Zf 5 Speed Transmission Repair Guide

Understanding the intricacies of a complex mechanical system can often seem daunting, yet it is essential for ensuring optimal performance and longevity. This guide delves into the inner workings of a specific five-gear assembly, providing valuable insights for enthusiasts and professionals alike. Through systematic examination and practical advice, we aim to equip you with the knowledge necessary to address common issues effectively.

The focus here lies in the nuances of maintenance and troubleshooting. With a blend of detailed explanations and step-by-step instructions, this resource is designed to enhance your familiarity with the components and their interactions. By fostering a deeper comprehension of the mechanisms involved, we hope to empower you to tackle challenges confidently.

Whether you are a seasoned technician or a curious novice, this exploration will shed light on essential practices. Our objective is to facilitate a smooth process of intervention and rejuvenation, ensuring that your five-gear apparatus remains in peak condition. With dedication and the right guidance, navigating the complexities of this machinery can become a rewarding endeavor.

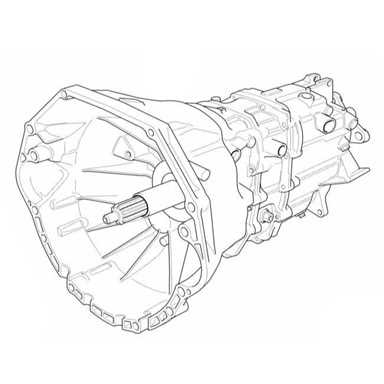

ZF 5 Speed Transmission Overview

The ZF 5-speed system is a remarkable piece of engineering, designed to enhance performance and efficiency in various vehicles. This innovative mechanism provides drivers with smooth gear transitions and improved power delivery, making it a popular choice among automotive manufacturers.

Key features of the ZF 5-speed assembly include:

- Robust construction for durability

- Optimized gear ratios for enhanced acceleration

- Efficient power management for reduced fuel consumption

- Compact design allowing for versatile applications

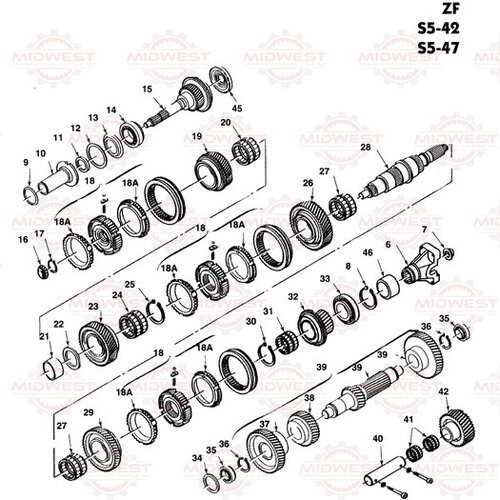

Understanding the components and operation of this system can greatly assist in appreciating its advantages:

- Gear Layout: The arrangement of gears is designed to facilitate quick shifts.

- Synchronization: Specialized mechanisms ensure smooth engagement of gears.

- Fluid Dynamics: Lubrication systems minimize wear and enhance performance.

In summary, the ZF 5-speed assembly represents a blend of sophistication and practicality, providing a reliable solution for modern automotive needs.

Common Issues with Zf Transmissions

Zf units are known for their durability, yet they can experience a range of challenges over time. Understanding these common problems can help in maintaining optimal performance and prolonging their lifespan. Below are some frequent issues that users encounter.

| Issue | Description |

|---|---|

| Fluid Leaks | Often caused by worn seals or gaskets, leading to reduced efficiency. |

| Shifting Delays | Can occur due to sensor malfunctions or low fluid levels, affecting responsiveness. |

| Unusual Noises | Grinding or whining sounds may indicate internal wear or lack of lubrication. |

| Overheating | Excessive heat can result from prolonged use or insufficient fluid circulation. |

| Sticking Gear Selector | Issues with the linkage or internal components may prevent smooth shifting. |

Essential Tools for Transmission Repair

When it comes to maintaining and restoring complex machinery, having the right instruments is crucial for achieving effective results. A well-equipped workspace not only enhances efficiency but also ensures precision during the entire process. Whether tackling a simple task or a more intricate overhaul, certain essentials are fundamental for anyone involved in this line of work.

Basic Hand Tools

A solid foundation of hand tools is indispensable. Wrenches, sockets, and screwdrivers of various sizes allow for the easy disassembly of components. Pliers and hammers also play significant roles, providing the leverage and force needed to manipulate stubborn parts. Investing in high-quality hand tools can greatly reduce the risk of damaging delicate components during the process.

