Comprehensive Guide to John Deere LX255 Repair Manual

Maintaining outdoor machinery is crucial for ensuring optimal performance and longevity. Understanding the intricacies of your equipment not only enhances its efficiency but also prevents costly repairs down the line. This section delves into the vital components and procedures necessary for keeping your machine in peak condition.

From routine inspections to troubleshooting common issues, a comprehensive understanding of your device’s workings can empower you to handle various maintenance tasks with confidence. This guide aims to equip users with practical knowledge and step-by-step instructions tailored to specific models, promoting a proactive approach to upkeep.

Whether you are a seasoned enthusiast or a newcomer to the world of lawn care tools, familiarizing yourself with essential maintenance techniques will pave the way for a smoother experience. With the right information at your fingertips, you can ensure that your equipment remains reliable and ready to tackle any task.

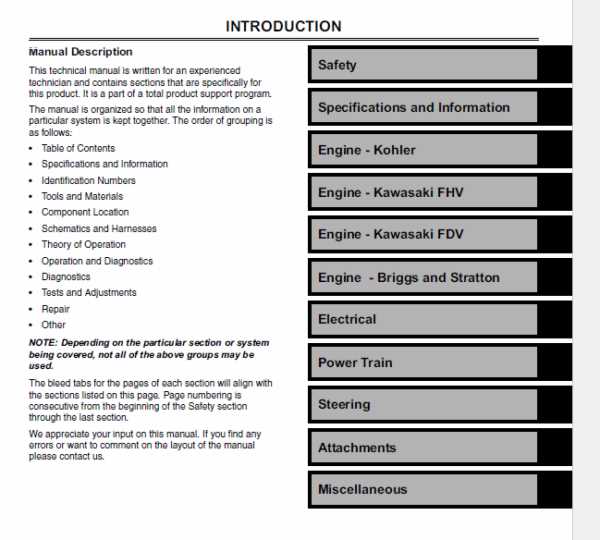

Understanding the John Deere LX255

This section delves into the nuances of a popular lawn maintenance machine, focusing on its features, functionalities, and overall performance. Designed for efficiency and user-friendliness, this model appeals to both novice and experienced operators.

Key attributes of this equipment include:

- Robust construction for durability.

- Intuitive controls for ease of operation.

- Powerful engine for enhanced performance.

- Versatile attachments for various tasks.

When assessing this machine, consider the following aspects:

- Engine Performance: The power output and efficiency ratings.

- Cutting Capability: The width and quality of the cutting deck.

- Maintenance Needs: Regular upkeep and service requirements.

- User Experience: Feedback from owners and operators.

Understanding these elements can significantly impact your ownership experience, ensuring optimal use and longevity of the equipment.

Common Issues with LX255 Lawn Tractors

Lawn tractors are invaluable for maintaining grassy areas, but like any machinery, they can encounter various challenges over time. Understanding these frequent problems can help users maintain their equipment effectively and ensure optimal performance.

One of the most common concerns is engine difficulty. Owners often report issues such as hard starting, stalling, or a lack of power during operation. These symptoms can be caused by several factors, including fuel quality, spark plug condition, and air filter cleanliness.

Another prevalent issue involves the cutting deck. Users may experience uneven grass cutting or a complete failure of the blades to engage. This can be linked to belt wear, pulley malfunction, or improper deck height adjustments.

Transmission problems can also arise, leading to reduced mobility or a complete inability to change speeds. These issues may stem from low fluid levels or worn components within the transmission system.

Lastly, electrical failures are not uncommon. Symptoms like dead batteries, faulty lights, or malfunctioning ignition switches can disrupt the operation. Regular inspections of the electrical system can help identify and resolve these issues before they escalate.

Essential Tools for LX255 Repairs

When undertaking maintenance or troubleshooting tasks on your lawn equipment, having the right set of instruments can significantly enhance the efficiency and effectiveness of your efforts. A well-prepared toolkit not only saves time but also ensures that each task is completed with precision, minimizing the risk of damage to components.

Basic Hand Tools

Starting with the fundamentals, a reliable collection of hand tools is crucial. This includes wrenches in various sizes to accommodate different bolts and nuts, screwdrivers with both flat and Phillips heads for versatile use, and pliers for gripping and manipulating parts. Having these tools readily available allows for quick adjustments and part replacements.

Specialized Equipment

In addition to standard tools, some specialized equipment can greatly aid in more complex procedures. A toroidal torque wrench ensures that all fasteners are tightened to the manufacturer’s specifications, while a multimeter is invaluable for diagnosing electrical issues. Investing in these tools can lead to more informed decisions during servicing and enhance overall functionality.

