Complete Guide to 5R55E Transmission Repair

The intricacies of automatic gear systems can often seem daunting to the average vehicle owner. These essential components play a critical role in ensuring smooth operation and optimal performance of your automobile. Having a comprehensive guide can greatly enhance your ability to maintain and troubleshoot issues related to these systems.

In this section, we will delve into various aspects of these intricate mechanisms. Understanding their design, functionality, and common challenges can empower you to approach maintenance tasks with confidence. A thorough grasp of the internal workings will also enable you to identify symptoms of malfunction and address them effectively.

By exploring detailed guidelines and insights into the structure of these systems, you can become better equipped to handle typical issues that may arise. Whether you’re looking to perform basic upkeep or facing more complex challenges, having access to valuable information will serve as a beneficial resource in your automotive journey.

Common Issues Faced by Owners

Many vehicle owners encounter a variety of challenges with their gear systems, leading to performance issues and unexpected repairs. Understanding these common problems can help drivers take proactive measures to maintain their vehicles effectively.

1. Fluid Leaks

One of the most prevalent issues is the occurrence of fluid leaks. This can significantly affect the performance of the entire system. Identifying and addressing these leaks early is crucial to prevent further damage.

- Check for puddles under the vehicle.

- Inspect seals and gaskets for wear and tear.

- Monitor fluid levels regularly.

2. Slipping Gears

Another common concern is slipping gears, where the vehicle unexpectedly changes gears or fails to engage properly. This can lead to unsafe driving conditions and should be diagnosed promptly.

- Listen for unusual sounds during gear changes.

- Be aware of any changes in engine revs.

- Seek professional assessment if slipping occurs frequently.

Essential Tools for Repair Work

When tackling any mechanical project, having the right instruments at your disposal is crucial for efficiency and effectiveness. A well-equipped workspace can significantly streamline the process, ensuring that tasks are completed accurately and safely. Here, we will explore some fundamental tools that are indispensable for any undertaking involving complex machinery.

Basic Hand Tools

Basic hand tools form the foundation of any maintenance kit. These tools are versatile and can be used for various tasks, making them essential for anyone working on intricate assemblies. A good selection should include:

| Tool | Purpose |

|---|---|

| Wrenches | To tighten or loosen bolts and nuts |

| Screwdrivers | For driving screws into different materials |

| Pliers | To grip, twist, or cut wires |

| Socket Set | For easier access to fasteners in tight spaces |

Specialized Equipment

In addition to standard tools, specialized equipment can greatly enhance your capabilities. These items are designed for specific tasks and can provide greater precision and efficiency. Consider including the following in your toolkit:

| Tool | Function |

|---|---|

| Torque Wrench | To apply a specific torque to fasteners |

| Oil Filter Wrench | To easily remove and install oil filters |

| Transmission Jack | For safe lifting and lowering of heavy assemblies |

| Digital Multimeter | To measure voltage, current, and resistance |

Step-by-Step Repair Procedures

This section provides a comprehensive guide to effectively addressing issues that may arise within a specific type of vehicle component. Following these detailed steps will help ensure successful diagnosis and resolution of problems, allowing for improved performance and longevity.

- Preparation:

- Gather all necessary tools and replacement parts.

- Ensure a clean, well-lit workspace to facilitate the process.

- Review safety precautions and wear appropriate protective gear.

