Comprehensive Guide to Yamaha Outboard Repair Manuals

Ensuring the longevity and performance of your aquatic machinery is essential for any boating enthusiast. This section provides valuable insights into various aspects of upkeep, troubleshooting, and enhancement of your engine’s functionality. With a wealth of resources available, you can easily navigate the complexities of engine care and maintenance.

In the following paragraphs, you will find comprehensive information tailored to assist both novice and seasoned users alike. From basic diagnostics to advanced adjustments, this guide covers a broad spectrum of topics that are crucial for optimal engine performance. Empower yourself with the knowledge to tackle common challenges and improve the reliability of your vessel.

Whether you are preparing for a day on the water or addressing specific issues, understanding the intricacies of your machinery will elevate your boating experience. By familiarizing yourself with the essential techniques and procedures outlined here, you will be better equipped to maintain your engine efficiently and effectively.

Understanding Yamaha Outboard Models

This section aims to explore various marine engine types produced by a renowned manufacturer, highlighting their distinct characteristics and applications. Grasping the differences between these models is essential for enthusiasts and professionals alike, as it aids in making informed decisions regarding maintenance, operation, and performance optimization.

Model Categories

Marine engines can be categorized based on power output, intended usage, and design features. Each category caters to specific needs, ensuring that users have options that suit their boating activities, whether for leisure, fishing, or racing.

| Model Type | Power Range | Typical Use |

|---|---|---|

| Portable Engines | 2-30 HP | Small boats, dinghies |

| Mid-Range Engines | 30-150 HP | Sport fishing, cruising |

| High-Performance Engines | 150-300 HP | Racing, offshore |

Key Features

Each model boasts unique features that enhance functionality and user experience. Key aspects to consider include weight, fuel efficiency, and technological advancements such as electronic fuel injection. Understanding these features can significantly impact performance and longevity.

Common Issues with Outboard Motors

Maintaining watercraft engines can present various challenges that enthusiasts frequently encounter. Understanding these common problems can help owners troubleshoot effectively and ensure optimal performance.

- Starting Difficulties: Many users report issues with ignition, which may stem from faulty connections, drained batteries, or malfunctioning starters.

- Overheating: Engines may overheat due to blocked cooling passages or insufficient coolant flow, which can lead to severe damage if not addressed promptly.

- Fuel System Problems: Contaminated fuel or clogged filters can disrupt the fuel supply, leading to performance issues and stalling.

- Electrical Failures: Wiring issues or component failures often result in erratic behavior or complete system shutdowns.

- Propeller Issues: Damage to the propeller or incorrect installation can hinder propulsion and efficiency, affecting overall operation.

Being aware of these typical concerns can empower users to take proactive measures, ensuring a smoother and more reliable experience on the water.

Tools Required for Repairs

Having the right instruments is crucial for effectively addressing mechanical issues. A well-equipped workspace ensures efficiency and accuracy during maintenance tasks, allowing for a smoother process and better results.

Below is a list of essential tools that will aid in the maintenance of marine engines:

| Tool | Description |

|---|---|

| Wrench Set | Variety of sizes for loosening and tightening bolts. |

| Screwdriver Set | Flathead and Phillips for various types of screws. |

| Pliers | For gripping and manipulating small components. |

| Torque Wrench | To ensure proper tightness of fasteners. |

| Multimeter | To check electrical connections and diagnose faults. |

| Oil Filter Wrench | For easy removal and installation of oil filters. |

By utilizing these tools, one can significantly enhance the ability to tackle various issues, ensuring longevity and performance of the equipment.

Step-by-Step Repair Process

This section outlines a systematic approach to addressing common issues with marine propulsion systems. Following a structured procedure can enhance efficiency and ensure thoroughness during the maintenance tasks. Each stage is designed to guide you through diagnostics, disassembly, and reassembly, facilitating a comprehensive understanding of the process.

Initial Diagnostics

Start by evaluating the performance of the unit. Listen for unusual sounds, check for leaks, and inspect components visually. Document any anomalies you observe, as these notes will assist in troubleshooting. Once the problem is identified, gather the necessary tools and parts for the subsequent steps.

