Honda 2000i Generator Repair Guide

Maintaining portable energy devices is essential for ensuring their longevity and optimal performance. This section focuses on practical insights and guidance for troubleshooting common issues that may arise with compact power sources. By understanding the fundamental components and functionality, users can effectively address problems and enhance the reliability of their equipment.

In this guide, readers will find detailed instructions and tips tailored to assist in diagnosing faults and performing necessary adjustments. Emphasizing clarity and accessibility, the information is designed to empower users to tackle challenges with confidence. Whether facing minor hiccups or more significant complications, this resource aims to facilitate effective solutions.

Equipping oneself with the right knowledge not only fosters a deeper appreciation for these devices but also promotes self-sufficiency in maintenance. With the right approach, users can extend the lifespan of their tools and ensure they operate efficiently for years to come.

Honda 2000i Generator Overview

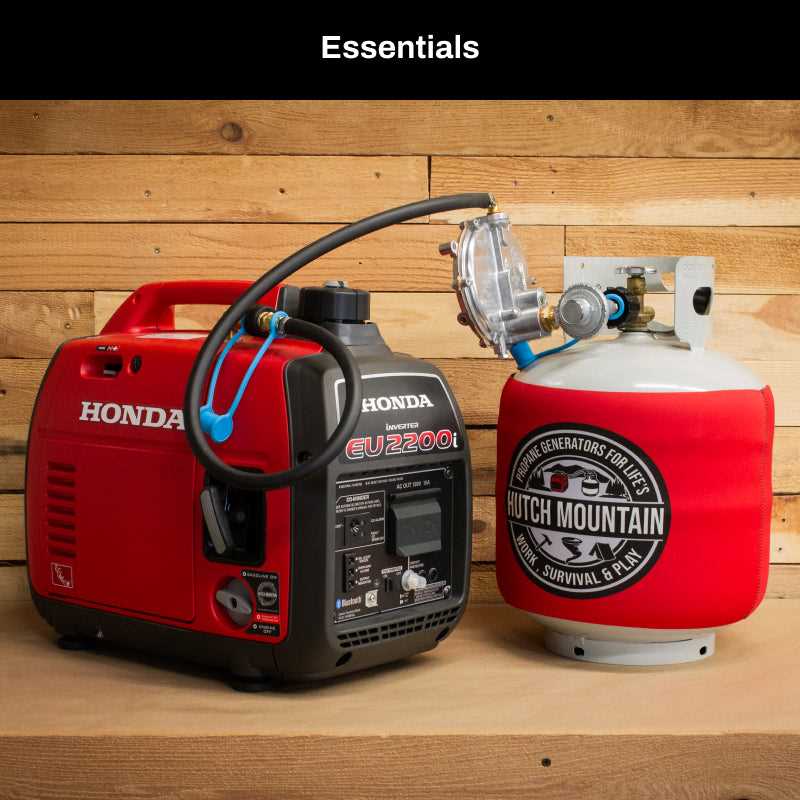

This section provides a comprehensive look at a portable power solution designed for versatility and reliability. Known for its efficient performance, this model is a popular choice among users who require a dependable source of electricity in various situations, such as outdoor activities or emergency backup.

Key Features and Benefits

The device is equipped with several features that enhance its functionality. A compact design allows for easy transport, while a quiet operation ensures minimal disturbance in serene environments. Additionally, fuel efficiency is a significant advantage, enabling extended use without frequent refueling.

Applications and Usability

This power unit is ideal for multiple applications, from camping trips to home backup during outages. Its straightforward interface makes it user-friendly, appealing to both seasoned users and newcomers. Understanding its capabilities can significantly enhance the experience for those seeking reliable portable power.

Common Issues with Honda Generators

When it comes to portable power sources, certain problems can frequently arise, impacting their functionality and reliability. Understanding these common complications can assist users in troubleshooting and maintaining their equipment effectively. Below are some prevalent concerns faced by users of these devices.

Power Output Problems

One of the main issues users encounter is insufficient power delivery. This can stem from various factors, such as improper load management or internal component failures. Regular checks can help identify potential causes before they escalate.

