Comprehensive Repair Manual for the 1998 Honda Accord

Maintaining a vehicle is essential for ensuring its longevity and optimal performance. Understanding the intricacies of car upkeep can empower owners to tackle common issues and perform routine tasks with confidence. This section aims to provide valuable insights into effective strategies for keeping your automobile in top shape.

Whether you’re a seasoned enthusiast or a newcomer to vehicle care, having access to clear, detailed instructions can make all the difference. From troubleshooting minor inconveniences to conducting essential checks, the right information can transform the way you interact with your car. Embracing this knowledge not only enhances your skills but also fosters a deeper appreciation for automotive craftsmanship.

In this guide, you will discover practical tips and step-by-step procedures that cater to various aspects of vehicle maintenance. Empower yourself with the ability to identify problems early and address them efficiently, ultimately saving time and money. By embracing a proactive approach, you can ensure that your ride remains reliable and enjoyable for years to come.

Overview of 1998 Honda Accord

This section provides a comprehensive look at a popular vehicle known for its reliability and performance. Launched in the late 90s, this model has gained a reputation for combining practicality with comfort, making it a favorite among drivers seeking a balanced ride.

Design and Features

The exterior boasts a sleek, aerodynamic silhouette that enhances both aesthetics and fuel efficiency. Inside, the cabin is designed for comfort, featuring high-quality materials and ample space for passengers and cargo. Modern conveniences, such as air conditioning, power windows, and an advanced audio system, contribute to an enjoyable driving experience.

Performance and Handling

Under the hood, this vehicle is equipped with a robust engine that delivers a smooth and responsive ride. The suspension system is engineered to absorb bumps effectively, providing stability and control on various road conditions. Whether commuting in the city or cruising on the highway, drivers appreciate the dependable handling and performance.

Safety and Reliability

Safety is a key priority, with numerous features designed to protect occupants. The model includes advanced airbags and anti-lock braking systems, reflecting a commitment to driver and passenger security. This reputation for safety, combined with low maintenance costs, contributes to its standing as a long-lasting option in the automotive market.

Common Issues and Solutions

Every vehicle has its own set of challenges that can arise over time. Understanding these typical problems and their corresponding fixes can enhance longevity and performance. Below are some frequent concerns that owners may encounter, along with practical solutions to address them.

Electrical System Failures

A malfunctioning electrical system can lead to a variety of issues, including problems with starting the engine or malfunctioning lights. Checking the battery and connections is crucial. If the battery is old or weak, replacing it can often resolve the problem. Additionally, inspect the fuses and wiring for any signs of wear or damage.

Suspension Noises

Unusual sounds coming from the suspension may indicate wear in components such as struts or shocks. Listening for clunks or rattles while driving can help identify the issue. If these noises are present, it’s advisable to have a professional inspect the suspension system and replace any faulty parts to ensure a smooth ride.

By addressing these common issues promptly, vehicle owners can maintain their automobile’s performance and reliability.

Maintenance Tips for Longevity

Ensuring the prolonged lifespan of your vehicle requires consistent care and attention. Implementing a few essential practices can help keep your automobile running smoothly and efficiently for many years.

- Regular Oil Changes: Change the engine oil and filter at recommended intervals to maintain optimal performance.

- Tire Care: Check tire pressure monthly and rotate them every 5,000 to 7,500 miles to promote even wear.

- Brake Inspection: Examine brake pads and rotors regularly to ensure effective stopping power and safety.

- Fluid Levels: Regularly check and top off fluids such as coolant, transmission fluid, and brake fluid to prevent overheating and mechanical failures.

In addition to these practices, adhering to a regular maintenance schedule as outlined by the manufacturer can significantly enhance the vehicle’s longevity. Not only does this involve replacing worn-out parts, but it also encompasses inspections that can catch potential issues before they become major problems.

- Battery Maintenance: Inspect the battery for corrosion and ensure terminals are clean. Replace the battery every 3-5 years.

