Complete Guide to John Deere 110 Lawn Tractor Repair Manual

This article aims to provide an extensive overview of essential techniques and insights for maintaining outdoor machinery effectively. Understanding how to care for these devices can enhance their longevity and performance, ensuring they serve you well for years to come.

In this guide, we will delve into various aspects of upkeep, from routine checks to addressing common issues. By mastering these skills, users can achieve the ultimate satisfaction in operating their equipment without unnecessary interruptions.

Equipping yourself with the right knowledge can empower you to tackle challenges with confidence. This resource is designed to serve both novices and seasoned enthusiasts, offering practical advice that caters to all experience levels.

Understanding John Deere 110 Lawn Tractors

This section aims to provide insights into a specific model of garden machinery, focusing on its features, functionality, and maintenance. By exploring this equipment, users can enhance their understanding and proficiency in managing their outdoor tasks efficiently.

Key aspects to consider include:

- Design and Build: The overall construction plays a crucial role in durability and performance.

- Engine Specifications: Knowledge of the power unit is essential for optimal operation.

- Features: Understanding the various attachments and capabilities can improve usability.

- Maintenance Requirements: Regular upkeep ensures longevity and efficiency.

Overall, gaining a comprehensive understanding of this equipment not only facilitates better handling but also contributes to effective yard management.

Common Issues in Lawn Tractor Operation

When operating outdoor power equipment, users often encounter various challenges that can hinder performance and efficiency. Recognizing these typical problems is essential for maintaining optimal functionality and prolonging the lifespan of the machine. Understanding common difficulties can help users troubleshoot effectively and avoid unnecessary downtime.

Engine Performance Problems

One of the most prevalent concerns is related to the engine. Symptoms such as difficulty starting, stalling, or a noticeable drop in power can indicate underlying issues. Fuel quality plays a crucial role; using old or contaminated fuel can lead to poor combustion. Additionally, a clogged air filter can restrict airflow, resulting in inefficient operation. Regular maintenance, including timely oil changes and filter replacements, is vital for smooth engine performance.

Cutting Mechanism Issues

The cutting system is another area where users frequently face difficulties. Uneven cuts or the machine leaving untrimmed patches can be frustrating. These problems may stem from dull blades or improper deck height settings. Sharpening the blades and adjusting the cutting height according to grass type and conditions can significantly improve results. It’s also important to check for any debris caught in the deck, which can affect performance.

Essential Tools for DIY Repairs

Having the right equipment is crucial for effective maintenance and restoration tasks. The right tools not only enhance efficiency but also ensure that projects are completed safely and accurately. Here’s a rundown of indispensable instruments every enthusiast should consider.

- Wrenches: A set of adjustable and fixed wrenches is essential for loosening and tightening various components.

- Screwdrivers: Both flathead and Phillips screwdrivers are necessary for handling different types of fasteners.

- Pliers: Needle-nose and standard pliers provide grip and leverage for various tasks.

- Socket Set: A comprehensive socket set allows for quick removal and installation of bolts and nuts.

- Torque Wrench: This tool is vital for applying the correct amount of force to fasteners, preventing damage.

In addition to basic tools, consider investing in specialized equipment:

- Multimeter: Essential for diagnosing electrical issues and testing voltage.

- Jack and Stands: Necessary for safely lifting and supporting heavy machinery during work.

- Oil Filter Wrench: Helps in easily removing and replacing oil filters during maintenance.

- Grease Gun: Useful for lubricating moving parts and extending their lifespan.

Equipping yourself with these fundamental tools will empower you to tackle a variety of tasks, ensuring your equipment remains in optimal condition.

Step-by-Step Maintenance Guidelines

Regular upkeep is essential for ensuring the longevity and efficient performance of your outdoor equipment. Following a systematic approach can prevent unexpected breakdowns and enhance the overall functionality. Below are detailed steps to maintain your machine effectively.

| Task | Frequency | Description |

|---|---|---|

| Check Oil Level | Every 5 hours of use | Inspect the oil level and top off as needed to ensure optimal engine performance. |

| Change Oil | Every 50 hours of use | Replace the oil and oil filter to keep the engine running smoothly. |

| Inspect Air Filter | Every 25 hours of use | Clean or replace the air filter to maintain proper airflow and engine efficiency. |

| Sharpen Blades | Every 20 hours of use | Ensure the cutting edges are sharp for a clean cut and to reduce strain on the engine. |

| Check Tire Pressure | Monthly | Verify that tires are inflated to the recommended pressure for better traction and performance. |

| Clean Underbelly | After each use | Remove grass clippings and debris to prevent rust and maintain efficiency. |

| Inspect Belts | Every 50 hours of use | Check for wear and proper tension to ensure reliable operation of the drive system. |

By adhering to these guidelines, you can prolong the lifespan of your equipment and enhance its operational efficiency. Consistent attention to maintenance tasks will provide peace of mind and optimal performance for all your outdoor endeavors.

