Comprehensive Guide to Repairing the 2000 Yamaha Grizzly 600

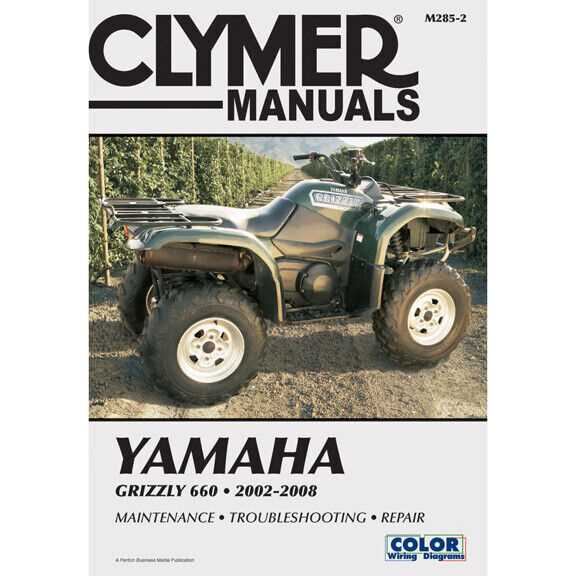

For enthusiasts of all-terrain vehicles, understanding the intricacies of upkeep is essential for ensuring optimal performance and longevity. This section delves into essential resources that provide step-by-step guidance for troubleshooting and servicing your vehicle, allowing you to tackle any issues that may arise. Whether you’re a novice or a seasoned rider, having access to detailed instructions can significantly enhance your maintenance skills.

Every machine requires regular attention to function at its best, and a thorough understanding of its components is key. This guide offers valuable insights into common challenges faced by owners, along with effective solutions. By familiarizing yourself with the vehicle’s systems, you can proactively address potential problems before they escalate, ensuring a smooth ride every time.

Equipped with the right knowledge, you can navigate the complexities of your ATV’s upkeep with confidence. From basic troubleshooting to more intricate repairs, having a reliable resource at your disposal empowers you to make informed decisions. This section aims to equip you with the tools needed to maintain your vehicle effectively, enhancing both your riding experience and the life of your machine.

Understanding the 2000 Yamaha Grizzly 600

This section delves into the key aspects of an all-terrain vehicle that has gained a reputation for its reliability and performance. Designed for both recreational and utility purposes, this model offers a robust experience in various terrains, making it a popular choice among enthusiasts and professionals alike. Understanding its features and functionalities can enhance the overall riding experience.

Key Features and Specifications

Equipped with a powerful engine, this model provides impressive torque and acceleration, ideal for navigating challenging landscapes. The durable chassis and advanced suspension system contribute to superior handling and stability, ensuring a smooth ride even on rough paths. Additionally, the versatile cargo capabilities allow users to transport equipment or supplies with ease.

Maintenance and Care

Regular upkeep is essential to maintain optimal performance. Routine checks on the engine, brakes, and tires can prevent potential issues and prolong the vehicle’s lifespan. Understanding the recommended service intervals and following best practices for care will ensure reliable operation and enhance safety during use. Being proactive in maintenance can significantly reduce the risk of unexpected breakdowns.

Common Issues with the Grizzly 600

All-terrain vehicles can encounter a variety of challenges over time, affecting their performance and reliability. Understanding these common problems can help owners maintain their machines effectively and enhance their riding experience.

Mechanical and Performance Problems

- Engine Difficulties: Issues such as hard starting or stalling can arise from various factors, including fuel delivery problems or ignition system failures.

- Transmission Troubles: Difficulty shifting gears or unusual noises during operation often indicate underlying transmission concerns.

- Suspension Wear: Over time, components may wear out, leading to decreased handling capabilities and ride comfort.

Electrical Issues

- Battery Failures: A weak or dead battery can cause starting issues, necessitating regular checks and maintenance.

- Lighting Problems: Flickering or non-functional lights may stem from faulty wiring or blown fuses.

