Comprehensive Guide to 1KR FE Engine Repairs

In the world of automotive mechanics, understanding the intricacies of a vehicle’s power source is essential for both enthusiasts and professionals. This segment delves into the vital aspects of maintaining and troubleshooting these complex systems. By familiarizing oneself with the essential components and procedures, one can ensure optimal performance and longevity.

Learning the nuances involved in the upkeep of a vehicle’s propulsion unit can be a rewarding journey. From basic adjustments to more advanced procedures, each step contributes to the overall efficiency and reliability of the machine. Embracing this knowledge not only enhances one’s skills but also empowers vehicle owners to take charge of their transportation needs.

Through systematic exploration of this subject, readers will uncover valuable insights and techniques that facilitate a deeper understanding of their vehicles. By prioritizing maintenance, one can avoid common pitfalls and ensure a smoother driving experience. The following sections will provide detailed instructions and tips to assist in navigating this essential aspect of automotive care.

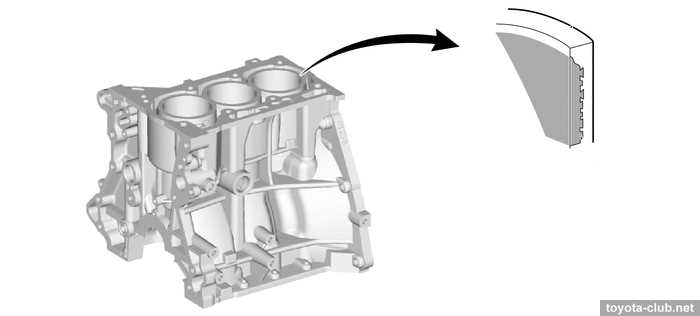

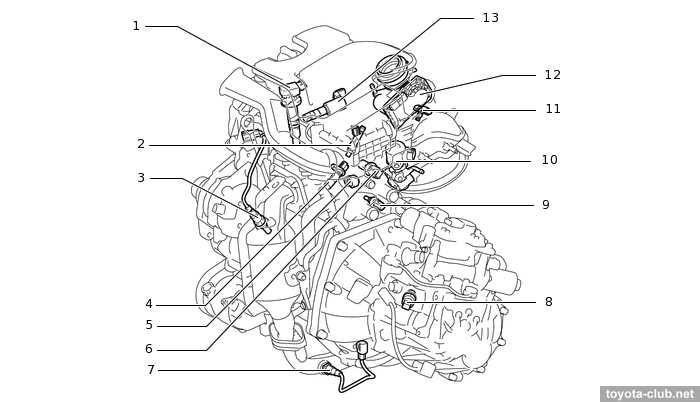

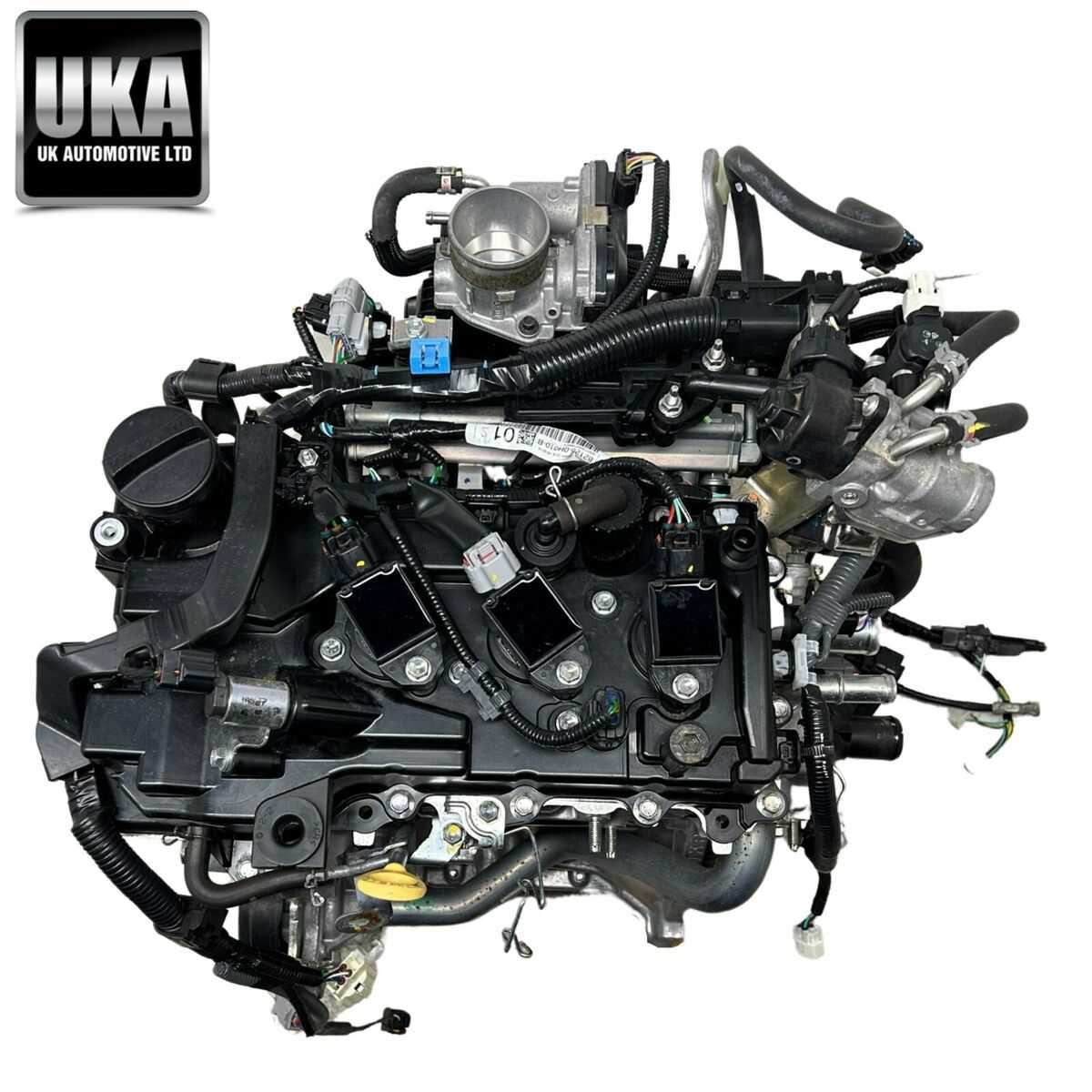

Overview of 1KR FE Engine

This section provides a comprehensive insight into a compact power unit that exemplifies efficiency and performance in its category. Designed with modern engineering principles, it combines durability with optimal fuel consumption, making it suitable for various applications.

The compact design allows for easy integration into various vehicle platforms, enhancing overall performance. This unit features a lightweight construction, which contributes to improved handling and responsiveness, vital for urban driving conditions.

Additionally, it incorporates advanced technology to minimize emissions while maximizing output, reflecting the ongoing commitment to environmental sustainability. Maintenance procedures are straightforward, ensuring longevity and reliability, appealing to both manufacturers and users alike.

Common Issues with 1KR FE Engine

