutions

Frequent challenges include fuel inefficiency, overheating, and starting difficulties. Recognizing symptoms early can lead to prompt interventions. Regular inspections and preventive measures are vital for minimizing downtime.

| Common Issue | Symptoms | Recommended Action |

|---|---|---|

| Fuel Inefficiency | Reduced power output | Check fuel filters and injectors |

| Overheating | High temperature readings | Inspect coolant levels and hoses |

| Starting Difficulties | Slow cranking or no start | Examine battery condition and connections |

Common Issues and Symptoms

Understanding the typical challenges that may arise with your machinery is essential for effective maintenance. Identifying symptoms early can help prevent more severe complications and ensure optimal performance.

Starting Problems: Difficulty in ignition can stem from various factors, including battery issues, faulty wiring, or fuel delivery problems. Recognizing these signs promptly is crucial to avoiding prolonged downtime.

Unusual Noises: Unexpected sounds such as knocking or grinding may indicate internal wear or damage. Paying attention to these auditory signals can provide valuable insights into potential malfunctions.

Overheating: Excessive heat can result from inadequate coolant levels or a malfunctioning cooling system. Monitoring temperature gauges and ensuring proper fluid levels can mitigate this issue.

Smoke Emission: Changes in exhaust color–such as black, blue, or white–can signify different underlying issues. Each color often points to specific concerns that require immediate attention.

Performance Drops: A noticeable decline in power or efficiency may be due to fuel system clogs, air leaks, or wear in critical components. Regular performance checks can help in early detection.

Essential Tools for Repairs

Having the right equipment is crucial for ensuring efficient maintenance and restoration of mechanical systems. Proper tools can significantly enhance the quality of work and reduce the time needed to complete tasks.

- Wrenches: A variety of sizes is essential for loosening and tightening fasteners.

- Screwdrivers: Both flathead and Phillips types are necessary for handling various screws.

- Socket Set: A comprehensive socket set allows for greater torque and access to tight spaces.

- Pliers: Useful for gripping, twisting, and cutting wires or other materials.

- Multimeter: An indispensable tool for measuring voltage, current, and resistance.

- Oil Filter Wrench: Specifically designed to easily remove oil filters without damage.

- Torque Wrench: Ensures that fasteners are tightened to the specified settings.

- Cleaning Supplies: Brushes and solvents are essential for maintaining cleanliness and preventing buildup.

Equipping yourself with these essential items can facilitate smoother operations and contribute to the longevity of machinery. Regular maintenance not only prevents costly breakdowns but also promotes optimal performance.

Step-by-Step Maintenance Procedures

This section outlines essential procedures for ensuring the longevity and optimal performance of your machinery. Following these systematic steps will help you maintain peak functionality and prevent common issues associated with wear and tear.

Regular Inspection Checklist

Conducting regular inspections is crucial for identifying potential problems before they escalate. Below is a checklist of key components to examine:

| Component | Frequency | Action |

|---|---|---|

| Fluid Levels | Every 50 hours | Check and top off as necessary |

| Filters | Every 100 hours | Replace as required |

| Belts and Hoses | Every 200 hours | Inspect for wear and replace if damaged |

Detailed Maintenance Steps

Implementing detailed maintenance steps ensures comprehensive care. Below are recommended procedures:

1. Fluid Change: Replace lubricants and fluids according to the manufacturer’s specifications to maintain optimal performance.

2. Filter Replacement: Regularly changing filters helps keep contaminants at bay, ensuring efficient operation.

3. Component Cleaning: Cleaning various parts minimizes buildup and enhances efficiency. Use appropriate cleaning agents and techniques.

4. Adjustments: Periodically check and adjust settings on components to maintain precision and effectiveness.

Fuel System Troubleshooting Tips

When addressing performance issues related to the delivery and management of fuel, it’s essential to systematically identify potential problems within the system. A well-structured approach can help isolate malfunctions and ensure efficient operation.