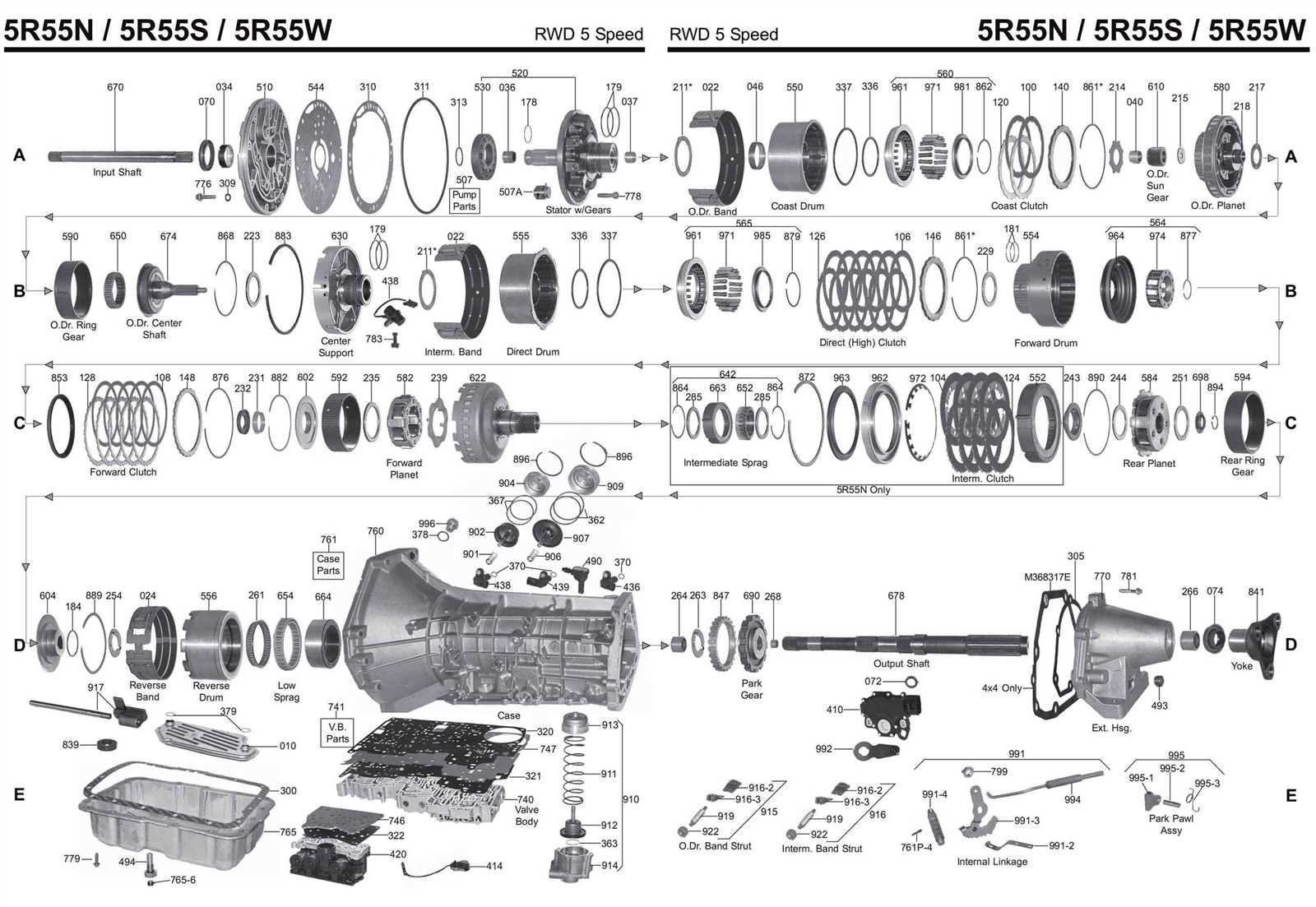

- Disassembly:

- Carefully remove the component from the vehicle.

- Take note of the arrangement of parts for easier reassembly.

- Inspect each piece for signs of wear or damage.

- Diagnosis:

- Identify the root cause of the malfunction.

- Utilize diagnostic tools to gather information.

- Consult specifications for proper function of components.

- Repair:

- Replace or fix damaged parts as needed.

- Ensure all components meet the required specifications.

- Apply lubricants or sealants where necessary.

- Reassembly:

- Carefully reassemble all components in the correct order.

- Double-check that all connections are secure.

- Test functionality before reinstallation in the vehicle.

- Final Checks:

- Reinstall the assembly back into the vehicle.

- Run a series of tests to ensure everything is functioning properly.

- Document any changes made during the process for future reference.

Fluid Types and Maintenance Tips

Choosing the right fluids and following proper maintenance procedures are essential for ensuring the longevity and efficiency of your vehicle’s performance system. Understanding the various types of fluids available and their specific functions can significantly enhance the overall functionality of the components involved.

Types of Fluids

Several fluid varieties are crucial for optimal operation. Hydraulic fluid is commonly used for its ability to transmit power and ensure smooth functionality. Oil, specifically formulated for these systems, provides necessary lubrication and heat dissipation. Always refer to the manufacturer’s specifications to select the most appropriate fluid type, as using incompatible fluids can lead to severe damage.

Maintenance Tips

Regular maintenance is key to preventing potential issues. Check fluid levels consistently and replace fluids according to the recommended schedule. Using a quality filter can help maintain fluid purity, which is vital for effective performance. Additionally, be attentive to any unusual noises or performance changes, as they may indicate underlying problems that require immediate attention.