Starting Difficulties

Another common challenge is the struggle to initiate operation. This may be linked to fuel supply issues, battery problems, or starter motor failures. Users are advised to inspect these elements routinely to ensure smooth functionality.

| Issue | Possible Cause | Solution |

|---|---|---|

| Insufficient power | Improper load management | Adjust load or inspect components |

| Starting difficulties | Fuel supply or battery issues | Check fuel levels and battery condition |

Maintenance Tips for Longevity

Proper upkeep is essential for enhancing the lifespan of your equipment. Regular attention to its components can prevent issues and ensure optimal performance over time. Following a systematic maintenance routine will not only enhance reliability but also reduce the risk of unexpected failures.

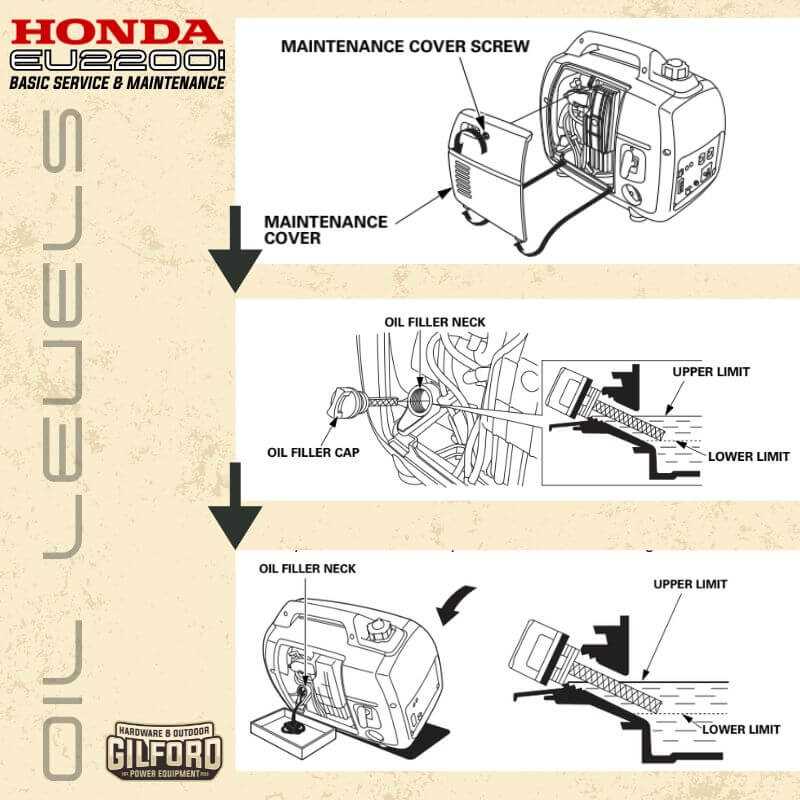

Regular Oil Changes

Changing the lubricant at recommended intervals is crucial for smooth operation. Fresh oil reduces friction and prevents overheating. Always use high-quality products suited for your specific model to achieve the best results.

Clean Air Filter and Fuel System

Keeping the air intake and fuel delivery systems clean is vital for efficient functioning. A blocked air filter can hinder performance, while clean fuel lines ensure proper combustion. Regular inspections and replacements will contribute significantly to overall effectiveness.

Step-by-Step Repair Guide

This section provides a comprehensive approach to troubleshooting and fixing common issues associated with portable power units. Following a structured method can significantly enhance the effectiveness of the maintenance process and ensure optimal functionality.

Identify the Problem: Begin by observing any irregularities in operation. Take note of symptoms such as unusual noises, failure to start, or inconsistent power output. Accurate identification of the issue is crucial for a successful resolution.

Gather Necessary Tools: Prepare all required tools and replacement components before starting the process. This preparation will help streamline the workflow and minimize interruptions during the repair.

Follow Manufacturer Guidelines: Refer to the provided documentation for specific instructions related to the unit in question. Adhering to these recommendations ensures that you are following best practices and safety measures throughout the procedure.

Perform Systematic Checks: Conduct thorough inspections of key components, including fuel systems, electrical connections, and ignition mechanisms. This step will help isolate the root cause of the malfunction and guide further actions.

