Comprehensive Guide to 2000 Grand Prix Repairs

Maintaining a vehicle is essential for ensuring its longevity and optimal performance. Understanding the intricacies of various systems can greatly enhance the driving experience and prevent potential issues. This section aims to provide valuable insights into the essential practices that every car owner should be familiar with.

Expert guidance on troubleshooting and routine upkeep can make a significant difference in how a vehicle operates over time. Familiarizing oneself with various components and their functions can empower owners to take charge of their automotive care. In this guide, readers will discover practical advice and tips to address common challenges and keep their vehicles in top condition.

Whether you are a seasoned enthusiast or a newcomer to automotive maintenance, having access to clear instructions and best practices is invaluable. This resource aims to equip you with the knowledge necessary to handle maintenance tasks confidently and effectively.

Understanding the 2000 Grand Prix

This section explores the essential aspects of a notable automobile model, emphasizing its features and design elements that appeal to enthusiasts and everyday drivers alike. The vehicle stands out for its blend of style, performance, and comfort, making it a popular choice in its category.

Key Features

- Elegant exterior design that captures attention

- Spacious interior with advanced comfort options

- Variety of engine choices to suit different driving preferences

- Innovative technology for improved driving experience

Driving Experience

The vehicle offers a smooth ride, characterized by responsive handling and solid performance on various terrains. Its suspension system contributes to stability and comfort, ensuring a pleasant journey for both driver and passengers.

Common Issues with the 2000 Model

Owners of this specific vehicle have encountered a range of recurring challenges that can impact performance and reliability. Understanding these prevalent concerns can aid in preventative measures and effective troubleshooting.

One notable problem involves the electrical system, where components may exhibit failure, leading to issues such as dimming lights or malfunctioning accessories. Additionally, the transmission can be a source of frustration, with some drivers reporting slipping gears or delayed shifting. These occurrences may stem from inadequate maintenance or inherent design flaws.

Another area of concern is the suspension system, which can exhibit premature wear, resulting in a rougher ride and compromised handling. Regular inspections can help identify signs of wear before they escalate into significant issues. Lastly, the engine may present challenges, particularly with oil leaks or overheating, which necessitate prompt attention to maintain optimal functionality.

Essential Tools for Repairing

When embarking on maintenance tasks for your vehicle, having the right equipment is crucial for achieving optimal results. A well-equipped workspace not only enhances efficiency but also ensures safety while working on various components. Below are some fundamental instruments that every automotive enthusiast should consider having on hand.

Basic Hand Tools

Having a collection of essential hand tools is the foundation of any automotive maintenance project. These tools allow for precise work on fasteners and components, making tasks easier and more efficient.

| Tool | Purpose |

|---|---|

| Wrenches | Used for loosening or tightening nuts and bolts. |

| Screwdrivers | Essential for driving screws into various materials. |

| Pliers | Helpful for gripping, bending, and cutting wires. |

| Socket Set | Provides various sizes for quick access to different fasteners. |

Specialized Equipment

In addition to hand tools, certain specialized equipment can greatly facilitate more intricate tasks. These tools are designed to tackle specific challenges that may arise during the upkeep process.

| Tool | Purpose |

|---|---|

| Torque Wrench | Ensures that bolts are tightened to the correct specifications. |

| Multimeter | Used for diagnosing electrical issues and measuring voltage. |

| Oil Filter Wrench | Facilitates the removal of stubborn oil filters. |

| Jack and Stands | Elevates the vehicle for safe access underneath. |

Step-by-Step Repair Procedures

This section provides a comprehensive approach to addressing various issues that may arise in the vehicle. By following these detailed steps, you can effectively troubleshoot and resolve common problems, ensuring optimal performance and longevity.

| Step | Description |

|---|---|

| 1 | Begin by assessing the symptoms to identify the specific area that requires attention. |

| 2 | Gather the necessary tools and materials needed for the task at hand. |

| 3 | Carefully follow the outlined procedures, ensuring all safety precautions are observed. |

| 4 | Replace or repair the faulty components as required, using appropriate methods. |

| 5 | Conduct a thorough inspection to confirm that all adjustments have been made correctly. |

| 6 | Test the system to verify that the issue has been resolved and functionality is restored. |

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended lifespan of your vehicle. By following a few key practices, you can enhance performance and prevent premature wear. Regular attention to various components will not only keep the vehicle running smoothly but also help avoid costly repairs down the line.

