Toyota 1DZ-II Engine Repair Guide

This section delves into essential aspects of maintaining and enhancing the performance of a specific power unit commonly found in various vehicles. Understanding its components and functionality is crucial for anyone seeking to ensure longevity and efficiency.

Effective upkeep requires familiarity with common issues and their solutions, which can significantly impact the overall performance of the machinery. By following systematic approaches and applying appropriate techniques, enthusiasts can achieve optimal results while minimizing the risk of complications.

Whether addressing minor adjustments or more substantial interventions, having access to detailed information and instructions is invaluable. This resource serves as a foundation for individuals aiming to gain insights and practical knowledge for effective care and restoration of their automotive power systems.

Overview of the 1DZ-II Power Unit

This section provides a comprehensive insight into a specific type of power unit known for its reliability and efficiency. Designed for various applications, this model is recognized for its robust construction and performance. Understanding its fundamental characteristics is essential for those working with or maintaining these units.

Key Features

The highlighted model boasts a strong design that facilitates longevity and dependable operation. Its configuration allows for effective power delivery, making it suitable for both commercial and recreational vehicles. Additionally, advancements in engineering have contributed to its fuel efficiency, enhancing its appeal to users seeking cost-effective solutions.

Applications

This power unit finds its use in diverse settings, including transportation and industrial machinery. Its versatility enables it to adapt to various requirements, ensuring that it meets the expectations of users across different sectors. The combination of durability and adaptability makes it a preferred choice among many operators.

Common Issues and Symptoms

This section highlights frequent complications and indicators that may arise with certain mechanical systems. Recognizing these signs early can aid in timely intervention, ensuring optimal performance and longevity of the unit.

Performance Degradation

A noticeable decline in efficiency often signals underlying problems. Drivers may experience reduced power output, sluggish acceleration, or unusual noises during operation, indicating that maintenance may be required.

Fluid Leaks

The presence of unexpected leaks beneath the unit is a clear symptom of potential issues. It is essential to identify the source of these leaks, as they can lead to further complications if left unaddressed.

Tools Required for Repairs

For efficient maintenance and service, having the right equipment is essential. Various instruments facilitate the troubleshooting process, ensuring that tasks are completed effectively and safely. Below is a compilation of essential tools needed for optimal functioning.

Basic Hand Tools

- Wrenches (adjustable and fixed)

- Screwdrivers (flathead and Phillips)

- Socket set

- Pliers (needle-nose and slip-joint)

- Hammer

Specialized Instruments

- Torque wrench

- Oil filter wrench

- Compression tester

- Timing light

- Multimeter

Using these tools will enhance the efficiency and accuracy of various tasks, promoting a thorough approach to servicing.

