Comprehensive Repair Guide for the 1998 Yamaha Grizzly 600

Understanding the intricacies of a powerful all-terrain vehicle can enhance its performance and longevity. This section delves into essential aspects of upkeep, ensuring that enthusiasts can navigate the complexities of their machinery with ease. From routine inspections to troubleshooting common issues, a comprehensive knowledge base is invaluable for any owner.

Whether you are a seasoned expert or a newcomer to the world of off-road vehicles, having access to detailed information can empower you to tackle various challenges. Knowledge of components, operational techniques, and maintenance practices is crucial for preserving the efficiency of your vehicle. With the right guidance, owners can optimize their experience and enjoy their adventures to the fullest.

This guide is designed to offer practical advice and insights into the essential processes involved in caring for your all-terrain vehicle. By following recommended practices, you can ensure not only optimal performance but also a safer ride. Engage with the content to unlock the full potential of your vehicle, fostering a deeper connection with your outdoor experiences.

Overview of the 1998 Yamaha Grizzly 600

This section provides an insight into a powerful all-terrain vehicle renowned for its durability and performance. Designed for off-road enthusiasts, this model has become a favorite due to its robust features and reliable capabilities. Understanding its design and specifications is essential for maintaining optimal functionality.

Key Features

- High-performance engine designed for rugged terrains

- Advanced suspension system for improved handling

- Durable frame construction ensuring longevity

- Spacious cargo capacity for transporting gear

Specifications

- Engine type: Single-cylinder, four-stroke

- Displacement: Standard for powerful performance

- Transmission: Automatic for easy operation

- Drive system: 4×4 for enhanced traction

This versatile vehicle is suitable for a variety of activities, from recreation to utility work, making it an excellent choice for adventurers and outdoor workers alike.

Essential Tools for Repairs

Having the right equipment is crucial for effective maintenance and restoration of your all-terrain vehicle. A well-equipped toolbox not only enhances efficiency but also ensures that tasks are completed safely and accurately. Familiarity with various tools can significantly streamline the process and improve overall performance.

Start with basic hand tools, such as wrenches, pliers, and screwdrivers, which are essential for disassembling and assembling components. Additionally, consider investing in a high-quality socket set to handle different sizes of fasteners. A torque wrench is vital for ensuring that bolts are tightened to the manufacturer’s specifications, preventing potential damage.

Power tools can also be beneficial, particularly for more extensive jobs. A reliable impact wrench can save time when removing stubborn bolts, while a drill with various bits allows for versatility in tasks. Safety gear, such as gloves and goggles, should not be overlooked, as they protect against injuries during maintenance activities.

Lastly, having a comprehensive repair guide can be invaluable. This resource can provide detailed instructions and specifications, aiding in the effective use of tools and enhancing your understanding of the vehicle’s mechanics. With the right tools and knowledge, you can ensure your machine remains in optimal condition.

Understanding the Engine Components

Engines are intricate machines that convert fuel into mechanical energy, enabling vehicles to perform efficiently. A comprehensive understanding of their components is crucial for maintaining optimal performance and longevity.

Key Components

- Cylinder Block: The main structure housing the cylinders and essential components.

- Pistons: Move within the cylinders to create pressure and facilitate combustion.

- Crankshaft: Transforms the linear motion of the pistons into rotational motion.

- Camshaft: Controls the timing of the valve openings and closings.

- Valves: Regulate the intake of air and the expulsion of exhaust gases.

- Timing Belt/Chain: Ensures the synchronization of the crankshaft and camshaft movements.

Functions and Importance

Each component plays a vital role in the overall function of the engine:

- The cylinder block provides the foundation for the engine, supporting all other parts.

- Pistons are essential for compressing the fuel-air mixture, initiating combustion.

- The crankshaft’s rotation powers the vehicle’s drivetrain.

- Timing mechanisms are critical for maintaining precise operation, ensuring efficiency and reducing wear.

Understanding these components aids in effective troubleshooting and enhances maintenance practices, ultimately leading to improved vehicle reliability.

Routine Maintenance Procedures

Regular upkeep is essential for ensuring optimal performance and longevity of your all-terrain vehicle. By adhering to a structured maintenance schedule, you can prevent potential issues and enhance the overall reliability of your machine. This section outlines key tasks that should be performed routinely to keep your vehicle in top condition.

