Comprehensive Guide for Yamaha G16A Repairs

Maintaining and addressing issues in your vehicle is essential for ensuring its longevity and optimal performance. This section offers insights into effective techniques and methods to keep your machine in top condition. Understanding the intricacies of your equipment can significantly enhance its reliability and efficiency.

By exploring detailed processes and practical tips, you’ll gain the knowledge necessary to tackle common challenges. Whether you are a seasoned expert or a novice, this guide aims to equip you with valuable information that fosters confidence in handling repairs and upkeep.

Regular care not only prevents potential problems but also promotes better functionality. With the right approach, you can enhance the overall experience of operating your vehicle, ensuring it serves you well for years to come.

Common Issues Faced by Users

Users often encounter a range of challenges while operating their vehicles, leading to frustration and decreased performance. Understanding these issues can help in identifying solutions and improving the overall experience.

Frequent Performance Problems

One of the most common concerns involves inconsistent performance, which can manifest as sluggish acceleration or difficulty in starting. Such issues may stem from various factors, including fuel delivery problems or electrical system faults.

Maintenance and Wear

Regular wear and tear can lead to a host of maintenance-related challenges. Components may become worn out, resulting in reduced efficiency and the need for timely replacements. Users should be vigilant about recognizing signs of wear to prevent further complications.

Essential Tools for Repairs

Having the right equipment is crucial for efficient maintenance tasks. The proper instruments not only streamline the process but also enhance the quality of the work performed. Here’s a list of essential tools that will assist in various repair activities.

- Wrenches: Adjustable and socket wrenches are vital for loosening and tightening nuts and bolts.

- Screwdrivers: A set of various sizes and types, including flathead and Phillips, is necessary for handling different fasteners.

- Pliers: Needle-nose and standard pliers are useful for gripping, twisting, and cutting wires or components.

- Torque Wrench: Ensures that bolts are tightened to the correct specifications, preventing over-tightening.

- Multimeter: Essential for diagnosing electrical issues by measuring voltage, current, and resistance.

- Cutting Tools: Wire cutters and utility knives aid in precise cutting of materials.

- Safety Gear: Protective glasses and gloves are necessary to ensure safety during maintenance tasks.

Investing in quality tools can make a significant difference in the outcome of any service task, leading to a more successful and efficient workflow.

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to regular upkeep, ensuring optimal performance and longevity of your equipment. Following these guidelines will help prevent common issues and enhance the overall efficiency of the unit.

Essential Maintenance Tasks

- Check fluid levels regularly to ensure proper functioning.

- Inspect all belts and hoses for wear and tear.

- Clean air filters to improve airflow and engine efficiency.

- Lubricate moving parts to reduce friction and prevent damage.

Maintenance Schedule

- Daily: Inspect the overall condition and check for leaks.

- Weekly: Clean filters and check fluid levels.

- Monthly: Perform a detailed inspection of belts and hoses.

- Annually: Conduct a thorough maintenance check and replace worn parts as necessary.

Electrical System Troubleshooting

This section addresses common issues related to the electrical components of your vehicle, guiding you through systematic checks and potential solutions. Understanding the typical problems can enhance your ability to maintain the system effectively.

Common Issues and Symptoms

Recognizing the signs of electrical failures is crucial for prompt intervention. Below are some frequent symptoms that may indicate problems within the electrical system:

- Inconsistent power supply

- Malfunctioning lights

- Unexpected battery drainage

Troubleshooting Steps

Follow these steps to diagnose and resolve electrical issues:

| Step | Action | Description |

|---|---|---|

| 1 | Inspect connections | Check all electrical connections for signs of corrosion or looseness. |

| 2 | Test battery voltage | Use a multimeter to measure the voltage of the battery to ensure it is within the normal range. |

| 3 | Check fuses | Inspect fuses for any that may be blown and replace as necessary. |

Engine Components Overview

This section provides a comprehensive look at the various elements that make up the power unit of a typical vehicle. Understanding these components is essential for diagnosing issues and ensuring optimal performance.

Core Elements

The primary parts of the power unit include the cylinder block, which houses the combustion chambers, and the crankshaft, responsible for converting linear motion into rotational energy. Additionally, the pistons and connecting rods play crucial roles in the combustion process, facilitating movement within the engine.