- Sensors Malfunction: Sensors can fail or become inaccurate, affecting the overall performance of the vehicle.

Being aware of these potential issues allows owners to take proactive steps in their vehicle maintenance, ensuring a smoother and more enjoyable ride.

Essential Tools for Repairs

When undertaking maintenance tasks, having the right instruments at your disposal is crucial for efficiency and effectiveness. The proper tools not only streamline the process but also ensure that tasks are completed safely and accurately. Below, we explore the fundamental implements that every enthusiast should consider when performing maintenance work.

Basic Hand Tools

Every toolkit should start with essential hand tools. Items such as wrenches, screwdrivers, and pliers are fundamental for loosening, tightening, and gripping various components. A comprehensive set will provide versatility for a range of tasks, allowing for both minor adjustments and more extensive modifications. Investing in quality tools can make a significant difference in your overall experience.

Power Tools and Equipment

In addition to hand tools, incorporating power tools into your maintenance routine can save time and effort. Drills, impact wrenches, and grinders are examples of equipment that can enhance your capabilities, especially for more demanding tasks. These tools not only expedite the work process but also enable you to tackle projects that might otherwise require professional assistance.

Step-by-Step Maintenance Guide

Proper upkeep of your all-terrain vehicle is essential for ensuring its longevity and optimal performance. This guide will walk you through the necessary steps to maintain your vehicle effectively, helping you to identify potential issues before they become serious problems.

Essential Maintenance Tasks

Regular maintenance tasks should be performed periodically to keep your vehicle in top condition. Below is a table outlining these tasks, their frequency, and the tools required.

| Task | Frequency | Tools Needed |

|---|---|---|

| Oil Change | Every 50 hours of use | Wrench set, oil filter, oil |

| Air Filter Inspection | Every 25 hours of use | Screwdriver |

| Tire Pressure Check | Monthly | Tire pressure gauge |

| Battery Check | Every 3 months | Multimeter, wrench |

Tips for Effective Maintenance

Following these guidelines can enhance the reliability of your vehicle. Always refer to your owner’s documentation for specific instructions tailored to your model. Additionally, keeping a maintenance log can help track completed tasks and anticipate future needs.

