Comprehensive Guide to Cat 3208 Repairs

In this guide, we’ll delve into the essential practices and key methods for keeping a robust engine in optimal working condition. Whether you’re a seasoned technician or an enthusiast looking to deepen your understanding, this resource provides a wealth of information to support consistent upkeep and effective issue resolution.

Understanding engine mechanics is crucial for anyone aiming to sustain long-term performance and efficiency. With an emphasis on foundational principles and specific adjustments, this guide addresses everything from essential checks to advanced tune-ups. You’ll find insights into typical complications, preventive measures, and adjustments that can enhance the life and resilience of your machinery.

Special attention is given to troubleshooting techniques that allow owners and technicians to identify potential issues early. Each section of this guide is designed to help you confidently handle maintenance and servicing tasks, ensuring you have a clear path to restore functionality when challenges arise. By following these steps, you can help safeguard your engine’s durability, efficiency, and reliability.

Understanding Engine Components

Understanding the main components of this robust diesel engine helps ensure proper function and longevity. In this section, we’ll look at how each element works together to generate power efficiently, supporting various mechanical applications.

Main Structural Parts

The primary structure includes the engine block, cylinder heads, and crankcase. These are foundational parts that house and protect internal moving components. The engine block is the core, accommodating cylinders and pistons, while the crankcase supports the rotation of the crankshaft, converting reciprocating energy into rotational power.

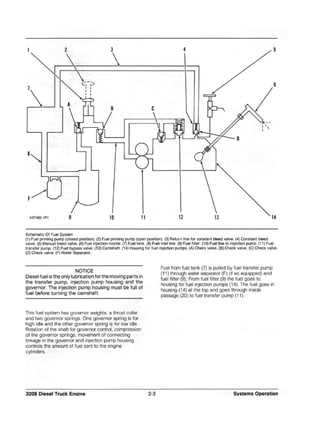

Fuel and Air Systems

The fuel delivery and air intake systems work hand-in-hand to provide the necessary mix for combustion. Fuel injectors introduce fuel into the cylinders, while the turbocharger and intake manifold supply pressurized air, maximizing combustion efficiency. The exhaust system then safely removes combustion gases, reducing back pressure and optimizing performance.

Common Issues with Cat 3208 Engines

Understanding common problems in diesel engines of this model can help owners identify and address issues before they become severe. Regular maintenance and awareness of typical symptoms are essential for prolonging the engine’s lifespan and ensuring it operates smoothly.

Fuel System Challenges

Fuel delivery problems are a frequent concern in these engines. Issues often arise from clogged filters, worn-out injectors, or fuel pump malfunctions. Such complications can lead to a drop in performance, rough idling, or, in some cases, complete stalling. Regular inspection and cleaning of fuel components can help mitigate these challenges.

Overheating Problems

Overheating is another notable concern, often due to coolant leaks, radiator blockages, or a failing water pump. When engines run hotter than recommended, it may result in damage to key components. Ensuring the cooling system is functional and free from obstructions is crucial to avoid overheating and associated repairs.

Essential Tools for Cat 3208 Repairs

Proper maintenance and servicing of machinery require a specific set of instruments to ensure efficient and effective performance. Using the right tools not only simplifies the process but also enhances safety and accuracy during the operation. Below is a list of essential implements that are invaluable for any technician working on these types of engines.

- Wrenches: A variety of sizes, including adjustable and socket wrenches, are necessary for loosening and tightening bolts and nuts.

- Screwdrivers: Both flathead and Phillips screwdrivers are vital for removing and securing screws on various components.

- Pliers: Needle-nose and regular pliers can assist in gripping and twisting wires or small parts.

- Torque Wrench: This tool is crucial for applying the correct amount of force when tightening bolts, ensuring components are securely fastened without damage.

- Multimeter: For checking electrical systems, a multimeter helps diagnose issues by measuring voltage, current, and resistance.

- Oil Filter Wrench: This specialized wrench makes removing and installing oil filters much easier.

