Briggs and Stratton Lawn Mower Engine Repair Guide

In the world of outdoor machinery, understanding the intricacies of small motor systems is essential for achieving optimal performance. This section delves into the critical aspects of maintaining these compact powerhouses, ensuring they operate smoothly and efficiently throughout their lifespan.

From diagnosing common issues to performing routine maintenance tasks, a comprehensive knowledge base equips users with the tools necessary for effective management. Whether addressing mechanical failures or enhancing operational efficiency, familiarity with these units fosters confidence in their upkeep.

Explore practical solutions and insightful tips designed to assist users in navigating the complexities of these vital machines. Emphasis on hands-on techniques and troubleshooting strategies will empower individuals to tackle challenges head-on, promoting longevity and reliability in outdoor equipment.

Engine Overview

This section provides a comprehensive insight into a well-known brand’s power units, highlighting their features, functionality, and common applications. These machines are widely recognized for their reliability and efficiency in various tasks, making them a preferred choice among users.

Key Features

- Durable construction for prolonged use

- Innovative technology enhancing performance

- Wide range of models suitable for different applications

- Ease of maintenance ensuring longevity

Common Applications

- Residential gardening and landscaping

- Commercial groundskeeping services

- Sporting fields maintenance

- Public park upkeep

Common Issues with Lawn Mower Engines

Regular maintenance and awareness of typical challenges are essential for keeping small outdoor power tools running smoothly. Users often encounter various complications that can affect performance and reliability. Understanding these frequent problems can aid in quick diagnosis and resolution, ensuring that machines operate efficiently.

1. Difficulty Starting

One of the most prevalent issues is the inability to start the machine. This may stem from a drained battery, faulty ignition components, or a clogged fuel system. Regular checks can help identify underlying causes before they escalate.

2. Excessive Smoke

Another common concern is the presence of excessive smoke during operation. This can indicate oil leakage or improper fuel mixture. Monitoring fluid levels and using the correct type of fuel can mitigate this issue.

3. Uneven Cutting

Users may notice inconsistent cutting performance, which can result from dull blades or misaligned components. Keeping blades sharp and ensuring proper alignment is crucial for achieving a clean cut.

4. Overheating

Overheating is a serious condition that can lead to engine failure. This problem is often caused by inadequate lubrication or blocked air intake. Regular oil changes and cleaning air filters can help maintain optimal operating temperatures.

5. Unusual Noises

Any unusual sounds during operation should be addressed immediately, as they may indicate mechanical issues. Routine inspections can help detect wear and tear on moving parts, allowing for timely repairs.

By recognizing these common challenges, users can take proactive steps to ensure the longevity and effectiveness of their equipment. Regular maintenance and attentiveness to performance can significantly reduce the likelihood of encountering these issues.

Tools Required for Engine Repairs

When tackling mechanical fixes, having the right instruments at your disposal is essential for achieving optimal results. This section outlines the necessary tools that facilitate efficient diagnostics and maintenance of small combustion units.

Basic Hand Tools

Start with a comprehensive set of hand tools, including wrenches, screwdrivers, and pliers. These items are fundamental for loosening and tightening various components. Ensure that your collection includes both metric and standard sizes to accommodate different fittings.

Specialized Equipment

In addition to standard tools, certain specialized equipment can enhance your capability. A compression gauge is vital for assessing cylinder performance, while a spark plug socket allows for easy access to ignition components. Having a multimeter on hand is also advantageous for diagnosing electrical issues.

Step-by-Step Engine Disassembly Guide

This section provides a detailed approach to dismantling the power unit for maintenance or troubleshooting. Following these instructions carefully will ensure a thorough understanding of the assembly’s components and their arrangement.

Before starting, gather the necessary tools and prepare a clean workspace. A methodical approach will facilitate the process and help avoid any missing parts.

| Step | Description |

|---|---|

| 1 | Disconnect the ignition source to prevent accidental starting. |

| 2 | Remove the protective covers to access the internal components. |

| 3 | Carefully detach the carburetor and set it aside in a safe location. |

| 4 | Unscrew the fasteners securing the casing and lift it off gently. |

| 5 | Identify and extract the key components, taking note of their positions. |

| 6 | Store all removed parts in labeled containers for easy reassembly. |

Completing these steps will prepare the assembly for further inspection or repairs. Keep all parts organized and refer back to this guide as needed.

How to Diagnose Engine Problems

Identifying issues with a power unit can be a straightforward process if approached methodically. A clear understanding of symptoms, coupled with systematic checks, enables efficient troubleshooting. This section will guide you through essential steps to accurately assess functionality.

First, observe the behavior of the unit during operation. Noting irregular sounds, vibrations, or performance inconsistencies can provide valuable clues. For instance, a lack of power might suggest fuel delivery issues, while unusual noises could indicate mechanical wear.