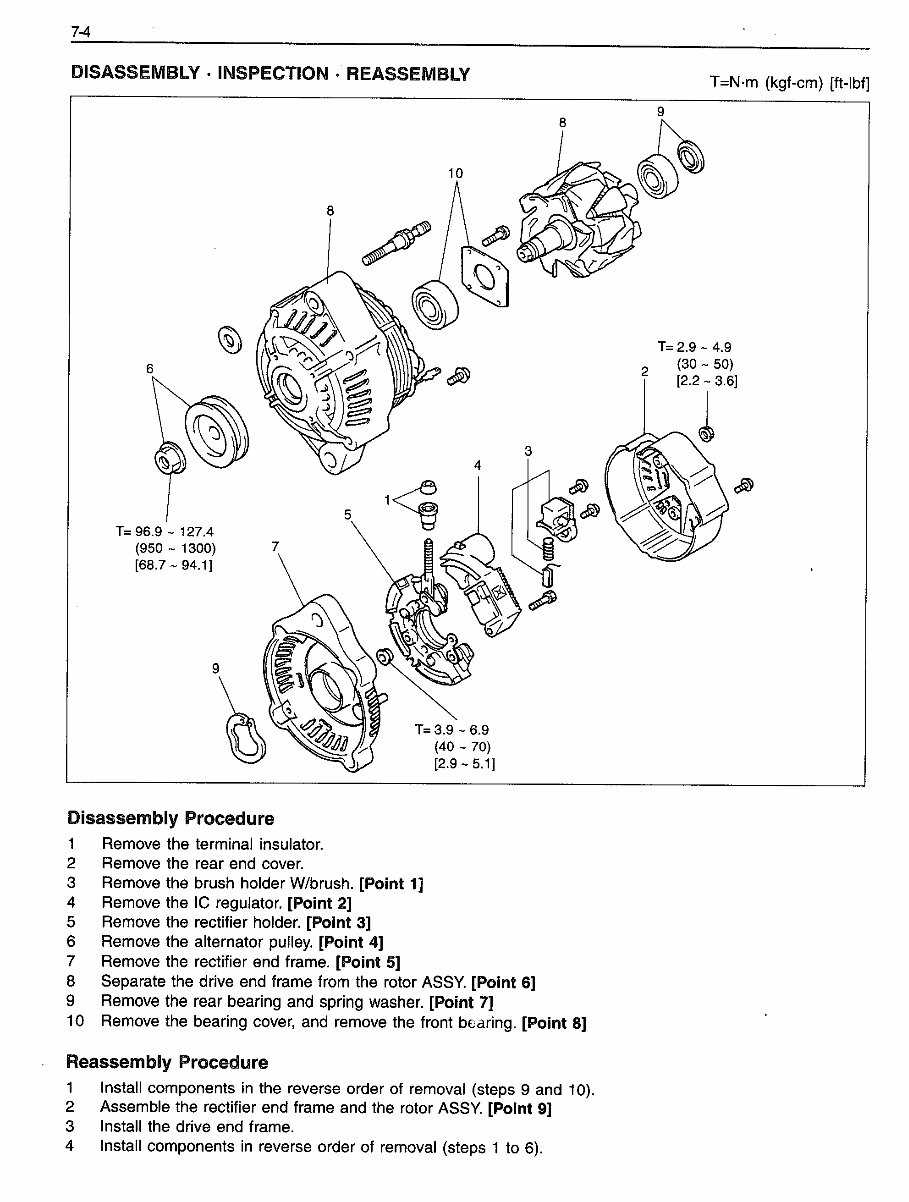

Step-by-Step Disassembly Guide

This section provides a comprehensive guide for systematically taking apart a complex machinery unit. Following a methodical approach ensures that components are carefully removed, preventing damage and facilitating efficient reassembly later on.

Preparation Before Disassembly

Before starting the disassembly process, it is crucial to gather the necessary tools and equipment:

- Wrenches and sockets

- Screwdrivers (flathead and Phillips)

- Torque wrench

- Plastic bags for small parts

- Workbench for organizing components

Additionally, ensure a clean workspace to prevent losing any small pieces during the process.

Disassembly Steps

- Begin by disconnecting any electrical connections to ensure safety.

- Remove any covers or housings that protect the internal components.

- Carefully detach hoses and pipes, noting their original positions for reinstallation.

- Loosen and remove fasteners securing the main components.

- Gradually lift off the main assemblies, ensuring to support them adequately to avoid dropping.

- Organize all removed parts into labeled bags for easier identification during reassembly.

Following these steps will help in achieving a successful disassembly, making the subsequent reassembly process smoother and more efficient.

Inspecting Engine Components

Evaluating the various parts of a power unit is crucial for maintaining optimal performance and longevity. This process involves a thorough examination of key components to identify any signs of wear, damage, or misalignment. Regular inspections can prevent more significant issues down the line and ensure the unit operates efficiently.

Key components to focus on during the assessment include:

| Component | Inspection Method | Signs of Wear |

|---|---|---|

| Crankshaft | Visual inspection and measurements | Scoring or discoloration |

| Pistons | Check for cracks and deformation | Uneven wear patterns |

| Rings | Measure gap and inspect for damage | Excessive wear or breakage |

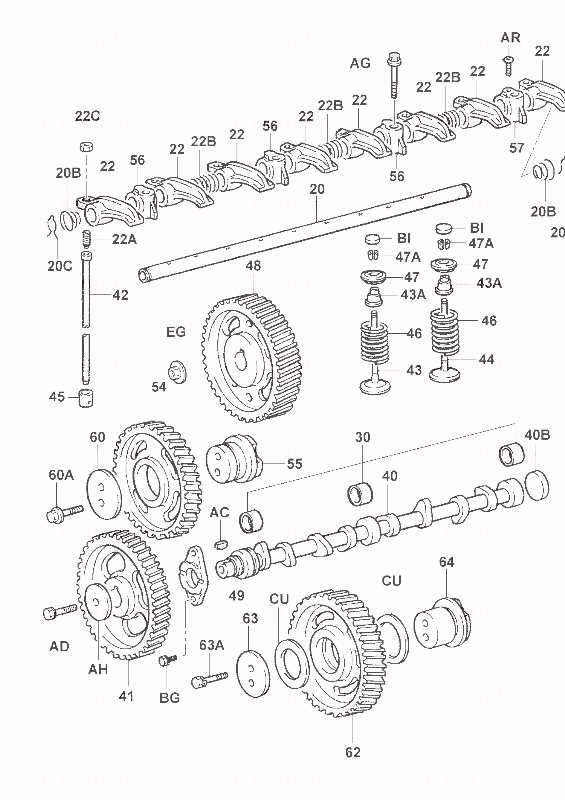

| Camshaft | Assess lobes and bearings for wear | Scoring or pitting |

| Valves | Check for seating and wear | Burn marks or bending |

By systematically inspecting these components, one can address potential issues before they escalate, ensuring reliable operation of the entire assembly.

Reassembly Tips and Tricks

When putting components back together, attention to detail is crucial for ensuring optimal functionality and longevity. Following systematic approaches can greatly enhance the reassembly process.

1. Organize Your Workspace: Begin by clearing your workspace and laying out all parts systematically. Using labeled containers can help keep track of small components, reducing the risk of loss.

2. Follow a Sequence: Adhering to the original assembly order can simplify the process. Create a checklist or refer to documentation to ensure that each step is completed without missing crucial parts.

3. Use the Right Tools: Ensure you have the correct tools for each task. Using the appropriate equipment not only simplifies reassembly but also minimizes the risk of damage to components.

4. Inspect Each Part: Before reassembly, thoroughly examine all components for wear or damage. Replacing worn-out parts during the process can prevent future issues and enhance overall performance.

5. Apply Lubrication: Use suitable lubricants on moving parts as needed. Proper lubrication reduces friction and can significantly improve efficiency and lifespan.

6. Torque Specifications: Pay close attention to torque specifications when fastening components. Using a torque wrench ensures that parts are secured properly without being overtightened, which could lead to damage.

7. Double-Check Connections: Before finalizing the assembly, double-check all connections and fittings. Ensuring that everything is secure can prevent leaks and operational failures.

8. Test Thoroughly: After reassembly, conduct thorough tests to confirm that everything is functioning correctly. This final step is essential to identify any potential issues before the unit is put back into service.

Maintenance Best Practices

Proper upkeep is essential for ensuring optimal performance and longevity of any mechanical system. Implementing effective strategies can prevent common issues and enhance reliability. Regular assessments and timely interventions are key components of successful management.

1. Regular Inspections: Conduct thorough examinations at scheduled intervals to identify wear and tear. This proactive approach helps in detecting potential problems before they escalate, saving time and resources in the long run.

2. Fluid Checks and Changes: Maintain proper levels of vital fluids such as lubricants and coolants. Regularly replacing these substances can significantly reduce friction and overheating, promoting smoother operation.

3. Cleaning Components: Keep parts free of debris and contaminants. Routine cleaning not only improves efficiency but also extends the lifespan of various components, preventing costly repairs.

4. Follow Manufacturer Guidelines: Adhering to specified maintenance schedules and recommendations ensures that all practices are aligned with the best standards for performance and safety.

5. Document Maintenance Activities: Keep detailed records of all maintenance work performed. This documentation can be invaluable for tracking the history and condition of the system, aiding in future decisions.

Upgrading Parts for Performance

Enhancing components can significantly boost the overall capabilities of your vehicle. By selecting the right upgrades, you can achieve better power output, improved efficiency, and a more enjoyable driving experience. This section explores key areas to focus on when considering enhancements.

- Air Intake System: Upgrading the air intake allows for improved airflow, resulting in better combustion and increased horsepower.

- Exhaust System: A performance exhaust can enhance exhaust flow, reducing back pressure and improving engine response.

- Tuning Software: Custom tuning software can optimize fuel maps and ignition timing, maximizing performance according to your modifications.

- Suspension Upgrades: Better suspension components can improve handling and stability, allowing for a more controlled ride.

- Brake System: Upgrading to high-performance brakes ensures effective stopping power, essential for high-performance applications.

When selecting parts for enhancement, consider compatibility and the overall balance of your vehicle. Each upgrade should work harmoniously to achieve optimal results.

Understanding Engine Specifications

Gaining insight into the technical characteristics of a power unit is crucial for effective maintenance and optimal performance. These specifications provide essential information regarding the mechanics and capabilities of the system, ensuring that it operates smoothly and efficiently.

