Comprehensive Guide to Servicing a 2004 Yamaha Kodiak 400

When it comes to keeping an all-terrain vehicle running smoothly, understanding the finer points of its mechanisms and components is essential. This guide provides insights into essential upkeep and detailed procedures for addressing common issues that may arise during regular use. Whether for tackling rugged landscapes or ensuring a safe ride, thorough knowledge of maintenance techniques proves invaluable for both seasoned riders and newcomers alike.

Within these sections, you’ll find step-by-step instructions, practical advice, and expert recommendations on a range of topics designed to support the durability and performance of your four-wheeled machine. From routine checks to addressing wear and tear, each aspect of this guide aims to help maximize reliability and longevity, making it a trusted resource for enthusiasts committed to quality care.

For those interested in the inner workings and functionality of various parts, this resource delves into specific maintenance routines and troubleshooting tips. Learn how each component contributes to overall performance, how to diagnose potential issues, and ways to keep your machine operating at its best. Whether it’s for rugged terrain or smooth trails, these insights will empower you to navigate maintenance tasks with confidence and expertise.

Comprehensive Guide to 2004 Yamaha Kodiak 400

This section provides an in-depth exploration of a widely recognized all-terrain vehicle, focusing on its key specifications, mechanical components, and essential maintenance insights. Designed for versatility and durability, this model is known for its robust design and reliability across various environments. Here, enthusiasts and repair professionals can find valuable guidance to understand its mechanisms and ensure longevity.

Core Features and Specifications

- Engine capacity tailored for balanced power and efficiency

- Optimized transmission system for smooth operation on diverse terrains

- Advanced suspension designed for enhanced stability and comfort

- Fuel efficiency calibrated to reduce environmental impact while maximizing range

Maintenance Essentials

Maintaining this vehicle is crucial for optimal performance and extended service life. Regular care and attention to various parts can prevent common issues and keep it functioning efficiently. Below are some of the primary maintenance tasks:

- Fluid Checks: Consistently monitor and refill engine oil, brake fluid, and coolant to prevent wear.

- Battery Maintenance: Inspect battery connections and ensure they are clean to avoid power issues.

- Tire Inspection: Check tire pressure and tread regularly to ensure proper traction and stability.

- Brake System: Examine brake pads and cables for wear, ensuring safe handling in all conditions.

For those passionate about keeping this model in peak condition, understanding these essential aspects can lead to a more dependable and enjoyable experience, allowing for greater adaptability across varying terrains and conditions.

Essential Maintenance Tips

Regular upkeep ensures that your vehicle remains dependable, efficient, and ready for diverse terrains. By following a few key practices, you can help prevent costly repairs and extend the lifespan of your equipment.

- Inspect Fluids Regularly: Check essential fluids, ensuring levels are optimal. Clean fluids contribute to smoother performance and help avoid overheating issues.

- Keep Air Filters Clean: Dust and debris clog filters over time, reducing airflow and engine efficiency. Routinely clean or replace filters to maintain peak performance.

- Examine Tires: Inspect tires for wear and maintain the recommended pressure. Properly inflated, undamaged tires enhance handling and safety.

- Grease Moving Parts: Lubricate joints and pivot points to reduce friction and extend component life. Pay attention to areas with frequent movement.

- Monitor Battery Health: Inspect battery terminals for corrosion and ensure connections are secure. A well-maintained battery improves reliability, especially in colder months.

Adopting these essential maintenance routines helps maintain optimal functionality and enhances the longevity of your vehicle.

Diagnosing Common Mechanical Issues

This section provides guidance on identifying and addressing frequent technical issues that may arise during regular use. By understanding how to pinpoint common malfunctions, owners can maintain optimal performance and longevity.

Recognizing Signs of Wear

Various parts experience natural wear and tear over time. Regularly checking key areas can prevent small issues from escalating into major mechanical problems. Look out for these common indicators:

- Unusual Sounds: Grinding, clanking, or whirring noises often signal internal issues that require prompt attention.