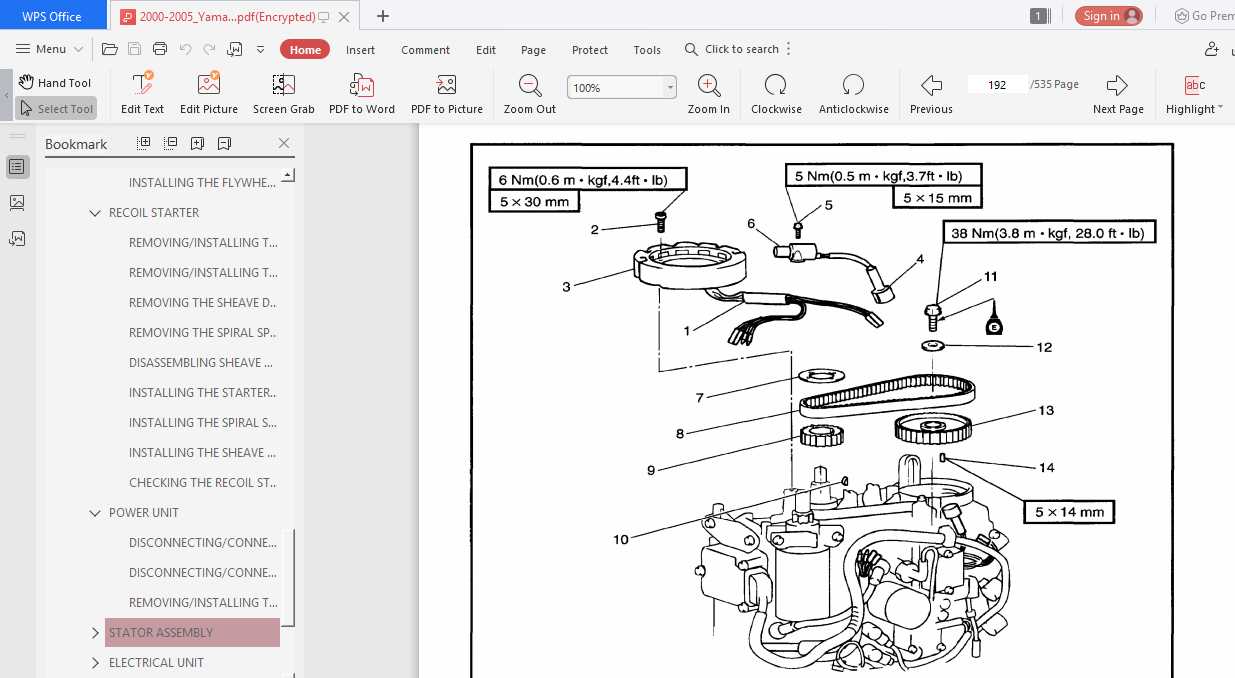

Disassembly and Inspection

Carefully disassemble the unit according to the manufacturer’s specifications. Pay attention to the arrangement of components to ensure correct reassembly. Inspect each part for wear, damage, or corrosion. Replace any defective elements as necessary, and clean components to remove debris. This meticulous attention to detail will improve the overall performance and longevity of the system.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the longevity of marine equipment. By following a few straightforward practices, users can enhance the performance and lifespan of their engines, reducing the likelihood of costly repairs and downtime.

Regular Inspections

Conducting frequent checks can identify potential issues before they escalate. Focus on the following areas:

- Inspect fuel lines for leaks and wear.

- Check for corrosion on metal components.

- Examine electrical connections for signs of damage.

Routine Cleaning

Keeping your equipment clean is vital. Regular cleaning helps prevent build-up and ensures optimal function. Consider these steps:

- Rinse off saltwater and debris after each use.

- Clean air filters regularly to maintain airflow.

- Use appropriate cleaners for different surfaces to avoid damage.

Incorporating these practices into your maintenance routine will promote efficiency and prolong the life of your marine equipment.

Electrical System Troubleshooting

Troubleshooting the electrical components of marine engines is crucial for ensuring optimal performance and reliability. Understanding how to identify and resolve issues can significantly enhance the longevity of the system and prevent unexpected failures. This section outlines common problems and effective strategies for diagnosing electrical faults.

Below is a summary of frequent electrical issues and their potential causes:

| Issue | Possible Causes |

|---|---|

| Engine Won’t Start | Weak battery, faulty ignition switch, poor connections |

| Intermittent Power Loss | Damaged wiring, corroded terminals, loose connections |

| Warning Lights Activated | Faulty sensors, wiring issues, malfunctioning control unit |

| Excessive Drain on Battery | Short circuits, faulty components, continuous power draw from accessories |

By systematically checking each potential issue and following a structured approach, you can effectively diagnose and resolve electrical system challenges. Utilize this guide to enhance your understanding and tackle electrical problems confidently.

Replacing Propellers and Shafts

Maintaining optimal performance in marine engines often involves the periodic replacement of key components. Among these, the blades that propel the vessel and the connecting shafts play crucial roles in ensuring efficiency and safety on the water. This section outlines the essential steps for executing these replacements effectively.