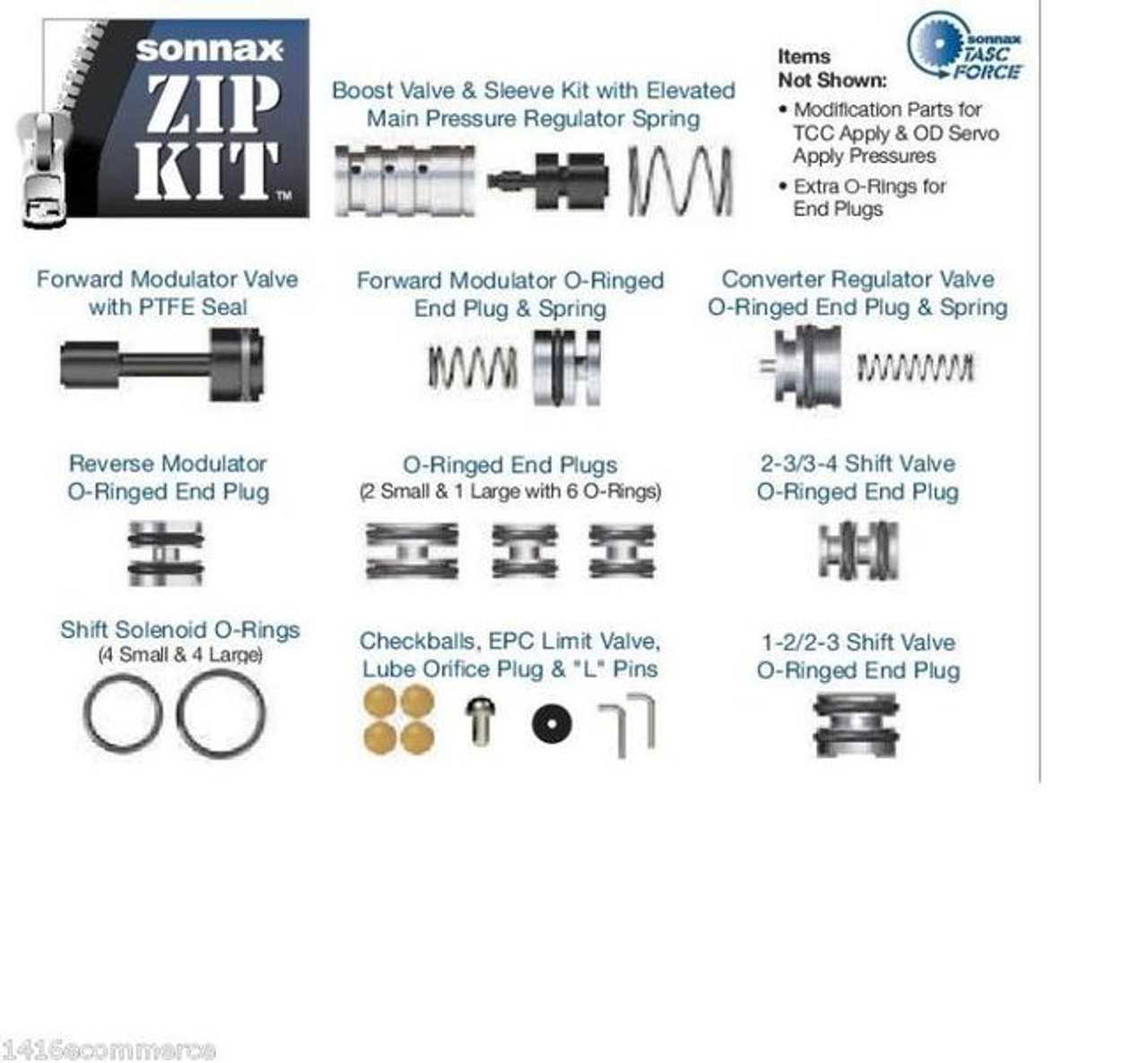

Upgrading Components for Performance

Enhancing the efficiency and capabilities of your vehicle’s shifting system can significantly impact overall driving experience. By focusing on key components, enthusiasts can achieve improved power delivery and responsiveness. This section explores various modifications that can elevate performance levels and provide a more engaging ride.

One of the primary areas to consider is the upgrade of the clutch system. A high-performance clutch can handle increased torque and provide better engagement, reducing slippage and improving acceleration. Additionally, the use of stronger friction materials can contribute to enhanced durability and responsiveness.

Another crucial aspect involves the valve body modifications. Optimizing the valve body can lead to quicker shifts and improved hydraulic efficiency. By upgrading to a performance valve body, you can experience firmer shifts and better overall control of gear changes, which can be particularly beneficial during spirited driving or towing scenarios.

Lastly, integrating a more efficient cooling system is vital for maintaining optimal operating temperatures. High-performance coolers can prevent overheating, which is essential for extending the lifespan of the system and ensuring consistent performance under demanding conditions. With these upgrades, you can unlock the full potential of your vehicle’s powertrain.

Diagnosing Electrical Problems

Identifying issues related to electrical systems is crucial for maintaining optimal vehicle performance. Understanding how to effectively troubleshoot can save time and resources while ensuring reliability. This section outlines key steps and considerations for diagnosing these types of complications.

Begin by inspecting the vehicle’s wiring and connections. Loose or corroded wires can lead to malfunctions, causing various symptoms that may not be immediately apparent. A visual examination is the first step to pinpoint potential problems.