Common Symptoms and Their Causes

| Symptom | Possible Cause |

|---|---|

| Difficulty starting | Clogged filters or insufficient pressure |

| Irregular operation | Air leaks or fuel contamination |

| Low power output | Blocked injectors or improper timing |

| Excessive smoke | Rich fuel mixture or malfunctioning injectors |

Essential Checks

Begin by examining the fuel filters for blockages and replace them if necessary. Inspect all connections for potential leaks, and ensure that the fuel lines are clear of debris. Additionally, verify that the fuel pump is delivering the correct pressure. These steps will help maintain optimal functionality and prevent further complications.

Cooling System Repair Techniques

Maintaining an efficient cooling mechanism is crucial for optimal performance. Proper attention to this area can prevent overheating and extend the lifespan of machinery. Below are several approaches to effectively address common issues within the cooling framework.

- Regular Inspections: Conduct routine examinations to identify leaks, corrosion, or blockages in hoses and components.

- Flushing the System: Periodically flush the cooling system to remove deposits and contaminants that can hinder flow.

- Replacing Components: If any part shows significant wear or damage, such as the radiator or water pump, replace it promptly to ensure reliability.

- Checking Fluid Levels: Maintain proper coolant levels and use the recommended type to enhance efficiency.

Implementing these strategies can lead to improved functionality and durability of the overall cooling structure.

Electrical System Diagnostics

This section focuses on the evaluation and troubleshooting of the electrical components crucial for optimal functionality. Accurate diagnostics are essential for identifying faults that may hinder performance, ensuring reliability in various operational conditions.

Begin by assessing the battery and charging system, as these are foundational for the electrical setup. Verify voltage levels and connections, looking for signs of corrosion or wear that could affect performance. Utilize a multimeter to measure the output and confirm proper operation.

Next, examine the wiring harnesses for any signs of damage or fraying. Faulty wiring can lead to intermittent issues that are often difficult to diagnose. Pay special attention to connectors and terminals, ensuring they are clean and securely fastened.

In addition, review the ignition and starting systems. Problems in these areas can lead to starting failures or erratic operation. Check for continuity in circuits and inspect switches for any malfunctioning components that might require replacement.

Lastly, implement systematic testing procedures for various sensors and control units. Use diagnostic tools to read error codes and monitor real-time data, allowing for informed decisions on necessary repairs or replacements.

Inspecting and Replacing Filters

Regular examination and substitution of filtration components are crucial for maintaining optimal performance and longevity of machinery. These elements play a vital role in ensuring that fluids remain clean, preventing contaminants from causing damage to internal systems.

To effectively conduct inspections and replacements, follow these essential steps:

- Gather necessary tools and replacement parts.

- Locate the filtration components, typically found in accessible areas.

- Carefully detach the old filters, ensuring that no debris falls into the surrounding areas.

- Inspect the old filters for signs of wear or contamination.

- Install the new filters, ensuring a secure fit to avoid leaks.

- Dispose of the old filters according to local regulations.

Regular checks should be part of a broader maintenance schedule, ensuring that all systems operate efficiently and reliably.

Consider the following tips to enhance the filtration process:

- Refer to specifications for correct filter types.

- Monitor fluid levels and quality periodically.

- Document each inspection and replacement to track maintenance history.

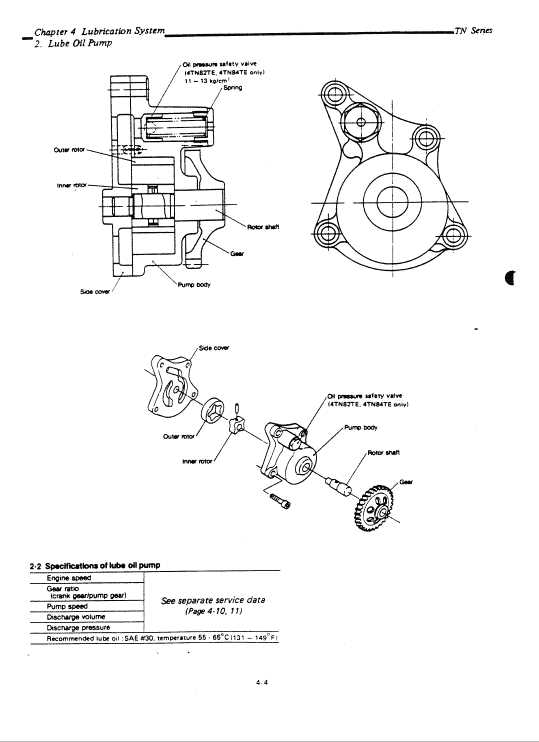

Working with Engine Lubrication

Proper management of lubrication systems is essential for maintaining optimal performance and longevity of mechanical systems. This section outlines key practices and considerations to ensure efficient operation.