Specialized Equipment

In addition to standard hand tools, specialized instruments are vital for more advanced tasks. Torque wrenches ensure that bolts are tightened to the correct specifications, while alignment tools help maintain proper positioning of components. Diagnostic devices can identify issues early, saving time and effort in the long run. Having access to a variety of these tools makes for a more thorough and effective approach to maintaining machinery.

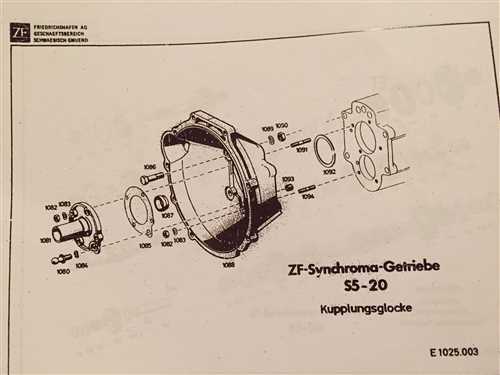

Step-by-Step Disassembly Process

The disassembly of complex machinery requires careful attention to detail and a systematic approach. This section outlines a comprehensive guide to breaking down the unit into its individual components, ensuring that each step is executed with precision to avoid damage or misplacement of parts.

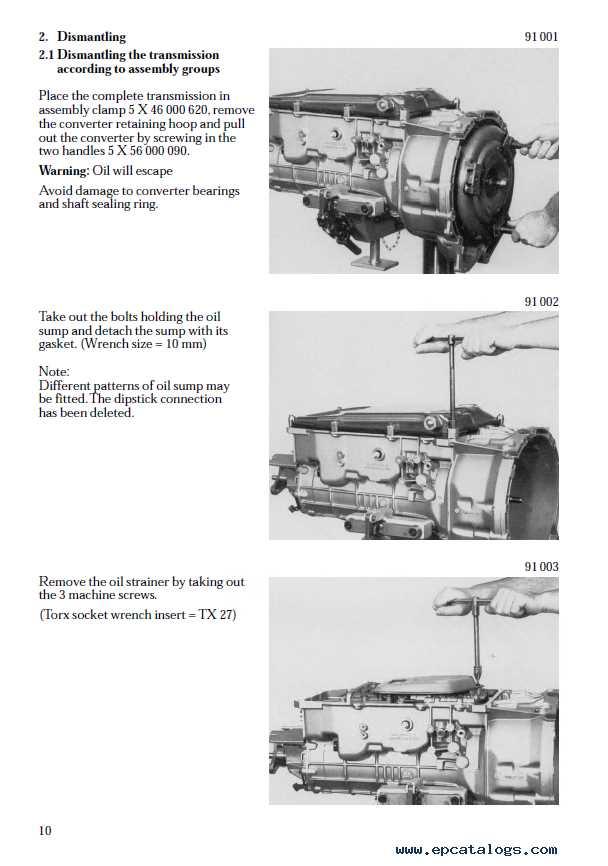

1. Preparation: Before beginning the disassembly, gather all necessary tools and safety equipment. Make sure to work in a clean and organized space, which will facilitate the process and help prevent any loss of small components.

2. Documentation: Take notes and photographs of the assembly as it exists before disassembly. This visual documentation will serve as a valuable reference for reassembly later.

3. Drain Fluids: Safely drain any fluids present in the unit to prevent spills and contamination. Proper disposal of these fluids is essential for environmental safety.

4. Remove External Covers: Start by taking off any external covers or housings. Use the appropriate tools to avoid stripping screws or damaging the surfaces.

5. Disconnect Components: Carefully disconnect any attached components, such as cables or brackets. Label each part as you remove it to ensure accurate reassembly.

6. Take Apart Internal Assemblies: Once external elements are removed, begin taking apart the internal assemblies. Follow the order outlined in your documentation to maintain the correct sequence.

7. Inspect Parts: As each part is disassembled, inspect for wear or damage. This assessment will guide you in determining which components need replacement.

8. Organize Components: Place each removed part in a labeled container. This organization is crucial for keeping track of all components during the reassembly phase.

9. Final Checks: Once disassembly is complete, conduct a final check to ensure all parts are accounted for and properly documented. This will help streamline the reassembly process.

By following these steps meticulously, the disassembly process can be completed efficiently, paving the way for effective maintenance or upgrades to the machinery.