Consider the following guidelines to maintain optimal condition:

| Tip | Description |

|---|---|

| Regular Oil Changes | Changing the oil at recommended intervals helps maintain engine health and efficiency. |

| Check Tire Pressure | Maintaining correct tire pressure enhances fuel efficiency and prolongs tire life. |

| Inspect Fluid Levels | Regularly check and top off fluids such as coolant, brake fluid, and transmission fluid to ensure safe operation. |

| Brake Maintenance | Inspecting and replacing brake pads and rotors as needed is crucial for safety and performance. |

| Battery Care | Keeping the battery clean and ensuring connections are tight can prevent starting issues. |

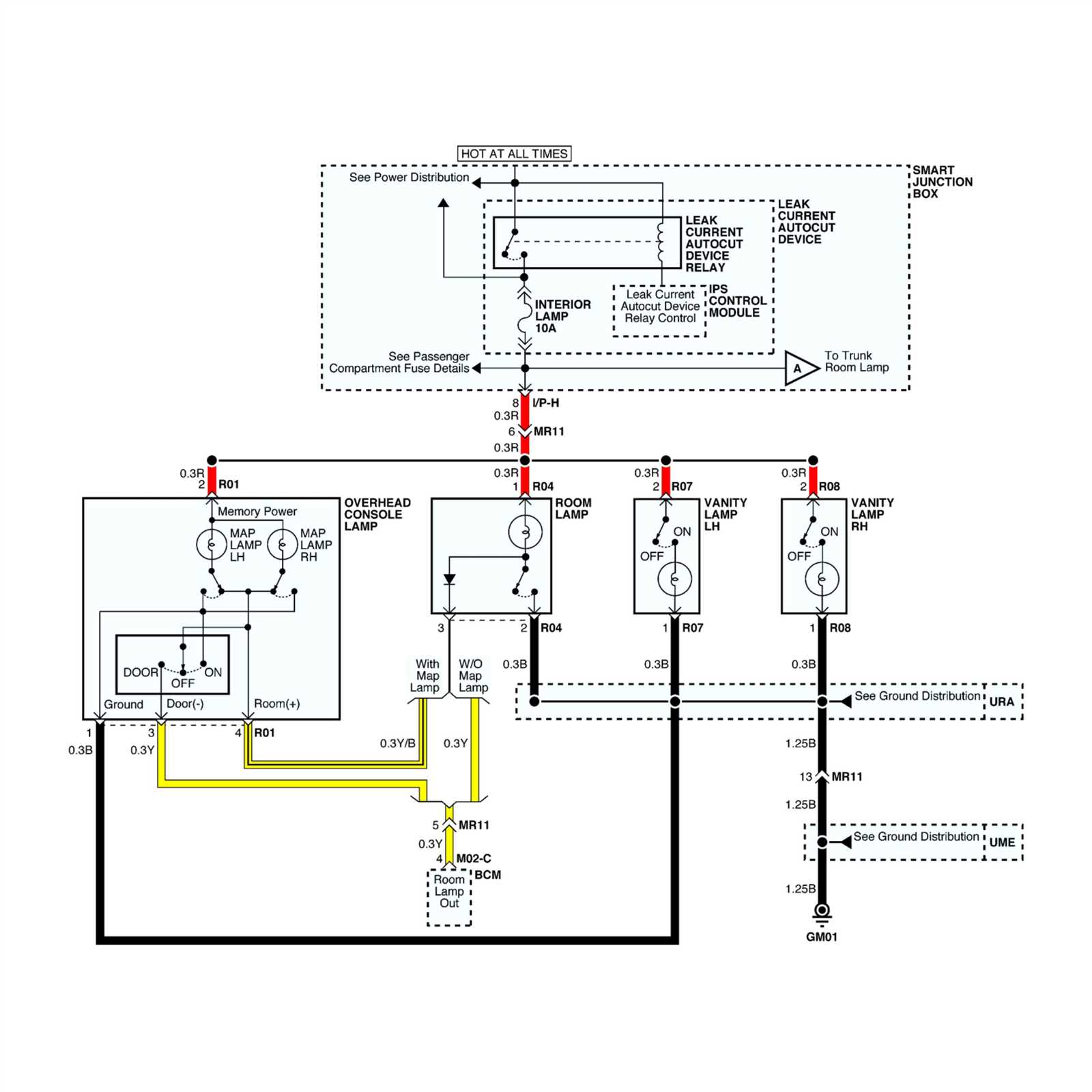

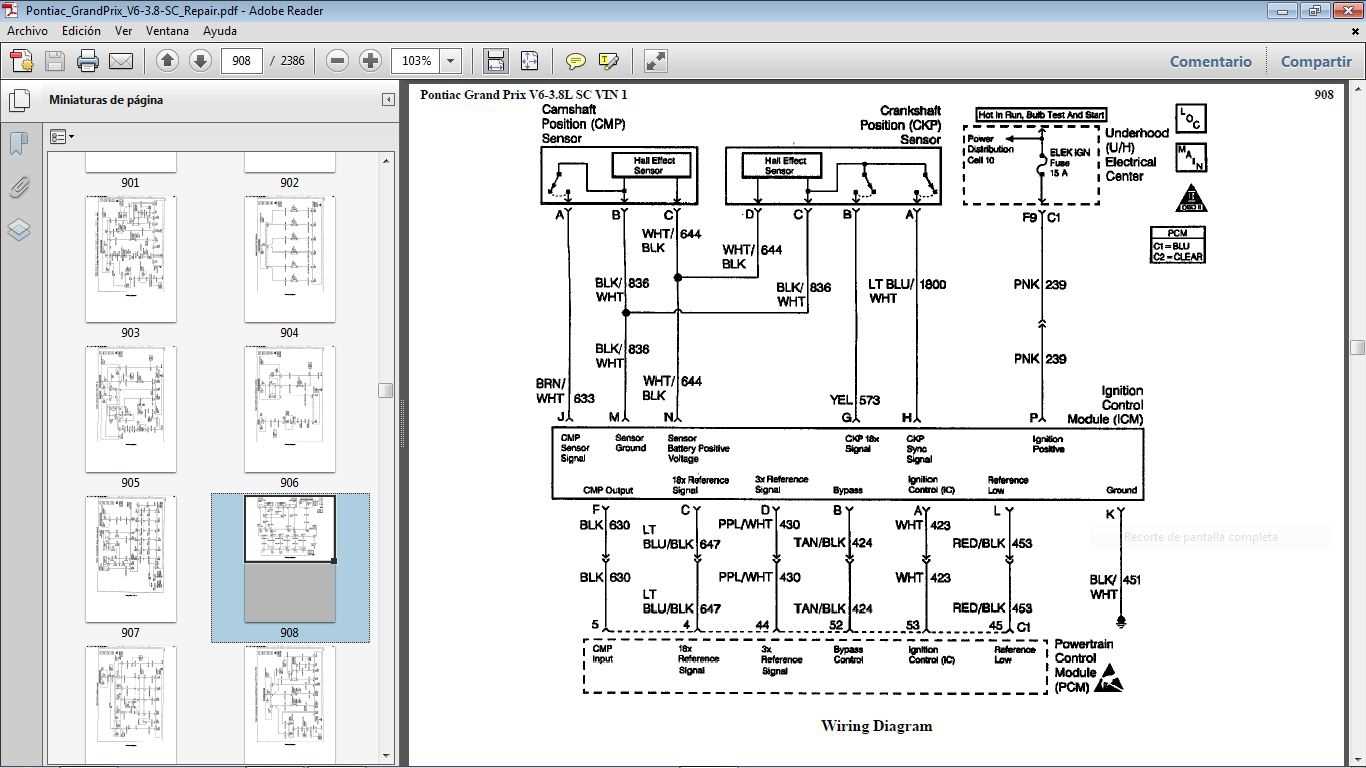

Electrical System Troubleshooting Guide

This section offers a comprehensive approach to diagnosing issues within the electrical framework of your vehicle. Understanding the common signs of electrical malfunctions can significantly aid in identifying the root causes, ensuring a smoother restoration process.