1. Oil and Filter Change: It is vital to replace the oil and filter at recommended intervals to ensure proper lubrication of the engine components. Fresh oil reduces friction and prevents overheating.

2. Air Filter Inspection: The air filter should be checked regularly for dirt and debris. A clean filter promotes efficient airflow, which is crucial for optimal engine performance.

3. Tire Maintenance: Regularly inspect tire pressure and tread depth. Properly inflated tires improve handling and fuel efficiency, while adequate tread ensures safety during operation.

4. Brake System Check: Regularly examine the brake pads and fluid levels. Ensuring that the braking system is in good working order is critical for rider safety.

5. Battery Care: Keep the battery terminals clean and check the charge level frequently. A well-maintained battery ensures reliable starting and operation.

6. Chain Lubrication: The drive chain should be lubricated and adjusted as needed to prevent wear and maintain smooth operation.

By following these essential maintenance tasks, you can significantly extend the life of your vehicle and enjoy a safer, more enjoyable riding experience.

Troubleshooting Common Issues

When dealing with off-road vehicles, it’s essential to be equipped with knowledge about frequent malfunctions that can arise. Addressing these problems promptly can enhance performance and extend the lifespan of your machine. Below are some prevalent concerns and steps to resolve them.

Starting Problems

If your vehicle fails to start, it may be due to a weak battery, faulty ignition system, or fuel delivery issues. To diagnose, check the battery charge and connections. Ensure the ignition components are in good condition, and inspect the fuel system for clogs.

Overheating

Excessive heat can be a sign of insufficient coolant levels, a malfunctioning thermostat, or a blocked radiator. To troubleshoot, verify coolant levels, examine the thermostat for proper operation, and ensure the radiator is clear of debris.

| Issue | Possible Cause | Recommended Action |

|---|---|---|

| Starting Issues | Weak battery, ignition failure, fuel problems | Check battery, inspect ignition, clean fuel system |

| Overheating | Low coolant, thermostat failure, blocked radiator | Verify coolant, test thermostat, clean radiator |

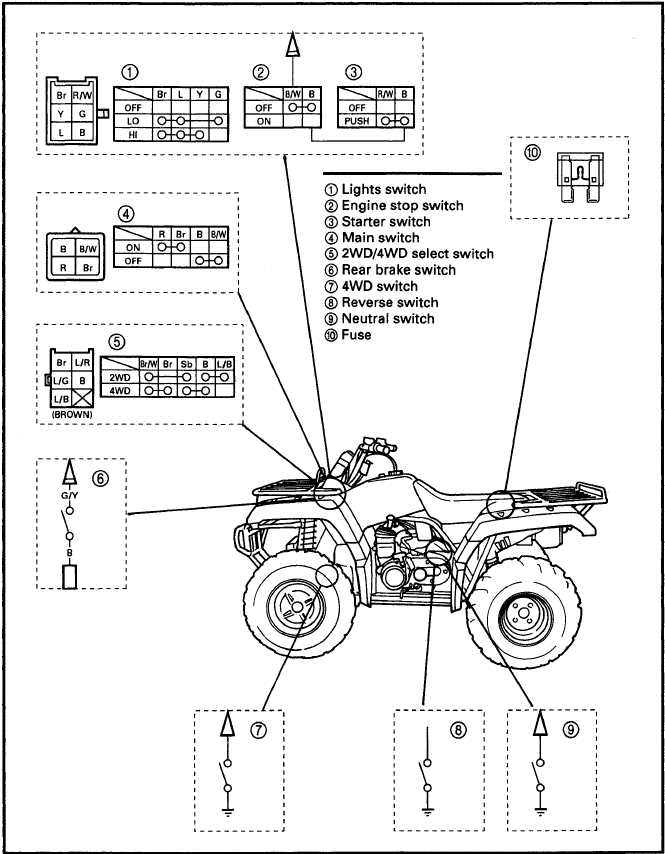

Electrical System Diagnostics

The efficient functioning of any vehicle’s electrical components is crucial for optimal performance. This section focuses on the assessment and troubleshooting of electrical systems, aiming to identify potential issues that may affect the overall operation. By understanding how to systematically diagnose electrical problems, users can ensure that all components work harmoniously.