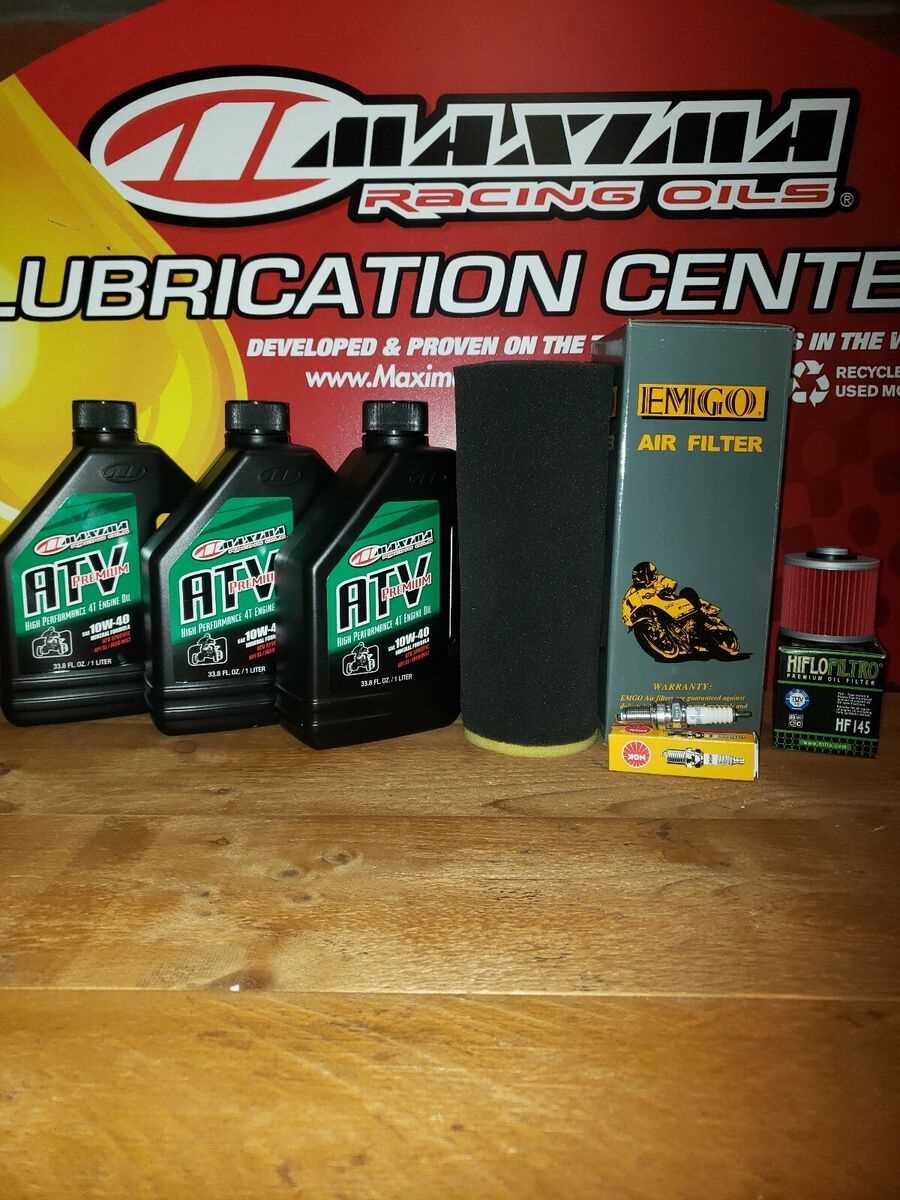

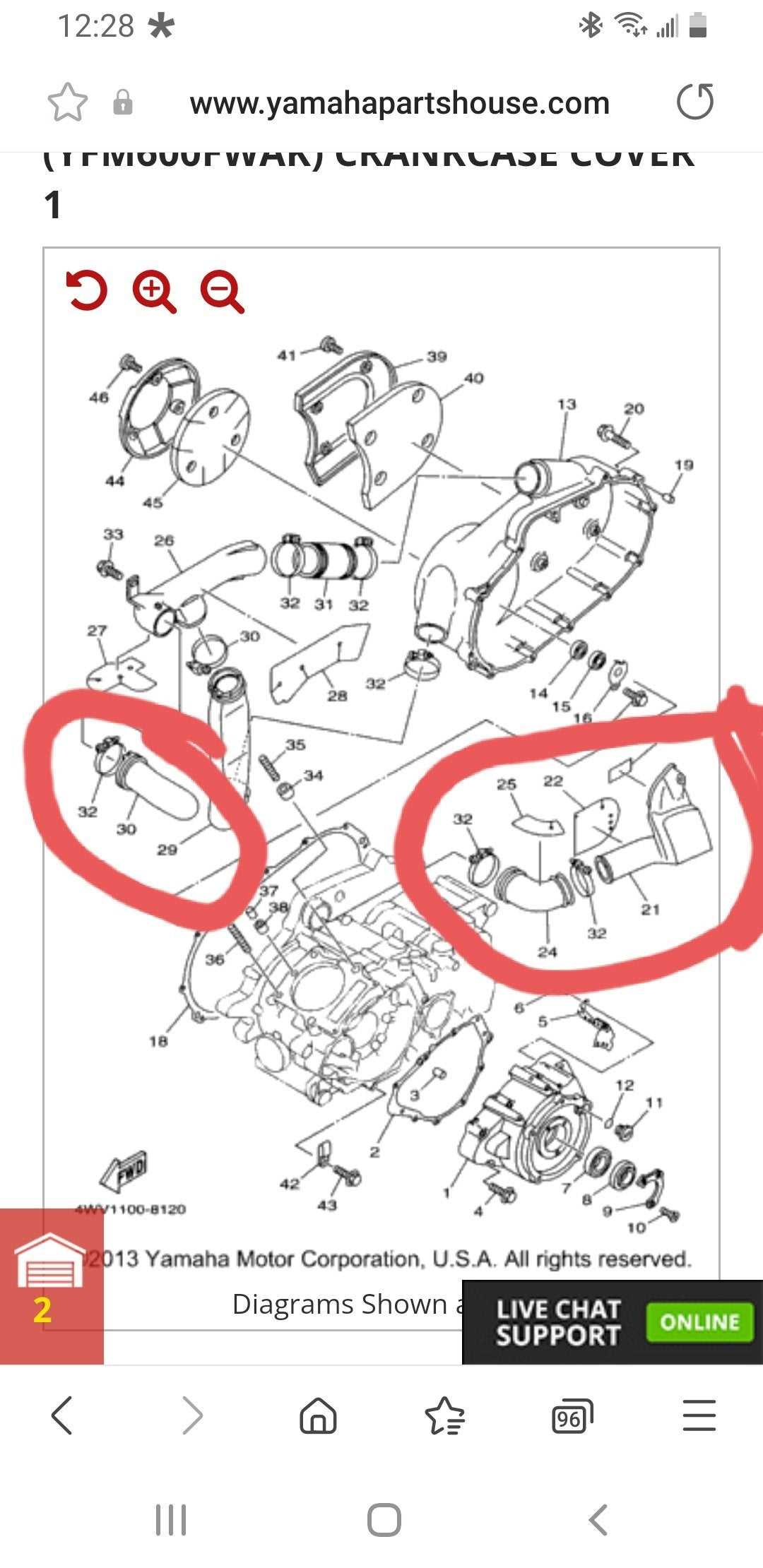

How to Replace Engine Oil

Changing the lubricant in your vehicle’s engine is a crucial maintenance task that ensures optimal performance and longevity. Regular oil changes help to remove contaminants and prevent wear, contributing to a smoother operation. This guide outlines the essential steps to perform this task effectively.

Gather Necessary Tools and Materials: Before starting, collect all required items such as a new oil filter, high-quality engine lubricant, an oil catch pan, a wrench, and a funnel. Having everything at hand will streamline the process.

Prepare the Vehicle: Park your vehicle on a level surface and allow the engine to cool down. Engage the parking brake to ensure stability during the procedure. Place the oil catch pan beneath the oil pan to capture the old lubricant.

Drain the Old Oil: Locate the drain plug on the oil pan and remove it using a wrench. Allow the old oil to fully drain into the catch pan. This process may take several minutes. Once drained, replace the drain plug and ensure it is securely tightened.

Replace the Oil Filter: Locate the oil filter, which is typically found near the engine block. Use an oil filter wrench to remove the old filter, ensuring any residual oil drains into the catch pan. Before installing the new filter, apply a small amount of fresh lubricant to the rubber gasket of the new filter to ensure a proper seal.

Add New Oil: With the new filter in place, use a funnel to pour the new engine lubricant into the designated opening. Refer to your owner’s manual for the correct type and quantity of oil required. After adding the oil, check the dipstick to ensure the level is within the recommended range.

Finalize the Process: Start the engine and let it run for a few minutes. This will allow the new lubricant to circulate and fill the new oil filter. Check for any leaks around the drain plug and oil filter. If everything appears secure, dispose of the old oil and filter properly, following local regulations.

By following these steps, you can efficiently replace the engine lubricant, ensuring your vehicle operates smoothly and efficiently.