Step-by-Step Maintenance Guide

Proper upkeep of your equipment is essential for optimal performance and longevity. Following a systematic approach can help prevent issues and ensure smooth operation. This guide provides clear instructions to assist you in maintaining your machinery effectively.

- Check Fluid Levels

- Inspect engine oil and replace if necessary.

- Ensure coolant levels are adequate.

- Examine hydraulic fluid and top up if low.

- Inspect Air Filter

- Remove the air filter cover.

- Examine the filter for dirt and debris.

- Clean or replace the filter as needed.

- Sharpen Blades

- Detach the blades following safety precautions.

- Use a sharpening tool to hone the edges.

- Reattach the blades securely.

- Check Tire Pressure

- Use a pressure gauge to assess tire inflation.

- Adjust pressure to the recommended levels.

- Inspect for any signs of wear or damage.

- Clean the Equipment

- Remove dirt and debris from surfaces.

- Wash with water and mild soap if necessary.

- Dry thoroughly to prevent rust.

By adhering to these steps regularly, you can enhance the performance and durability of your machine, ensuring it remains in prime condition for years to come.

Diagnosing Engine Problems in LX255

Identifying issues with the power unit is crucial for maintaining optimal performance and longevity. Various symptoms can indicate malfunctions, and recognizing these early can prevent further damage. This section will guide you through common signs of trouble and the steps to take for effective diagnosis.

Common Symptoms of Engine Malfunction

Several indicators can signal that the engine requires attention. Here are some frequent symptoms to watch for:

| Symptom | Possible Cause |

|---|---|

| Unusual noises | Loose components or wear in moving parts |

| Difficulty starting | Battery issues or fuel supply problems |

| Excessive smoke | Oil leaks or improper fuel mixture |

| Poor performance | Clogged filters or spark plug failures |

Steps for Effective Diagnosis

To accurately diagnose the underlying issues, follow these steps:

1. Visual Inspection: Begin with a thorough examination of the engine compartment for any visible signs of damage or leaks.

2. Listen for Sounds: Pay attention to any abnormal noises while the engine is running, which can provide clues to internal issues.

3. Check Fluid Levels: Ensure that oil, coolant, and fuel levels are adequate and that there are no leaks present.

4. Test Components: Use diagnostic tools to check the functionality of critical components like the ignition system and fuel injectors.

5. Consult Documentation: Reference any available guides for troubleshooting specific problems related to the engine’s design.

By following these steps, you can effectively pinpoint the root cause of engine issues and determine the necessary actions to restore functionality.

Electrical System Troubleshooting Tips

Identifying issues within the electrical components of your equipment can be a challenging yet essential task. Proper diagnosis not only ensures smooth operation but also enhances the longevity of your machinery. Below are some valuable strategies to effectively troubleshoot electrical problems.

- Visual Inspection: Start with a thorough visual examination of the wiring and connections. Look for any signs of wear, corrosion, or loose terminals.

- Check Fuses: Inspect all fuses and circuit breakers. Replace any blown fuses and reset tripped breakers to restore functionality.

- Use a Multimeter: Employ a multimeter to measure voltage, continuity, and resistance. This tool is essential for pinpointing faulty components.

- Battery Condition: Examine the battery for signs of damage and ensure it is fully charged. A weak or dead battery can lead to a host of electrical problems.

Following these steps will help you narrow down potential electrical issues and guide you toward a solution. Consistent maintenance and timely repairs can prevent future complications.

- Inspect Ground Connections: Ensure all ground connections are secure and free from rust or corrosion.

- Examine Wiring Harness: Check the wiring harness for any frays or breaks that could disrupt electrical flow.

- Look for Short Circuits: Investigate areas where wires may be pinched or damaged, leading to short circuits.

By implementing these troubleshooting techniques, you can address electrical concerns effectively and maintain optimal performance of your machinery.

Replacing Blades on Your LX255

Maintaining the cutting components of your mower is essential for optimal performance and a pristine lawn. Over time, these parts can become dull or damaged, leading to less efficient cutting and an uneven appearance. Regularly replacing the blades not only enhances the mower’s functionality but also prolongs its lifespan.