To effectively troubleshoot, consider the following steps:

- Begin by inspecting the battery and its connections for corrosion or looseness.

- Check the fuses for any blown components and replace them if necessary.

- Examine the wiring harness for any visible damage or wear.

- Test the functionality of switches and relays, ensuring they operate correctly.

Utilizing a multimeter can provide valuable insights. Here are some recommended tests:

- Measure the voltage across the battery terminals; it should be around 12.6 volts when fully charged.

- Check for voltage drop across connections to identify potential issues.

- Test circuit continuity to ensure signals are transmitted correctly.

By following these guidelines, you can systematically address electrical problems, enhancing the overall performance and reliability of your vehicle’s systems.

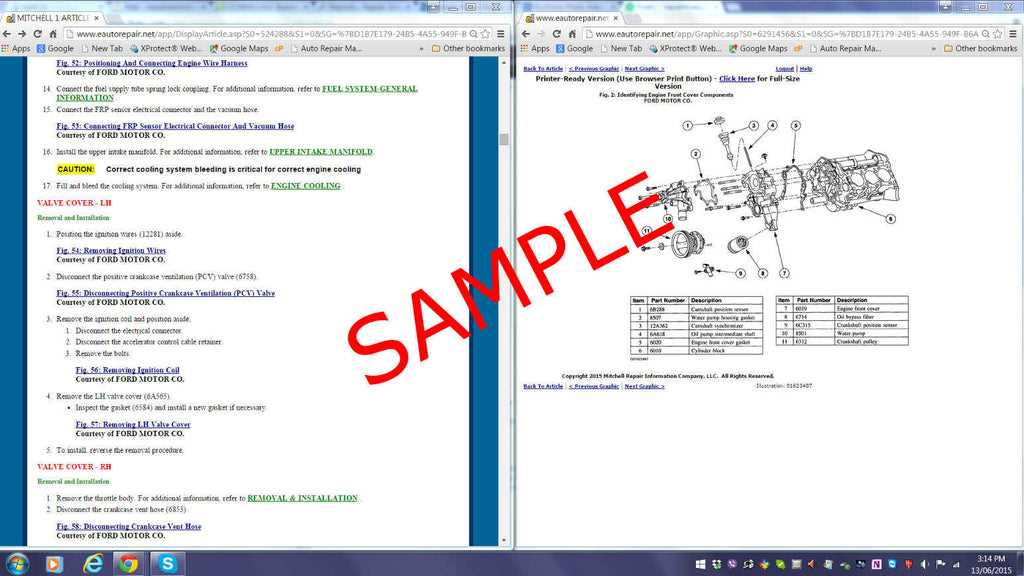

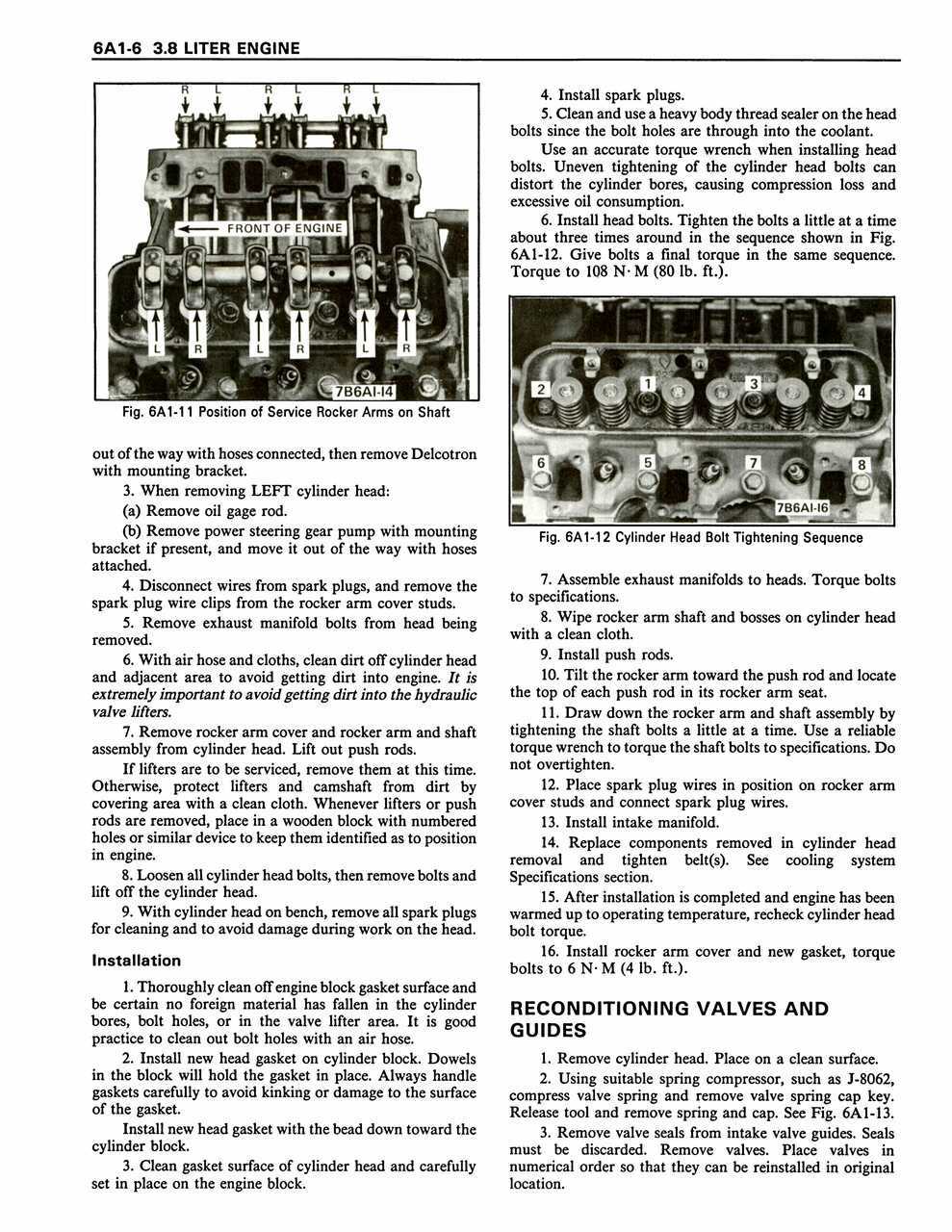

Engine Overhaul Techniques Explained

Understanding the intricate processes involved in rejuvenating an automotive power unit is essential for enthusiasts and professionals alike. This section delves into the fundamental methods employed to enhance performance, extend longevity, and ensure reliability in engine function.

Disassembly is often the first critical step in this journey, where careful removal of components is executed to prevent damage. Each part must be cataloged meticulously to facilitate a smooth reassembly later. Following this, cleaning becomes paramount; removing deposits and contaminants ensures that the engine operates efficiently.

Next, inspection plays a vital role. Each component is examined for wear and tear, allowing for informed decisions on what needs replacement or refurbishment. After identifying problematic areas, machining techniques can be applied to restore parts to their original specifications, thereby optimizing performance.

Finally, reassembly and proper torque specifications ensure that the engine operates seamlessly. This meticulous approach not only enhances power delivery but also promotes overall operational harmony, culminating in a rejuvenated power unit ready to tackle the road ahead.

Transmission Repair Insights

Understanding the intricacies of transmission systems is essential for effective maintenance and troubleshooting. This section delves into crucial aspects of these mechanisms, highlighting common issues and solutions.

Key considerations for optimal functionality include:

- Regular fluid checks to ensure proper lubrication.

- Identifying signs of wear or damage in components.

- Utilizing diagnostic tools for accurate assessments.