How to Troubleshoot Engine Problems

Troubleshooting engine issues can be a straightforward process if you approach it systematically. Identifying symptoms and following a methodical check can help you pinpoint the underlying cause of the malfunction. This guide will provide you with essential steps to diagnose common engine problems effectively.

1. Check the Fuel Supply: Ensure that there is adequate fuel in the tank. Old or contaminated fuel can lead to starting difficulties. If the fuel is stale, consider draining it and replacing it with fresh fuel.

2. Inspect the Spark Plug: A faulty spark plug can cause poor performance or prevent the engine from starting. Remove the plug and check for signs of wear or carbon buildup. Replace it if necessary, and ensure the gap is correctly set.

3. Examine the Battery: A weak or dead battery can lead to engine starting problems. Test the battery’s charge and connections, ensuring they are clean and secure. Recharge or replace the battery if it shows signs of failure.

4. Look for Leaks: Check for any signs of fluid leaks around the engine area. Oil or coolant leaks can indicate underlying issues that need to be addressed. Clean the area and monitor for any reoccurring leaks.

5. Assess the Air Filter: A clogged air filter can restrict airflow and affect engine performance. Inspect the filter for dirt and debris, and clean or replace it as needed to ensure proper air intake.

6. Listen for Unusual Noises: Pay attention to any strange sounds coming from the engine while it operates. Knocking or grinding noises may signal internal issues that require immediate attention. Document these sounds to help diagnose the problem accurately.

By following these steps, you can effectively troubleshoot engine issues and take the necessary actions to restore optimal performance.

Transmission and Drive System Repairs

The efficiency of a vehicle’s power transfer system is crucial for optimal performance. This section focuses on the essential aspects of maintaining and troubleshooting the transmission and drive mechanisms, ensuring smooth operation and longevity. Understanding the components involved can lead to effective resolutions for common issues.

Common Issues and Symptoms

- Difficulty in shifting gears

- Unusual noises during operation

- Vibration or shaking while in motion

- Slipping or loss of power

Recognizing these signs early can prevent further damage and costly repairs. Regular inspections are key to identifying potential problems before they escalate.

Basic Repair Steps

- Check Fluid Levels: Ensure that the transmission fluid is at the recommended level and in good condition.

- Inspect Belts and Cables: Look for wear and tear on belts and cables, replacing any that show signs of damage.

- Examine Gears: Inspect gears for wear or misalignment and address any issues promptly.

- Test Drive: After making adjustments or replacements, conduct a test drive to ensure proper functionality.

Following these guidelines will help maintain the drive system’s performance, providing a reliable experience. Regular maintenance and prompt repairs contribute to a longer lifespan of the components involved.

Replacing Blades and Deck Maintenance

Maintaining the cutting components and the undercarriage of your equipment is crucial for optimal performance and longevity. Regularly replacing worn-out parts ensures efficient operation, preventing uneven cuts and unnecessary strain on the engine. This section delves into essential steps for effective upkeep.

Choosing the Right Blades

Selecting appropriate blades is vital for achieving the ultimate cutting efficiency. Ensure compatibility with your equipment model and consider the material and design that best suits your mowing conditions. Sharpening blades regularly will enhance performance and extend their lifespan.

Deck Cleaning and Maintenance

Regular cleaning of the deck prevents buildup of grass and debris, which can affect performance and lead to rust. Use a stiff brush or pressure washer to clear clippings after each use. Inspect the deck for any damage and repair it promptly to maintain functionality.

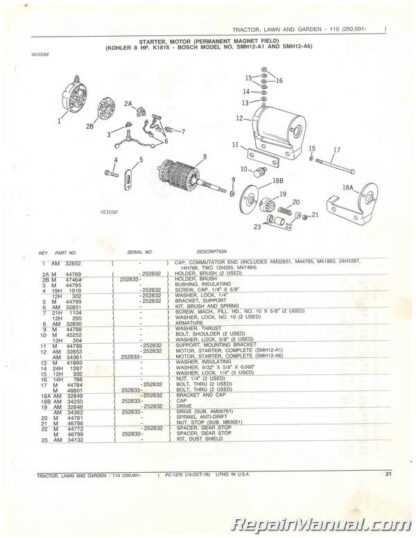

Electrical System Diagnostics and Fixes

Diagnosing and resolving issues within the electrical framework of outdoor machinery is crucial for optimal performance. Understanding the various components and their interconnections can significantly aid in identifying faults. This section provides insights into common problems, diagnostic methods, and effective solutions.