- Belts and Hoses: Examine belts and hoses for signs of wear and replace them according to the service recommendations to avoid breakdowns.

- Exterior Care: Regularly wash and wax the exterior to protect the paint and prevent rust.

- Interior Maintenance: Keep the interior clean and condition leather or upholstery to prolong its life.

By following these maintenance tips, you can enjoy a reliable and durable vehicle that serves you well for years to come.

Step-by-Step Repair Procedures

This section outlines detailed guidelines for addressing various issues that may arise in your vehicle. Following these systematic instructions will help ensure effective troubleshooting and maintenance, leading to improved performance and longevity.

| Procedure | Description | Tools Needed |

|---|---|---|

| Engine Check | Inspect the engine for any unusual noises or leaks. | Socket set, wrench |

| Brake System Inspection | Examine brake pads and discs for wear and damage. | Jack, brake cleaner |

| Transmission Fluid Change | Drain and replace old transmission fluid. | Drain pan, funnel |

| Battery Maintenance | Clean terminals and check for corrosion. | Wire brush, multimeter |

By adhering to these structured steps, you can efficiently address common concerns, ensuring your vehicle remains in optimal condition. Regular attention to these areas is crucial for preventative maintenance.

Essential Tools for DIY Repairs

When tackling automotive projects on your own, having the right equipment is crucial. A well-stocked toolkit can make the difference between a smooth process and frustrating setbacks. Below are some fundamental items every enthusiast should consider adding to their collection.

- Wrenches: A variety of sizes, including both open-end and box-end, will help you tackle most fasteners.

- Screwdrivers: A set of flathead and Phillips screwdrivers in different sizes is essential for various tasks.

- Socket Set: Ratchet sockets in multiple sizes allow for quick and efficient removal of nuts and bolts.

- Torque Wrench: Ensures that bolts are tightened to the manufacturer’s specifications, preventing damage.

- Pliers: Needle-nose and locking pliers are versatile tools for gripping and manipulating objects.

- Jack and Stands: A reliable jack and sturdy stands are necessary for safely elevating the vehicle.

- Multimeter: Useful for diagnosing electrical issues and checking voltage levels.

Equipping yourself with these basic tools not only enhances your capability but also boosts confidence in handling various tasks. As you gain experience, you can expand your toolkit to include more specialized equipment for specific jobs.

Understanding Engine Components

The engine is the heart of any vehicle, comprised of various parts that work together to create power and efficiency. Understanding these elements is essential for anyone looking to grasp how their automobile functions and to diagnose issues effectively. Each component plays a pivotal role, contributing to the overall performance and longevity of the machine.

Below is a table highlighting key engine components along with their primary functions:

| Component | Function |

|---|---|

| Cylinder Block | Houses the cylinders and provides the foundation for the engine assembly. |

| Pistons | Move up and down within the cylinders, converting fuel energy into mechanical energy. |

| Crankshaft | Transforms the linear motion of the pistons into rotational motion. |

| Camshaft | Controls the opening and closing of the engine valves. |

| Valves | Regulate the flow of air and fuel into the cylinders and exhaust gases out. |

| Timing Belt | Synchronizes the rotation of the crankshaft and camshaft. |

By familiarizing oneself with these essential components, vehicle owners can better understand maintenance needs and performance enhancements.

Electrical System Troubleshooting

When facing issues within the electrical network of a vehicle, a systematic approach is essential. Understanding the components and their interactions can help diagnose problems efficiently. This section outlines key steps to identify and resolve electrical malfunctions effectively.

- Visual Inspection:

- Check for frayed wires or loose connections.

- Look for signs of corrosion on terminals and connectors.

- Examine fuses for any that may be blown.

- Testing Voltage:

- Use a multimeter to measure voltage at various points.

- Ensure the battery is fully charged and functioning properly.

- Check voltage drop across connections to identify resistance issues.

- Component Evaluation:

- Test the alternator to ensure it is charging the battery.

- Inspect the starter motor for proper operation.