Make Necessary Adjustments: Once the issues have been identified, proceed with the appropriate adjustments or replacements. This may involve tightening loose connections, replacing worn-out parts, or cleaning filters to restore functionality.

Test the Unit: After completing the adjustments, conduct a series of tests to verify that the power source operates correctly. Monitor its performance under various loads to ensure reliability and efficiency.

Document Findings: Keep a record of the steps taken and any changes made during the process. This documentation can be invaluable for future reference or if similar issues arise.

Essential Tools for Repairs

When addressing maintenance and troubleshooting tasks for portable power sources, having the right equipment is crucial. This section highlights the fundamental instruments that facilitate effective service and ensure longevity.

Basic Hand Tools

Essential hand tools are vital for various tasks, from disassembling components to tightening connections. Consider the following:

- Screwdrivers: A set of flathead and Phillips screwdrivers

- Wrenches: Adjustable and socket wrenches for different nut sizes

- Pliers: Needle-nose and standard pliers for gripping and bending

Specialized Equipment

In addition to basic tools, specialized equipment can enhance the efficiency of your tasks. Key items include:

- Multimeter: For measuring voltage, current, and resistance

- Torque wrench: To ensure bolts are tightened to the correct specification

- Cleaning supplies: Brushes and cloths to maintain component cleanliness

Diagnosing Electrical Problems

Identifying issues within an electrical system is crucial for restoring functionality and ensuring optimal performance. Common symptoms, such as flickering lights or unexpected shutdowns, often indicate underlying faults that require thorough investigation.

To begin troubleshooting, check all connections for looseness or corrosion. A multimeter can be invaluable in measuring voltage and continuity, allowing for the detection of shorts or breaks in the circuit. Pay close attention to fuses and circuit breakers, as these components can provide immediate insight into potential problems.

If the issue persists, consider inspecting the components for wear or damage. Look for signs of overheating or physical wear that may disrupt the flow of electricity. Regular maintenance can prevent many issues, making it easier to diagnose and resolve electrical problems efficiently.

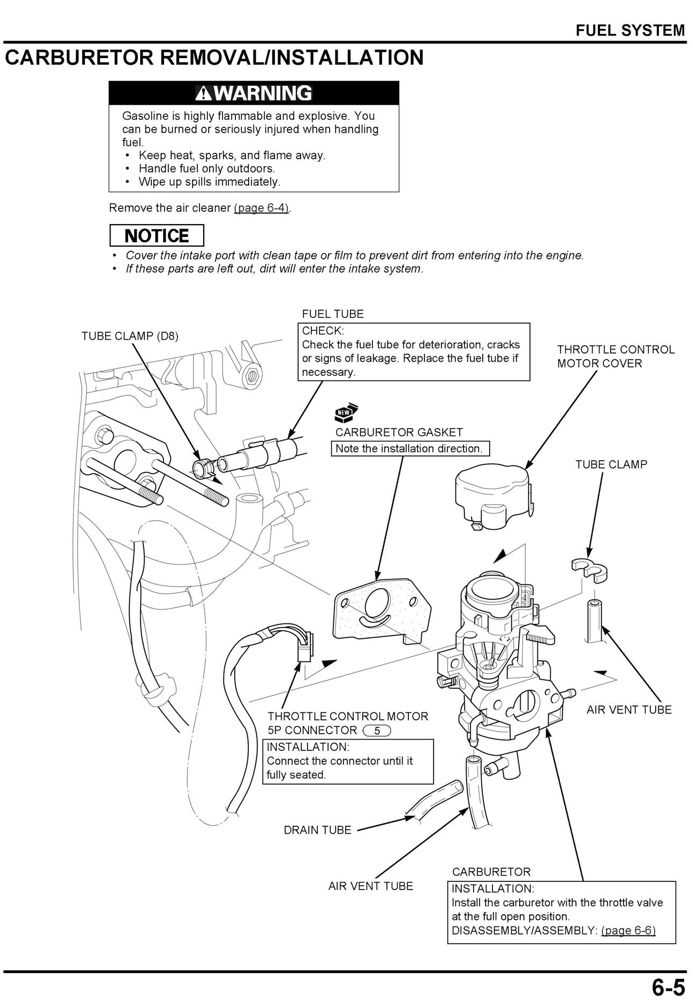

Fuel System Troubleshooting

Diagnosing issues within the fuel delivery system is crucial for maintaining optimal performance. Problems can arise from various sources, including blockages, leaks, or improper fuel mixture. Understanding these common issues can aid in effective resolution.