In the realm of compact powertrains, certain challenges frequently arise that can affect performance and reliability. Understanding these prevalent concerns is crucial for maintaining optimal function and longevity.

One common problem relates to overheating, often resulting from inadequate coolant levels or a malfunctioning thermostat. Regular checks of the cooling system can help prevent this issue.

Additionally, irregularities in fuel efficiency can stem from clogged injectors or air intake obstructions. Ensuring clean pathways for fuel and air is essential for maintaining the expected performance metrics.

Moreover, unusual noises during operation may indicate worn-out components, necessitating a thorough inspection to identify and address any potential failures before they escalate.

Lastly, electrical issues, such as faulty sensors, can lead to erratic behavior in performance. Routine diagnostics can assist in detecting and resolving these electrical anomalies efficiently.

Essential Tools for Repairs

Having the right equipment is crucial for effective maintenance and troubleshooting. Proper tools not only enhance efficiency but also ensure that tasks are performed safely and accurately. Here’s a look at some fundamental instruments you should consider for optimal performance.

- Wrenches: These are essential for loosening or tightening bolts and nuts, available in various sizes and types.

- Screwdrivers: A variety of screwdrivers, including flathead and Phillips, will help tackle different fasteners.

- Socket Set: A comprehensive socket set allows for the application of greater torque on fasteners, making it easier to handle stubborn components.

- Pliers: Useful for gripping, twisting, and cutting wires or other small objects.

- Torque Wrench: Ensures that bolts are tightened to the correct specifications, preventing damage from over-tightening.

Additionally, other supportive tools can enhance your toolkit:

- Jack and Jack Stands: Necessary for lifting the vehicle securely for undercarriage work.

- Diagnostic Scanner: Helps in identifying issues by reading error codes from the system.

- Flashlight: Provides visibility in dimly lit areas, ensuring that you can see what you are working on.

Equipping yourself with these essential tools will facilitate smoother and more effective work processes, ultimately leading to better outcomes.