- Loss of Power: If performance dips or if the machine struggles under usual load, it may point to fuel or airflow restrictions.

- Vibrations: Excessive vibration can indicate loose or misaligned components, which may need realignment or tightening.

Essential Checks and Solutions

Routine inspections of vital systems can help isolate issues before they lead to larger repairs. Here are recommended areas to focus on during maintenance:

- Fuel System: Check for clogs or leaks in lines and ensure filters are clean to avoid fuel delivery issues.

- Air Intake: Clear blockages and inspect for signs of debris buildup to ensure efficient airflow.

- Suspension Components: Regularly examine bushings, shocks, and bearings to prevent rough handling and ensure stability.

- Battery Health: Ensure strong connections and check voltage levels periodically, replacing if power is insufficient.

Consistently addressing these areas helps prevent frequent issues and prolongs the operational lifespan of the machine.

Engine Tune-Up Procedures

Regular maintenance of the engine ensures smooth and efficient performance, helping to extend the lifespan of the system. This section covers essential steps to enhance the power and efficiency of the engine, addressing key areas that influence its overall functionality.

Begin by inspecting the fuel system, including the fuel lines and filters, to guarantee unobstructed flow and clean combustion. Replacing or cleaning the filter is recommended if there are signs of clogging, as this improves fuel efficiency and power output.

Next, examine the air intake for any blockages or accumulated debris that might restrict airflow. Cleaning the air filter or replacing it, if necessary, supports optimal air-to-fuel ratios, contributing to consistent engine response and longevity.

Check the spark plug for wear and carbon deposits. Replacing a worn plug or cleaning minor deposits can greatly improve ignition, ensuring that the engine starts reliably and runs smoothly. Always confirm the correct gap on the spark plug to prevent misfires and other ignition issues.

Finally, monitor fluid levels, including oil and coolant, as these play a crucial role in keeping the engine from overheating and ensuring proper lubrication. Replace or top up fluids according to the manufacturer’s recommendations to avoid engine strain and extend its durability.

By following these steps, you ensure the engine remains in peak condition, ready to perform effectively over time, with fewer unexpected issues and a reliable output.

Replacing Key Parts Efficiently

Understanding how to swiftly and effectively replace essential components can significantly extend the lifespan and performance of your vehicle. Whether addressing wear and tear or managing unexpected issues, an efficient replacement process minimizes downtime and ensures smoother operation.

Preparing for a Smooth Replacement

Before diving into a replacement task, gathering the correct tools and reviewing part specifications is crucial. Identifying compatible options, verifying installation guidelines, and organizing necessary materials beforehand makes the replacement smoother and prevents common pitfalls that can arise during disassembly and reassembly.

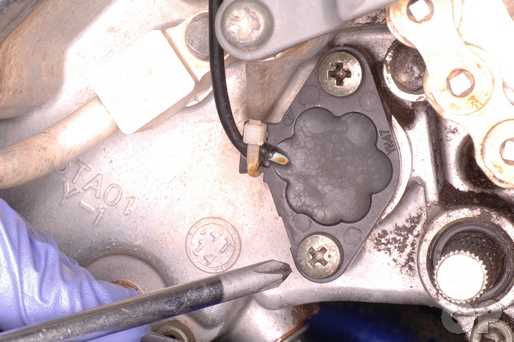

Step-by-Step Approach for Key Components

Working methodically through each replacement step is key. Start by safely removing existing parts and carefully inspecting the surrounding components to identify any additional issues. Installing new parts with precision, following best practices for securing fasteners and connections, ensures each component is properly integrated into the system.

Optimizing Brake System Performance

Enhancing the efficiency of the braking system is crucial for ensuring safety and reliability during operation. A well-maintained brake mechanism not only improves responsiveness but also extends the lifespan of components. This section outlines key strategies for maximizing brake performance, focusing on maintenance practices and component upgrades.