Identifying Blockages

Blockages in the fuel lines can prevent proper flow, leading to inadequate power output. To identify this, inspect the lines for debris or kinks that might hinder fuel passage. Regular maintenance is essential to prevent such occurrences.

Checking for Leaks

Leaks can significantly impact performance and safety. Inspect the fuel tank, lines, and connectors for signs of leaking fuel. Prompt repair of any leaks is necessary to ensure safe operation and to maintain the efficiency of the system.

Engine Performance Enhancements

Improving the efficiency and power output of small engines can significantly enhance their overall functionality and longevity. By implementing specific modifications and maintenance practices, users can achieve better performance, ensuring that the unit operates at its best under various conditions.

Key Modifications for Improvement

- Air Intake Upgrades: Enhancing the air intake system allows for better airflow, resulting in improved combustion efficiency.

- Exhaust System Optimization: A more efficient exhaust can reduce back pressure and improve engine performance.

- Fuel System Adjustments: Upgrading fuel filters and injectors ensures a more precise fuel delivery, optimizing combustion.

Maintenance Practices for Peak Performance

- Regularly change the oil to keep the engine lubricated and reduce wear.

- Check and clean spark plugs to ensure reliable ignition.

- Inspect air filters frequently and replace them as necessary to maintain airflow.

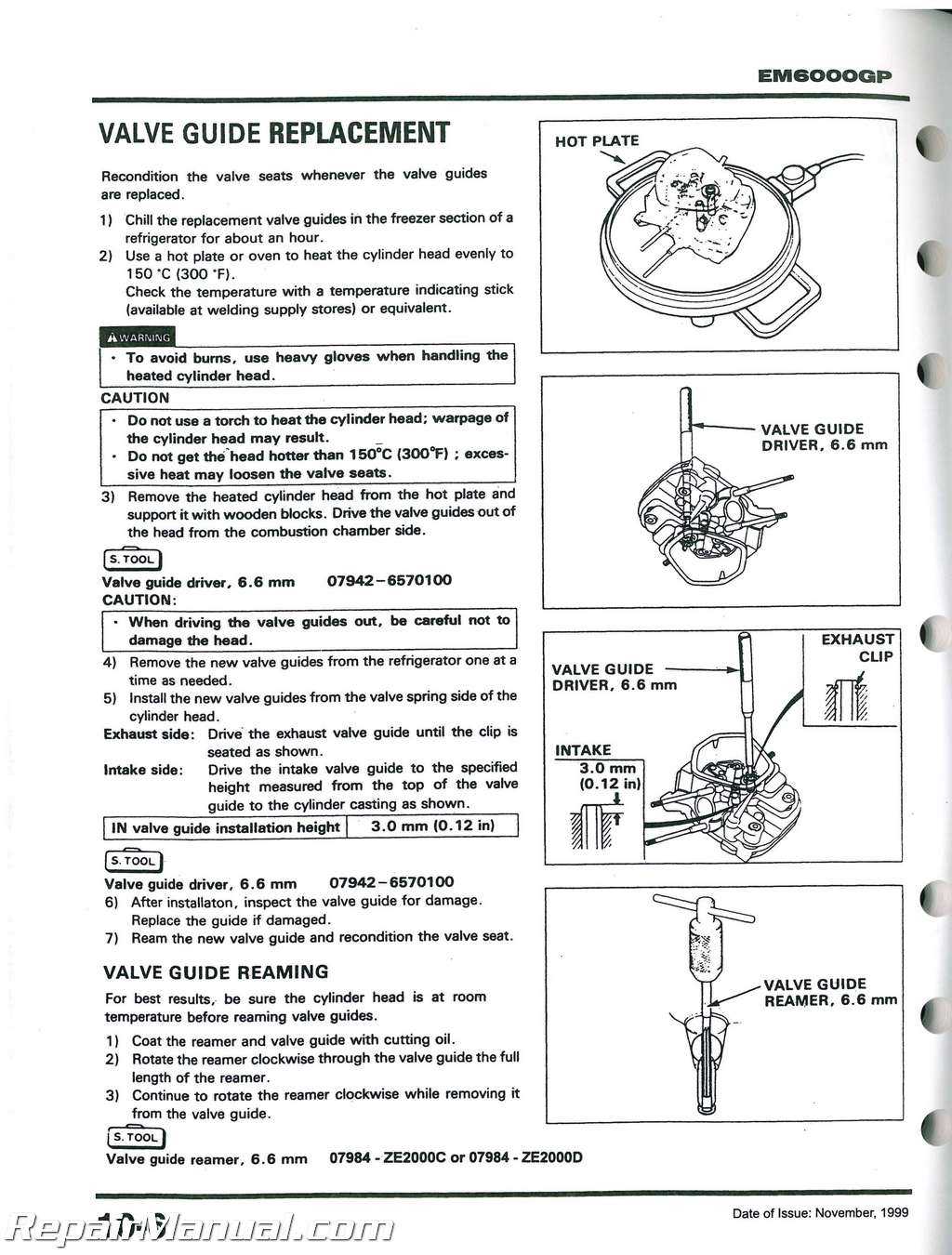

Replacing Worn Components

Maintaining the efficiency and longevity of portable power units requires attention to deteriorating parts. Over time, components may wear out due to regular usage, leading to decreased performance and potential failures. Addressing these issues promptly ensures reliable operation and can prevent more extensive damage.