Understanding Common Issues

Several symptoms may indicate an underlying electrical fault, such as dim lights, erratic instrument readings, or difficulties starting the engine. Recognizing these signs early can prevent more significant complications and costly repairs.

Diagnostic Process

Start by performing a visual inspection of the wiring harness and connectors for any signs of wear, corrosion, or loose connections. Next, utilize a multimeter to check voltage levels and continuity across critical circuits. This step will help pinpoint the location of any malfunctioning components.

Component Testing

After identifying suspect areas, proceed with testing individual electrical parts, including the battery, starter, and alternator. Each component should be assessed according to its specifications, ensuring that they meet the required operational standards.

Final Thoughts

Implementing a thorough diagnostic approach allows for a structured examination of electrical systems, leading to timely repairs and enhanced reliability. By following these guidelines, users can maintain their vehicle’s electrical integrity and prevent unexpected failures.

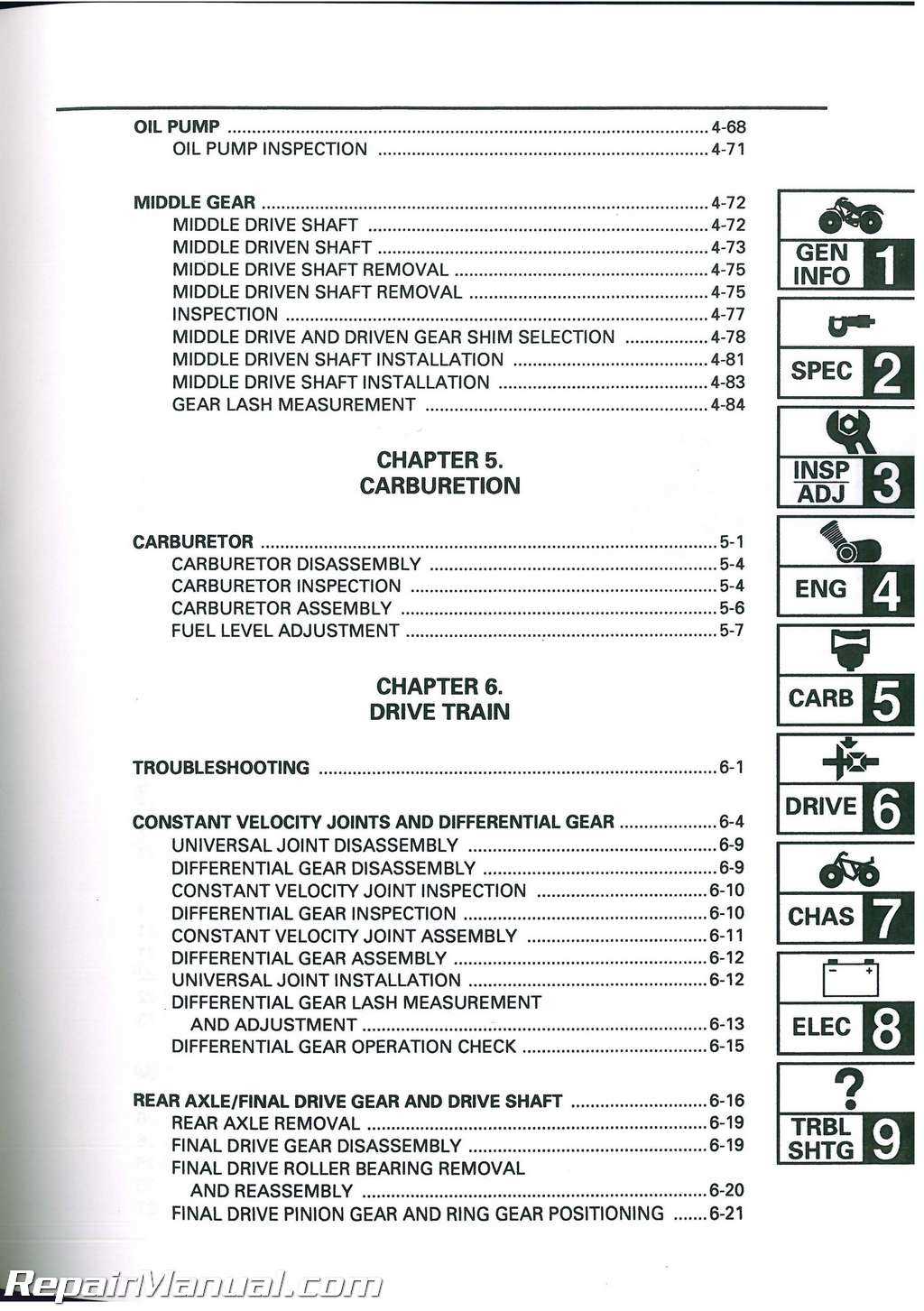

Transmission and Drivetrain Insights

The transmission and drivetrain are crucial components in the functionality of any all-terrain vehicle. Understanding their operation and maintenance can greatly enhance performance and longevity.

In this section, we will explore the various aspects of these systems, including their design, common issues, and best practices for upkeep. The transmission system is responsible for transferring power from the engine to the wheels, enabling efficient movement across different terrains.

Key Components: The primary elements of the drivetrain include the gearbox, differentials, and axles. Each plays a vital role in ensuring smooth power delivery and traction. Regular checks of these components can help prevent unexpected failures.

Common Issues: Some frequent challenges encountered with these systems include slipping gears, unusual noises, and overheating. Identifying these signs early can save time and costs associated with repairs.

Maintenance Tips: Routine maintenance should include checking fluid levels, inspecting for leaks, and ensuring that all connections are secure. Keeping the drivetrain clean and well-lubricated can enhance its efficiency and lifespan.

By gaining insights into the transmission and drivetrain, operators can ensure their vehicles remain reliable and perform optimally in various conditions.

Brake System Inspection and Repair

Ensuring optimal functionality of the braking mechanism is crucial for safety and performance. This section will guide you through the essential steps for evaluating and maintaining the brake components, focusing on their condition, effectiveness, and any necessary adjustments.

