Toyota K310 CVT Transmission Repair Guide

The intricacies of a vehicle’s gear mechanism are crucial for its overall functionality and performance. Understanding how these components operate not only enhances driving experience but also ensures longevity and efficiency. This section delves into the essential aspects of maintaining and troubleshooting these systems, providing valuable insights for enthusiasts and professionals alike.

In this guide, we will explore the vital processes involved in maintaining the gear shifting system, focusing on the common challenges faced by users. By equipping yourself with the right knowledge and techniques, you can address issues proactively and ensure your vehicle remains in optimal condition.

Whether you are a seasoned mechanic or a car owner looking to gain a deeper understanding of your vehicle, this resource aims to empower you with the necessary skills and information. By following the outlined procedures and recommendations, you can achieve a smoother driving experience and prevent potential malfunctions.

Overview of the Continuously Variable System

This section provides an insightful exploration of a specific automatic gear system designed for enhanced efficiency and performance. Understanding its functionality is crucial for anyone interested in the mechanics behind modern vehicles.

This innovative mechanism offers a seamless driving experience by allowing the engine to operate at optimal RPMs, thus improving fuel efficiency and reducing emissions. Its design is characterized by a series of belts and pulleys that enable smooth transitions between different speeds without the typical shift points found in traditional systems.

Additionally, this type of gear arrangement enhances acceleration responsiveness, making it particularly suitable for urban environments where quick starts and stops are common. Maintaining this system involves regular inspections to ensure that components remain in optimal condition, thereby prolonging the overall lifespan of the vehicle.

Common Issues with CVT Transmissions

Continuous variable systems are often praised for their efficiency and smooth operation, yet they can experience a range of challenges over time. Understanding these issues can help in maintaining optimal performance and ensuring longevity.

Overheating is a prevalent problem that can arise from prolonged use or inadequate fluid levels. This condition can lead to significant damage if not addressed promptly, resulting in costly repairs.

Another frequent concern is slipping, where the mechanism fails to engage properly, causing a loss of power and acceleration. This issue may stem from worn components or fluid contamination.

Noises such as whining or grinding during operation can indicate underlying issues. These sounds often suggest that internal parts are experiencing excessive wear or that lubrication is insufficient.

Finally, a check engine light activation can serve as an early warning signal of various malfunctions. Diagnosing the underlying cause is crucial to prevent further complications and ensure reliable functionality.

Symptoms of Transmission Failure

Identifying issues with the power delivery system in a vehicle is crucial for maintaining optimal performance. Certain signs can indicate that this system is experiencing difficulties, potentially leading to more severe complications if not addressed promptly.

Common Indicators

Drivers may notice unusual noises, such as grinding or whining, when the vehicle is in motion. Additionally, slipping sensations during gear changes can signal underlying problems. These issues often manifest as delayed responses or a complete inability to engage gears, which can significantly affect driving safety.

Fluid Leaks and Overheating

Another critical sign is the presence of fluid leaks under the vehicle. Low fluid levels can result in overheating, which further exacerbates performance issues. Monitoring fluid conditions and levels is essential for preventing damage and ensuring smooth operation.

Essential Tools for Repair

When it comes to addressing complex mechanical issues, having the right instruments is crucial for achieving effective results. A well-equipped workspace ensures that every task can be tackled with precision and efficiency.

The following table lists the fundamental instruments necessary for effective servicing, providing a clear overview of their purpose and importance:

| Tool | Description |

|---|---|

| Socket Set | Essential for loosening and tightening various fasteners with ease. |

| Torque Wrench | Allows for precise application of torque to fasteners, preventing damage. |

| Fluid Extractor | Facilitates the safe removal of fluids, reducing spills and contamination. |

| Diagnostic Scanner | Helps identify faults through electronic diagnostics, streamlining troubleshooting. |

| Bench Vise | Provides stability for holding components securely during work. |

Equipping your workspace with these vital tools enhances the overall efficiency and effectiveness of mechanical tasks, leading to successful outcomes.

Step-by-Step Repair Process

This section outlines a comprehensive approach to addressing issues commonly found in automatic gear systems. By following a structured sequence of actions, you can effectively diagnose and resolve problems, ensuring optimal performance and longevity of the mechanism.

Preparation Phase

Before beginning the procedure, gather all necessary tools and components. Ensure that the work area is clean and well-lit to facilitate a smooth process. Having the right equipment on hand will save time and enhance efficiency.

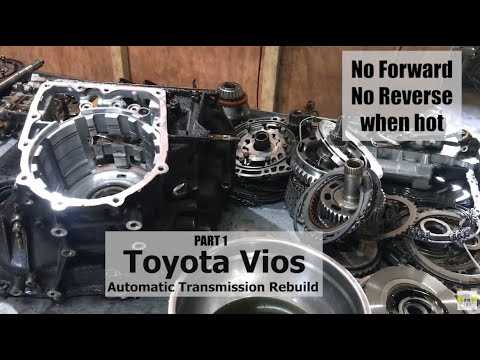

Disassembly and Inspection

The initial step involves carefully taking apart the unit to access internal parts. During this phase, inspect each component for wear and damage. Document any findings to assist in the reassembly and future reference.

| Component | Condition | Action Required |

|---|---|---|

| Input Shaft | Worn | Replace |

| Gear Set | Intact | Clean |

| Seals | Deteriorated | Replace |

After completing the inspection, proceed with necessary replacements and repairs. This methodical approach will enhance the functionality of the system and contribute to its reliability.

Fluid Replacement Guidelines

Regular maintenance of your vehicle’s fluid is essential for optimal performance and longevity. This section outlines the recommended practices for replacing the essential lubricant, ensuring that your system operates smoothly and efficiently.