Identifying Commonly Affected Parts

Regular inspection is crucial for recognizing which elements may need replacement. Commonly affected parts include seals, filters, and ignition systems. Monitoring for signs of wear, such as unusual noises or decreased output, can help pinpoint components that require attention.

Steps for Component Replacement

When replacing worn elements, start by gathering the necessary tools and replacement parts. Follow these steps:

- Disconnect the power source: Always ensure safety by unplugging the unit.

- Remove the damaged part: Carefully detach the worn component, taking note of how it fits.

- Install the new part: Align and secure the replacement component as per the manufacturer’s guidelines.

Taking these precautions can enhance the reliability of your unit, allowing for seamless operation in the future.

Safety Precautions During Repairs

When engaging in maintenance tasks on any mechanical device, it is crucial to prioritize safety to prevent accidents and injuries. Proper precautions ensure a secure working environment and contribute to effective troubleshooting and service.

First and foremost, always disconnect the power source before starting any work. This simple action significantly reduces the risk of electric shock and equipment damage. Additionally, make sure to use personal protective equipment, such as gloves and goggles, to shield against potential hazards.

Another vital step is to work in a well-ventilated area. Emissions from fuel or lubricants can be harmful, so ensuring adequate airflow helps mitigate health risks. Furthermore, keep your workspace organized and free of clutter to avoid tripping hazards and facilitate easier access to tools and parts.

