Guide to Repairing Kenmore Sewing Machines

Understanding how to maintain and enhance the performance of your fabric tool is essential for achieving quality results in your projects. This section will provide insights into common issues and their solutions, ensuring a smoother crafting experience.

Every crafting enthusiast may encounter challenges during their creative journey. By familiarizing yourself with effective strategies for addressing these difficulties, you can extend the life of your tool and improve its functionality. This guide aims to empower users with knowledge, making the process less daunting.

Effective troubleshooting can transform your crafting experience. Whether it’s adjusting settings or identifying minor malfunctions, the right approach can lead to successful outcomes. Embrace the journey of learning and enhance your crafting skills.

Guide to Fixing Kenmore Sewing Machines

This section provides insights into troubleshooting and enhancing the performance of a popular brand of stitching devices. Understanding common issues and solutions can significantly improve functionality and prolong the lifespan of these tools. A systematic approach to maintenance will ensure efficient operation and satisfaction in usage.

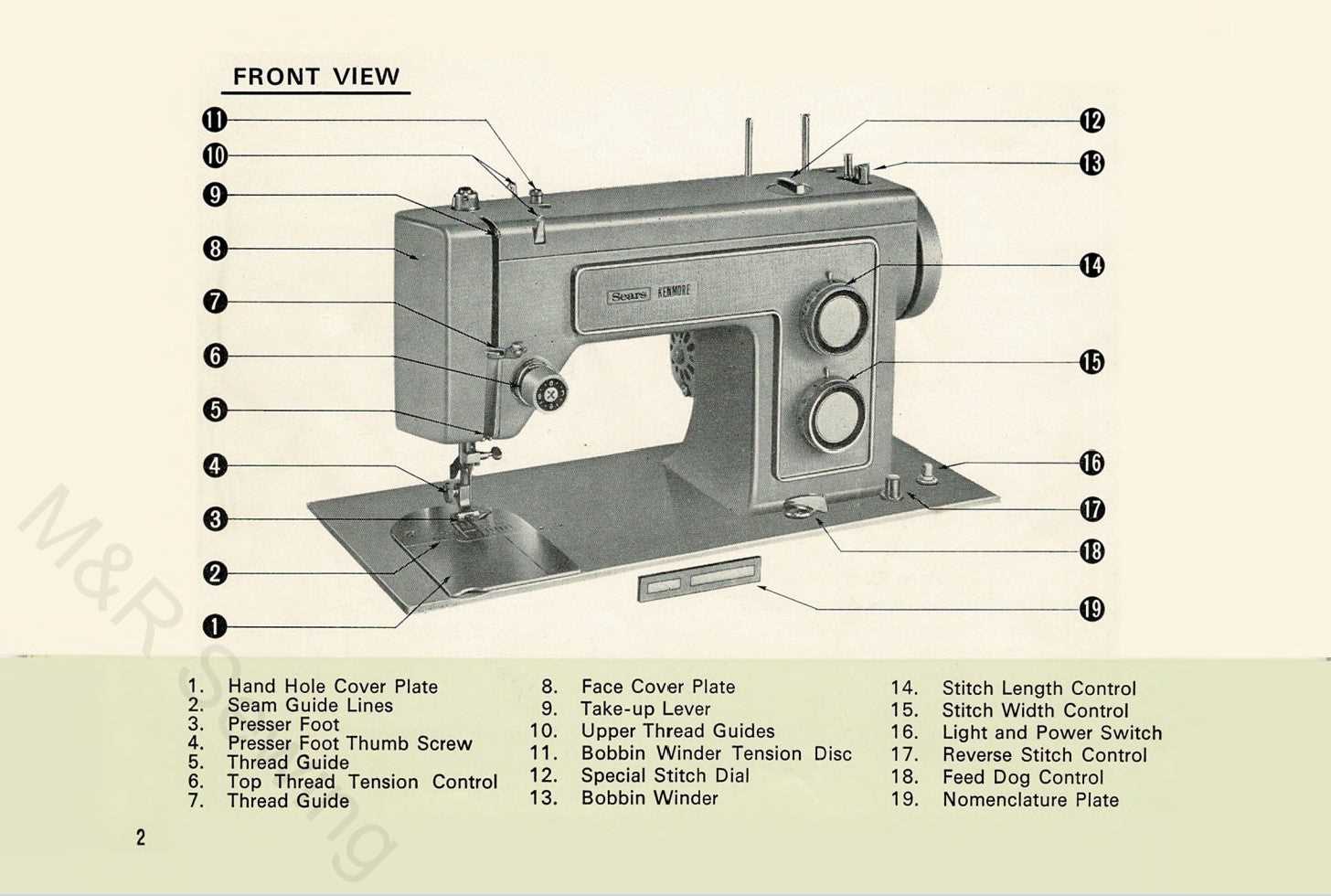

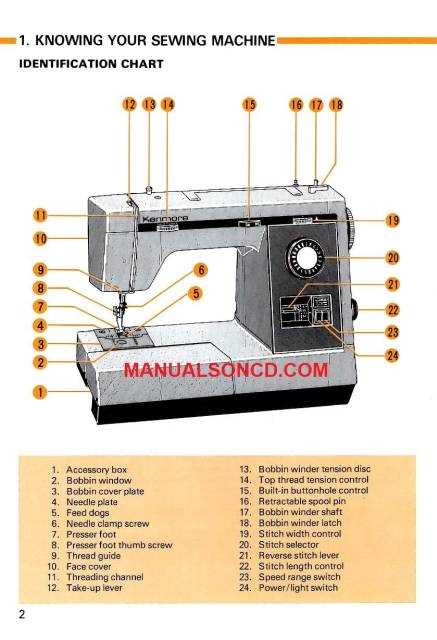

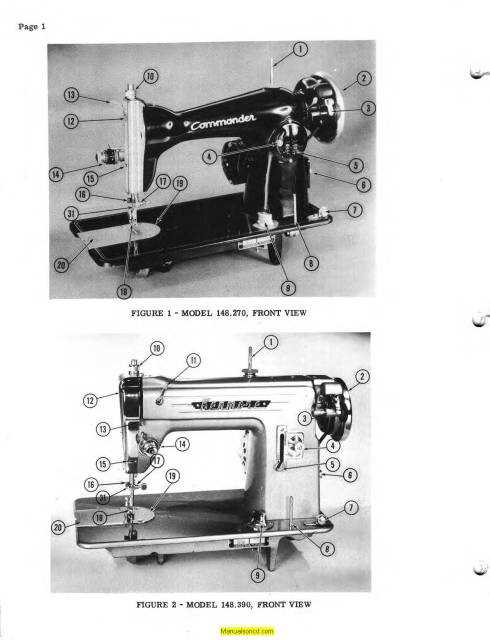

Begin by examining the key components, as many difficulties arise from simple misalignments or wear. Regular cleaning and lubrication can prevent problems, while timely interventions can resolve minor glitches before they escalate. Referencing specific symptoms and their corresponding fixes is essential for effective problem-solving.

Common Issues with Kenmore Models

Many users encounter various challenges when operating their devices, often stemming from typical problems that can affect performance. Understanding these common difficulties can assist in troubleshooting and improving functionality.

Threading Complications

One frequent concern involves issues with threading. Improperly loaded threads can lead to uneven stitches or even machine jams. Ensuring correct threading technique is essential for smooth operation.

Stitch Quality Variations

Another prevalent issue is the inconsistency in stitch quality. Factors such as fabric type, thread selection, and tension settings may contribute to this problem. Regular adjustments and maintenance can enhance overall performance.

Essential Tools for Repairs

When addressing issues with fabric crafting devices, having the right instruments at hand is crucial. These essential items not only facilitate effective troubleshooting but also enhance the overall experience of maintenance. Being well-equipped can significantly streamline the process and ensure optimal functionality.