Tools and Materials Needed

- Wrench set

- Screwdriver

- Replacement propeller

- New shaft (if necessary)

- Lubricant

- Safety gear (gloves, goggles)

Step-by-Step Process

- Ensure the vessel is securely anchored or on a stable platform.

- Remove the existing propeller by loosening the central nut using the appropriate wrench.

- Carefully slide off the propeller and inspect the shaft for any wear or damage.

- If necessary, detach the shaft following the manufacturer’s guidelines.

- Clean the area thoroughly, removing any debris or old lubricant.

- Apply a suitable lubricant to the new components before installation.

- Attach the new propeller and secure it with the nut, ensuring it is tightened to the specified torque.

- Reattach the shaft if it was removed, checking that all connections are secure.

- Test the assembly by running the engine at low speed to ensure everything operates smoothly.

Fuel System Cleaning Techniques

Maintaining the integrity of the fuel delivery system is essential for optimal performance and longevity. Regular cleaning can prevent blockages and ensure that fuel flows smoothly to the engine, enhancing efficiency and responsiveness.

Initial Inspection: Begin by examining the entire system for any visible signs of contamination or damage. Look for debris in the fuel tank, filters, and lines that may hinder performance.

Removing Deposits: Utilize a specialized cleaner designed for fuel systems to dissolve varnish and carbon deposits. Following the product instructions, introduce the cleaner into the system, allowing it to circulate for the recommended duration.

Filter Replacement: Replacing filters at regular intervals is crucial. This not only captures impurities but also improves the overall functionality of the system. Ensure that all new filters meet the specifications for your setup.

Flushing the System: A thorough flush with clean fuel can help remove any lingering contaminants. This process involves disconnecting the fuel line and running clean fuel through the system, ensuring that all passages are clear.

Final Check: After cleaning, conduct a comprehensive inspection and test the system under operational conditions. Monitoring for leaks or irregularities will confirm that the cleaning process was successful.

Finding Genuine Replacement Parts

When maintaining marine engines, sourcing authentic components is essential for optimal performance and longevity. Using original parts ensures compatibility and reliability, preventing potential issues that may arise from inferior substitutes.

Here are some strategies for locating genuine components:

- Authorized Dealers: Seek out certified retailers who specialize in marine equipment. They often have a selection of genuine parts and knowledgeable staff to assist you.

- Manufacturer’s Website: Explore the official site of the engine’s manufacturer for a list of authentic parts and authorized distributors. This resource can guide you to trusted sources.

- Online Marketplaces: Utilize reputable e-commerce platforms that guarantee original products. Look for seller ratings and customer reviews to ensure reliability.

- Community Forums: Engage with fellow enthusiasts in online communities. Members can share their experiences and recommend where to find authentic parts.

By prioritizing genuine components, you contribute to the efficiency and lifespan of your marine engine, ensuring safe and enjoyable outings on the water.

Safety Precautions During Repairs

Ensuring a safe environment is essential when undertaking maintenance tasks. Proper precautions can prevent accidents and injuries, allowing for a smoother and more efficient process. It is crucial to be aware of the potential hazards associated with working on machinery and to take steps to mitigate risks.

First and foremost, always wear appropriate personal protective equipment (PPE). This includes gloves, safety goggles, and closed-toe shoes to protect against sharp objects, chemical splashes, and heavy equipment. Additionally, ensure that your workspace is well-ventilated to avoid inhaling harmful fumes.

Before starting any procedure, familiarize yourself with the equipment and its components. Understanding how different parts function together can help identify potential issues and prevent mishaps. Make sure to disconnect power sources and secure any moving parts to avoid accidental activation.

Furthermore, keep your workspace organized and free from clutter. A tidy area reduces the likelihood of tripping hazards and allows for easy access to tools and components. Always store tools properly after use to prevent accidents.

Finally, do not hesitate to seek assistance if unsure about any aspect of the task. Collaborating with others can provide valuable insights and enhance safety. Remember, prioritizing safety not only protects you but also contributes to the successful completion of maintenance tasks.

Online Resources for Further Learning

In today’s digital age, a wealth of information is readily available for those seeking to enhance their knowledge and skills in maintenance and troubleshooting. Utilizing online platforms can significantly improve one’s understanding of various techniques and practices.

Educational Websites

Numerous websites offer extensive tutorials, videos, and articles focused on the intricacies of maintenance. These platforms often feature expert advice and user-generated content, providing a diverse range of perspectives. Engaging with these resources can deepen your comprehension and keep you updated on the latest innovations.

Community Forums

Participating in online communities and discussion boards allows individuals to share experiences and seek guidance. These forums create a collaborative environment where users can ask questions and receive support from fellow enthusiasts. Networking with others can foster learning and help troubleshoot specific challenges effectively.