Comprehensive Guide to ZF AS Tronic Transmission Repair

In the realm of modern automotive engineering, the complexities of advanced shifting systems have become increasingly significant. Understanding the intricacies of these innovative mechanisms is essential for optimal vehicle performance. This section delves into the essential aspects of maintaining and troubleshooting these sophisticated units, ensuring drivers can enjoy a seamless experience on the road.

The importance of a well-functioning shifting assembly cannot be overstated. It plays a critical role in enhancing driving dynamics and fuel efficiency. With the rise of automated systems, it becomes imperative to familiarize oneself with the operational principles and potential challenges that may arise during usage.

This comprehensive guide provides valuable insights and practical steps for effectively addressing common issues encountered in these advanced gear-changing systems. By following these outlined strategies, enthusiasts and professionals alike can contribute to the longevity and reliability of their vehicles, ultimately leading to a more enjoyable driving experience.

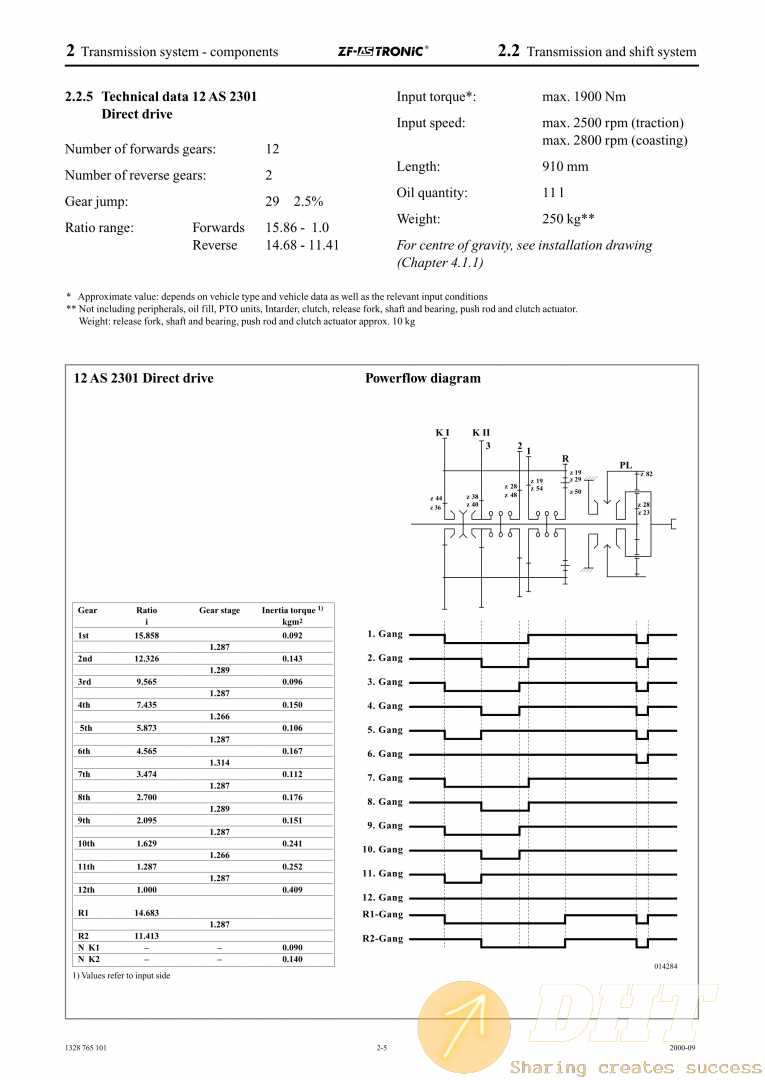

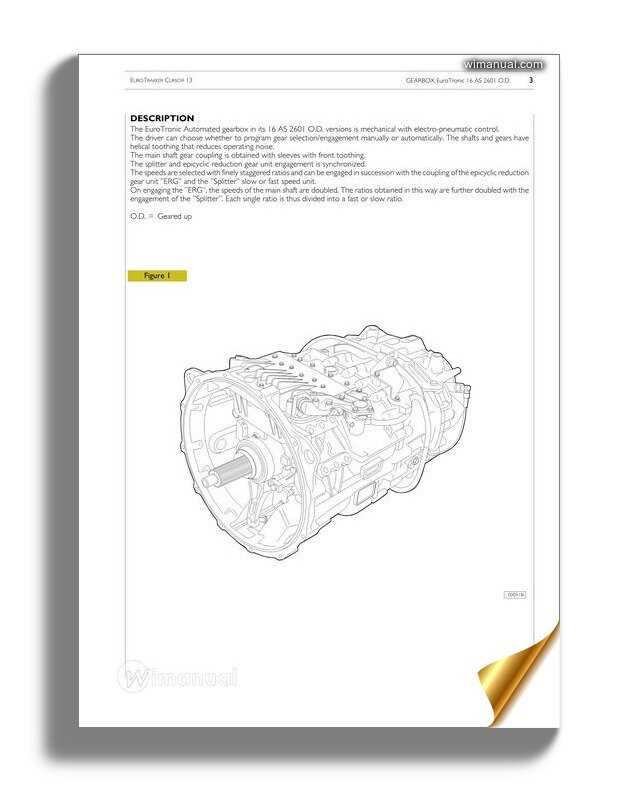

Overview of ZF As Tronic Transmission

The ZF As Tronic system represents a significant advancement in automated gear shifting technology, combining efficiency with seamless performance. This innovative design enhances vehicle dynamics, providing drivers with an optimal balance of power and fuel economy.

Utilizing sophisticated electronic control mechanisms, the system allows for precise gear changes without driver intervention, ensuring smooth acceleration and deceleration. Its intelligent design adapts to various driving conditions, making it suitable for a wide range of applications, from commercial vehicles to luxury automobiles.

Maintenance and troubleshooting of this advanced mechanism require a thorough understanding of its components and functionalities. Familiarity with its operating principles is essential for anyone working to ensure its reliability and performance over time.

Common Issues with As Tronic Systems