Before you start the replacement process, gather the necessary tools and ensure you are working in a safe environment. The following table outlines the key steps to follow for a smooth blade replacement:

| Step | Description |

|---|---|

| 1 | Ensure the mower is turned off and disconnected from any power source. |

| 2 | Wear protective gloves to prevent injury while handling the blades. |

| 3 | Using a wrench, remove the bolt securing the blade to the spindle. |

| 4 | Carefully lift the blade off the spindle, taking note of its orientation. |

| 5 | Install the new blade in the same position, ensuring it is aligned properly. |

| 6 | Secure the blade by tightening the bolt firmly. |

| 7 | Reconnect the power source and conduct a test run to check for proper operation. |

By following these steps, you can effectively replace the blades on your mower, ensuring a clean and even cut each time you mow. Regular maintenance, including blade replacement, is key to achieving the best results and maintaining the health of your equipment.

Checking and Changing Fluids

Regular maintenance of various fluids in your equipment is crucial for optimal performance and longevity. Ensuring that these liquids are at the correct levels and in good condition helps prevent mechanical issues and enhances efficiency.

There are several key fluids to monitor:

- Engine oil

- Transmission fluid

- Coolant

- Hydraulic fluid

- Fuel

Follow these steps to check and change the fluids effectively:

- Gather Tools: Collect the necessary tools, including wrenches, a funnel, fluid containers, and rags.

- Check Levels: Use dipsticks or sight glasses to verify fluid levels. Ensure all fluids are within the recommended range.

- Inspect Condition: Look for signs of contamination, such as discoloration or debris, which may indicate a need for change.

- Drain Fluids: If changing, carefully drain old fluids into appropriate containers, following safety procedures.

- Refill: Use the correct type of fluid and refill to the recommended level, avoiding overfilling.

- Dispose Properly: Dispose of old fluids in accordance with local regulations to ensure environmental safety.

By routinely checking and replacing these essential fluids, you help maintain the reliability and efficiency of your machinery.

How to Adjust the Mower Deck

Proper alignment and adjustment of the mowing apparatus are essential for achieving an even cut and maintaining the health of your lawn. Ensuring that the cutting unit is correctly positioned can help prevent uneven wear and promote optimal performance. This guide will outline the necessary steps to adjust the mowing deck effectively.

Step 1: Gather Necessary Tools

Step 2: Check the Tire Pressure

Before making any adjustments, verify that the tire pressure is within the manufacturer’s recommended range. Uneven tire pressure can affect the height of the cutting deck and lead to inconsistent results.

Step 3: Measure the Deck Height

Using a measuring tape, determine the current height of the mowing deck from the ground. Most models have a recommended height setting, so compare your measurement with the specifications provided.

Step 4: Adjust the Deck Level

If the deck is not at the desired height, locate the adjustment mechanism, typically found near the deck support brackets. Use the wrench to modify the height accordingly. Ensure that the deck is level from side to side and front to back.

Step 5: Test the Adjustment

After making the necessary adjustments, conduct a test run. Mow a small area of grass to observe the results. If the cut appears uneven, revisit the previous steps to fine-tune the settings.

Conclusion

Regularly checking and adjusting the mowing deck is vital for effective lawn maintenance. Following these steps will help you achieve a consistent cut and prolong the lifespan of your equipment.

Upgrading Parts for Enhanced Performance

Enhancing the functionality of your machinery often involves upgrading various components. By selecting high-quality parts, you can significantly improve efficiency, durability, and overall performance. This process not only optimizes the equipment but also ensures it meets the demands of more intensive tasks.

Choosing the Right Components is crucial. When considering upgrades, focus on parts that are designed to work synergistically with existing systems. For instance, improved air filters can enhance engine performance by increasing airflow, while upgraded spark plugs can lead to more efficient combustion, resulting in better fuel economy.

Additionally, upgrading the transmission can lead to smoother operation and improved power transfer. A performance-oriented transmission allows for better handling of power loads, particularly in challenging conditions, thereby extending the lifespan of the equipment.

Finally, don’t overlook the importance of regular maintenance alongside upgrades. Keeping all components in top condition ensures that the enhancements you’ve made will deliver their full benefits, providing you with the reliability and effectiveness you expect from your machinery.

Where to Find LX255 Repair Manuals

When it comes to maintaining your outdoor equipment, having access to detailed guidance is crucial. Finding the right resources can help you troubleshoot issues, perform routine maintenance, and ensure optimal performance. Fortunately, there are various avenues to explore for acquiring comprehensive literature that covers everything you need to know.

Online Resources

The internet is a treasure trove of information. Numerous websites specialize in providing documentation and guides for different machinery. Search for reputable sites that offer downloadable files or interactive resources. Additionally, forums and community groups can be invaluable, as experienced users often share their own insights and copies of relevant literature.