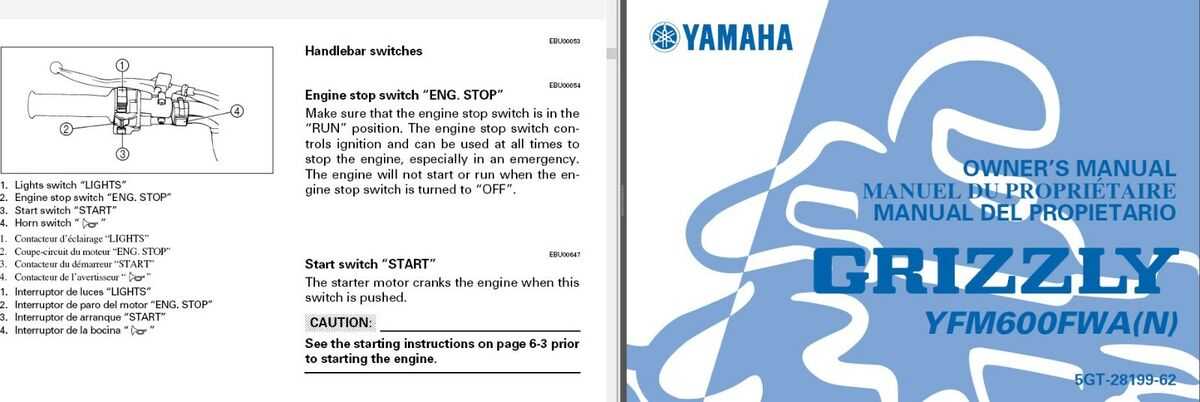

Inspecting the Electrical System

Regular assessment of the electrical components is crucial for ensuring optimal performance and reliability of your vehicle. A well-functioning electrical system not only powers essential functions but also enhances safety during operation. This section provides guidance on how to effectively evaluate the various elements of the electrical setup.

Begin with the Battery: Check the battery for any signs of corrosion, loose connections, or leaks. Ensure that the terminals are clean and securely attached. A weak or damaged battery can lead to starting issues and unreliable electrical performance.

Examine the Wiring: Inspect all wiring for frays, cracks, or other damage. Look for signs of wear, especially in areas where the wires may rub against other components. Proper insulation is key to preventing short circuits and maintaining system integrity.

Test the Fuses: Fuses act as safety devices within the electrical system. If certain functions are not working, check the fuses to see if any have blown. Replacing a faulty fuse is a simple task that can restore functionality quickly.

Evaluate the Switches and Connectors: Ensure that all switches are operational and that connectors are free of dirt and corrosion. Properly functioning switches and connectors are vital for the effective operation of electrical components.

Assess the Lighting: Verify that all lights, including headlights, taillights, and indicators, are functioning correctly. Dim or non-working lights can pose safety risks, so timely replacement of bulbs is essential.

By following these steps, you can maintain a reliable electrical system, contributing to the overall performance and safety of your vehicle. Regular inspections can help identify potential issues before they become significant problems.