Understanding the typical challenges faced by these automated gear-shifting systems is crucial for effective troubleshooting. Users may encounter a variety of symptoms that indicate underlying faults, often leading to performance issues or operational inefficiencies.

Frequent Problems

- Unresponsive Gear Changes

- Inconsistent Shifting Patterns

- Delayed Engagement or Release

- Warning Lights on the Dashboard

- Unusual Noises During Operation

Potential Causes

- Low Fluid Levels or Contamination

- Malfunctioning Sensors

- Electrical System Failures

- Wear and Tear of Internal Components

- Software Glitches or Calibration Issues

Addressing these common issues promptly can help maintain the efficiency and longevity of the system, ensuring reliable performance in various driving conditions.

Tools Needed for Repair Process

Successful completion of the task at hand relies heavily on the right assortment of instruments and equipment. Having the appropriate tools not only enhances efficiency but also ensures precision and safety throughout the procedure.

Essential Hand Tools: A comprehensive set of hand tools is fundamental. This includes wrenches, pliers, screwdrivers, and sockets. These instruments will allow for effective manipulation and adjustment of various components.

Specialized Equipment: Depending on the specific components involved, specialized tools such as torque wrenches or alignment jigs may be required. These tools help achieve the exact specifications needed for optimal performance.

Diagnostic Tools: Modern systems often require diagnostic devices to identify issues accurately. A quality diagnostic scanner can provide valuable insights into the functionality of the various elements.

Safety Gear: Safety should always be a priority. Equip yourself with gloves, goggles, and protective clothing to minimize risks during the undertaking.

By assembling the right collection of instruments and ensuring safety, you pave the way for a smooth and effective undertaking, leading to successful outcomes.

Step-by-Step Repair Instructions

This section provides a comprehensive guide to addressing common issues related to the ZF system. By following these organized steps, users can systematically diagnose and resolve malfunctions, ensuring optimal performance and longevity of the equipment.