- Assess relays and switches for functionality.

- Diagnostic Tools:

- Utilize an OBD-II scanner to retrieve error codes.

- Refer to wiring diagrams for clarity on circuit layouts.

- Use specialized tools for precise measurements and analysis.

By following these steps, one can methodically troubleshoot electrical issues, leading to effective resolutions and ensuring optimal performance of the vehicle’s systems.

Transmission Problems and Fixes

The transmission system is a critical component of any vehicle, and issues can arise that affect performance and safety. Understanding common malfunctions and their solutions can help maintain the vehicle’s reliability and longevity. This section addresses frequent transmission challenges and provides guidance on how to tackle them effectively.

Common Issues

Drivers may encounter various problems with the transmission, including slipping, unusual noises, or failure to engage gears. These symptoms often indicate underlying issues that require prompt attention. Early diagnosis can prevent further damage and costly repairs.

Solutions and Recommendations

Here are some common transmission problems along with recommended fixes:

| Issue | Description | Recommended Action |

|---|---|---|

| Slipping Gears | The vehicle unexpectedly changes gears or fails to stay in gear. | Check fluid levels and condition; consider a fluid change or professional inspection. |

| Noisy Transmission | Unusual sounds such as grinding or whining when shifting. | Inspect for worn bearings or damaged gears; seek professional assistance. |

| Fluid Leaks | Visible puddles under the vehicle may indicate leaking transmission fluid. | Identify the source of the leak and repair or replace damaged seals or gaskets. |

| Delayed Engagement | A noticeable delay before the vehicle engages when shifting from park to drive. | Check fluid levels; if low, top off and monitor for further issues. |

Brake System Maintenance Guide

Proper upkeep of the braking mechanism is essential for ensuring safe driving and optimal vehicle performance. Regular checks and timely interventions can prevent serious issues and extend the lifespan of your braking components. This guide outlines key practices to maintain the braking system effectively.

Routine Inspections

Conducting frequent inspections of the braking system is vital. Look for signs of wear, such as unusual noises, vibrations, or decreased responsiveness. Inspect brake pads, rotors, and fluid levels, and replace components as needed. Keeping a maintenance log can help track these inspections.

Fluid Management

Brake fluid plays a crucial role in the overall performance of the braking system. Ensure the fluid is clean and at the appropriate level, as contamination can lead to reduced efficiency. It’s recommended to change the fluid at regular intervals to prevent moisture buildup and corrosion within the system.

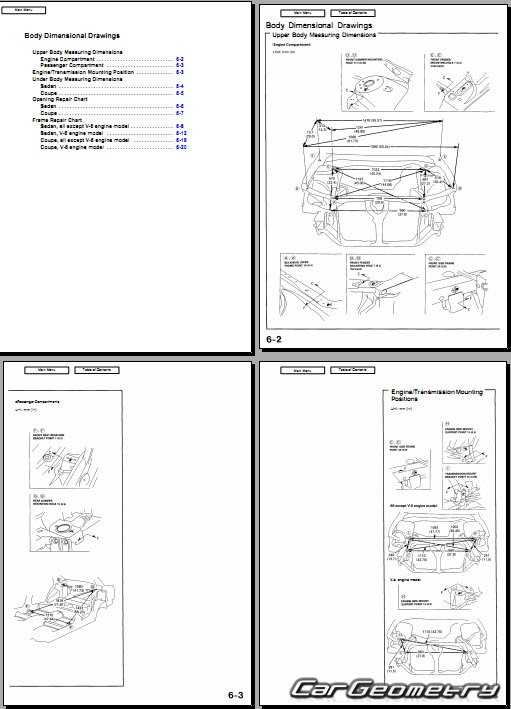

Suspension and Steering Repairs

The suspension and steering systems play a vital role in ensuring vehicle stability and driver control. Proper maintenance and timely interventions in these areas are essential for safe and smooth operation. This section provides guidance on common issues and solutions related to these crucial components.