- Diagnostic Tools: Various electronic diagnostic devices can help identify issues quickly and accurately.

- Safety Gear: Gloves, goggles, and ear protection are essential to ensure personal safety during maintenance tasks.

Utilizing the right tools not only facilitates a smoother workflow but also extends the life of the machinery by ensuring that all tasks are performed correctly and safely.

Engine Overhaul Guidelines for Cat 3208

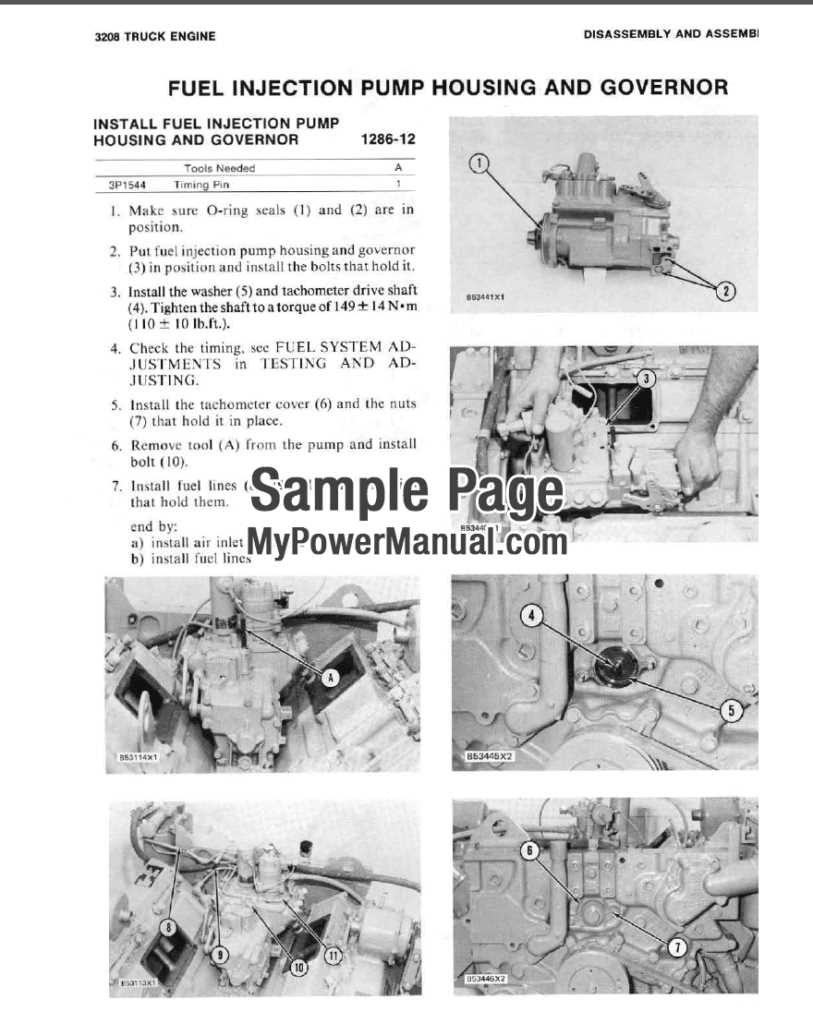

Performing an overhaul on a diesel power unit requires careful planning and execution to ensure optimal performance and longevity. This process encompasses several critical steps that must be followed diligently to restore the engine to its full operational capabilities.

- Preparation: Gather all necessary tools, parts, and safety equipment before commencing work. Ensure the workspace is clean and organized.