Preparation and Tools

Before beginning, gather all necessary tools and components. A clean workspace is essential to prevent contamination. Ensure that you have diagnostic equipment, wrenches, and replacement parts readily available. Review the initial symptoms and establish a clear understanding of the issues at hand.

Systematic Troubleshooting

Start by conducting a thorough inspection of the components involved. Check for leaks, worn parts, and electronic connections. Utilize diagnostic tools to identify error codes and performance discrepancies. Document your findings as you progress, allowing for a structured approach to resolving the identified problems.

Diagnosing Transmission Faults

Identifying issues within a vehicle’s shifting mechanism is crucial for ensuring optimal performance and safety. A systematic approach can help pinpoint problems, allowing for effective solutions. This process often involves careful observation of symptoms, utilization of diagnostic tools, and interpretation of data to uncover underlying causes.

Common Symptoms to Observe

Drivers may notice various indicators suggesting that the shifting system requires attention. These can include unusual noises during gear changes, slipping gears, or delayed responses when accelerating. Other signs might be fluid leaks or warning lights illuminating on the dashboard. Recognizing these symptoms early can lead to quicker resolution of issues.

Diagnostic Tools and Techniques

Utilizing appropriate equipment is essential for accurate assessment. OBD-II scanners can provide valuable diagnostic trouble codes (DTCs) that highlight specific areas of concern. In addition, performing a visual inspection of components such as seals, hoses, and connectors can reveal physical wear or damage. Combining these methods helps build a comprehensive picture of the system’s condition, guiding the next steps for addressing the faults.

Essential Maintenance Tips for Longevity

Maintaining the performance and reliability of your vehicle’s key components is crucial for ensuring its longevity. By adhering to a routine care regimen, you can prevent issues before they arise, ultimately saving time and resources. Here are some vital practices to consider.

- Regular Fluid Checks: Ensure that all essential fluids, such as oil, coolant, and hydraulic fluid, are at appropriate levels and free from contamination.

- Consistent Filter Replacements: Replace filters regularly to ensure optimal performance and efficiency, minimizing wear on critical parts.

- Routine Inspections: Schedule periodic inspections to identify any potential problems early, focusing on components that experience significant stress.

Implementing these practices can significantly enhance the durability and functionality of your vehicle’s essential systems. Consider the following additional tips:

- Adhere to Manufacturer Guidelines: Always follow the manufacturer’s recommendations for maintenance intervals and service requirements.

- Monitor Driving Habits: Adopt smoother driving techniques to reduce strain on components, promoting longevity.

- Stay Informed: Keep updated with the latest technical bulletins and service advisories to be aware of any known issues.

By incorporating these essential maintenance tips, you can greatly enhance the lifespan and reliability of your vehicle, ensuring it remains in peak condition for years to come.