Start by visually inspecting the brake pads and rotors for wear and tear. Look for any uneven surfaces, scoring, or excessive wear that may indicate the need for replacement. Check the brake fluid level and its condition; fluid should be clear and free from contamination. If it appears dark or contains debris, it’s advisable to replace it.

Next, examine the brake lines for any signs of leaks or damage. Cracks or abrasions can compromise the system’s integrity. If any issues are found, it is crucial to address them immediately to prevent fluid loss. Additionally, ensure that all connections are secure and that there are no loose fittings.

Testing the brake system involves applying pressure to the brake pedal and observing the response. The pedal should feel firm and engage without excessive travel. If there is sponginess or a decrease in effectiveness, air may be present in the lines, necessitating a bleed of the brake system.

Finally, if any components require replacement, choose parts that meet or exceed manufacturer specifications to ensure compatibility and reliability. Regular maintenance will not only enhance performance but also extend the lifespan of the braking system, contributing to overall safety during operation.

Suspension Adjustments and Upgrades

Enhancing the performance and comfort of your all-terrain vehicle begins with understanding its suspension system. Proper adjustments can significantly improve handling, stability, and overall ride quality. Whether you’re navigating rough trails or cruising on smooth paths, optimizing suspension settings is essential for a tailored experience.

Understanding Suspension Settings

Suspension components play a crucial role in absorbing shocks and maintaining traction. Adjustments can involve modifying preload, compression, and rebound settings to suit your riding style and terrain conditions. Preload affects the initial height and stiffness, while compression and rebound settings control how the suspension reacts to impacts and returns to its original position. Experimenting with these parameters can yield a customized setup that enhances control and comfort.

Upgrading Components for Improved Performance

In addition to adjustments, considering upgrades can further enhance your vehicle’s capabilities. Upgrading to high-performance shocks can provide superior damping characteristics, offering a more responsive ride. Additionally, aftermarket springs can improve load capacity and handling. Investing in quality suspension components not only boosts performance but also increases the longevity of your vehicle, ensuring it remains reliable for years to come.

