Tiger Shark Jet Ski Maintenance Guide

Understanding the intricacies of your aquatic vehicle is essential for ensuring optimal performance and longevity. This section will provide you with valuable insights and guidelines tailored to enhance your knowledge of maintenance practices, empowering you to tackle various issues effectively.

Regular upkeep not only prolongs the life of your vessel but also enhances safety during your outings. By familiarizing yourself with essential procedures and troubleshooting methods, you will be better equipped to address common challenges that may arise.

Proper care involves a combination of routine inspections and timely interventions. As you delve into the specifics outlined here, you will discover how to navigate common repairs and maintenance tasks with confidence. Embrace this opportunity to learn and master the art of caring for your watercraft.

Having the right equipment is crucial for maintaining and fixing watercraft effectively. Various tools help streamline the process, ensuring that every task can be completed efficiently and accurately.

| Tool | Purpose |

|---|---|

| Socket Set | Ideal for loosening and tightening bolts and nuts. |

| Screwdriver Set | Used for various screws found in the machinery. |

| Wrench | Essential for adjusting and securing fittings. |

| Pliers | Helpful for gripping and twisting components. |

| Multimeter | Used for electrical diagnostics and troubleshooting. |

| Grease Gun | Necessary for lubricating moving parts. |

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to ensuring optimal performance and longevity of your watercraft. Regular upkeep is essential for smooth operation and can prevent more significant issues down the line.

Routine Checkups

Start with periodic inspections of key components. Look for signs of wear or damage, particularly in the engine and propulsion system. Keeping these areas in good condition is crucial for reliable performance.

Fluid Maintenance

Ensure that all necessary fluids are at the correct levels. This includes checking the oil, coolant, and fuel systems. Regularly changing the oil and replacing filters will contribute to the overall health of the engine. Neglecting these tasks can lead to serious problems.

By following these guidelines, you can enhance the performance and reliability of your watercraft.

Electrical System Troubleshooting

The electrical system is crucial for optimal performance and safety in watercraft. When issues arise, it’s important to systematically identify and resolve problems to ensure reliability. This section will guide you through common troubleshooting techniques for electrical malfunctions, helping to restore functionality effectively.

Identifying Common Issues

Begin by examining the battery and connections, as these are often the source of power-related problems. Look for signs of corrosion or loose terminals, which can impede electrical flow. Additionally, verify the condition of fuses and wiring for any damage that may disrupt the system.

Testing Components

Utilize a multimeter to test voltage at various points in the system. Start with the battery and then move on to individual components such as switches and lights. Ensure that readings are within the specified ranges. If discrepancies are noted, it may indicate a failing part that requires replacement.

Engine Repair Techniques

Maintaining and enhancing the functionality of your watercraft’s power source requires a comprehensive understanding of various approaches. By mastering these methods, enthusiasts can ensure optimal performance and longevity of their vessels.

Identifying Common Issues

Before initiating any maintenance, it’s crucial to diagnose prevalent problems. This involves thorough inspections and evaluating symptoms that could indicate underlying complications. Recognizing issues early can prevent more extensive damage.

Utilizing Proper Tools

Equipping oneself with the right instruments is essential for effective maintenance. From basic hand tools to specialized equipment, having the appropriate gear at your disposal facilitates efficient work and enhances the likelihood of successful outcomes.