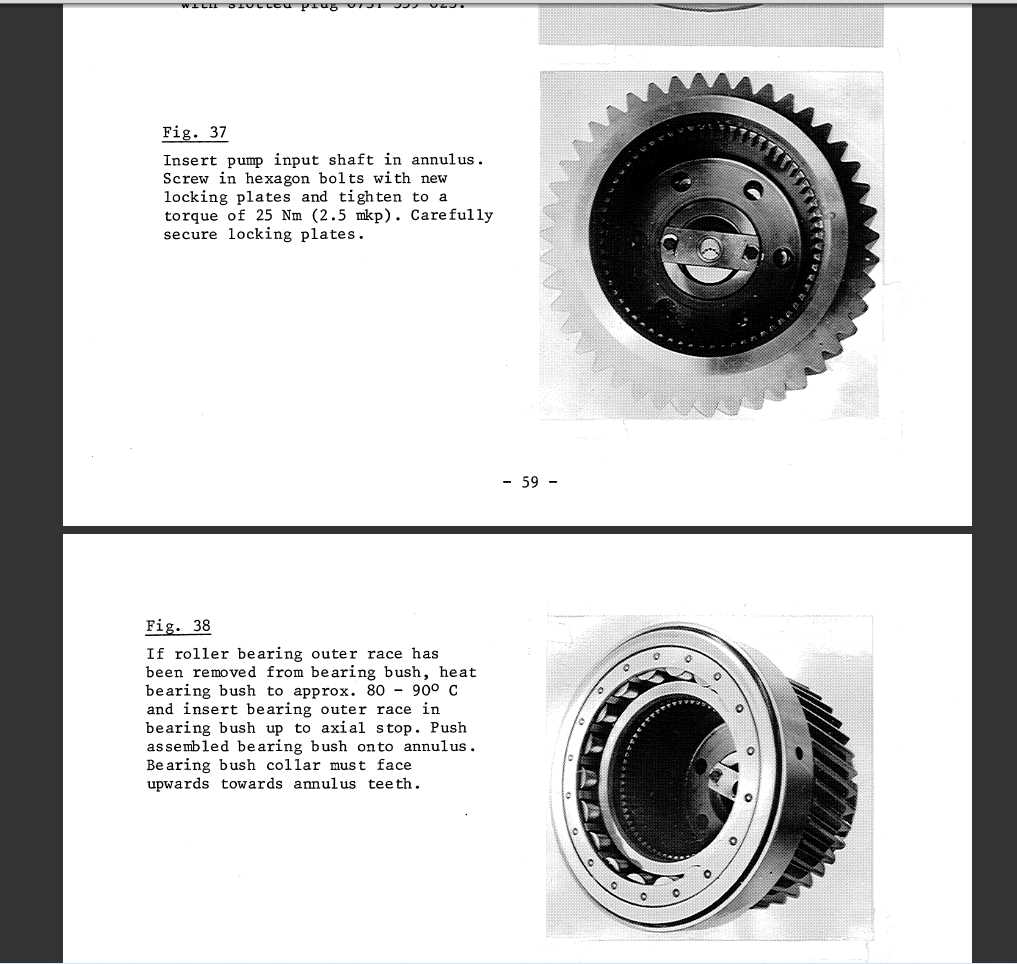

Parts Replacement Guide

This section aims to provide a comprehensive overview for replacing essential components within the specified system. Understanding the importance of each part and its role can significantly enhance the overall performance and longevity of the vehicle. Proper identification and selection of replacement elements are crucial for maintaining optimal functionality.

Before proceeding with the substitution process, ensure you have the necessary tools and safety equipment. Begin by consulting the specifications for the components in question, which will guide you in selecting the appropriate alternatives. It’s also advisable to familiarize yourself with the installation procedures to avoid any complications during the replacement.

When replacing a component, start by carefully removing any surrounding parts that may obstruct access. Take note of the arrangement and connections, as this will assist in the reassembly phase. Always handle new parts with care, inspecting them for any defects before installation.

Once the new part is in place, double-check all connections to ensure everything is secured properly. After reassembly, conduct a thorough inspection and test the system to confirm that it operates smoothly. Regular maintenance and timely replacements will contribute to the vehicle’s performance and reliability.

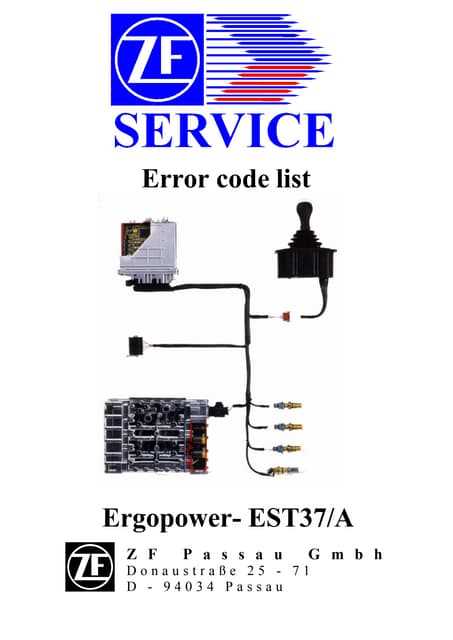

Understanding Error Codes and Diagnostics

Recognizing and interpreting error codes is essential for maintaining optimal vehicle performance. These codes serve as vital indicators of underlying issues within the complex systems of modern automobiles. Properly decoding these signals allows for timely interventions, ultimately enhancing safety and functionality.

