Comprehensive Repair Guide for the 1996 Yamaha Wave Venture 1100

In the realm of aquatic recreation, ensuring the longevity and optimal performance of your personal watercraft is essential. This guide aims to provide enthusiasts with essential insights and strategies for effective upkeep and troubleshooting. Whether you’re a seasoned rider or a newcomer, understanding the intricacies of your vessel can significantly enhance your experience on the water.

Maintenance is not merely a task but a vital component of safe and enjoyable adventures. By familiarizing yourself with the key systems and components, you can prevent minor issues from escalating into major repairs. This resource will delve into various aspects of care, empowering you to tackle challenges confidently and efficiently.

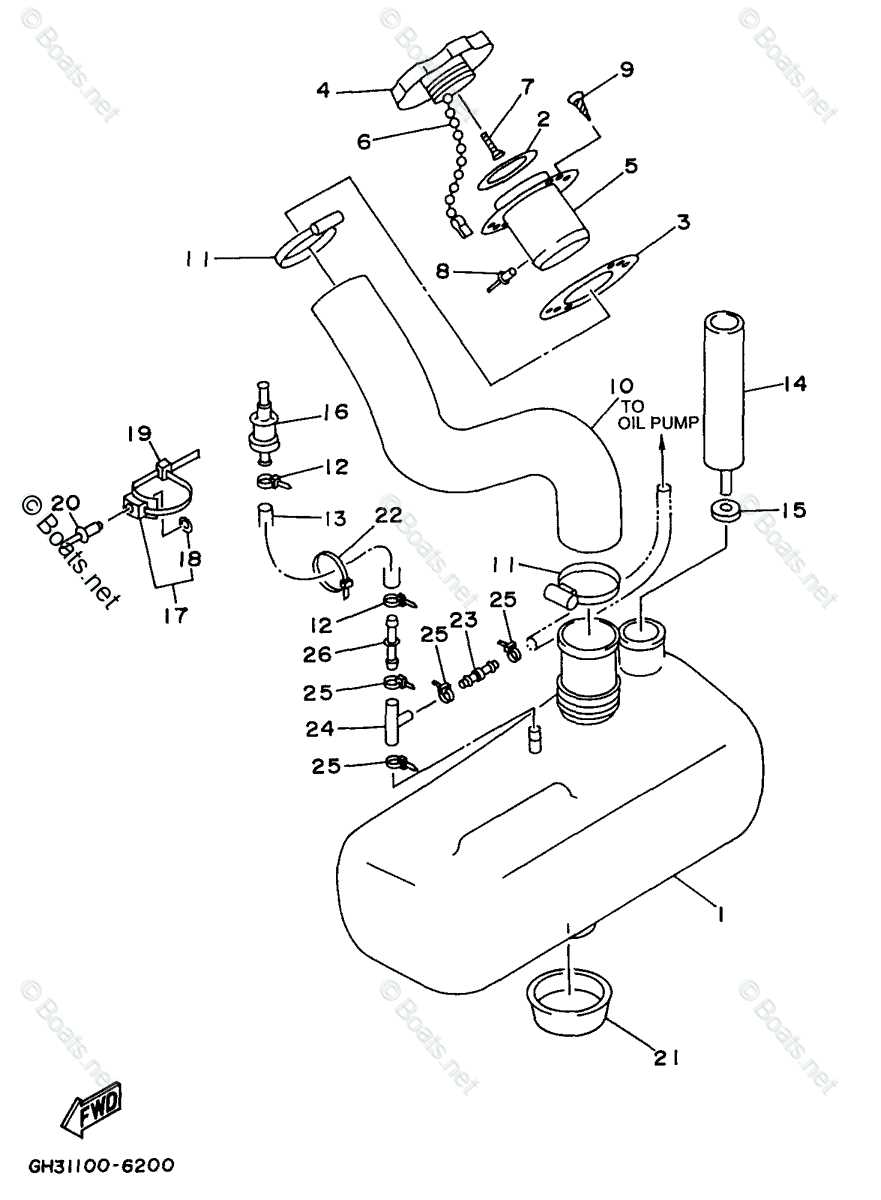

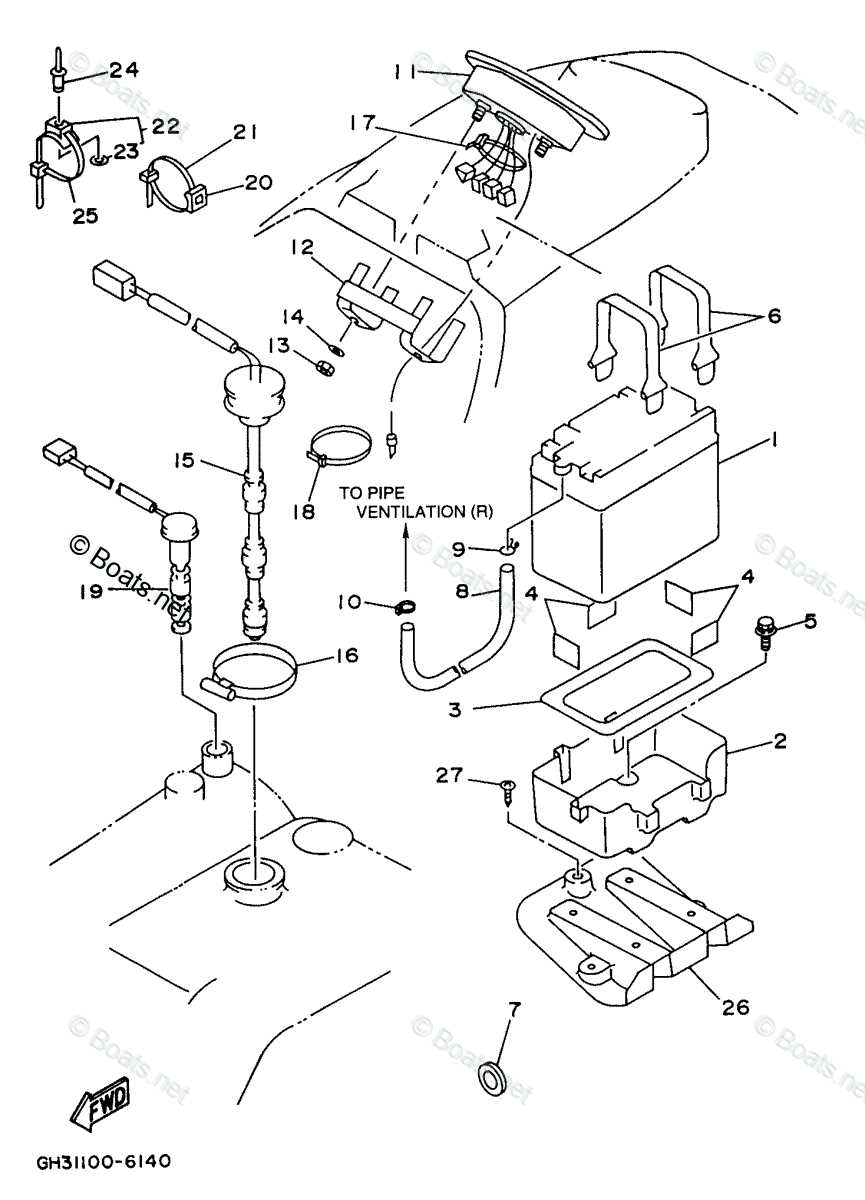

Moreover, having access to detailed instructions and diagrams can make the maintenance process smoother and more straightforward. The importance of regular checks and timely interventions cannot be overstated, as they ensure both safety and reliability. Join us as we explore the fundamental practices that will keep your watercraft in peak condition for years to come.