Identifying Wear and Damage

Recognizing signs of deterioration and impairment in mechanical components is crucial for maintaining optimal functionality. This section will guide you through common indicators that suggest components may need attention, ensuring longevity and performance.

Common Signs of Wear

- Unusual Noises: Grinding, whining, or clunking sounds can indicate issues with gears or bearings.

- Fluid Leaks: Any visible leaks may suggest seal or gasket failure.

- Excessive Play: Noticeable movement in components can signal wear in bushings or bearings.

Identifying Damage

- Visual Inspection: Look for cracks, chips, or discoloration on the surface of components.

- Surface Wear: Check for uneven surfaces or scoring, which can affect performance.

- Heat Damage: Signs of overheating, such as burnt or melted materials, require immediate evaluation.

By being vigilant and aware of these signs, you can prevent further damage and ensure reliable operation of your equipment.

Cleaning and Maintenance Procedures

Maintaining optimal performance of your vehicle’s drivetrain involves regular cleaning and upkeep. Proper attention to these areas not only extends the lifespan of components but also enhances overall efficiency. Establishing a routine that addresses both internal and external cleanliness is crucial.

Regular Inspections: Begin with frequent examinations of the unit for signs of wear or contamination. This proactive approach helps identify potential issues before they escalate, ensuring smooth operation.

Fluid Replacement: Over time, fluids can degrade and become contaminated. It is essential to drain and replace these substances according to the manufacturer’s recommendations. Using high-quality alternatives can significantly improve performance and reliability.

Component Cleaning: Utilize suitable solvents to clean critical parts, removing dirt and debris. Pay special attention to filters and seals, as these play a vital role in maintaining optimal functioning. Ensure all components are thoroughly dried before reassembly.

Protective Measures: After cleaning, consider applying protective coatings to vulnerable areas. This can help shield components from environmental factors and prolong their life. Regularly check these coatings for wear and reapply as necessary.

By following these guidelines, you can ensure the longevity and effectiveness of your vehicle’s drivetrain, ultimately leading to a smoother and more reliable driving experience.