Error codes are generated by the vehicle’s onboard diagnostic system, which continuously monitors various components. Understanding these codes requires familiarity with their meanings and implications.

- Common Error Code Types:

- Generic Codes: These are standardized codes applicable across multiple vehicle makes and models.

- Manufacturer-Specific Codes: Unique codes that provide insights into issues specific to a brand or model.

- Diagnostic Process:

- Retrieve the error codes using a diagnostic scanner.

- Consult the code database for meanings and recommended actions.

- Inspect related components based on the information provided by the codes.

Regular monitoring of these codes can prevent minor issues from escalating into major problems. Additionally, being proactive in addressing identified faults fosters better overall vehicle reliability.

Performance Enhancements Post-Repair

After addressing any mechanical issues, many vehicle owners seek ways to elevate their automotive experience. Enhancements not only improve efficiency but also optimize overall driving dynamics. Here are some strategies to consider:

- ECU Tuning: Modifying the engine control unit can lead to improved power delivery and responsiveness.

- Upgraded Components: Installing high-performance parts such as clutches or differential systems can enhance performance.

- Fluid Quality: Using superior quality lubricants can significantly impact operational efficiency and longevity.

- Weight Reduction: Removing unnecessary components or utilizing lighter materials can enhance acceleration and handling.

Furthermore, regular maintenance practices can ensure sustained improvements:

- Monitor fluid levels and quality regularly.

- Keep an eye on tire health and pressure for optimal grip.

- Schedule routine inspections to catch potential issues early.

By implementing these enhancements, drivers can experience a noticeable uplift in vehicle performance and enjoyment on the road.

Safety Precautions During Repairs

Ensuring a secure environment while conducting maintenance tasks is paramount. Adopting appropriate safety measures minimizes risks and enhances efficiency throughout the process. Whether handling complex components or performing basic checks, awareness and caution are essential.

First and foremost, protective gear is a must. Always wear gloves, safety glasses, and appropriate footwear to shield yourself from potential hazards. These items serve as your first line of defense against injuries.

Additionally, ensure the workspace is organized and free from clutter. A tidy area reduces the likelihood of accidents and allows for smoother workflow. Always have tools and equipment readily accessible, but stored safely to prevent tripping or other mishaps.

Furthermore, disconnecting the power source before starting any work is crucial. This simple step can prevent electrical shocks and unexpected machinery activation, protecting both you and the equipment. Always follow proper lockout/tagout procedures to reinforce safety protocols.

Finally, being aware of your surroundings and potential hazards is essential. Regularly assess the environment for any risks, such as spills or unstable structures, and address them immediately. A proactive approach to safety not only safeguards you but also promotes a more effective working atmosphere.

When to Seek Professional Help

Addressing issues with your vehicle’s performance can sometimes be a straightforward task, but there are instances when the complexities demand the expertise of a skilled technician. Recognizing the right moment to consult a professional can save you time, money, and potential hazards on the road.

First and foremost, if you notice unusual noises, persistent warning lights, or changes in the way your vehicle handles, it is advisable to seek assistance. These symptoms often indicate underlying problems that may not be immediately visible and could worsen over time.

Additionally, if you have attempted basic troubleshooting and the issue persists, don’t hesitate to reach out for help. Professional mechanics possess the necessary tools and knowledge to diagnose and resolve complications effectively, ensuring your vehicle operates smoothly and safely.

Lastly, if your vehicle requires complex adjustments or parts replacement, consulting an expert is essential. Attempting to tackle intricate issues without proper training can lead to further complications and increased repair costs.