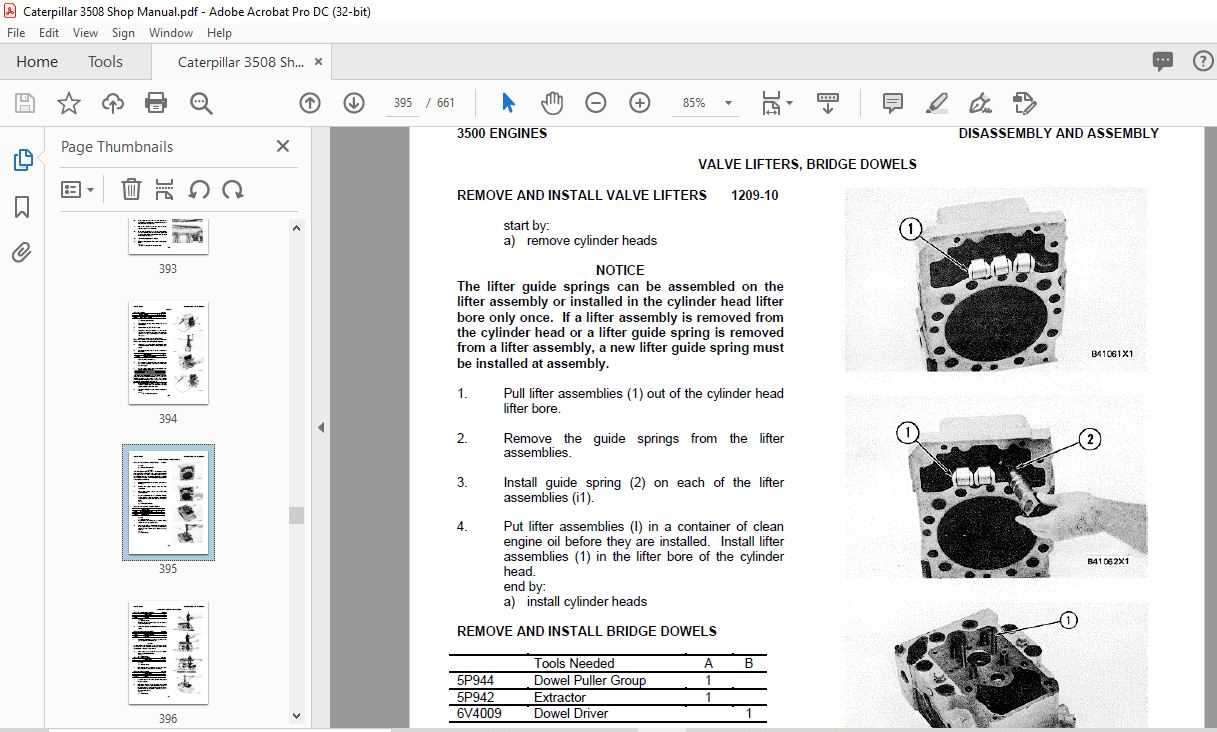

- Disassembly: Begin by removing components such as the intake manifold, exhaust system, and fuel delivery systems. Document the disassembly process for easier reassembly.

- Inspection: Carefully examine all parts for wear and damage. Focus on the cylinder heads, pistons, and crankshaft. Replace any components that do not meet specifications.

- Cylinder Reboring: If the cylinder walls show signs of wear, reboring may be necessary. This ensures a proper fit for new piston rings.

- Component Cleaning: Clean all components using appropriate solvents to remove carbon buildup and debris. This step is vital for preventing contamination during reassembly.

- Reassembly: Begin reassembling the engine by following the documented process in reverse. Pay special attention to torque specifications and sealing surfaces.

- Testing: After reassembly, perform a series of tests to check for leaks and verify the engine runs smoothly. Monitor performance closely during initial operations.

By adhering to these guidelines, one can ensure a successful overhaul that enhances the efficiency and reliability of the diesel power unit.

Fuel System Maintenance for Cat 3208

Proper upkeep of the fuel system is essential for optimal engine performance and longevity. Regular maintenance ensures that the fuel delivery system operates efficiently, preventing potential issues that could lead to reduced efficiency or damage. This section outlines key practices for maintaining the fuel system to achieve reliable functionality.

1. Regular Inspection: Periodic checks of the fuel lines and filters are crucial. Inspect for any signs of leaks, cracks, or deterioration. Ensure that the fuel filters are replaced according to the manufacturer’s recommendations to prevent contaminants from entering the fuel system.