Overview of Yamaha Wave Venture 1100

This section provides a comprehensive look at a popular watercraft model known for its robust performance and user-friendly features. Designed for both recreational and performance enthusiasts, this machine offers an enjoyable experience on the water. With its combination of power and stability, it has become a favored choice for many riders seeking adventure and leisure.

Key specifications and features enhance its appeal, making it suitable for a variety of activities, from casual outings to more demanding explorations. Understanding these aspects is essential for anyone considering this model for their aquatic adventures.

| Feature | Specification |

|---|---|

| Engine Type | Two-stroke |

| Seating Capacity | Up to three riders |

| Weight | Approximately 750 lbs |

| Fuel Capacity | 15 gallons |

| Length | 10.5 feet |

With its blend of reliability and performance, this model remains a top contender in the market, appealing to a wide range of watercraft enthusiasts. Familiarity with its specifications and features can greatly enhance the ownership experience.

Common Issues with the 1996 Model

The specific model in question is known for several recurring problems that users may encounter over time. Understanding these issues can help in effective maintenance and timely repairs, ensuring a better experience on the water.

- Engine Performance:

Many owners report difficulties with the engine running smoothly, including:

- Starting issues, particularly in colder conditions.

- Inconsistent power delivery during acceleration.

- Excessive vibration, which can indicate underlying mechanical issues.

- Fuel System:

Problems with the fuel system can lead to inefficiencies, such as:

- Clogged fuel filters that restrict flow.

- Old or damaged fuel lines causing leaks.

- Carburetor issues that result in poor fuel-air mixture.

- Electrical Components:

Electrical malfunctions are also common, including:

- Battery drainage due to faulty wiring.

- Malfunctioning gauges that fail to display accurate readings.

- Starter issues that prevent the engine from cranking.

- Hull and Body:

Physical damage can affect performance and safety, such as:

- Cracks or chips in the hull, which may lead to leaks.

- Worn-out paint that can compromise aesthetics and protection.

- Corrosion, especially around hardware and fittings.

lessCopy code

Being aware of these potential issues allows for proactive measures to maintain performance and reliability.

Essential Tools for Repairs

Having the right instruments is crucial for maintaining and fixing watercraft effectively. A well-equipped toolkit not only streamlines the process but also ensures that tasks are completed safely and efficiently. This section highlights the fundamental equipment every enthusiast should consider when embarking on maintenance projects.

Basic Tools

The following list includes essential items that form the backbone of any maintenance toolkit:

| Tool | Purpose |

|---|---|

| Socket Wrench Set | To tighten or loosen various bolts and nuts. |

| Phillips and Flathead Screwdrivers | For handling different types of screws. |

| Pliers | To grip and manipulate small components. |

| Torque Wrench | To ensure proper tightness on critical fasteners. |

| Utility Knife | For cutting through various materials. |

Specialized Instruments

In addition to basic tools, certain specialized instruments can enhance the efficiency of your maintenance efforts:

| Tool | Purpose |

|---|---|

| Multimeter | For testing electrical systems and components. |

| Compression Tester | To assess the performance of the engine. |

| Fuel Pressure Gauge | To check fuel system performance. |

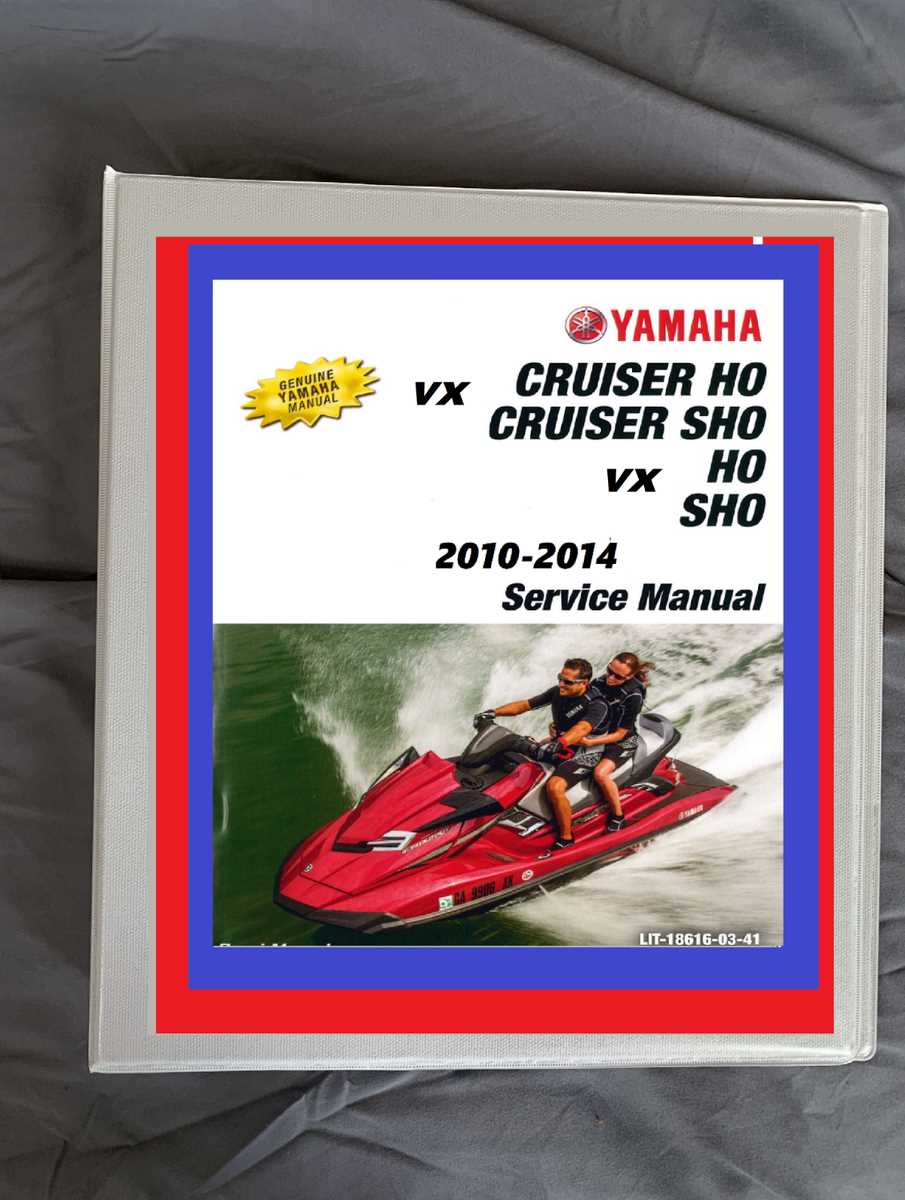

| Shop Manual | Provides specific guidelines and diagrams for repairs. |

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to keeping your personal watercraft in top condition. Regular upkeep ensures optimal performance, enhances longevity, and promotes safety on the water. Following a structured maintenance routine can prevent minor issues from developing into major repairs.

Essential Tools and Supplies

- Socket set

- Screwdrivers (flathead and Phillips)

- Wrench set

- Oil and filters

- Grease

- Cleaning supplies (soap, sponges, rags)

- Fuel stabilizer

- Safety gear (gloves, goggles)

Maintenance Steps

- Inspect the Hull: Check for cracks, scratches, or signs of wear. Clean the exterior thoroughly.

- Check the Engine: Examine oil levels, replace filters, and change the oil as needed.

- Examine the Cooling System: Ensure water intake screens are clear and hoses are in good condition.

- Inspect Electrical Components: Test the battery, connections, and all electrical systems for functionality.

- Review the Fuel System: Change the fuel filter and use a stabilizer to protect the fuel.

- Test Safety Equipment: Check the condition of life jackets, flares, and fire extinguishers.

By adhering to these guidelines, you can maintain your watercraft efficiently, ensuring enjoyable outings and peace of mind.