Importance of Lubrication

Effective lubrication plays a crucial role in minimizing friction and wear between moving components. It also helps in heat dissipation and contamination control. Here are the main benefits:

- Reduces friction and wear

- Enhances thermal management

- Prevents rust and corrosion

- Extends the lifespan of components

Lubrication Maintenance Practices

Regular maintenance of lubrication systems is vital. Consider the following practices:

- Check oil levels frequently to prevent dry running.

- Change lubricant at recommended intervals to ensure optimal performance.

- Inspect filters and replace them as necessary to maintain cleanliness.

- Monitor for leaks and rectify any issues promptly.

Engine Overhaul Best Practices

When undertaking a significant restoration of internal combustion systems, adhering to proven methodologies is crucial for achieving optimal performance and longevity. Implementing best practices not only ensures reliability but also enhances efficiency, reducing the likelihood of future complications.

Preparation and Planning

Thorough preparation is the cornerstone of any successful overhaul. Begin by gathering all necessary tools and parts, ensuring that you have everything required for the task at hand. An organized workspace is essential; it allows for a systematic approach and minimizes the chances of losing components during the process. Documentation of the original configuration is vital, as it provides a reference for reassembly.

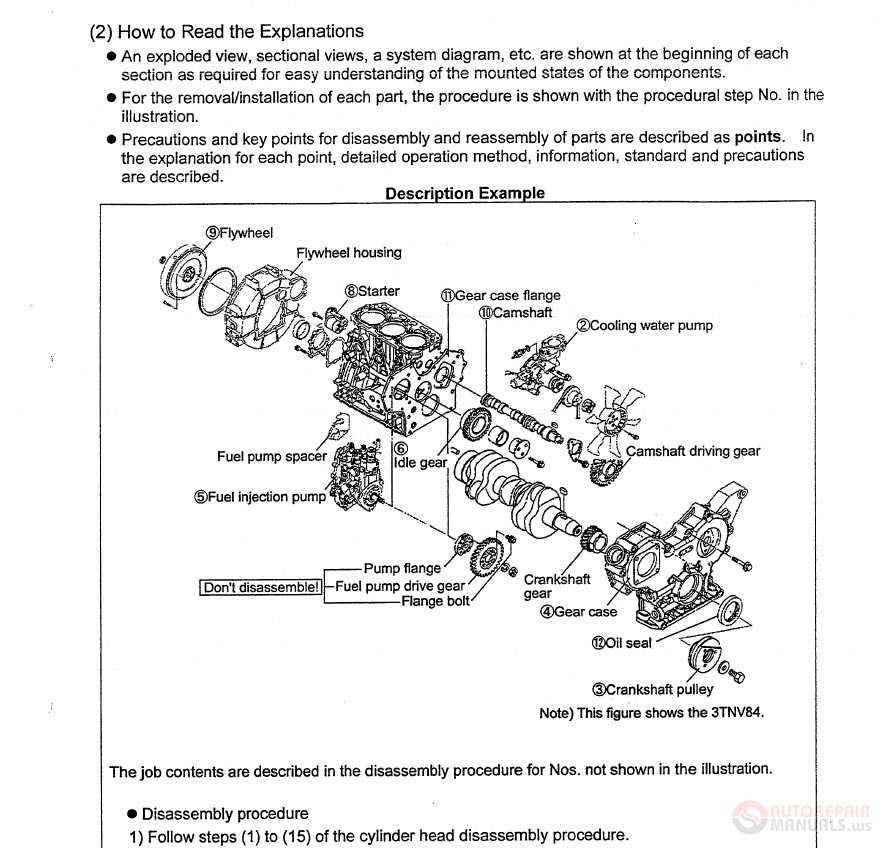

Attention to Detail

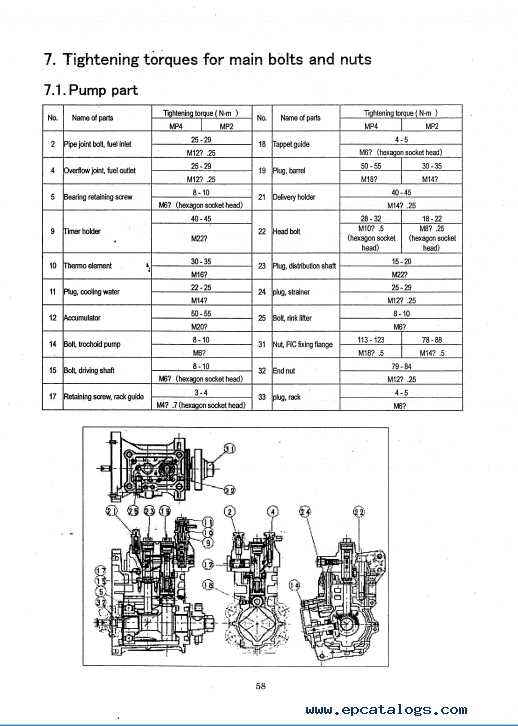

During disassembly, meticulous attention to detail can prevent potential pitfalls. Inspect all components for signs of wear or damage, and clean parts thoroughly before reinstallation. Utilizing high-quality lubricants and following specified torque settings will significantly impact the overall performance. Regular checks throughout the process help to maintain alignment and fit, ensuring that each piece functions harmoniously within the system.

Safety Precautions During Repairs

Ensuring safety is paramount when working on complex machinery. Proper precautions can help prevent accidents and protect both the technician and the equipment. By adhering to a set of guidelines, individuals can create a secure environment for maintenance activities.

Essential Guidelines

- Always wear appropriate personal protective equipment, including gloves, goggles, and hearing protection.

- Maintain a clean workspace to minimize hazards.

- Ensure proper ventilation in the area to avoid inhaling harmful fumes.

- Disconnect all power sources before beginning any work.

