Comprehensive Guide to Snapper Rear Engine Rider Repairs

In the world of outdoor machinery, ensuring the longevity and efficiency of your equipment is essential for optimal performance. This section provides valuable insights into the upkeep and troubleshooting of specialized lawn care devices, helping users to navigate common challenges they may encounter.

Understanding the intricacies of these machines can empower owners to perform essential tasks independently, thus enhancing their knowledge and confidence. From routine checks to more complex issues, this guide aims to equip users with the necessary skills to maintain their machines effectively.

By following the suggested practices outlined here, you can keep your machinery running smoothly, ultimately contributing to a healthier and more vibrant outdoor space. Whether you are a seasoned professional or a beginner, this resource will serve as a helpful companion in your maintenance journey.

This section provides a comprehensive overview of a specific category of lawn care machinery designed for ease of use and efficiency. Understanding the fundamentals of these machines is essential for proper maintenance and functionality.

- Introduction to Lawn Maintenance Machines

- Key Features of Riding Mowers

- Advantages of Using a Rear-Mounted System

- Common Uses and Applications

- Components of the Machine

- Safety Features and Precautions

- Basic Maintenance Procedures

- Identifying Common Issues

- Tools Required for Upkeep

- When to Seek Professional Help

- Upgrading and Customizing Options

- Long-term Care and Storage Tips

This outline serves as a roadmap for delving deeper into the various aspects of these machines, ensuring users can maximize their performance and longevity.

Common Issues Faced by Users

When operating lawn care equipment, users often encounter a variety of challenges that can hinder performance and efficiency. Understanding these common problems can help in troubleshooting and maintaining optimal functionality.

Starting Difficulties

One of the frequent issues users experience is trouble starting the machinery. This may result from factors such as fuel quality, battery condition, or ignition system malfunctions. Regularly checking and maintaining these components can significantly improve reliability.

Uneven Cutting

Another prevalent concern is uneven cutting performance. This can be attributed to dull blades, improper deck height adjustments, or worn-out components. Ensuring that blades are sharp and regularly inspecting the cutting deck can enhance overall cutting efficiency.

Maintenance Tips for Longevity

Ensuring the prolonged functionality of your machinery requires regular upkeep and attention. By implementing effective maintenance practices, you can significantly enhance performance and extend the lifespan of your equipment. Here are some essential tips to consider.

| Tip | Description |

|---|---|

| Regular Cleaning | Keep the exterior and components free from debris and dirt to prevent damage and corrosion. |

| Fluid Checks | Periodically inspect and change oils and fluids as needed to ensure optimal operation. |

| Sharpen Blades | Maintain sharp cutting edges for efficient performance and to reduce strain on the machinery. |

| Battery Care | Check battery condition regularly and clean terminals to prevent electrical issues. |

| Inspect Belts and Cables | Examine for wear or fraying and replace as necessary to avoid unexpected failures. |

By following these guidelines, you can ensure that your equipment remains in excellent condition, ready for use whenever needed.

Tools Required for Repairs

When it comes to maintaining and fixing outdoor equipment, having the right instruments is essential for achieving effective results. A well-equipped toolkit not only facilitates the repair process but also ensures safety and efficiency while working.

Here is a list of essential tools you will need:

- Wrenches: A variety of sizes will help with loosening or tightening bolts and nuts.

- Screwdrivers: Both flathead and Phillips types are necessary for handling screws in different components.

- Pliers: These are useful for gripping, twisting, and cutting wire or other materials.

- Socket Set: A comprehensive set will make it easier to work with various fasteners.

- Torque Wrench: This ensures that fasteners are tightened to the manufacturer’s specifications.

- Jack Stands: Essential for safely supporting the equipment during maintenance.

- Safety Gear: Gloves and goggles protect you while you work.

Having these tools on hand will make the maintenance and servicing process smoother and more efficient, allowing you to keep your outdoor machinery in optimal condition.

Step-by-Step Repair Procedures

This section outlines a systematic approach to fixing common issues with your machine. By following these detailed instructions, you can ensure that each stage of the process is executed correctly for optimal performance.

-

Preparation: Gather all necessary tools and materials before starting. This may include wrenches, screwdrivers, and replacement parts.

-

Safety Measures: Always disconnect power sources and wear appropriate safety gear to protect yourself during the process.

-

Assessment: Inspect the unit for any visible signs of damage or wear. Identify specific components that need attention.

-

Disassembly: Carefully remove any coverings or parts that obstruct access to the area needing attention. Keep track of all screws and components.