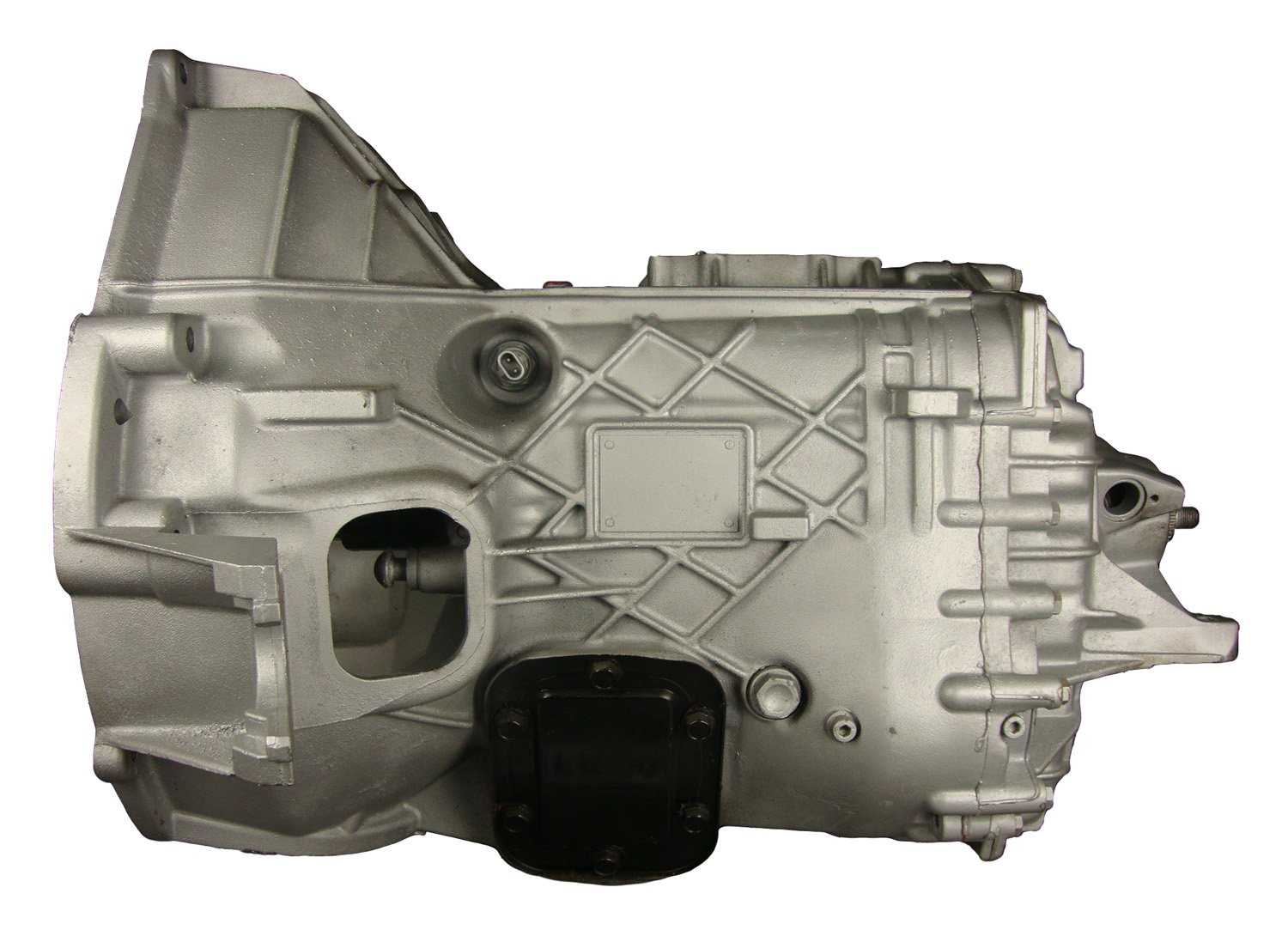

Reassembling the Transmission Properly

Reassembling a complex mechanical system requires precision and attention to detail. Ensuring that each component is correctly positioned and secured is crucial for optimal performance and longevity. This section outlines the essential steps to achieve a successful reassembly, minimizing the risk of errors that could lead to future complications.

1. Organize Components: Before beginning the reassembly process, it is vital to arrange all parts systematically. This can be done by laying them out in the order they will be reattached. Having everything in view will help avoid confusion and missing pieces.

2. Clean Surfaces: Ensure that all mating surfaces are free from debris and old sealant. A clean surface promotes proper sealing and reduces the likelihood of leaks. Use a suitable solvent and lint-free cloth to wipe down parts as necessary.

3. Follow Torque Specifications: Refer to the original specifications for tightening components. Applying the correct torque is essential for securing parts without causing damage. Utilize a calibrated torque wrench to achieve the specified tightness, ensuring uniform pressure across connections.

4. Inspect and Replace Seals: Check all gaskets and seals for wear. Replacing these components is often a small investment that can prevent significant issues later on. Ensure that new seals are properly seated before securing the housing.

5. Verify Alignment: As you assemble the parts, frequently check that everything aligns correctly. Misalignment can lead to premature wear and operational failure. Take your time to ensure that shafts and gears fit snugly within their respective housings.

6. Conduct Final Checks: Once the assembly is complete, perform a thorough inspection. Look for any misplaced components or signs of potential issues. It is beneficial to have a checklist to ensure no step has been overlooked.

By adhering to these guidelines, one can achieve a successful reassembly that enhances the reliability and efficiency of the entire system. Patience and diligence during this process will pay off in the long run.

Fluid Types and Specifications

Understanding the various types of lubricants and their specifications is essential for ensuring optimal performance and longevity of your vehicle’s mechanical systems. The right choice of fluid not only enhances efficiency but also plays a critical role in protecting components from wear and tear. Selecting the appropriate product based on manufacturer guidelines can prevent potential issues and contribute to the overall health of the machinery.

Recommended Fluids

Manufacturers typically provide specific recommendations regarding the types of fluids suitable for different applications. Common choices include synthetic oils, mineral oils, and specific formulations designed for high-performance scenarios. Each option comes with its own set of properties, making it vital to consult the guidelines to choose the correct variant for your needs.

Specifications and Standards

Specifications are outlined to ensure compatibility and effectiveness of the fluids used. These may include viscosity ratings, additives, and performance standards that meet or exceed industry benchmarks. It is crucial to pay attention to these details when selecting a lubricant, as using a fluid that does not align with the recommended standards can lead to subpar performance and potential damage.

Troubleshooting Common Problems

When dealing with mechanical systems, various issues may arise that can affect performance and functionality. Identifying these problems early is crucial for ensuring smooth operation. This section will explore typical difficulties encountered and offer guidance on how to address them effectively.