Common problems encountered may involve:

- Slipping gears that can indicate low fluid levels.

- Unusual noises that may signal internal damage.

- Delayed engagement when shifting from park to drive.

To effectively address these concerns, it is advisable to follow a structured approach:

- Inspect and replace worn-out parts as necessary.

- Flush and refill transmission fluid at recommended intervals.

- Seek professional assistance when complex issues arise.

By remaining vigilant and proactive, one can enhance the longevity and performance of these critical systems.

Brake System Inspection and Service

Ensuring the optimal performance of the braking mechanism is crucial for vehicle safety. Regular assessment and maintenance of this system not only enhance stopping power but also prolong the lifespan of related components. Thorough inspections help identify potential issues before they escalate, providing peace of mind for drivers.

Visual Inspection should be the initial step in evaluating the braking system. Check for signs of wear on the brake pads, rotors, and lines. Look for any leaks or damage that may compromise functionality. Maintaining clean and free surfaces is essential for effective operation.

Fluid Quality is another vital aspect of system upkeep. Ensure that the brake fluid is at the appropriate level and free from contaminants. Old or dirty fluid can lead to diminished performance and should be replaced periodically to maintain responsiveness.

Performance Testing is recommended to assess the overall effectiveness of the system. Conduct tests under various conditions to evaluate responsiveness and ensure that all components function harmoniously. Any irregularities should prompt immediate attention to prevent safety hazards.

Suspension and Steering Adjustments

The proper alignment and calibration of suspension and steering systems are essential for optimal vehicle handling and comfort. These components play a critical role in maintaining stability, enhancing maneuverability, and ensuring a smooth ride. Adjustments made to these systems can significantly impact performance, safety, and tire wear.

Key Considerations for Suspension

When addressing suspension adjustments, it is vital to evaluate factors such as ride height, camber, and toe settings. Ensuring these elements are correctly set can prevent uneven tire wear and improve overall vehicle dynamics.

Steering System Calibration

For the steering system, precise adjustments to the steering angle and alignment are crucial. These modifications help in maintaining accurate control and responsiveness, allowing for a safer driving experience.

| Adjustment Type | Recommended Setting | Notes |

|---|---|---|

| Camber | -0.5° to -1.0° | Check for even tire wear |

| Toe | 0.0° to +0.2° | Minimize drag and improve handling |

| Ride Height | Standard Manufacturer Specifications | Ensure clearance and stability |

| Steering Angle | 0.0° at center | Optimize turning response |

Cooling System Maintenance Advice

Maintaining the cooling system is essential for ensuring optimal performance and longevity of your vehicle. A well-functioning cooling system prevents overheating and promotes efficient engine operation. Regular attention to this system can help identify potential issues before they escalate, thereby saving time and costs associated with extensive repairs.

Routine Checks

- Inspect the coolant level regularly and top it up as needed.

- Check for leaks around hoses, radiators, and fittings.

- Examine the condition of hoses for signs of wear or cracking.

Fluid Maintenance

- Flush the cooling system periodically to remove contaminants and sludge.

- Replace the coolant according to the manufacturer’s recommendations to ensure optimal performance.

- Consider using a coolant tester to check the effectiveness of your fluid.

Using Diagnostic Tools Effectively

Employing diagnostic instruments is essential for identifying issues within vehicles. Mastering these tools enhances problem-solving capabilities and ensures efficient maintenance practices. This section outlines strategies to optimize their use for accurate assessments.

Understanding Tool Types

Various diagnostic instruments serve distinct purposes. Familiarity with each type can significantly improve diagnostic efficiency:

- Code Readers: Useful for retrieving trouble codes from the vehicle’s computer.

- Multimeters: Essential for measuring voltage, current, and resistance.

- Oscilloscopes: Beneficial for analyzing waveforms and signals.

Best Practices for Usage

To achieve the best results, consider the following practices:

- Always refer to the manufacturer’s guidelines for each tool.

- Perform regular calibration to ensure accuracy.

- Document findings for future reference and analysis.

- Stay updated on software and tool advancements.