-

Replacement: Replace faulty components with new ones. Ensure all connections are secure and properly aligned.

-

Reassembly: Reassemble the unit in the reverse order of disassembly, making sure each piece fits correctly.

-

Testing: Once reassembled, reconnect power and test the functionality to ensure everything operates smoothly.

-

Final Check: Conduct a thorough inspection to confirm that all tools are removed from the work area and that there are no loose parts.

By adhering to these guidelines, you can successfully navigate the process and restore your machine to peak condition.

Identifying Engine Problems

Recognizing issues within a power unit is essential for maintaining optimal performance. Various symptoms may indicate underlying complications that need addressing. Observing unusual sounds, vibrations, or changes in operation can provide valuable clues to potential malfunctions.

One common sign of trouble is an irregular sound during operation. If the unit produces knocking, rattling, or excessive noise, it may suggest mechanical wear or misalignment. Additionally, fluctuations in power or stalling can indicate problems with fuel delivery or ignition systems.

Visual inspections also play a critical role in identifying issues. Checking for leaks, damaged components, or unusual wear patterns can help pinpoint specific areas needing attention. Regular maintenance and timely interventions are key to prolonging the lifespan of the machinery.

Utilizing diagnostic tools can further assist in evaluating performance. Gauges that monitor temperature, pressure, and other metrics can reveal deviations from normal operating conditions. Addressing these signs promptly can prevent more significant failures in the future.

Electrical System Troubleshooting

Troubleshooting the electrical system is essential for maintaining optimal performance in any machinery. Understanding the basic components and their functions can significantly aid in identifying issues. A systematic approach will help pinpoint malfunctions and ensure that all elements are operating correctly.

Start by examining the battery. Check for any signs of corrosion on the terminals and ensure that connections are tight. A weak or dead battery is often the culprit in electrical failures. If the battery appears to be functioning properly, proceed to inspect the wiring harness for any frayed or damaged wires, as these can interrupt the flow of electricity.

Next, evaluate the ignition system. Ensure that all components, including the ignition coil and spark plug, are in good condition. A faulty ignition system can lead to starting issues or erratic engine behavior. Testing the components with a multimeter can provide insights into their functionality.

Finally, consider the safety features, such as the seat switch and brake interlock. These systems are designed to prevent operation under unsafe conditions. Verify that these switches are working correctly, as they can prevent the machinery from starting if they detect a problem.

By methodically checking each of these areas, one can effectively troubleshoot electrical issues and ensure smooth operation.

Replacing Blades and Deck Parts

Maintaining optimal performance of your mowing equipment involves regular replacement of cutting components and related structures. Over time, these parts can become worn or damaged, affecting efficiency and the quality of the cut. Understanding how to properly replace these components ensures your machine operates smoothly and effectively.

To begin the process, ensure the device is powered down and securely positioned. Remove any debris around the cutting area to facilitate easy access. Carefully detach the existing blades by unscrewing the fasteners that hold them in place. It is important to inspect both the blades and the deck for any signs of wear or damage before installing new components.

Select high-quality replacements that fit the specifications of your equipment. Position the new blades correctly, ensuring they are oriented as intended for optimal performance. Secure them firmly with the appropriate fasteners, taking care not to overtighten, which could lead to damage.

After replacing the blades, inspect and, if necessary, replace other related parts of the deck. This may include belts, pulleys, or any additional components that assist in the mowing function. Ensure all connections are tight and properly aligned before reassembling the equipment.

Regular maintenance and timely replacement of cutting components will not only extend the lifespan of your equipment but also enhance its overall performance, providing a cleaner and more efficient mowing experience.

Fuel System Maintenance Guidelines

Maintaining the fuel system is crucial for ensuring optimal performance and longevity of your machine. Proper care can prevent common issues that may arise from neglect, leading to improved efficiency and reliability.

- Regularly check fuel lines for any signs of wear or leaks.

- Ensure that the fuel filter is clean and replaced as needed to prevent clogs.

- Use high-quality fuel to avoid contamination that can affect performance.

- Inspect the fuel tank for debris and clean it periodically to maintain proper flow.

It is also essential to store fuel correctly and in suitable containers to minimize degradation. Following these guidelines can significantly enhance the operational capabilities of your equipment.

- Consider using fuel stabilizers to prolong shelf life when storing for extended periods.

- Always check for the proper fuel type as specified in the guidelines.

By adhering to these maintenance tips, you can ensure a well-functioning fuel system that supports your machinery’s overall performance.