Engine Troubleshooting Techniques

Troubleshooting engine issues is a critical skill for maintaining optimal performance and longevity of your watercraft. Identifying symptoms and implementing appropriate diagnostic methods can help pinpoint the root cause of mechanical problems. This section outlines effective strategies to systematically evaluate engine performance and resolve common malfunctions.

Identifying Symptoms

Start by observing the engine’s behavior. Unusual sounds, irregular vibrations, or decreased power can indicate underlying issues. Pay attention to warning lights on the dashboard and monitor engine temperature. Conduct a visual inspection for signs of leaks, corrosion, or loose connections, as these can provide valuable clues about potential problems.

Diagnostic Procedures

Utilize basic diagnostic tools such as multimeters and compression testers to assess engine health. Checking fuel pressure and examining ignition systems can reveal faults affecting performance. Additionally, consult technical specifications for your specific model to ensure accurate measurements. Document findings to track changes over time and facilitate informed decisions on repairs or maintenance.

Electrical System Diagnostics

The electrical system of any watercraft is crucial for its optimal performance and reliability. Diagnosing issues within this system involves a methodical approach to identifying faults and ensuring all components are functioning correctly. This section outlines essential techniques and tools that aid in pinpointing electrical problems effectively.

Common Electrical Issues

Several typical problems may arise within the electrical framework, including dead batteries, faulty wiring, and malfunctioning switches. Each of these can significantly impact the operation of the vessel. Understanding how to recognize symptoms, such as dimming lights or inconsistent starting, is vital for effective troubleshooting.

Diagnostic Tools and Techniques

Utilizing appropriate diagnostic tools is key to a successful assessment. A multimeter, for instance, can measure voltage, current, and resistance, helping to identify shorts or breaks in the circuit. Visual inspections of connectors and wiring harnesses can also reveal signs of wear or corrosion that may hinder performance. Always ensure to follow a systematic approach to isolate problems accurately.

By applying these methods, operators can maintain the integrity of the electrical system and enhance the overall performance of the craft.