Basic Equipment

Some fundamental tools include screwdrivers, pliers, and scissors. These items are indispensable for making adjustments and addressing common challenges. Each tool serves a specific purpose, enabling users to tackle various tasks efficiently.

Specialized Accessories

In addition to basic items, specialized accessories can further aid in the upkeep of these devices. For instance, oiling tools and cleaning brushes help maintain performance and longevity. Investing in quality accessories can greatly enhance the overall user experience.

Step-by-Step Troubleshooting Process

When faced with issues in the functioning of your equipment, a systematic approach to identifying and resolving problems is essential. This guide offers a clear pathway to diagnosing common challenges, enabling you to restore optimal performance effectively.

Identify the Symptoms

Begin by observing any irregularities in operation. Note specific issues such as unusual noises, incomplete tasks, or malfunctioning parts. Recording these details will assist in narrowing down potential causes.

Check Basic Settings

Review fundamental configurations to ensure everything is set correctly. Verify the tension settings, ensure proper threading, and confirm that all components are securely in place. Making these adjustments can often resolve minor problems.

Cleaning and Maintenance Tips

Regular upkeep is essential to ensure optimal performance and longevity of your crafting tool. By following some simple practices, you can keep it in excellent condition and enhance its functionality over time.

Routine Cleaning Steps

Start by removing dust and debris from the exterior using a soft cloth. Pay special attention to areas where lint can accumulate, as this can affect performance. Regularly clean the interior components according to the guidelines provided by the manufacturer to avoid any build-up that could hinder operation.

Maintenance Practices

Incorporate lubrication of moving parts into your schedule to ensure smooth operation. It’s advisable to check the tension and threading systems periodically for optimal function. Always refer to specific guidance to ensure you are performing these tasks correctly and effectively.

Replacing the Sewing Machine Needle

Changing the needle in your crafting device is a vital task that ensures optimal performance and stitch quality. A fresh needle can make a significant difference in your projects, enhancing precision and preventing issues such as skipped stitches or fabric damage.