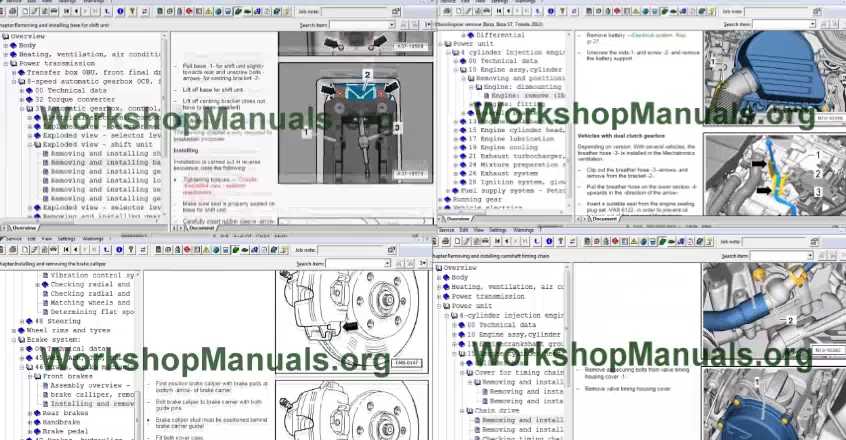

Step-by-Step Repair Procedures

This section outlines a systematic approach to address issues within the specified mechanical unit. Following a structured process not only enhances efficiency but also ensures that all necessary steps are taken to achieve optimal results.

Begin by gathering the essential tools and materials required for the task. This preparation is crucial for a smooth workflow and minimizes interruptions during the process.

- Identify the specific symptoms or malfunctions present.

- Consult available documentation for troubleshooting guidance.

- Prepare the work area to ensure safety and organization.

Next, execute the following procedures:

- Disconnect power sources to prevent accidents.

- Carefully disassemble the unit, taking note of each component’s placement.

- Inspect parts for wear, damage, or defects that may require attention.

- Replace or repair any faulty components as necessary.

- Reassemble the unit, ensuring all parts are securely fastened.

- Reconnect power sources and conduct tests to verify functionality.

By adhering to these outlined steps, you can effectively address and resolve issues, ensuring the longevity and reliability of the unit.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring optimal performance and extending the lifespan of your machinery. By implementing consistent maintenance practices, you can prevent costly breakdowns and enhance efficiency over time.

Regular Inspections

Conducting periodic evaluations is crucial. Look out for signs of wear and tear that might affect functionality. Here are key areas to check:

- Fluid levels

- Belts and hoses for cracks

- Battery condition

- Cooling system integrity

Routine Cleaning

Keeping components clean prevents debris buildup, which can lead to overheating and inefficiency. Follow these steps for effective cleaning:

- Remove any dirt and grime from surfaces.

- Ensure that air filters are clear of obstructions.

- Clean cooling fins to enhance airflow.

Engine Performance Enhancements

Optimizing the capabilities of a power unit can significantly elevate the driving experience. This section delves into various methods and modifications that can lead to improved efficiency and responsiveness.

Upgraded Air Intake Systems can enhance airflow, allowing for better combustion and power output. By replacing factory components with high-performance alternatives, the volume of air entering the combustion chamber is increased, resulting in more efficient fuel use.

Exhaust Modifications play a crucial role in reducing back pressure, facilitating smoother exhaust flow. By installing performance exhaust systems, one can ensure that gases exit quickly, thereby improving overall power and torque.

ECU Tuning is another effective strategy. Adjusting the electronic control unit’s parameters enables precise management of fuel injection and ignition timing. This can lead to noticeable gains in both horsepower and torque.

Additionally, lighter components such as flywheels and pulleys can reduce rotational mass, enhancing throttle response and acceleration. Each of these enhancements contributes to a more dynamic driving experience.

Implementing these enhancements not only boosts performance but also fosters a deeper connection between the driver and their vehicle, transforming each journey into an exhilarating adventure.

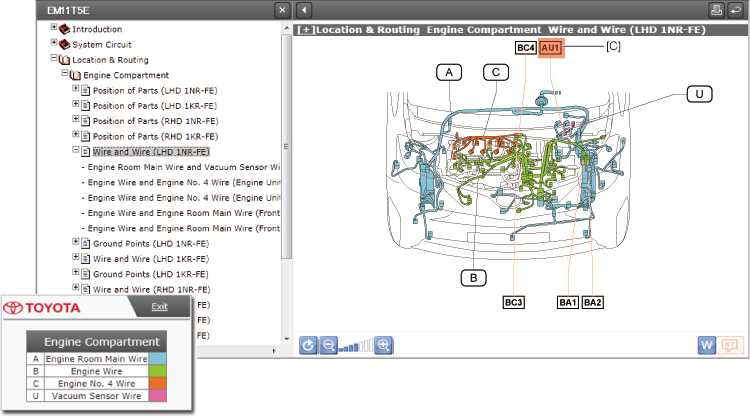

Diagnostic Techniques for Troubleshooting

Effective diagnostics play a crucial role in identifying and resolving issues within mechanical systems. By employing systematic approaches, one can pinpoint the source of a problem, ensuring efficient repairs and maintenance. This section explores various techniques that can aid in diagnosing faults and improving overall system performance.