Utilizing diagnostic tools is essential for accurate evaluation. Employing a multimeter allows for checking voltage levels, ensuring that all components are receiving the correct power supply. Additionally, a scan tool can provide error codes that help in identifying specific issues within the electrical system.

| Common Electrical Issues | Symptoms | Possible Solutions |

|---|---|---|

| Faulty Wiring | Inconsistent power supply | Inspect and repair connections |

| Blown Fuses | Loss of function in components | Replace blown fuses |

| Weak Battery | Difficulties starting the engine | Test and replace if necessary |

After gathering data and performing visual inspections, cross-reference findings with vehicle specifications. This process ensures that all electrical components are functioning within their designed parameters. Documenting the diagnosis will aid in tracking recurring issues and implementing long-term solutions.

Transmission Removal and Installation Guide

This section provides essential guidance on the process of detaching and reattaching the gear mechanism in vehicles. Proper handling and attention to detail are crucial for a successful procedure, ensuring optimal performance and longevity of the system.

Preparation Steps

- Gather necessary tools and equipment, including wrenches, sockets, and safety gear.

- Ensure the vehicle is parked on a flat surface and secure it with wheel chocks.

- Disconnect the battery to prevent electrical hazards during the process.

Removal Process

- Drain the fluid from the system to prevent spills.

- Remove any components obstructing access to the unit, such as exhaust pipes or crossmembers.

- Carefully unbolt the unit from its mounting points.

- Gently lower the assembly and detach any electrical connectors and linkage.

Following these steps ensures a smooth disconnection, setting the stage for maintenance or replacement. Always refer to vehicle specifications for torque settings and detailed procedures.

Installation Steps

- Position the new or serviced unit in place, ensuring alignment with the mounting points.

- Reconnect electrical connectors and linkage securely.

- Bolting the assembly in place requires attention to torque specifications.

- Reinstall any previously removed components.

- Refill the fluid and check for any leaks before reconnecting the battery.

By adhering to this guide, you can ensure a successful reinstallation, restoring the vehicle’s functionality and reliability.

Safety Precautions During Repairs

Ensuring safety while performing maintenance on vehicle components is crucial for both the technician and the equipment. Proper precautions help minimize risks and prevent accidents, creating a secure working environment. Understanding the necessary safety measures is essential for successful and hazard-free service.

1. Personal Protective Equipment (PPE): Always wear appropriate PPE, including gloves, goggles, and steel-toed boots, to safeguard against potential injuries. This gear protects against chemical spills, sharp objects, and heavy equipment hazards.

2. Workspace Organization: Keep your workspace tidy and free from clutter. A well-organized area reduces the likelihood of accidents and enables easy access to tools and components.

3. Vehicle Stability: Before beginning any maintenance, ensure that the vehicle is securely positioned on a flat surface. Use wheel chocks and jack stands to prevent unexpected movement while working underneath the vehicle.

4. Proper Ventilation: If working in enclosed spaces, ensure adequate ventilation to prevent the accumulation of harmful fumes. Use fans or open windows to enhance air circulation, especially when dealing with fluids or chemicals.

5. Awareness of Hazards: Familiarize yourself with potential hazards associated with the components being serviced. Understanding risks helps in taking the necessary precautions to mitigate them effectively.

Testing Transmission After Repairs

Once the necessary adjustments and fixes have been completed, it is crucial to evaluate the system’s performance. This process ensures that everything functions correctly and efficiently. Proper assessment helps identify any lingering issues that might need attention, thereby confirming the integrity of the overall mechanism.

Steps to Evaluate Performance

- Check fluid levels and ensure they meet the required specifications.

- Inspect for any leaks or unusual noises during operation.

- Perform a series of test drives under different conditions.

- Monitor shifts for smoothness and responsiveness.

Common Issues to Watch For

- Inconsistent shifting patterns.

- Unusual vibrations during gear changes.

- Overheating after extended use.

- Fluid discoloration or burnt smell.

By following these guidelines, individuals can ensure that the system operates optimally and remains reliable for future use.

Resources for Further Learning

Gaining a deeper understanding of vehicle systems and their intricacies is essential for both enthusiasts and professionals. A variety of materials are available to enhance your knowledge and skills in this field, ranging from books to online platforms.

Books focused on automotive technology often provide comprehensive insights into various components, offering both theoretical knowledge and practical applications. Additionally, numerous online courses are designed to cater to different learning styles, featuring video tutorials and interactive exercises that can help solidify your understanding.

Forums and communities dedicated to automotive discussions are invaluable resources. Engaging with experienced individuals can provide real-world insights and troubleshooting tips that are not found in traditional literature. Moreover, manufacturer’s websites frequently offer technical bulletins and service updates that are beneficial for staying current with the latest advancements and best practices.