Regular Maintenance Practices

- Inspect Brake Pads: Regularly check the thickness of the pads and replace them if they are worn down to the minimum thickness.

- Fluid Quality: Ensure that brake fluid is clean and free from contaminants. Replace it periodically to maintain hydraulic efficiency.

- Check for Leaks: Inspect brake lines and fittings for any signs of leakage, which can compromise performance.

- Bleed the System: Regularly bleed the brake lines to remove air bubbles that can cause sponginess in the brake lever.

Component Upgrades

- High-Performance Brake Pads: Consider upgrading to pads that offer superior friction and heat resistance.

- Stainless Steel Brake Lines: Replace rubber lines with stainless steel options for improved durability and responsiveness.

- Enhanced Rotors: Opt for vented or slotted rotors that provide better heat dissipation and performance under extreme conditions.

- Brake Caliper Upgrade: Install performance calipers to increase clamping force and improve braking efficiency.

By implementing these strategies, one can significantly enhance the effectiveness and safety of the braking system, ensuring optimal performance for every ride.

Understanding Electrical Component Functions

In any mechanical system, electrical elements play a crucial role in ensuring efficient operation and overall functionality. Understanding the roles and interactions of these components is essential for effective maintenance and troubleshooting. Each part contributes to the larger framework, enabling the system to perform its designated tasks reliably.

Connectors serve as vital links between various electrical components, ensuring that power and signals can flow seamlessly throughout the system. These interfaces facilitate communication and control, enabling components to respond appropriately to user inputs and environmental conditions.

The battery is a critical component that stores and supplies energy. It powers essential systems, allowing the machinery to function even when not connected to an external source. A well-maintained battery is crucial for the longevity and reliability of the entire setup.

Another important element is the relay, which acts as a switch that controls the flow of electricity to different parts of the system. By managing power distribution efficiently, relays help prevent overloads and ensure that components operate within their specified limits.

Additionally, sensors monitor various parameters, providing real-time feedback to the control unit. They play an essential role in adjusting performance based on changing conditions, thereby enhancing efficiency and safety.

Finally, wiring harnesses organize and protect the electrical connections, ensuring that signals and power reach their destinations without interference. Proper installation and maintenance of these harnesses are vital to prevent electrical failures and ensure optimal performance.

Troubleshooting Transmission Problems

Transmission issues can lead to significant challenges in the operation of your vehicle. Identifying and addressing these problems early can prevent further damage and enhance performance. This section provides a comprehensive guide to diagnosing and resolving common transmission complications.

Common Symptoms of Transmission Issues

- Slipping gears or difficulty in shifting

- Unusual noises such as grinding or whining

- Delayed engagement when changing from park to drive

- Fluid leaks beneath the vehicle

- Warning lights on the dashboard

Steps for Diagnosis

- Check the transmission fluid level and condition. Ensure it is at the recommended level and free of contaminants.

- Inspect for external leaks around seals and gaskets.

- Listen for unusual sounds while the engine is running, which could indicate internal wear.

- Test the shifting mechanism to ensure it operates smoothly and correctly.

- Use a diagnostic scanner to retrieve any trouble codes that may indicate specific faults.

By following these steps, you can pinpoint the root cause of the transmission issue and take the necessary actions for repair or adjustment.

Battery Care and Replacement Guide

Proper maintenance of the energy storage unit is crucial for the optimal performance of your vehicle. Understanding how to care for and replace this component can prolong its lifespan and enhance overall functionality. Regular checks and timely replacements can prevent unexpected breakdowns and ensure a smooth ride.

Maintenance Tips

To keep the energy storage unit in top condition, regularly inspect it for any signs of corrosion, leaks, or damage. Clean the terminals with a mixture of baking soda and water to remove any buildup that may impede the electrical connection. Additionally, ensure that the fluid levels are adequate, and if applicable, top them up with distilled water. Periodically check the charge level to avoid deep discharges that can reduce the lifespan of the unit.