Identifying Symptoms

Recognizing the signs of potential issues is the first step toward resolution. Common indicators include:

- Unusual noises during operation

- Difficulty in engaging or disengaging

- Unresponsive behavior or hesitation

- Fluid leaks in the surrounding area

Common Issues and Solutions

Below are some frequent challenges and their respective remedies:

-

Noisy Operation:

This may indicate worn components. Check for proper lubrication and inspect for damaged parts.

-

Difficulty Engaging Gears:

Ensure that the linkage is correctly adjusted and free from obstructions. Inspect the hydraulic system for leaks.

-

Fluid Leaks:

Identify the source of the leak and replace any damaged seals or gaskets.

-

Unresponsive Performance:

Check the electrical connections and ensure that all sensors are functioning properly. A faulty sensor can cause erratic behavior.

By systematically diagnosing these issues, you can maintain optimal functionality and extend the lifespan of the system.

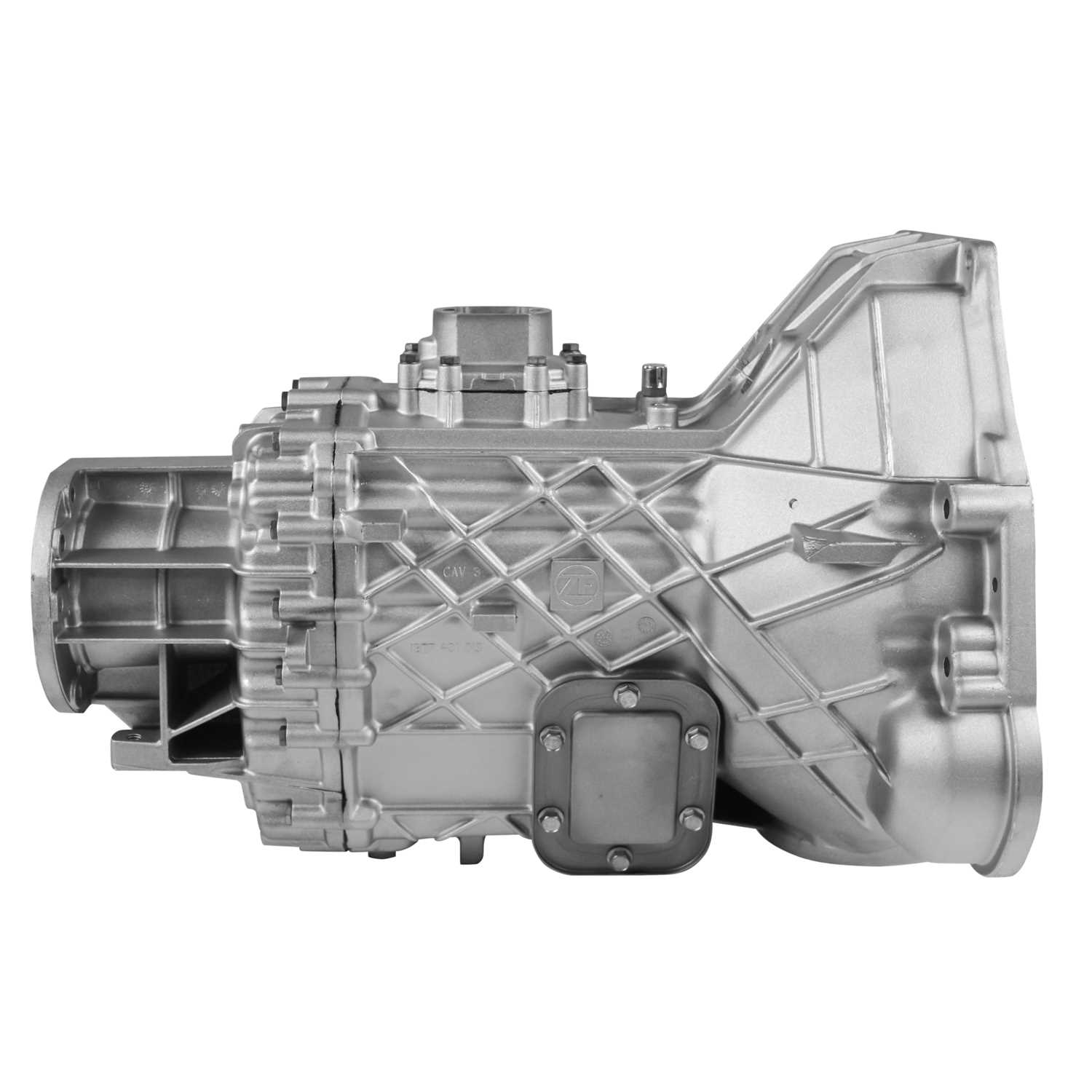

Performance Upgrades for Zf Transmissions

Enhancing the efficiency and responsiveness of Zf gear systems can significantly elevate vehicle performance. By implementing various modifications, enthusiasts can achieve smoother shifting, improved power delivery, and increased durability, ultimately transforming the driving experience.