Wheel and Tire Maintenance Tips

Proper upkeep of your vehicle’s wheels and tires is essential for ensuring optimal performance, safety, and longevity. Regular attention to these components not only enhances handling but also contributes to overall driving comfort. Below are some valuable tips for maintaining wheels and tires effectively.

| Maintenance Task | Frequency | Tips |

|---|---|---|

| Tire Pressure Check | Monthly | Maintain the recommended pressure to improve fuel efficiency and extend tire life. |

| Tread Depth Inspection | Every 3,000 miles | Use a tread depth gauge; replace tires if the tread is below 2/32 of an inch. |

| Visual Inspection | Monthly | Look for signs of wear, cracks, or foreign objects lodged in the tread. |

| Wheel Alignment | Every 6,000 miles | Check alignment if you notice uneven tire wear or drifting while driving. |

| Tire Rotation | Every 5,000 to 7,500 miles | Rotate tires to promote even wear and extend their lifespan. |

By adhering to these guidelines, you can enhance the safety and performance of your vehicle while prolonging the life of its wheels and tires. Regular maintenance will ensure that you enjoy a smoother and safer ride.

Fuel System Cleaning Techniques

Maintaining a clean fuel system is crucial for optimal performance and longevity of any vehicle. Regular cleaning techniques help prevent clogs and ensure smooth operation by removing deposits that accumulate over time. This section outlines effective methods to achieve a pristine fuel delivery system, enhancing overall engine efficiency.

One of the most effective techniques involves using specialized cleaning solutions designed for fuel systems. These products can be added directly to the fuel tank, allowing them to circulate through the entire system. Additionally, physical cleaning methods, such as removing and flushing components like injectors and filters, can further enhance cleanliness.

| Technique | Description |

|---|---|

| Fuel Additives | Incorporating specific cleaners into the fuel to dissolve carbon deposits and clean injectors. |

| Injector Cleaning | Removing injectors for ultrasonic cleaning or using specialized equipment to clear blockages. |

| Filter Replacement | Regularly changing the fuel filter to ensure contaminants do not impede flow. |

| Fuel Tank Cleaning | Draining and cleaning the tank to remove sludge and sediment that can enter the fuel system. |

Implementing these techniques not only improves fuel efficiency but also prolongs the lifespan of engine components. Regular maintenance and cleaning are essential for any enthusiast looking to maintain peak performance.

Body and Frame Care Guidelines

Maintaining the integrity of the chassis and exterior components is essential for optimal performance and longevity. Proper attention to these areas can prevent deterioration and enhance the overall functionality of your vehicle.

Regular Inspection: Conduct frequent checks for any signs of wear, rust, or damage. Pay close attention to critical points such as joints and welds, as these areas are prone to stress and corrosion.

Cleaning: Keep the body and frame clean from dirt and debris. Use a mild detergent and water to wash surfaces, ensuring that any accumulated grime is removed. This practice helps prevent rust formation and maintains a polished appearance.

Protective Coatings: Applying protective treatments or coatings can shield metal surfaces from moisture and harmful elements. Consider using rust inhibitors and sealants to enhance durability and extend the life of the materials.

Storage Practices: When not in use, store the vehicle in a dry, sheltered location. Covering it can provide additional protection against environmental factors, ensuring that the body and frame remain in prime condition.

Addressing Damage Promptly: If any issues are identified, such as scratches or dents, address them immediately. Timely repairs can prevent further complications and maintain the structural integrity of the vehicle.

Safety Practices During Repairs

Ensuring a secure environment while conducting maintenance tasks is crucial for both personal safety and the integrity of the equipment. Adopting appropriate safety measures can prevent accidents and enhance the efficiency of the work process.

- Always wear protective gear, including gloves, goggles, and appropriate footwear.

- Work in a well-ventilated area to avoid inhaling harmful fumes or dust.

- Keep a first-aid kit accessible and familiarize yourself with its contents.

- Ensure that all tools are in good condition and properly stored when not in use.

Prior to starting any task, it is essential to review the equipment’s specifications and guidelines. Understanding the functioning and limitations of the machinery contributes to safer practices.

- Disconnect the power source before beginning any work to prevent accidental starts.

- Use tools as intended, following the manufacturer’s recommendations.

- Secure loose clothing and long hair to avoid entanglement with moving parts.

Regularly inspecting your workspace for hazards can significantly reduce risks. Clearing clutter and ensuring adequate lighting are simple yet effective steps to maintain a safe working environment.