- Use tools that are suitable for the task at hand, and check them for any damage before use.

Emergency Preparedness

- Familiarize yourself with the location of emergency exits and fire extinguishers.

- Have a first aid kit readily accessible in case of accidents.

- Know the emergency contact numbers and procedures in case of serious incidents.

Following these precautions not only ensures personal safety but also promotes efficient and effective maintenance practices. Prioritizing safety leads to a smoother workflow and better outcomes in technical tasks.

Recommended Spare Parts and Suppliers

Maintaining optimal performance requires using high-quality components. This section provides guidance on essential replacement items and trusted sources for procurement, ensuring reliability and efficiency in operations.

When selecting spare components, consider the following key categories:

- Filters: Regular replacement of oil, fuel, and air filters is crucial for system longevity.

- Gaskets and Seals: Ensuring proper sealing prevents leaks and maintains pressure.

- Belt and Hoses: Regular checks and replacements of belts and hoses help avoid breakdowns.

- Electrical Components: Batteries, starters, and alternators are vital for smooth functionality.

For acquiring these items, the following suppliers are recommended:

- Local Dealers: Authorized distributors often provide genuine parts tailored for specific needs.

- Online Marketplaces: Websites specializing in machinery components can offer a wide range of products with user reviews.

- Aftermarket Suppliers: Many manufacturers provide compatible alternatives at competitive prices.

Choosing the right suppliers ensures access to reliable parts, ultimately enhancing the overall performance of the machinery.

Frequently Asked Questions

This section addresses common inquiries that users may have regarding maintenance and troubleshooting procedures. Here, you’ll find helpful insights to enhance understanding and facilitate effective solutions.

| Question | Answer |

|---|---|

| What are the signs of a malfunction? | Typical indicators include unusual noises, decreased performance, and abnormal fluid levels. |

| How often should maintenance be performed? | Regular checks should occur every 100 hours of operation, with comprehensive servicing annually. |

| What tools are essential for basic upkeep? | A standard toolkit, including wrenches, screwdrivers, and diagnostic instruments, is recommended. |

| Are there specific lubricants to use? | Always use high-quality lubricants that meet the specifications outlined in the reference guide. |

| Where can I find replacement parts? | Authorized dealers and reputable online retailers offer a wide selection of compatible components. |