2. Fuel Quality Monitoring: Using high-quality fuel is vital for the proper functioning of the engine. Regularly monitor the fuel for impurities or water contamination. Implement a filtration system if necessary to ensure that only clean fuel reaches the engine.

3. System Cleaning: Over time, deposits can accumulate in the fuel injectors and lines. Regular cleaning of these components helps maintain efficient fuel atomization and combustion. Use appropriate cleaning agents designed for the specific fuel system to avoid damage.

4. Pump Maintenance: The fuel pump should be inspected periodically to ensure proper operation. Listen for unusual noises and check for adequate fuel pressure. Replace the pump if any issues are detected to avoid potential engine failure.

Implementing these maintenance practices will significantly enhance the efficiency and reliability of the fuel system, ultimately contributing to the overall performance of the engine.

Cooling System Repairs for Cat 3208 Engines

The efficient operation of an engine heavily relies on its cooling system. Regular maintenance and prompt attention to issues can prevent severe damage and ensure optimal performance. This section covers essential aspects of addressing cooling system problems in a specific engine type, focusing on common issues, diagnostic steps, and solutions.

Common Issues

- Overheating

- Coolant leaks

- Corrosion in components

- Clogged hoses or radiators

Diagnostic Steps

- Check the coolant level and top off if necessary.

- Inspect hoses for any signs of wear or leakage.

- Examine the radiator for debris or blockages.

- Test the thermostat for proper operation.

Solutions

Depending on the identified issues, several solutions may be applied:

- Replace worn or damaged hoses.

- Flush the cooling system to remove contaminants.

- Repair or replace the thermostat if it is malfunctioning.

- Seal leaks with appropriate sealants or replace faulty components.

By addressing these areas, one can ensure the cooling system remains effective, thereby enhancing the longevity and performance of the engine.

Electrical Troubleshooting on Cat 3208

This section provides essential insights into diagnosing and resolving electrical issues related to a specific engine model. Understanding the fundamental components and systems involved is crucial for effective troubleshooting. By identifying common problems, one can implement suitable solutions to restore optimal functionality.

Common Electrical Issues

Electrical problems can arise from various sources, often resulting in poor performance or complete failure. Here are some frequent issues encountered:

| Issue | Possible Causes | Suggested Solutions |

|---|---|---|

| Starting Problems | Weak battery, faulty starter motor, or poor connections | Check battery voltage, inspect connections, and test starter functionality |

| Electrical Shorts | Worn insulation, loose wires, or corroded terminals | Inspect wiring harness, replace damaged sections, and clean terminals |

| Dashboard Warning Lights | Sensor failure, wiring issues, or software glitches | Run diagnostic tests, check sensor integrity, and update software if needed |

Diagnostic Tools and Techniques

Utilizing the right tools is vital for effective troubleshooting. Here are some recommended instruments:

- Multimeter for voltage and continuity testing

- Wiring diagrams for reference

- Diagnostic scanner for error code retrieval

Valve Adjustments for Optimal Performance

Proper tuning of the engine’s valve mechanisms is essential for achieving peak efficiency and functionality. By ensuring that the clearance between the components is within specified limits, you can enhance performance, reduce emissions, and prolong the life of the engine.

To begin the adjustment process, consult the specifications provided by the manufacturer. These guidelines typically outline the ideal gap measurements for both intake and exhaust valves, which are crucial for effective combustion. Regular checks and adjustments can prevent potential issues caused by wear and tear, leading to improved power output and fuel economy.

When making adjustments, it is vital to carefully follow the sequence recommended in the guidelines. This sequence is designed to ensure that all valves are accurately set without causing unnecessary stress on the engine components. After making the necessary changes, it is advisable to conduct a performance test to confirm that the adjustments have positively impacted the engine’s operation.

Preventative Maintenance for Cat 3208

Regular upkeep is essential for ensuring the longevity and optimal performance of any heavy machinery. Implementing a consistent maintenance routine can significantly reduce the likelihood of unexpected breakdowns and costly repairs. This approach not only enhances the reliability of the equipment but also improves its efficiency in various operational settings.