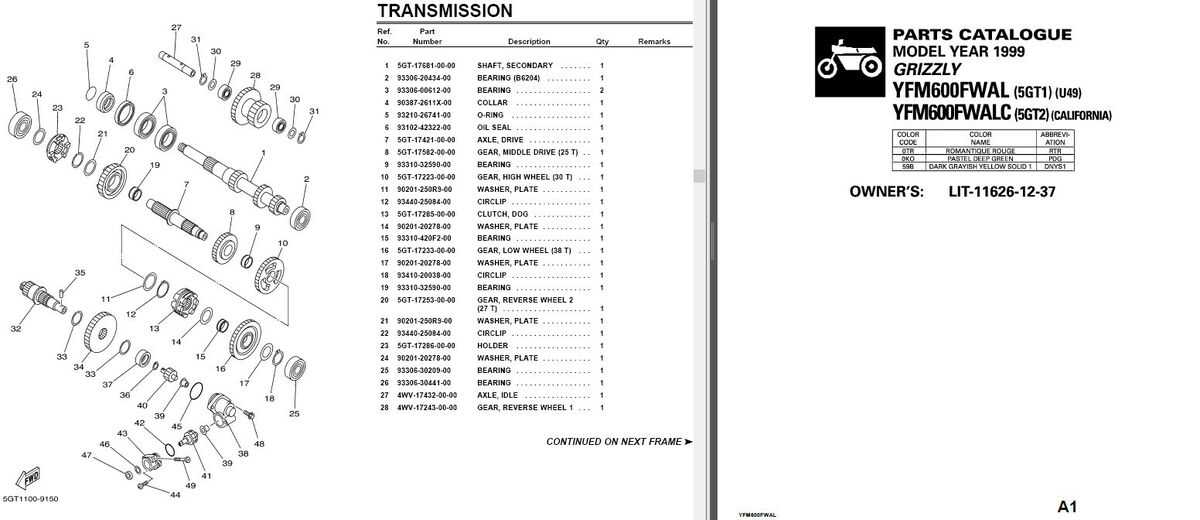

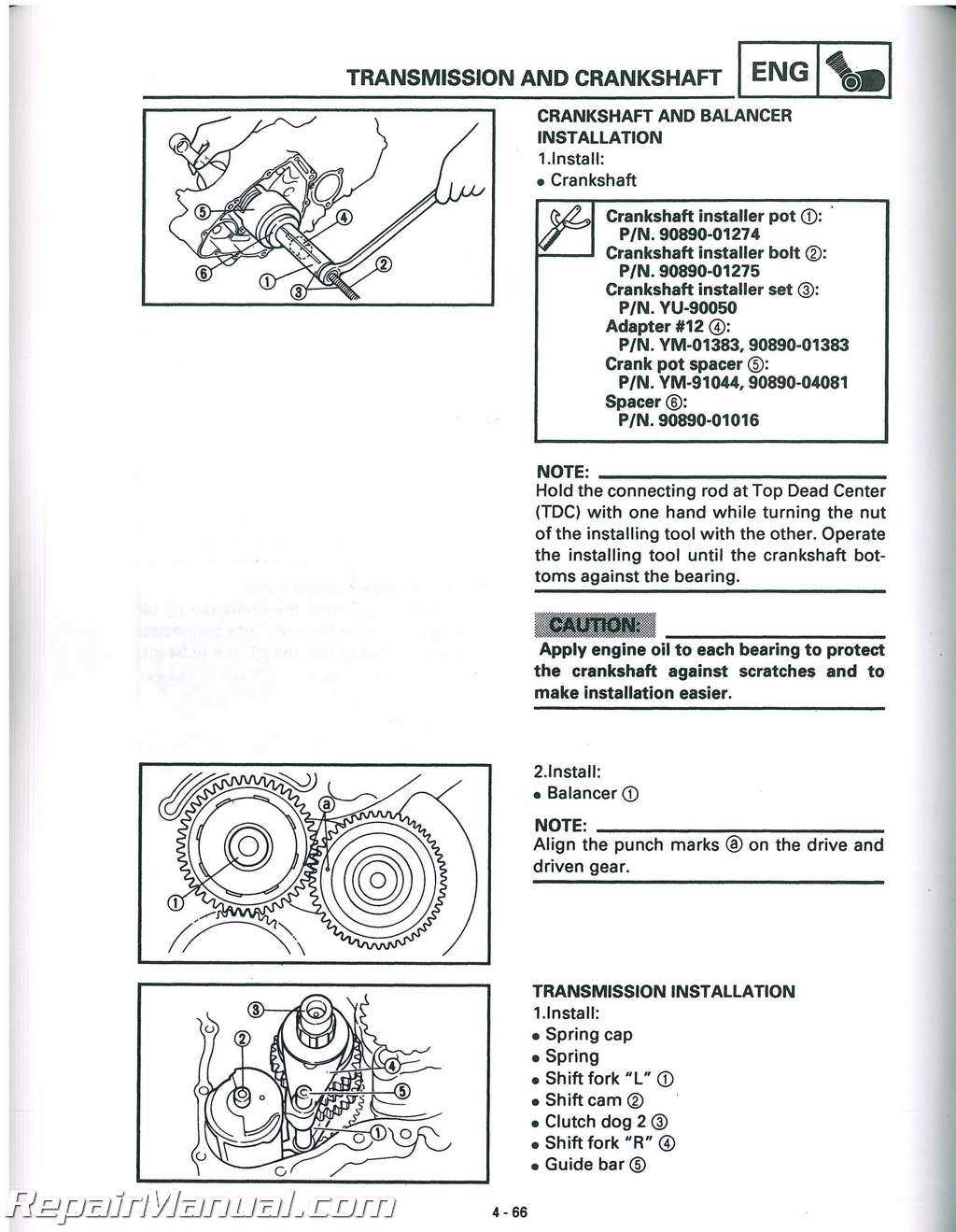

Handling Transmission Problems

Transmission issues can significantly impact the performance and reliability of your vehicle. Recognizing the signs early can save time and resources. This section aims to provide insights into diagnosing and addressing common transmission challenges that enthusiasts may encounter.

First, it is essential to understand the symptoms that indicate a transmission malfunction. These can range from unusual noises to slipping gears. By observing these warning signs, one can take proactive measures to prevent further damage.

| Symptom | Possible Cause | Recommended Action |

|---|---|---|

| Slipping Gears | Low fluid level or worn components | Check fluid levels and replace worn parts |

| Unusual Noises | Faulty bearings or damaged gears | Inspect components and perform necessary repairs |

| Delayed Engagement | Clogged filter or low fluid | Change fluid and replace the filter |

| Fluid Leaks | Damaged seals or gaskets | Locate and fix leaks, replacing seals as needed |

After identifying the issue, the next step involves performing maintenance tasks or seeking professional assistance. Regular checks and timely interventions can ensure a smooth-running transmission system and enhance the longevity of the vehicle.

Braking System Troubleshooting Tips

The braking system is crucial for the safe operation of any vehicle. When issues arise, it’s essential to identify and address them promptly to ensure optimal performance and safety. Below are some valuable tips for diagnosing and resolving common braking problems.

Common Issues and Symptoms

- Spongy Pedal: This may indicate air in the brake lines or low fluid levels.