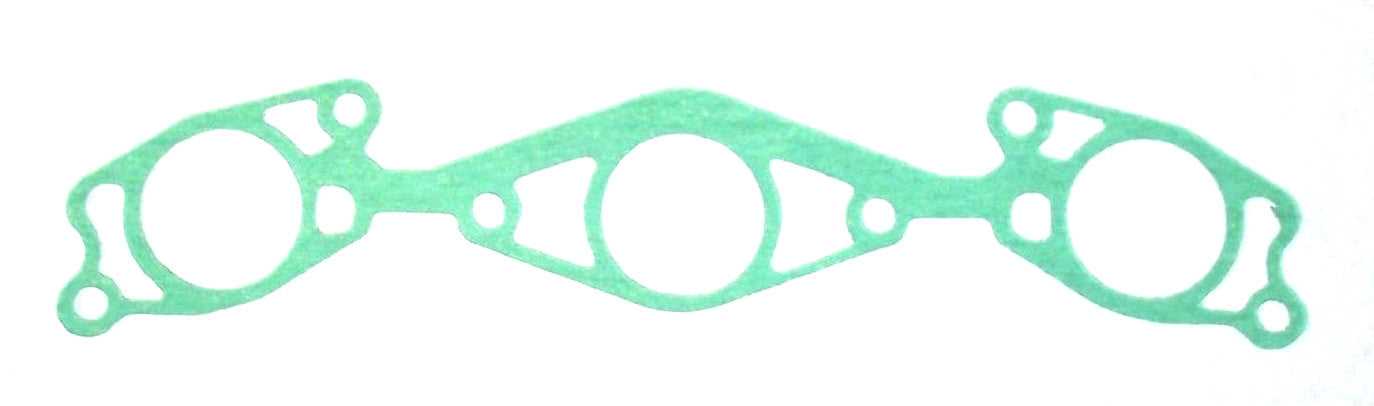

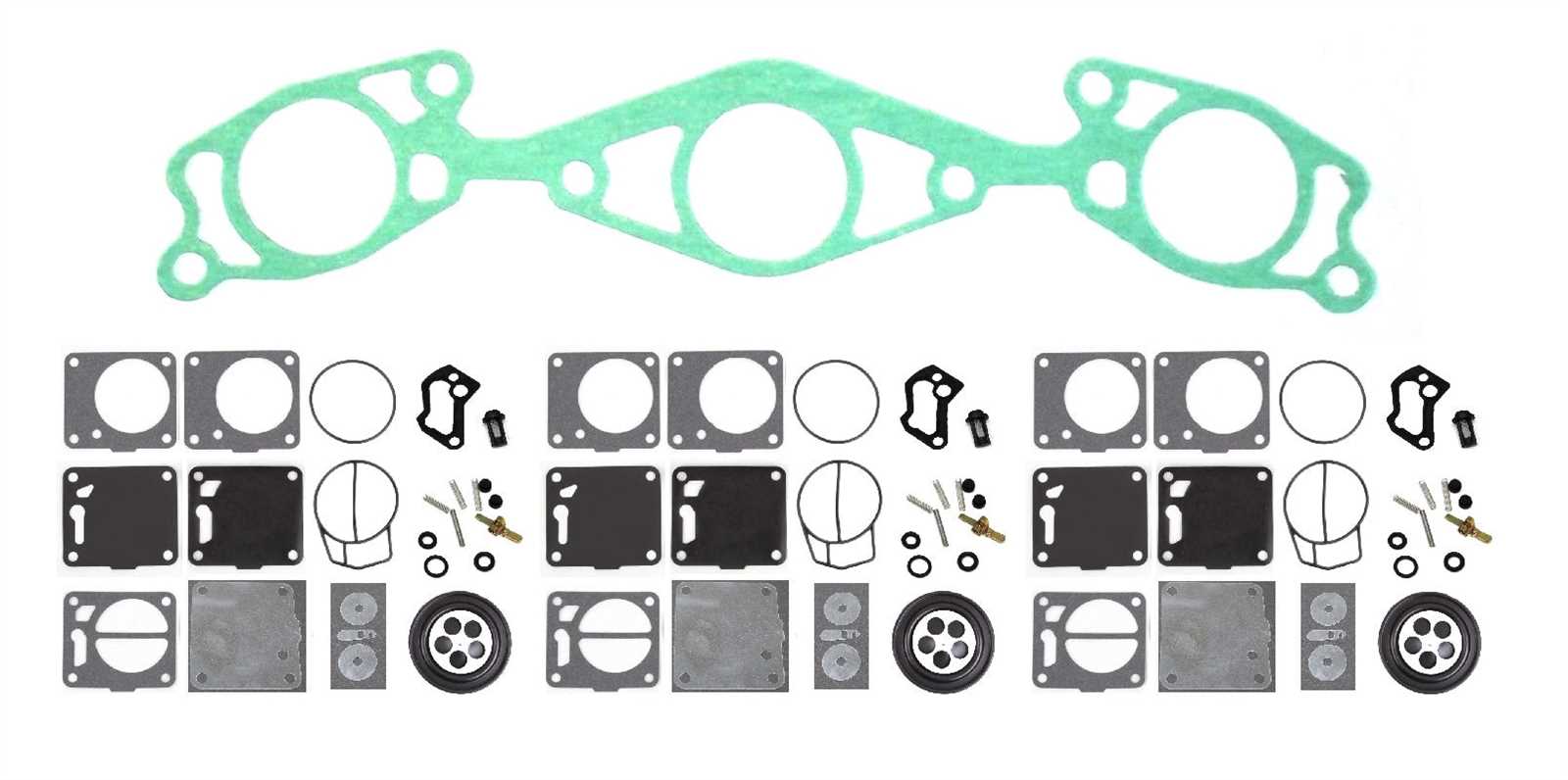

Parts Replacement Recommendations

Ensuring optimal performance and longevity of your watercraft involves timely replacement of key components. Regularly assessing wear and tear is crucial to maintaining efficiency and safety. This section outlines essential recommendations for parts that may require attention during routine maintenance or troubleshooting.