To start, gather the necessary tools and materials, including the new needle and a screwdriver if needed. Always make sure to power off the device before beginning the replacement process to ensure safety.

Steps for Replacement:

- Loosen the needle clamp by turning it counterclockwise.

- Remove the old needle by gently pulling it downward.

- Insert the new needle with the flat side facing the back, pushing it up until it stops.

- Tighten the needle clamp securely.

Finally, test the device with a scrap piece of fabric to ensure everything is functioning smoothly. Regularly replacing the needle can help maintain the longevity and efficiency of your equipment.

Adjusting Tension Settings Correctly

Achieving the right balance in thread tension is essential for quality stitching. Proper adjustment ensures that fabric layers are held together securely without puckering or fraying. Understanding the factors that influence tension can greatly enhance your crafting experience.

When it comes to making adjustments, it’s important to know how different elements interact. Here are some key considerations:

| Factor | Impact |

|---|---|

| Thread Type | Different threads may require unique tension settings to achieve optimal results. |

| Fabric Weight | Heavier fabrics often need increased tension, while lighter materials may require a looser setting. |

| Stitch Style | Certain stitches may perform better with adjusted tension for a cleaner finish. |

Regularly checking and adjusting the tension according to these factors will contribute to successful projects and improve overall craftsmanship.

Fixing Thread Jamming Problems

Encountering issues with thread entanglement can be frustrating, but understanding the underlying causes is essential for resolving these challenges effectively. Various factors can contribute to this problem, including improper threading, tension settings, and maintenance issues.

Common Causes of Thread Jamming

One of the most frequent reasons for entangled threads is incorrect threading through the components. Ensure that the thread follows the designated path, and check that the spool is properly positioned. Additionally, worn-out or damaged parts can hinder smooth operation, leading to further complications.

Solutions and Best Practices

To alleviate jamming issues, start by re-threading the device, paying close attention to each step. Adjusting the tension settings may also be necessary, as too tight or too loose tension can cause complications. Regular cleaning and maintenance will help keep all components in optimal condition, minimizing the risk of future occurrences.

Servicing the Bobbin Mechanism

Maintaining the bobbin system is essential for ensuring smooth operation and optimal performance. Proper attention to this component can enhance functionality and prevent common issues associated with thread management. Understanding the intricacies of this mechanism is vital for achieving consistent results in your projects.

Inspecting the Bobbin Area

Start by examining the bobbin compartment for any debris or thread remnants that may hinder performance. Cleaning this area regularly will prevent jamming and ensure that the bobbin winds evenly. Use a soft brush or a lint roller to remove any dust or buildup.

Adjusting Tension Settings

The tension settings play a crucial role in how the thread interacts with the bobbin. If you notice irregular stitches, consider adjusting the tension to achieve a balanced stitch formation. Test the settings on a scrap fabric to find the optimal configuration for your specific projects.

Electrical Components and Wiring Checks

Ensuring the proper functionality of electrical elements and connections is vital for optimal performance. This section provides insights into the essential checks needed to maintain and troubleshoot these systems effectively.

Key Electrical Parts

- Power Supply Unit

- Control Board

- Wiring Harness

- Foot Pedal

Wiring Inspection Steps

- Disconnect from the power source.

- Examine all visible wiring for wear and damage.

- Check connections at the control board for secure fittings.

- Test the foot pedal for responsiveness.

- Ensure continuity of the power supply unit.

By regularly conducting these checks, users can enhance the longevity and reliability of their equipment.

Lubrication Techniques for Smooth Operation

Maintaining optimal functionality in a crafting device requires careful attention to various techniques that enhance its performance. Proper lubrication plays a vital role in ensuring that all moving parts operate seamlessly, reducing friction and wear over time.

Types of Lubricants

- Oil: A light oil is typically used for regular maintenance, providing adequate coverage without attracting dust.

- Grease: Thicker than oil, grease is suitable for components that endure heavier loads and require longer-lasting protection.

- Specialized Lubricants: Certain devices may benefit from specific lubricants designed for unique applications.

Application Techniques

- Ensure the device is turned off and unplugged before starting the lubrication process.

- Identify key areas that require lubrication, such as joints, gears, and other moving parts.

- Apply a small amount of lubricant to each designated area, avoiding excess to prevent buildup.

- Operate the device briefly to distribute the lubricant evenly throughout the mechanisms.

- Regularly check and reapply lubricant as needed to maintain optimal performance.

When to Seek Professional Help

Understanding the right moment to call in an expert can be crucial for effective troubleshooting. Certain issues may arise that require specialized knowledge and tools beyond basic home techniques.

Signs Indicating Professional Assistance

When you encounter persistent problems that do not resolve with standard adjustments, it may be time to consult a professional. Unusual noises, inconsistent performance, or visible damage can signify that a deeper issue is present.

Benefits of Expert Intervention

Engaging a qualified technician not only ensures accurate diagnosis but also saves time and potential frustration. Their expertise can lead to efficient solutions, prolonging the lifespan of your equipment and enhancing its functionality.