Key aspects of a proactive maintenance strategy include regular inspections, fluid changes, and component checks. By systematically assessing the condition of essential parts, operators can identify potential issues before they escalate. Moreover, maintaining proper fluid levels and replacing worn-out components will ensure that the machinery operates smoothly, reducing wear and tear over time.

Additionally, adhering to the manufacturer’s recommendations for service intervals is crucial. These guidelines provide a framework for maintenance tasks that should be performed at specific milestones. Keeping detailed records of all maintenance activities can also aid in tracking performance trends and anticipating future needs.

Turbocharger Repair and Replacement Tips

Maintaining optimal performance in turbocharged engines requires careful attention to the components that enhance efficiency and power. When addressing issues with the turbocharger, understanding its functionality and recognizing signs of wear can significantly improve the process of servicing or substituting this vital unit.

Identifying Common Issues

Before proceeding with any maintenance, it’s essential to identify common problems associated with turbochargers. Symptoms may include unusual noises, reduced power output, or excessive exhaust smoke. By conducting a thorough inspection, one can determine whether the component needs servicing or full replacement.

Replacement Steps Overview

When it’s time to replace the turbocharger, following a systematic approach can ensure a successful installation. Key steps include:

| Step | Description |

|---|---|

| 1 | Disconnect the battery and drain fluids. |

| 2 | Remove any surrounding components obstructing access to the turbocharger. |

| 3 | Detach the old turbocharger and inspect the mounting surfaces for damage. |

| 4 | Install the new unit, ensuring all connections are secure and leak-free. |

| 5 | Reconnect the battery and refill any fluids as needed. |

Following these guidelines can help ensure the longevity and effectiveness of the turbocharger, leading to better overall engine performance.

Lubrication System Checks for Cat 3208

Ensuring the effective functioning of the lubrication system is vital for the longevity and performance of any engine. Regular inspections and maintenance of this system help prevent potential damage and ensure smooth operation. This section will outline key checks to maintain optimal lubrication performance.

Key Components to Inspect

- Oil Filter: Check for clogs and replace as necessary.

- Oil Pump: Ensure proper functioning and verify pressure readings.

- Oil Reservoir: Inspect for leaks and proper oil levels.

- Lubrication Lines: Examine for wear, kinks, or blockages.

Routine Maintenance Steps

- Check oil levels regularly and top up as required.

- Replace the oil filter at recommended intervals to maintain flow.

- Monitor for unusual noises or changes in pressure during operation.

- Perform visual inspections of all components to identify potential issues.

Following these guidelines will help ensure the lubrication system operates efficiently, promoting a longer lifespan for the engine.

Cat 3208 Emissions Control Adjustments

The proper management of exhaust emissions is crucial for maintaining engine performance and environmental compliance. Adjustments to the emissions control systems ensure that the engine operates efficiently while minimizing harmful output. This section discusses essential modifications and calibrations necessary for optimizing emissions systems.

Understanding Emissions Systems is the first step in making the right adjustments. These systems typically include components such as the exhaust gas recirculation (EGR) valve and various sensors that monitor the engine’s performance. Ensuring that these elements are functioning correctly is vital for reducing pollutants and enhancing fuel efficiency.

When it comes to making adjustments, it is important to follow specific guidelines. Begin by checking for any fault codes that might indicate issues within the emissions system. After identifying potential problems, inspect the EGR valve for any blockages or wear. A clean and properly functioning valve will help to reduce nitrogen oxide (NOx) emissions effectively.

Calibration of sensors is another key aspect. Ensuring that all sensors provide accurate readings allows for optimal fuel-air mixtures and efficient combustion. Regular testing and recalibration of these sensors are recommended to maintain their effectiveness.

Finally, regular maintenance of the entire emissions control system will prolong its lifespan and ensure compliance with regulations. This includes periodic inspections, cleaning of components, and timely replacement of any defective parts.