Supporting Systems

Several auxiliary systems contribute to the overall functionality of the engine. These include the cooling system, which maintains optimal operating temperatures, and the lubrication system, ensuring that all moving parts receive adequate oil. Proper maintenance of these systems is vital for preventing overheating and wear.

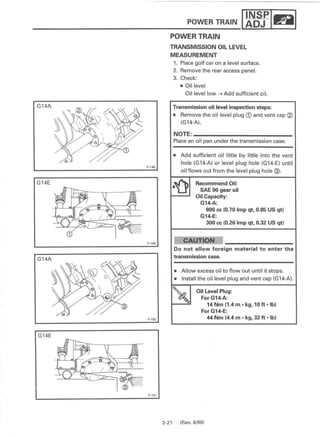

Transmission and Drive System Repair

This section focuses on the essential aspects of maintaining and restoring the functionality of the transmission and drive components of a vehicle. A well-functioning system ensures smooth operation and optimal performance, making it crucial for overall vehicle reliability.

Common Issues and Diagnostics

Identifying common problems in the transmission and drive assembly is the first step toward effective resolution. Symptoms such as unusual noises, slipping gears, or delayed engagement can indicate underlying issues. Regular inspections and diagnostic tests are vital for early detection and prevention of further complications.

Maintenance Procedures

Proper maintenance of the transmission and drive system involves several key tasks. Regular fluid changes, inspection of seals and gaskets, and adjustment of cable tensions contribute to longevity and performance. Ensuring that all components are clean and free from debris will also aid in smooth operation and reduce wear and tear.

Cleaning and Care Tips

Maintaining the performance and longevity of your equipment requires regular cleaning and proper care. By following a few simple steps, you can ensure that your machine remains in optimal condition and operates efficiently.

Regular Cleaning Schedule

Establishing a routine cleaning schedule is essential. Remove dirt and debris after each use to prevent buildup that can affect functionality. Use a soft cloth or brush to clean surfaces, focusing on areas that are prone to grime accumulation.

Protective Measures

Implement protective measures to shield your device from environmental factors. Store it in a dry, cool place when not in use. Additionally, consider using covers or cases to guard against dust and moisture. Regularly check for any signs of wear or damage and address them promptly to maintain optimal performance.

Parts Replacement Procedures

Replacing components is an essential aspect of maintaining optimal functionality in any mechanical system. This section outlines the steps necessary to ensure proper substitution of parts, enhancing performance and extending the lifespan of the equipment.

Assessment of the Component: Begin by identifying the part that requires replacement. Conduct a thorough examination to determine the extent of wear or damage. This assessment will inform the choice of a suitable replacement and whether any additional components need to be addressed.

Gathering Required Tools: Before proceeding, ensure you have all necessary tools and replacement parts on hand. This preparation minimizes downtime and allows for a smoother workflow during the replacement process.

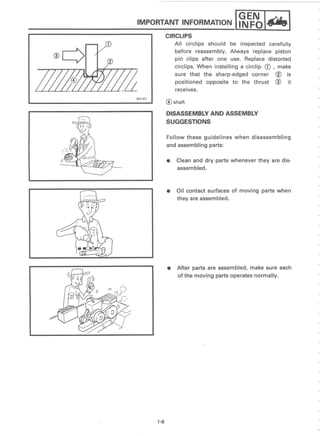

Disassembly: Carefully disassemble the relevant sections of the equipment. Take note of how parts are arranged and connected, as this will aid in reassembly. Utilize appropriate techniques to avoid causing further damage during this stage.

Installation of New Part: Place the new component into position, ensuring it fits securely and aligns with existing structures. Follow any specific guidelines provided for the part to guarantee proper installation.

Reassembly and Testing: Once the new part is in place, reassemble the equipment methodically. After reassembly, conduct tests to verify that the replacement has restored functionality and performance to desired levels.

Safety Precautions During Repairs

When undertaking maintenance or restoration tasks on mechanical devices, it is crucial to prioritize safety to prevent accidents and injuries. Adhering to specific guidelines can significantly mitigate risks associated with handling tools and components.

Personal Protective Equipment: Always wear appropriate safety gear, including gloves, goggles, and masks, to shield against potential hazards. This equipment serves as the first line of defense against injuries.

Workspace Organization: Maintain a clean and organized workspace to reduce the likelihood of accidents. Ensure that all tools are properly stored and that there is ample space to maneuver safely.