| Part Name | Recommended Replacement Interval | Notes |

|---|---|---|

| Fuel Filter | Every 100 hours | Prevents clogging and ensures proper fuel flow. |

| Oil Seal | Every 2 years | Avoids leaks and maintains pressure in the system. |

| Spark Plugs | Every 50 hours | Critical for ignition; ensure proper gap and type. |

| Battery | Every 3 years | Check for corrosion and ensure reliable starting. |

| Impeller | As needed | Inspect for damage and wear to maintain thrust efficiency. |

Regular monitoring of these components will help prevent unexpected failures and extend the lifespan of your vessel. Always consult with a qualified technician for specific guidance based on usage and environmental conditions.

Winterizing Your Watercraft

Preparing your vessel for the colder months is essential to ensure its longevity and performance. Proper winterization protects critical components from damage caused by freezing temperatures, moisture, and stagnation. Following a systematic approach can help you avoid costly repairs and ensure a smooth launch when the warmer weather returns.

Draining Fluids is one of the most crucial steps. Remove any remaining water from the engine, cooling system, and fuel lines. This prevents ice formation, which can lead to cracks and severe damage. Additionally, consider replacing the oil and filter to remove contaminants that could cause corrosion during the off-season.

Stabilizing Fuel is another key aspect of preparation. Adding a fuel stabilizer to the tank helps prevent degradation and gumming, which can hinder engine performance. Be sure to run the engine for a few minutes after adding the stabilizer to ensure it circulates throughout the system.

Cleaning and Protecting the exterior surfaces is vital as well. Thoroughly wash and dry your craft, removing any debris or contaminants. Applying a protective wax can shield the finish from harsh winter elements and UV damage.

Finally, storing your craft in a dry, temperature-controlled environment is ideal. If indoor storage isn’t an option, use a high-quality cover that fits snugly to protect against moisture and debris. Regular checks throughout the winter can help catch any potential issues early.

By taking these steps, you can ensure that your vessel remains in excellent condition and is ready for adventure when the boating season resumes.

Safety Precautions During Repairs

Ensuring safety while working on machinery is essential to prevent accidents and injuries. Adhering to specific guidelines can create a secure environment and enhance overall effectiveness during maintenance tasks.

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and sturdy footwear.

- Work in a well-ventilated area to avoid inhaling harmful fumes or dust.

- Ensure that the machine is turned off and disconnected from any power source before beginning work.

- Keep your workspace organized to minimize hazards and distractions.

- Be aware of your surroundings and the potential risks associated with the tools and materials you are using.

Following these precautions can significantly reduce the likelihood of accidents, allowing for a more efficient and enjoyable experience during mechanical tasks.

Upgrading Performance Features

Enhancing the capabilities of your watercraft can significantly improve its responsiveness and overall enjoyment on the water. By focusing on key components, you can elevate speed, stability, and handling, ensuring a more exhilarating ride. This section explores various modifications that can yield noticeable gains in performance.

Engine Modifications

One of the most effective ways to boost performance is through engine upgrades. Consider replacing the stock components with high-performance parts such as a better intake system or a more efficient exhaust. These modifications can increase airflow and enhance combustion efficiency, resulting in improved horsepower and torque. Additionally, tuning the engine for optimal performance can lead to smoother operation and increased throttle response.

Weight Reduction and Handling Enhancements

Another strategy involves reducing weight and improving handling. Replacing heavy components with lighter alternatives can lead to better acceleration and maneuverability. Upgrading the hull with advanced materials or adding aftermarket trim tabs can also improve stability and control. Furthermore, ensuring that the watercraft is properly balanced will enhance its agility, allowing for sharper turns and a more dynamic riding experience.