Diagnosis of Suspension Issues

Identifying problems in the suspension system often starts with unusual noises or changes in handling. Common signs include clunking sounds when driving over bumps, excessive body roll during turns, or uneven tire wear. Conducting a thorough visual inspection can help pinpoint issues such as worn bushings, damaged shock absorbers, or sagging springs.

Steering System Maintenance

Maintaining the steering assembly is equally important. Look for signs like stiffness in steering or vibrations during operation. Regular checks of the steering fluid levels and the condition of the steering components, including tie rods and rack-and-pinion systems, can prevent more significant problems down the line.

Common Repairs

Repairing suspension and steering components often involves replacing worn parts. Shock absorbers, control arms, and sway bar links may need to be addressed. Additionally, steering alignments are crucial after any component replacements to ensure optimal handling and tire longevity.

Safety Precautions

When performing maintenance, always prioritize safety. Use appropriate tools, secure the vehicle on a level surface, and wear protective gear. If unsure about any procedure, consult a professional to avoid potential hazards.

Cooling System Check and Repair

The efficiency of a vehicle’s cooling mechanism is crucial for maintaining optimal engine performance. A well-functioning system prevents overheating, ensures longevity, and enhances overall reliability. Regular inspections and timely interventions can mitigate potential issues that could lead to more significant problems down the road.

Key Components to Inspect

- Radiator: Check for leaks, blockages, and corrosion.

- Hoses: Inspect for cracks, bulges, and wear.

- Water Pump: Ensure it’s functioning correctly and not leaking.

- Thermostat: Verify it opens and closes at the correct temperatures.

- Coolant: Assess the level and quality, and replace if necessary.

Steps for Troubleshooting

- Start with a visual inspection of all components.

- Check coolant levels in the reservoir and radiator.

- Test the thermostat by removing it and placing it in boiling water to see if it opens.

- Run the engine and observe the temperature gauge for any irregularities.

- If overheating occurs, turn off the engine immediately to avoid damage.

Fuel System Inspection Techniques

Regular examination of the fuel delivery system is essential for ensuring optimal engine performance. Effective assessment techniques can help identify potential issues before they lead to significant complications. This section outlines various methods for inspecting the fuel system components to maintain vehicle reliability and efficiency.

Visual Inspection

Begin with a thorough visual check of the fuel lines, filters, and injectors. Look for signs of wear, such as cracks, leaks, or corrosion. Any irregularities may indicate the need for immediate attention. Pay special attention to the connections and clamps, as they can be common sources of fuel loss.

Pressure Testing

Utilizing a pressure gauge is crucial for assessing the integrity of the fuel system. Connect the gauge to the fuel rail and start the engine. Observe the readings; they should align with the manufacturer’s specifications. A drop in pressure may signify a failing pump or clogged filter. Additionally, check for any fluctuations that could suggest issues with the fuel pressure regulator.

Incorporating these inspection techniques will not only enhance the performance of the vehicle but also extend its lifespan. Regular maintenance ensures that the fuel system operates efficiently, providing the necessary power for a smooth driving experience.

How to Read Diagnostic Codes

Understanding how to interpret diagnostic codes is essential for effective vehicle maintenance and troubleshooting. These codes provide valuable insights into potential issues within the engine and other systems, allowing for timely interventions and repairs. Knowing how to access and decode these signals can save both time and money.

Accessing the Codes

To begin, locate the diagnostic port, usually found under the dashboard. Once you connect an appropriate scanning tool, it will communicate with the vehicle’s computer, retrieving stored codes. Each code corresponds to specific malfunctions or anomalies, which can be referenced in a detailed guide or database.

Interpreting the Codes

After gathering the codes, it’s crucial to interpret them correctly. Codes typically consist of a letter followed by four digits, indicating the type and area of the fault. Utilize a reliable source to look up these codes, and pay attention to any patterns that might indicate broader issues. Thorough analysis can lead to an accurate diagnosis and ultimately, an effective solution.