- Squeaking or Grinding Noise: Worn brake pads or damaged rotors could be the culprits.

- Pulling to One Side: Uneven brake wear or misalignment can cause this issue.

- Vibrations When Braking: Warped rotors may lead to a pulsating sensation.

Troubleshooting Steps

- Check fluid levels and inspect for leaks.

- Examine brake pads for wear and replace if necessary.

- Inspect rotors for damage or warping and resurface or replace as needed.

- Bleed the brake lines to remove any air.

- Verify alignment and adjust if the vehicle pulls to one side.

By following these troubleshooting tips, you can effectively diagnose and remedy issues within the braking system, ensuring safe and reliable operation.

Suspension Adjustments and Repairs

Proper maintenance of the suspension system is crucial for ensuring optimal performance and comfort in off-road vehicles. This section focuses on the necessary adjustments and potential fixes that can enhance handling and stability, contributing to a smoother ride.

Begin by checking the preload settings, which affect the initial compression of the springs. Adjusting these settings allows for fine-tuning based on the weight of the rider and any additional cargo. It’s important to consult the specifications to achieve the ideal balance.

Next, inspect the shock absorbers for signs of wear or leakage. Replacing damaged components is essential to maintain effective damping, which absorbs shocks from rough terrain. Regularly clean the seals and lubricate moving parts to extend their lifespan.

Additionally, alignment of the suspension components should be routinely evaluated. Misalignment can lead to uneven tire wear and compromised handling. Use a level or professional alignment tool to ensure everything is positioned correctly.