To streamline the troubleshooting process, it is essential to follow a systematic approach. Begin by gathering necessary tools, such as a multimeter, and familiarize yourself with the wiring diagrams. This will help in pinpointing potential malfunctions efficiently.

| Issue | Symptoms | Diagnosis Steps | Recommended Fixes |

|---|---|---|---|

| No Start | Engine fails to crank | Check battery voltage and connections | Replace battery or clean connections |

| Dim Lights | Weak illumination | Test alternator output | Replace alternator or adjust belt tension |

| Intermittent Power | Fluctuating performance | Inspect wiring for damage | Repair or replace damaged wires |

| Blown Fuses | Electrical components inoperative | Check for short circuits | Replace fuses and fix short circuits |

By adhering to these guidelines, owners can effectively address electrical system challenges. Regular maintenance and vigilant monitoring of electrical components will not only prolong the lifespan of the equipment but also enhance overall functionality.

Tips for Proper Tire Care

Caring for your vehicle’s tires is essential for ensuring safety and extending their lifespan. Proper maintenance not only enhances performance but also contributes to fuel efficiency. Here are some effective strategies to keep your tires in optimal condition.

Regular Inspection: Frequently check your tires for any signs of wear and damage. Look for uneven tread wear, cracks, or objects lodged in the rubber. Addressing these issues promptly can prevent more serious problems.

Maintaining Correct Pressure: Ensure that your tires are inflated to the manufacturer’s recommended pressure. Under-inflated or over-inflated tires can lead to poor handling and reduced fuel efficiency. Use a reliable gauge to check pressure regularly.

Rotation: Rotate your tires according to the schedule recommended in your owner’s guide. This practice promotes even wear and can extend the life of the tires.

Alignment and Balancing: Have your vehicle’s alignment and tire balance checked periodically. Misalignment can lead to uneven wear and affect driving performance.

Proper Storage: If you need to store your tires, do so in a cool, dry place away from direct sunlight. Keep them stacked or hung, and avoid placing heavy objects on top to maintain their shape.

Seasonal Changes: Consider switching to seasonal tires if you live in an area with extreme weather conditions. Winter tires can provide better traction in snow and ice, while summer tires offer superior performance in warm conditions.

By following these guidelines, you can ensure that your tires remain in excellent shape, ultimately enhancing your vehicle’s performance and safety on the road.

Seasonal Preparation and Storage Tips

Proper seasonal preparation and storage are essential to ensure the longevity and performance of your outdoor equipment. Taking the time to maintain and store your machinery appropriately can prevent issues and enhance efficiency when it’s time to use them again. Here are some key practices to consider as the seasons change.

Preparation for Seasonal Use

- Inspect and clean the equipment thoroughly to remove any dirt or debris.

- Check the fluid levels, including oil and fuel, and replace them as necessary.

- Sharpen blades or cutting tools to ensure optimal performance.

- Examine belts and cables for signs of wear and replace if needed.

- Test the battery and ensure it is fully charged.

Storage Guidelines

- Store in a dry, sheltered location to protect from the elements.

- Use a cover to shield the equipment from dust and moisture.

- Remove fuel to prevent degradation; consider using a fuel stabilizer if storage is prolonged.

- Elevate equipment off the ground to avoid contact with moisture.

- Periodically check the stored equipment to ensure it remains in good condition.

Resources for Parts and Upgrades

Finding quality components and enhancements for your outdoor equipment can significantly improve its performance and longevity. A variety of resources are available to help you locate the necessary parts and consider upgrades to optimize your machine.

Where to Find Parts

- Online Retailers: Websites like Amazon and eBay offer a wide range of components from various suppliers.

- Local Dealers: Authorized dealerships often provide genuine parts and can assist with specific needs.

- Aftermarket Suppliers: Companies specializing in aftermarket components can be a cost-effective alternative.

- Salvage Yards: These can be treasure troves for hard-to-find parts at lower prices.

Upgrading Your Equipment

Consider enhancing your machine’s capabilities with the following upgrades:

- Improved Blades: Opt for high-performance blades for better cutting efficiency.

- Enhanced Tires: Switching to high-traction tires can improve handling and performance on various terrains.

- Performance Enhancements: Upgrading the engine or air filter can lead to better fuel efficiency and power.

- Comfort Features: Adding ergonomic seats or handles can greatly enhance user comfort during operation.

Utilizing these resources can ensure that your equipment remains functional and efficient for years to come.