Electrical Safety: Before starting any work, disconnect power sources to prevent electrical shocks. Use insulated tools and avoid wet conditions to further enhance safety measures.

Tool Handling: Handle tools with care, ensuring they are in good condition and appropriate for the task. Follow the manufacturer’s instructions for proper usage to avoid mishaps.

Emergency Preparedness: Familiarize yourself with the location of emergency equipment, such as fire extinguishers and first aid kits. Knowing how to respond in case of an emergency can save lives.

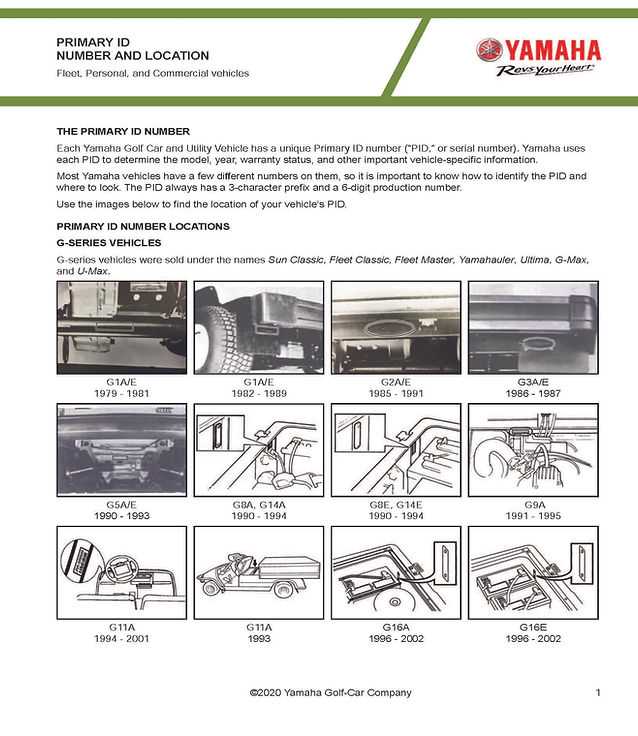

Finding Genuine Replacement Parts

When it comes to maintaining and restoring your vehicle, sourcing authentic components is crucial for optimal performance and longevity. Utilizing original parts ensures compatibility and quality, which can significantly impact the functionality of your machinery.

Start by checking with authorized dealers or official retailers who specialize in your specific model. These sources often carry a comprehensive inventory of genuine components, along with knowledgeable staff who can assist with your needs. Online marketplaces also offer a range of options, but it’s essential to verify the seller’s credibility to avoid counterfeit products.

In addition, engaging with community forums or user groups can provide insights into reputable suppliers and recommendations for sourcing parts. Fellow enthusiasts often share their experiences and can point you toward trustworthy vendors.

Finally, consider reaching out directly to the manufacturer for guidance on where to obtain authentic components. They may offer resources or a list of approved distributors, ensuring that you have access to the best quality parts available.

Helpful Resources and Support

Accessing reliable information and assistance can greatly enhance your experience with your vehicle. Various platforms and communities offer valuable insights, troubleshooting tips, and expert advice to help you navigate any issues that may arise.

Online Forums and Communities

Engaging with fellow enthusiasts in dedicated online forums can provide a wealth of knowledge. These communities often share personal experiences, solutions to common problems, and recommendations for specific tools and techniques.

Official Websites and Documentation

Exploring official websites can yield access to a range of resources, including technical specifications, maintenance guidelines, and contact information for professional support. This information is crucial for ensuring the longevity and optimal performance of your equipment.

Frequently Asked Questions

This section addresses common inquiries related to maintenance and troubleshooting of various models. Here, you will find answers to the most prevalent concerns that users encounter.

- What should I do if my device won’t start?

Check the battery connections and ensure they are secure. If the issue persists, inspect the ignition system for faults.

- How can I improve performance?

Regular maintenance, including air filter cleaning and proper fuel use, can enhance efficiency.

- What is the recommended maintenance schedule?

It’s advisable to follow the manufacturer’s guidelines for routine inspections and servicing.

- How do I address unusual noises?

Identify the source of the sound. It may indicate a mechanical issue that requires immediate attention.

- Where can I find replacement parts?

Authorized dealers or online retailers typically offer a range of components suitable for your model.