1. Importance of Fluid Quality

Using high-quality lubricant is crucial, as it helps reduce friction and wear on the internal components. Always choose fluids that meet the specifications outlined in your vehicle’s guidelines to maintain proper function.

2. Replacement Frequency

It is advisable to change the fluid at specified intervals, typically every 30,000 to 60,000 miles, or as indicated by your vehicle’s service schedule. Regular checks can prevent potential issues and ensure the system remains in good condition.

3. Procedure for Replacement

Begin by warming up the engine, as this allows the lubricant to flow more freely. Drain the old fluid completely, and inspect it for any signs of contamination or degradation. After draining, refill with the appropriate amount of new lubricant, ensuring it reaches the optimal level.

4. Environmental Considerations

Dispose of the old fluid responsibly, following local regulations. Many service centers and recycling facilities accept used fluids, helping to protect the environment.

Checking Electrical Connections

Ensuring proper functionality of the system requires thorough inspection of electrical links. Faulty connections can lead to performance issues and malfunctions, making this step critical in the overall assessment.

Begin by examining all connectors for signs of wear or corrosion. Clean any dirt or debris that may obstruct the connection. Use appropriate tools to tighten loose terminals, ensuring a secure fit. Inspect wiring for frays or damage, as these can interrupt the flow of electricity and cause erratic behavior.

Additionally, test the integrity of the circuits with a multimeter. Verify that voltage levels are within specified ranges to confirm functionality. Document any discrepancies and address them promptly to maintain optimal operation.

Diagnosing Fault Codes

Understanding fault codes is essential for effective vehicle maintenance and troubleshooting. These codes serve as indicators of various issues within the automotive system, guiding technicians in pinpointing the root causes of malfunctions.

When encountering fault codes, follow these steps to accurately diagnose the problem:

- Retrieve Codes: Utilize an appropriate diagnostic scanner to extract the fault codes stored in the vehicle’s onboard computer.

- Reference Code List: Consult a comprehensive list of fault codes to interpret the retrieved information. This list provides details on potential issues associated with each code.

- Evaluate Symptoms: Analyze the vehicle’s performance and symptoms in conjunction with the fault codes. This can help narrow down the possible causes.

- Inspect Related Components: Perform a thorough inspection of components linked to the identified fault codes. Look for signs of wear, damage, or disconnection.

- Conduct Tests: Execute specific tests based on the suspected issues. This may include electrical tests, fluid checks, or physical inspections.

- Clear Codes: After addressing the issue, clear the fault codes from the system and conduct a test drive to ensure the problem has been resolved.

By systematically following these steps, technicians can efficiently diagnose and address issues, ensuring optimal vehicle performance and longevity.

Preventive Maintenance Tips

Regular upkeep is essential for ensuring the longevity and efficiency of your vehicle’s performance system. By implementing a few straightforward practices, you can avoid major issues and enhance the overall functionality of your automobile.

Key Practices for Maintenance

| Practice | Description |

|---|---|

| Fluid Checks | Regularly inspect and replace fluids to ensure optimal operation and prevent overheating. |

| Filter Replacements | Change filters periodically to maintain cleanliness and prevent debris accumulation. |

| Inspections | Conduct thorough examinations of components to identify wear and tear early. |

Scheduled Servicing

Establishing a routine service schedule can greatly assist in prolonging the lifespan of your vehicle’s systems. Adhering to the manufacturer’s recommendations will keep everything running smoothly and help you avoid unexpected breakdowns.

Rebuilding vs. Replacing Transmissions

When faced with issues in a vehicle’s shifting mechanism, owners often weigh the options of overhauling the existing unit or opting for a brand-new one. Each choice presents its own set of advantages and drawbacks that can significantly impact both performance and budget.

Rebuilding involves disassembling the current unit to inspect and replace worn or damaged components. This process can restore functionality while often being more cost-effective than acquiring a new unit. Additionally, it allows for customization based on specific performance needs.

On the other hand, replacement offers a simpler solution, providing a fresh start with a new assembly. This option typically guarantees reliability and might come with a warranty, ensuring peace of mind. However, it often involves a higher initial investment and may not address any underlying issues that led to the failure of the original unit.

Ultimately, the decision between overhauling and replacing hinges on individual circumstances, including budget constraints, the extent of the damage, and long-term vehicle goals. Understanding these factors can lead to a more informed choice that best suits the owner’s needs.

Cost Estimates for Repairs

When it comes to addressing issues with your vehicle’s gear shifting system, understanding the financial implications is crucial. Various factors contribute to the overall costs, including labor, parts, and complexity of the task at hand.

Factors Influencing Costs

- Labor Rates: The hourly rates charged by mechanics can vary significantly based on location and expertise.

- Parts Availability: The cost of replacement components may fluctuate depending on whether they are readily available or need to be ordered.

- Severity of the Issue: Minor adjustments will generally cost less than extensive overhauls or replacements.

Estimated Cost Ranges

Here is a general outline of what you might expect to pay:

- Minor adjustments: $100 – $300

- Replacement of certain components: $300 – $800

- Full system overhaul: $1,000 – $3,500

It’s advisable to obtain multiple quotes from different service centers to ensure you are getting a fair price for the necessary work.

Frequently Asked Questions

This section addresses common inquiries regarding the maintenance and troubleshooting of specific automotive components. Understanding these aspects can significantly enhance the longevity and performance of your vehicle.

What are the signs of a potential issue?

Indicators such as unusual noises, fluid leaks, or erratic behavior during gear shifts often suggest that a thorough examination is needed. Early detection can prevent further complications and costly interventions.

How can I maintain optimal performance?

Regular checks and timely fluid changes are essential for ensuring smooth operation. Following recommended service intervals and being attentive to any changes in behavior can help in maintaining functionality.