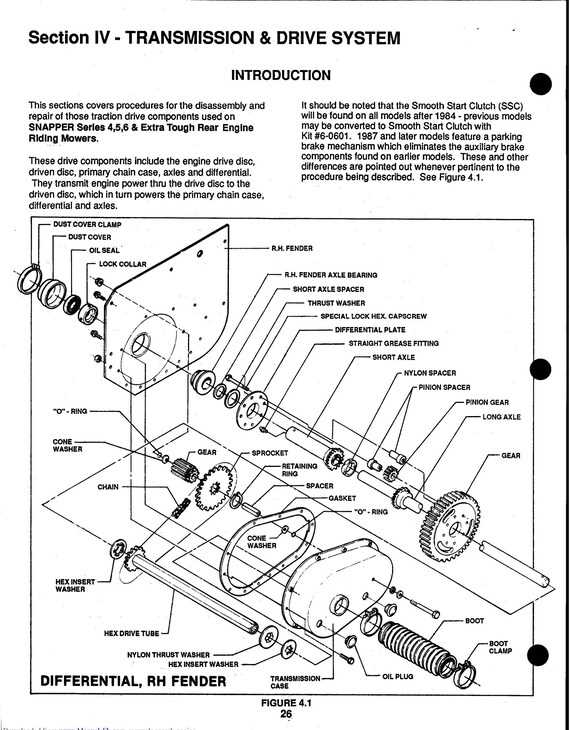

Transmission Adjustments and Repairs

Proper functioning of the drive system is essential for optimal performance and longevity of your equipment. Ensuring the correct alignment and tension within the transmission components can significantly enhance efficiency and prevent wear. Regular adjustments and inspections will help identify any issues early on, allowing for timely interventions and prolonging the lifespan of critical parts.

Common Adjustment Techniques

Adjustments typically involve checking the tension of belts, alignment of pulleys, and the condition of gears. Ensuring that these elements are within specified tolerances can prevent slippage and improve power transfer. Here are some common techniques used during adjustments:

| Technique | Description |

|---|---|

| Belt Tensioning | Adjusting the tightness of the drive belt to prevent slippage and ensure efficient power transfer. |

| Pulley Alignment | Ensuring pulleys are aligned correctly to minimize wear and improve operational smoothness. |

| Gear Lubrication | Applying appropriate lubricant to moving parts to reduce friction and prevent overheating. |

Identifying and Fixing Common Issues

Awareness of common issues can help in early detection and resolution. Symptoms such as unusual noises, vibrations, or difficulty in engagement often indicate the need for further examination. Addressing these problems promptly can prevent more extensive damage. Consider the following issues:

| Issue | Possible Cause |

|---|---|

| Noisy Operation | Worn or misaligned gears causing friction. |

| Slipping Drive | Improper belt tension or damaged components. |

| Delayed Engagement | Low lubrication levels or air trapped in the system. |

Safety Precautions During Repairs

Ensuring a secure environment while working on machinery is essential for both personal safety and effective maintenance. Adhering to proper protocols minimizes the risk of accidents and enhances overall efficiency in the task at hand.

Before beginning any work, always disconnect power sources to prevent unintended activation. Utilize protective gear, such as gloves and safety goggles, to shield against potential hazards. Additionally, maintaining a clean workspace free of clutter can significantly reduce the chances of slips or falls.

It’s crucial to familiarize yourself with the equipment’s features and specifications, as understanding how each component operates aids in performing tasks safely. Moreover, having the right tools readily available ensures that adjustments can be made swiftly and accurately, minimizing the time spent in potentially dangerous situations.

Lastly, follow the manufacturer’s recommendations and guidelines to maintain safety standards throughout the process. Regularly assessing your surroundings and staying alert will contribute to a safer and more productive working experience.

Finding Replacement Parts EasilyFeel free to adjust any headings as needed!

Locating suitable components for your machine can be a straightforward process when you know where to look. Various resources are available to help you find the necessary items, ensuring that your equipment remains functional and efficient.

Start by checking online marketplaces that specialize in parts for outdoor machinery. These platforms often provide a wide range of options, including both original and aftermarket components. Additionally, many websites offer detailed specifications to assist you in choosing the correct items.

Local retailers and specialty stores can also be valuable resources. Many of these establishments stock essential parts or can order them for you. Establishing a relationship with local suppliers may lead to helpful advice and insights regarding the best products for your needs.

Don’t overlook community forums and user groups, where enthusiasts share their experiences and recommendations. These platforms can be a treasure trove of information, offering insights into compatibility and performance of various components.

Lastly, consult the documentation that came with your equipment. It often includes parts lists and diagrams that can simplify the process of identifying the specific components you require.