Replacement Procedure

When it’s time to replace the energy storage unit, begin by disconnecting the negative terminal followed by the positive terminal to prevent any electrical shorts. Carefully remove the old unit and install the new one, ensuring that it is securely fastened. Reconnect the terminals, starting with the positive terminal first, followed by the negative terminal. Finally, test the system to confirm that everything is functioning properly.

Suspension Adjustments for Better Handling

Fine-tuning the suspension system is crucial for enhancing the overall handling and stability of your all-terrain vehicle. Proper adjustments can lead to improved ride quality, better traction, and increased comfort, allowing for a smoother experience on various terrains. This section explores the essential settings and considerations for optimizing your suspension setup.

Understanding Suspension Components

The suspension system comprises several components, each playing a significant role in vehicle dynamics. Familiarity with these parts enables effective adjustments:

| Component | Function |

|---|---|

| Shocks | Dampen vibrations and control rebound |

| Springs | Support weight and determine ride height |

| Linkages | Connect various parts of the suspension system |

Key Adjustment Techniques

To achieve optimal handling, consider the following adjustment techniques:

- Preload Settings: Adjusting spring preload influences ride height and firmness. Increasing preload tightens the suspension, enhancing responsiveness.

- Damping Adjustments: Tuning compression and rebound damping helps control how quickly the suspension reacts to bumps and irregularities in the terrain.

- Alignment: Ensuring proper alignment of wheels and suspension components minimizes tire wear and maximizes contact with the ground.

Cleaning and Protecting Exterior Components

Maintaining the exterior of your vehicle is essential for preserving its appearance and functionality. Regular cleaning and protection not only enhance the aesthetic appeal but also extend the lifespan of various components. This section discusses effective methods and materials for keeping the outer surfaces in optimal condition.

To achieve the best results, it is crucial to utilize appropriate cleaning agents and protective coatings. Below is a summary of recommended products and techniques for different exterior elements:

| Component | Recommended Cleaning Method | Protective Product |

|---|---|---|

| Plastic Body Panels | Use a soft sponge and mild soap solution, rinse thoroughly. | UV protectant spray to prevent fading. |

| Metal Surfaces | Apply a gentle cleaner and microfiber cloth, buff to shine. | Wax or sealant to create a protective barrier. |

| Glass | Use glass cleaner and lint-free cloth for a streak-free finish. | Water-repellent coating for improved visibility. |

| Tires | Scrub with a brush and soapy water, rinse well. | Tire dressing to restore shine and protect from cracking. |

By implementing these cleaning and protection practices, you can maintain the integrity and visual appeal of your vehicle’s exterior components, ensuring they remain in excellent condition for years to come.

Winterizing and Off-Season Storage

Preparing your vehicle for the colder months is essential to ensure its longevity and optimal performance. Proper maintenance during this period can prevent potential issues and protect your investment from the elements. This section outlines key steps to effectively winterize and store your vehicle when it’s not in use.

- Clean Thoroughly: Begin by washing the exterior and cleaning the interior to remove dirt and debris. Pay special attention to any areas prone to corrosion.

- Drain Fluids: It is advisable to drain the fuel tank and add a fuel stabilizer to prevent degradation. Additionally, consider changing the oil and filter to keep the engine components in good condition.

- Protect the Battery: Disconnect the battery and store it in a cool, dry place. Regularly check its charge level and recharge if necessary.

- Inspect Tires: Ensure tires are properly inflated and consider placing the vehicle on blocks to prevent flat spots during extended storage.

- Cover the Vehicle: Use a breathable cover to shield your vehicle from dust and moisture. This will help prevent scratches and protect the finish.

By following these essential steps, you can ensure that your vehicle remains in excellent condition and is ready for use when the warmer months return. Consistent attention to these maintenance practices can significantly extend the lifespan of your machine.