Common Diagnostic Approaches

- Visual Inspection: Examine components for signs of wear, damage, or misalignment.

- Performance Testing: Assess functionality under various conditions to identify irregularities.

- Data Analysis: Utilize diagnostic tools to collect and analyze operational data.

Utilizing Diagnostic Tools

Employing specialized tools can enhance the diagnostic process significantly. Consider the following:

- Multimeters: Essential for measuring voltage, current, and resistance.

- Oscilloscopes: Useful for visualizing electrical signals and detecting anomalies.

- Scan Tools: Facilitate communication with control units to retrieve fault codes and data.

Parts Replacement Guide

This section provides essential insights for effectively substituting various components within your vehicle’s system. Understanding when and how to replace parts is crucial for maintaining optimal performance and longevity.

Before initiating any replacements, it’s important to consider the following steps:

- Identify the component that requires substitution.

- Ensure you have the correct tools and replacement parts on hand.

- Follow the guidelines for disassembly and reassembly.

Key components that often need attention include:

- Filters – Regularly changing filters can improve efficiency.

- Belt and hoses – Inspect for wear and tear to avoid breakdowns.

- Fluid levels – Keep an eye on all fluids to ensure smooth operation.

By adhering to these recommendations, you can enhance your vehicle’s reliability and performance. Regular maintenance and timely part replacements are vital for any successful upkeep strategy.

Safety Precautions During Repairs

When undertaking maintenance tasks on machinery, ensuring a safe working environment is crucial. Proper safety measures protect both the individual and the equipment involved. By following specific guidelines, one can minimize the risk of accidents and injuries.

Before starting any work, it is essential to equip oneself with appropriate protective gear. This includes items such as gloves, goggles, and sturdy footwear. These precautions help shield against potential hazards encountered during the process.

| Protective Equipment | Purpose |

|---|---|

| Gloves | To protect hands from cuts and chemicals |

| Goggles | To shield eyes from debris and harmful substances |

| Footwear | To prevent foot injuries from heavy objects |

| Ear Protection | To reduce exposure to loud noises |

Additionally, ensuring a clean and organized workspace significantly reduces the likelihood of accidents. Tools should be stored properly, and any spills should be cleaned immediately to prevent slips. Taking these precautions contributes to a more efficient and safer working experience.

Cost Considerations for Engine Repairs

When addressing the intricacies of overhauling a vehicle’s power source, various financial aspects come into play. Understanding these factors can help owners make informed decisions about maintenance and potential upgrades. From parts and labor to unforeseen expenses, it’s crucial to evaluate the overall investment required for restoring optimal performance.

Components of Repair Expenses

The costs associated with refurbishment can vary significantly based on several elements. Key contributors include the price of replacement parts, the hourly rates charged by mechanics, and any additional services that may be necessary during the process.

| Cost Component | Average Price |

|---|---|

| Replacement Parts | $300 – $1,500 |

| Labor Costs | $100 – $150 per hour |

| Diagnostic Fees | $50 – $150 |

Long-term Financial Implications

Investing in proper maintenance not only addresses immediate issues but can also prevent costly repairs in the future. Regular assessments and timely interventions may save vehicle owners from significant financial burdens down the line. Considering these long-term benefits can help in making prudent choices regarding upkeep.

FAQs About 1KR FE Engine

This section aims to address common inquiries regarding a specific compact power unit, offering insights into its functionality, maintenance, and troubleshooting. Understanding these aspects can help users maximize performance and longevity.

Common Issues and Solutions

One frequent question concerns the performance drop experienced during acceleration. This can often be attributed to fuel delivery problems or air intake restrictions. Regular maintenance checks and cleaning of the air filter can mitigate these issues. Additionally, ensuring that the fuel system is free from contaminants will enhance efficiency.

Maintenance Recommendations

Regular upkeep is crucial for optimal operation. It is advisable to follow a strict schedule for oil changes, replacing filters, and checking the cooling system. Users should also pay attention to any unusual sounds or vibrations, as these may indicate underlying problems. Keeping a detailed log of maintenance activities can assist in early detection of potential issues.