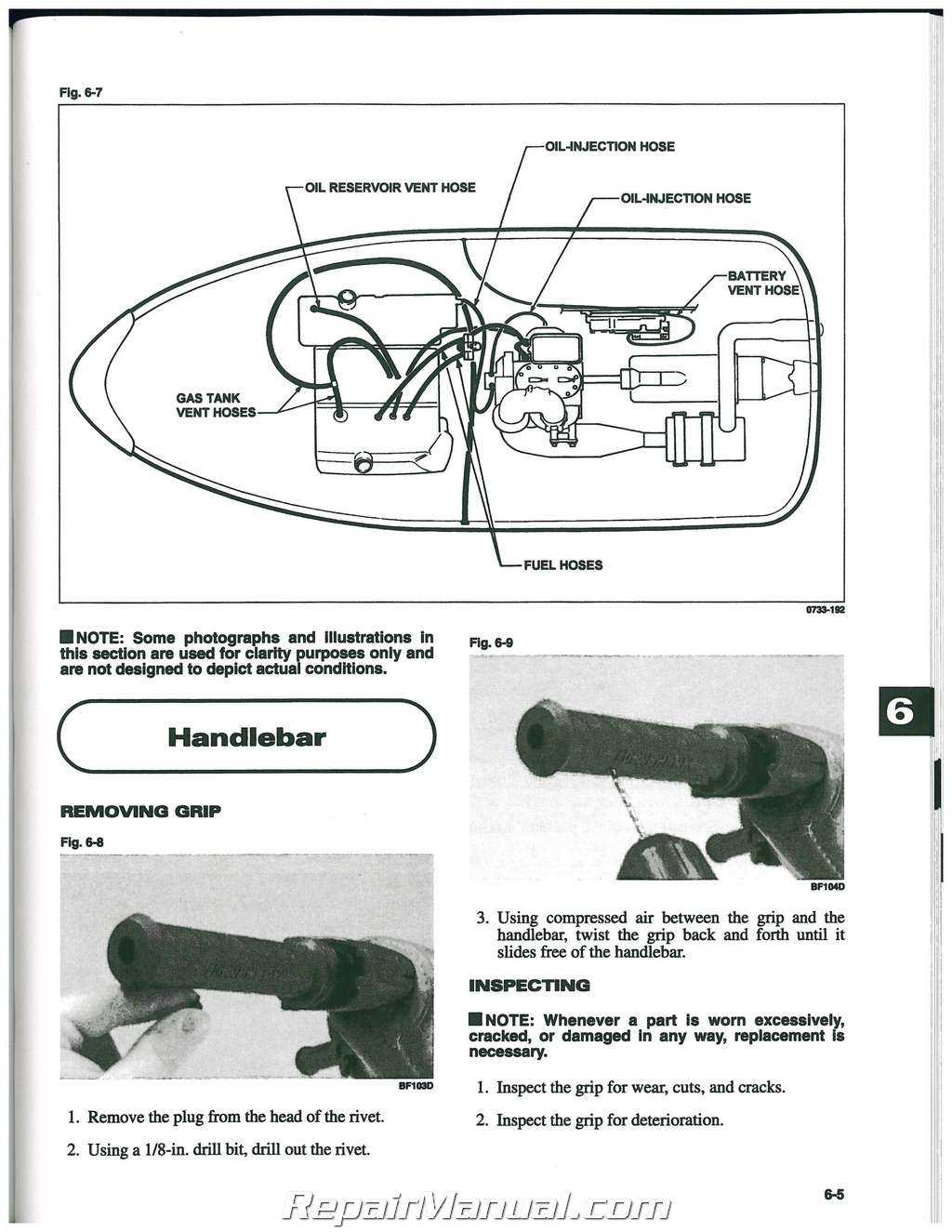

Fuel System Cleaning Procedures

Maintaining the cleanliness of the fuel system is essential for optimal performance and longevity. Regular cleaning ensures that the fuel flow remains uninterrupted, preventing potential issues and enhancing efficiency.

Initial Inspection Steps

Before commencing the cleaning process, it is vital to conduct a thorough inspection. This helps identify any visible contaminants or wear in the components. Follow these steps:

| Step | Description |

|---|---|

| 1 | Check for leaks or damage in hoses and connections. |

| 2 | Examine filters for blockages or deterioration. |

| 3 | Inspect the fuel tank for debris or sediment. |

Cleaning Procedure

After completing the inspection, proceed with the cleaning. Utilize appropriate cleaning solutions and methods to ensure all components are free of contaminants:

- Drain the fuel tank and remove any debris.