Key elements include the displacement, which refers to the total volume of all cylinders, and the compression ratio, indicating the degree to which the air-fuel mixture is compressed before combustion. Additionally, the power output, measured in horsepower or kilowatts, reflects the unit’s performance capabilities. Understanding these details aids in making informed decisions about modifications, servicing, and troubleshooting.

Another important aspect involves the torque curve, which illustrates the relationship between rotational force and engine speed. This information helps determine the most effective operating range, allowing users to maximize efficiency and responsiveness during various driving conditions. Properly interpreting these specifications contributes significantly to the longevity and reliability of the power unit.

In summary, familiarizing oneself with these technical details not only enhances the user’s knowledge but also promotes better maintenance practices, leading to improved overall performance.

Diagnostics and Troubleshooting Techniques

Effective diagnosis and resolution of mechanical issues require a systematic approach. Identifying problems accurately is crucial for ensuring optimal performance and longevity of the vehicle. This section outlines key strategies and methodologies for diagnosing common issues.

Begin with a thorough assessment of symptoms. Here are steps to follow:

- Gather Information: Collect detailed descriptions of the issues faced. Ask questions about performance, noises, or other irregularities.

- Visual Inspection: Examine the components for any visible signs of wear, damage, or leaks. Pay close attention to connections, hoses, and belts.

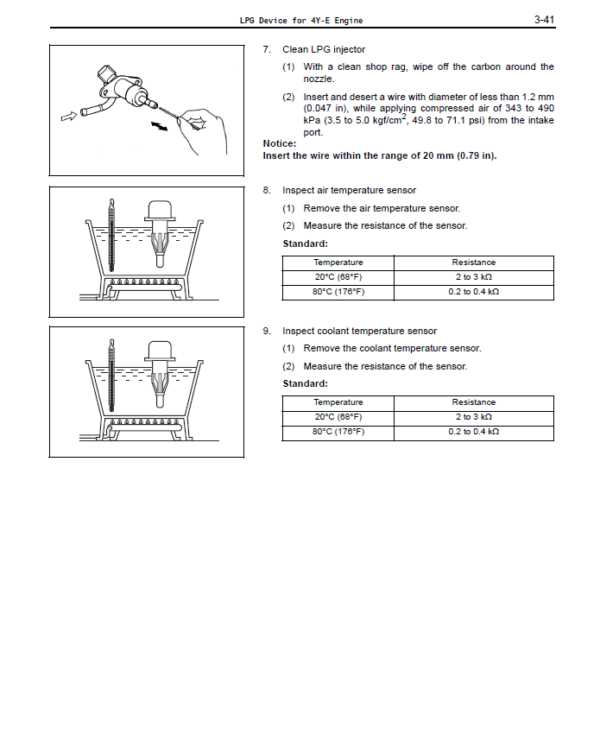

- Utilize Diagnostic Tools: Employ appropriate equipment such as multimeters and pressure gauges to measure parameters. This data helps identify deviations from normal specifications.

- Perform Functional Tests: Conduct specific tests to evaluate the performance of various systems. This may include checking fluid levels, electrical circuits, and other operational aspects.

Once the diagnostic process is underway, consider the following troubleshooting techniques:

- Elimination Method: Isolate each potential issue by testing one component at a time. This method helps narrow down the source of the problem.

- Consult Technical Resources: Refer to manuals, online forums, and databases for information on common problems and solutions.

- Document Findings: Keep detailed records of observations and repairs made. This documentation can be invaluable for future reference and trend analysis.

By following these guidelines, individuals can enhance their ability to diagnose and rectify issues efficiently, leading to improved vehicle reliability and performance.

Resources for Further Learning

Enhancing your knowledge about vehicle maintenance and troubleshooting can significantly improve your hands-on skills. Numerous resources are available to assist enthusiasts and professionals alike in expanding their understanding of various components and systems.

- Online Forums and Communities: Engage with other enthusiasts to share experiences and gain insights.

- Technical Workshops: Participate in hands-on sessions that provide practical knowledge and skills.

- Instructional Videos: Utilize platforms like YouTube for visual guidance on specific tasks and techniques.

- Books and Publications: Explore literature focusing on automotive mechanics and system diagnostics.

- Manufacturer Resources: Access official documentation and specifications that provide detailed information.

Utilizing these resources can greatly enhance your proficiency and confidence in working with various automotive systems.