Enhanced Fluid and Cooling Solutions

One of the most effective upgrades involves optimizing the fluid used within the system. High-quality synthetic lubricants can reduce friction, leading to improved efficiency. Additionally, incorporating an upgraded cooling system helps maintain optimal temperatures, preventing overheating and prolonging component life.

Strengthened Internal Components

Another crucial area for improvement is the internal architecture. Upgrading components such as clutches, gears, and bearings can significantly enhance performance under higher loads. Forged or billet parts provide increased strength and reliability, enabling the assembly to handle greater torque without failure. These modifications not only boost performance but also enhance overall longevity.

Tips for Successful Gear Shifting

Achieving seamless transitions between gears is crucial for optimal performance and longevity of your vehicle. Proper techniques can enhance both driving experience and mechanical efficiency. Here are some essential suggestions to ensure smooth shifts.

- Know Your Vehicle: Familiarize yourself with your car’s specifications and requirements. Understanding how your particular model responds will help you make better shifting decisions.

- Maintain Clutch Health: Regularly check and service the clutch system. A well-functioning clutch is vital for effortless gear changes.

- Use the Right RPM: Shift at appropriate revolutions per minute (RPM) to prevent strain on the engine and drivetrain. This helps in achieving smoother transitions.

- Practice Double Clutching: For manual vehicles, mastering double clutching can significantly improve gear engagement and reduce wear.

- Be Gentle with the Gear Stick: Apply gentle pressure when moving the gear lever. Forceful shifts can lead to mechanical issues over time.

- Listen for Feedback: Pay attention to sounds and vibrations. Unusual noises may indicate issues that require attention.

Implementing these tips can greatly enhance your driving experience while ensuring the mechanical components operate efficiently. Consistent practice and attention to detail will lead to better results on the road.

Safety Precautions During Repair

Ensuring a secure environment while performing maintenance tasks is essential for both personal well-being and the integrity of the equipment. Adopting specific safety measures can significantly reduce the risk of accidents and enhance the overall efficiency of the process.

Proper Attire: Always wear appropriate clothing, including gloves and safety goggles, to protect against potential hazards. Avoid loose-fitting garments that may become entangled in moving parts.

Workspace Organization: Keep the area tidy and free from clutter. This minimizes the chance of tripping or misplacing tools, which can lead to injuries or damage.

Use of Tools: Ensure all tools are in good condition and suitable for the tasks at hand. Using the right tool not only improves effectiveness but also decreases the likelihood of accidents.

Electrical Safety: When dealing with electrical components, always disconnect power sources. This prevents unexpected shocks or short circuits that could cause harm.

Following Guidelines: Adhere strictly to safety protocols and manufacturer recommendations. Familiarizing yourself with the specific requirements helps in preventing common mistakes and ensuring safe practices.

Emergency Preparedness: Keep a first-aid kit and fire extinguisher readily accessible. Being prepared for emergencies can make a critical difference in responding to unexpected situations.

By prioritizing safety through these measures, individuals can work with confidence and protect themselves while maintaining their equipment effectively.

Resources for Further Learning

Expanding your knowledge on the intricacies of vehicle systems can greatly enhance your skills. Whether you’re a novice or an experienced enthusiast, there are numerous avenues to explore that can deepen your understanding and refine your expertise.

| Resource Type | Description | Link |

|---|---|---|

| Books | Comprehensive guides covering various aspects of automotive mechanics. | Explore Books |

| Online Courses | Structured learning programs that offer in-depth knowledge and practical insights. | View Courses |

| YouTube Channels | Visual tutorials that demonstrate techniques and concepts in real-time. | Check Channels |

| Forums | Communities where enthusiasts share experiences, tips, and solutions. | Join Forums |

| Workshops | Hands-on sessions that provide practical experience and expert guidance. | Find Workshops |