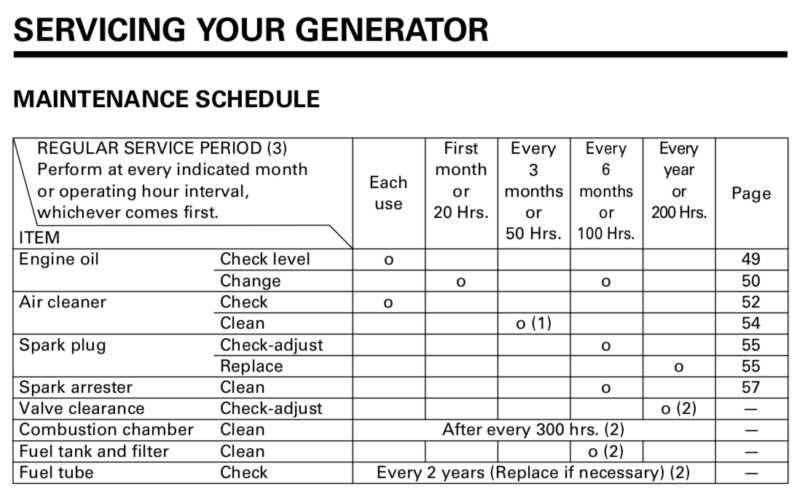

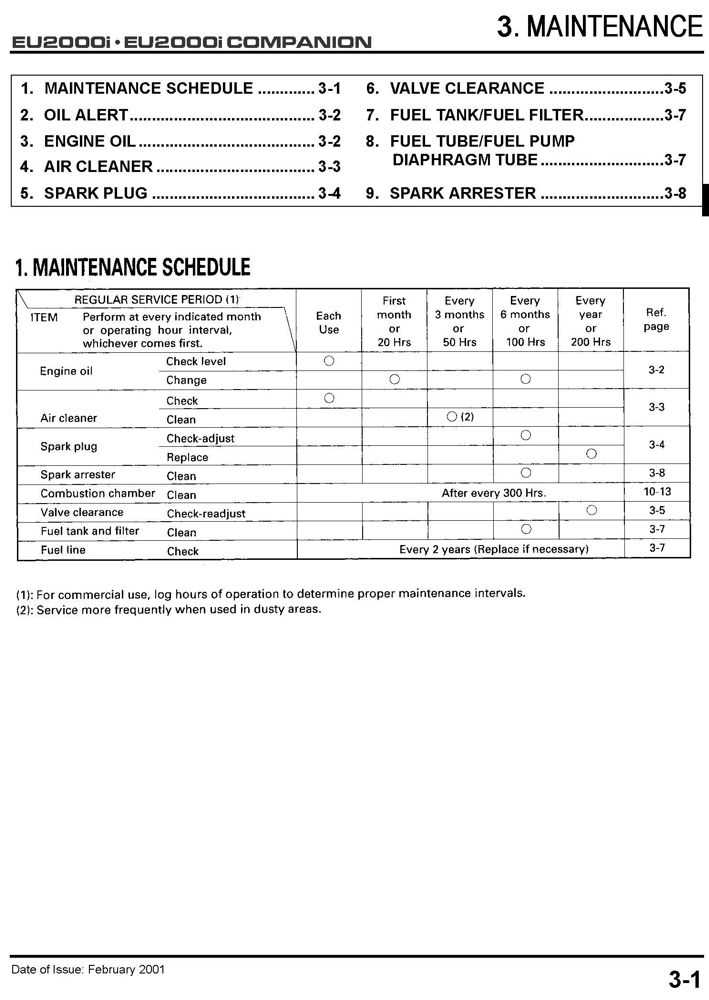

Service Interval Recommendations

Regular maintenance is essential for ensuring optimal performance and longevity of portable power units. Following a structured schedule for servicing can help prevent potential issues and keep the equipment running smoothly.

The following intervals are suggested for various maintenance tasks:

- Oil Change: Every 50 hours of operation or at least once a year.

- Air Filter Inspection: Check every 25 hours and clean or replace as necessary.

- Spark Plug Replacement: Replace every 100 hours or annually.

- Fuel System Maintenance: Inspect fuel lines and connections every 50 hours; replace fuel filter every 100 hours.

Additionally, a thorough inspection of the unit before extended use is recommended. This includes checking for any signs of wear or damage and ensuring all connections are secure. Keeping a maintenance log can be helpful in tracking service intervals and addressing issues promptly.

Resources for Further Assistance

When facing challenges with your portable power device, various resources can provide valuable support and guidance. These references include online forums, instructional videos, and professional services, all aimed at helping users troubleshoot and maintain their equipment effectively.

Online Communities and Forums

Engaging with fellow users can be beneficial. Online platforms often host discussions where individuals share their experiences and solutions to common issues. Joining these communities can provide insights and practical advice from those who have faced similar problems.

Professional Support Services

If you require expert assistance, consider reaching out to certified service centers. These professionals possess the knowledge and tools necessary to diagnose and resolve complex issues. They can offer personalized support tailored to your specific needs.

| Resource Type | Examples |

|---|---|

| Online Forums | Reddit, Generator Forums |

| Video Tutorials | YouTube, Vimeo |

| Professional Services | Authorized Service Centers |