Finally, pay attention to the bushings and bearings within the suspension system. Over time, these can degrade, resulting in excessive play and noise. Replacing worn parts will not only enhance performance but also improve overall safety during rides.

Cleaning the Air Filter Properly

Maintaining a clean air filter is essential for optimal engine performance. Regular cleaning not only enhances airflow but also prevents dirt and debris from entering the engine, which can lead to increased wear and reduced efficiency. Following proper procedures ensures longevity and reliable operation.

Tools and Materials Needed

- Cleaning solution or soap

- Water

- Soft brush

- Dry cloth or towel

- Protective gloves

Step-by-Step Cleaning Process

- Remove the air filter from its housing, taking care not to damage any components.

- Use a soft brush to gently remove loose dirt and debris from the filter surface.

- Prepare a cleaning solution by mixing water with a mild detergent.

- Submerge the filter in the solution and let it soak for a few minutes.

- Gently scrub the filter with a soft brush to dislodge any remaining particles.

- Rinse the filter thoroughly with clean water to remove all soap residue.

- Allow the filter to air dry completely before reinstallation.

By following these steps, you can ensure that your air intake system remains efficient, providing the necessary airflow for your engine to perform at its best.

Upgrading Parts for Enhanced Performance

Improving the capabilities of your all-terrain vehicle can lead to a more thrilling experience and better functionality. By focusing on specific components, enthusiasts can unlock greater power, efficiency, and handling. This section will explore key upgrades that can significantly enhance overall performance.

Engine Enhancements: Upgrading the engine components, such as the intake and exhaust systems, can increase airflow and boost horsepower. Consider adding a high-performance air filter and a free-flowing exhaust to maximize efficiency.

Suspension Upgrades: Enhancing the suspension system is crucial for better handling and ride quality. Installing high-quality shocks can provide improved stability and comfort over rough terrain.

Transmission Modifications: Tweaking the transmission settings can improve acceleration and responsiveness. Look into performance clutches or gearing changes to achieve desired results.

Tire Selection: Choosing the right tires is vital for traction and control. Opt for specialized tires that suit your riding style and the terrain you encounter most often.

Brake Improvements: Upgrading the braking system ensures safety while maximizing stopping power. Consider performance brake pads and larger rotors for better heat dissipation.

By strategically upgrading these parts, you can achieve the ultimate enhancement in performance, making your riding experience more enjoyable and effective.

Finding Replacement Parts Online

Locating suitable components for your vehicle can be a daunting task. Fortunately, the internet provides a wealth of resources that simplify this process. With just a few clicks, you can discover a variety of options, from OEM pieces to aftermarket alternatives.

| Type of Parts | Where to Find | Considerations |

|---|---|---|

| OEM Parts | Manufacturer Websites, Authorized Dealers | Guaranteed compatibility, often higher cost |

| Aftermarket Parts | Online Retailers, Auction Sites | Varied quality, often more affordable |

| Used Parts | Salvage Yards, Online Marketplaces | Cost-effective, condition varies |

Exploring these avenues will enhance your chances of finding the ultimate components you need, ensuring your vehicle remains in optimal condition.

Safety Tips During Repairs

Engaging in maintenance activities can be rewarding, but it is essential to prioritize safety to avoid accidents and injuries. Adhering to basic precautions can create a secure environment and ensure smooth operations.

Preparation Before Starting

- Wear appropriate personal protective equipment (PPE) such as gloves, goggles, and sturdy footwear.

- Ensure that your workspace is clean and organized to prevent hazards.

- Have all necessary tools and materials ready before you begin to minimize distractions.

While Working

- Always disconnect the power source or remove the battery before performing any task.

- Keep your workspace well-ventilated, especially when working with chemicals or flammable materials.

- Follow the manufacturer’s guidelines closely to avoid potential risks associated with incorrect handling.

- Be mindful of sharp edges and hot surfaces; use protective gear as needed.

By following these guidelines, you can ensure a safer and more efficient experience while working on maintenance tasks.