- Clean the filters using a suitable solvent.

- Flush the fuel lines with a recommended cleaning agent.

Propeller and Drive System Care

Proper maintenance of the propulsion components is essential for optimal performance and longevity. Regular attention to these parts ensures smooth operation and helps prevent potential issues.

- Inspection: Routinely check the propeller and drive system for any signs of wear or damage. Look for cracks, dents, or corrosion that could affect performance.

- Cleaning: After each use, clean the components to remove debris, salt, or other contaminants. This practice helps prevent build-up that can lead to corrosion.

- Lubrication: Apply appropriate lubricants to moving parts as specified by the manufacturer. This reduces friction and enhances the lifespan of the components.

- Alignment: Ensure that the propeller and drive system are correctly aligned. Misalignment can cause unnecessary strain and reduce efficiency.

By following these maintenance guidelines, you can enhance the reliability and efficiency of your propulsion system, ensuring a smoother experience on the water.

Preventive Measures for Longevity

Ensuring the extended lifespan of watercraft involves regular maintenance and attention to key components. By implementing strategic practices, users can significantly enhance performance and reduce the likelihood of unexpected issues.

Routine inspections should focus on vital areas such as the propulsion system, fuel lines, and electrical components. Keeping these elements clean and free from debris will contribute to overall efficiency.

Additionally, utilizing protective covers during periods of inactivity can shield the equipment from environmental factors, thus preventing premature wear. Regular flushing of the cooling system is essential to remove salt or contaminants, promoting optimal functionality.

Lastly, adhering to a consistent schedule for part replacements and servicing can further ensure reliability. By prioritizing these preventive measures, enthusiasts can enjoy a smooth and enjoyable experience on the water for years to come.

Safety Guidelines During Repairs

Ensuring a safe working environment is crucial when undertaking maintenance tasks. Proper precautions help prevent accidents and injuries while enhancing the overall efficiency of the process.

Before starting any work, it is essential to prepare adequately and understand the necessary safety measures. Here are some guidelines to follow:

| Guideline | Description |

|---|---|

| Wear Protective Gear | Always use appropriate safety equipment, including gloves, goggles, and helmets, to protect against hazards. |

| Ensure Adequate Ventilation | Work in a well-ventilated area to avoid inhaling harmful fumes or dust particles. |

| Use Proper Tools | Utilize the right tools for each task to minimize risks associated with improper usage. |

| Keep Workspace Organized | Maintain a clean and clutter-free area to prevent trips and falls. |

| Follow Manufacturer’s Instructions | Adhere to guidelines provided by the manufacturer to ensure safe practices during maintenance. |

Frequently Asked Questions

This section aims to address common inquiries related to the maintenance and functionality of personal watercraft. Understanding these topics can enhance your experience and ensure optimal performance.

| Question | Answer |

|---|---|

| What regular maintenance is required? | Routine checks should include examining the fuel system, battery, and overall mechanical components to ensure proper operation. |

| How can I improve performance? | Regularly cleaning the water intake and ensuring the propeller is in good condition can significantly enhance efficiency. |

| What should I do if I encounter issues? | It is advisable to consult a professional or refer to specific guidelines for troubleshooting common problems. |

| Are there specific safety measures to follow? | Wearing appropriate safety gear and adhering to local regulations are crucial for a safe experience on the water. |

Resources for Further Learning

Expanding your knowledge on aquatic vehicle maintenance can greatly enhance your skills and confidence. Various resources are available to help you delve deeper into this subject, providing insights and techniques for effective upkeep.

| Resource Type | Description | Link |

|---|---|---|

| Books | Comprehensive guides covering maintenance techniques and troubleshooting tips. | Explore Books |

| Online Forums | Communities where enthusiasts share experiences and advice. | Visit Forums |

| Video Tutorials | Visual guides demonstrating maintenance practices step-by-step. | Watch Tutorials |

| Workshops | Hands-on sessions led by experts focusing on various aspects of maintenance. | Join Workshops |