Next, check the fuel supply. Ensure that the tank is filled with fresh, clean fuel. Stale or contaminated fuel can lead to poor performance. Additionally, inspect the fuel lines for any blockages or leaks that may impede flow.

Inspect the ignition system. A malfunctioning spark mechanism can prevent proper combustion. Remove the spark plug and examine it for carbon buildup or damage. A healthy spark plug should appear clean and dry. If not, consider replacing it.

Finally, evaluate air intake. A clogged air filter can restrict airflow, affecting performance. Clean or replace the filter as needed to ensure optimal air supply for combustion.

By following these steps, you can effectively pinpoint the source of issues, paving the way for effective solutions.

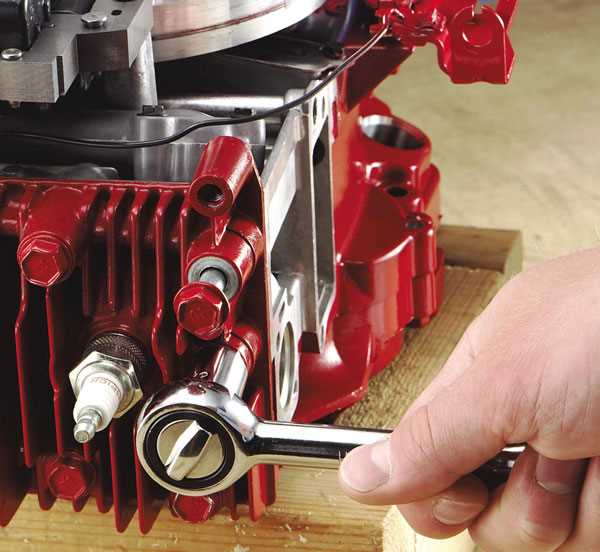

Replacing Spark Plugs Effectively

Changing ignition components is a crucial maintenance task that can significantly enhance performance. This process ensures optimal firing and contributes to smoother operation. Properly executing this task can extend the lifespan of your equipment and improve efficiency.

Step 1: Before starting, gather necessary tools such as a socket wrench, spark plug socket, and gap gauge. Ensure the unit is cool and disconnected from any power source to avoid accidents.

Step 2: Locate the ignition part and remove any covering if applicable. Carefully unscrew the old component, taking care not to damage surrounding areas.

Step 3: Inspect the old part for wear and damage. Check the gap specifications for the new component using a gauge, ensuring it matches manufacturer recommendations.

Step 4: Install the new part by gently screwing it in place. Be cautious not to overtighten, as this can lead to damage.

Step 5: Reattach any coverings and reconnect the power source. Conduct a test run to confirm proper function.

Regular maintenance, including the timely replacement of ignition parts, can lead to improved reliability and longevity of your machinery.

Fuel System Maintenance Tips

Proper upkeep of the fuel system is essential for optimal performance and longevity of your machinery. Regular attention to this component ensures that it runs smoothly and efficiently.

- Inspect Fuel Lines: Regularly check for cracks, leaks, or signs of wear in the fuel lines. Replace any damaged sections to prevent fuel loss.

- Clean Fuel Filter: Ensure the fuel filter is free from debris. A clogged filter can hinder fuel flow, affecting overall performance.

- Use Quality Fuel: Always use high-quality fuel to prevent buildup of deposits that can impair functionality.

- Check for Water Contamination: Water in the fuel can cause significant issues. Use a separator to remove any water present.

- Store Properly: If not in use for an extended period, empty the fuel tank to avoid stale fuel and buildup of varnish.

By following these maintenance tips, you can enhance the reliability and efficiency of your machine, ensuring it operates at its best for years to come.

Oil Change Procedures Explained

Regular maintenance of mechanical devices is crucial for optimal performance and longevity. One essential aspect of this upkeep involves replacing the lubrication fluid to ensure smooth operation and prevent wear.

This section will outline the steps involved in performing a fluid replacement, ensuring that your equipment runs efficiently.

-

Gather Necessary Tools:

- New lubrication fluid

- Drain pan

- Wrench or socket set

- Funnel

- Rags or towels

-

Prepare the Equipment:

- Ensure the device is on a flat surface.

- Allow the mechanism to cool if it has been in use recently.

-

Drain Old Lubrication:

- Locate the drain plug and use the wrench to remove it.

- Position the drain pan beneath the opening to collect the old fluid.

- Let the used lubrication completely drain out.

-

Replace the Drain Plug:

- Once fully drained, reinstall the drain plug and tighten it securely.

-

Add New Lubrication:

- Using a funnel, pour the new fluid into the designated fill port.

- Refer to the manufacturer’s specifications for the correct amount.

-

Check the Level:

- After adding the new fluid, check the level using the dipstick if available.

- Adjust as necessary to reach the recommended level.

Following these steps will ensure that the lubrication is replaced properly, enhancing the performance and lifespan of your machinery.

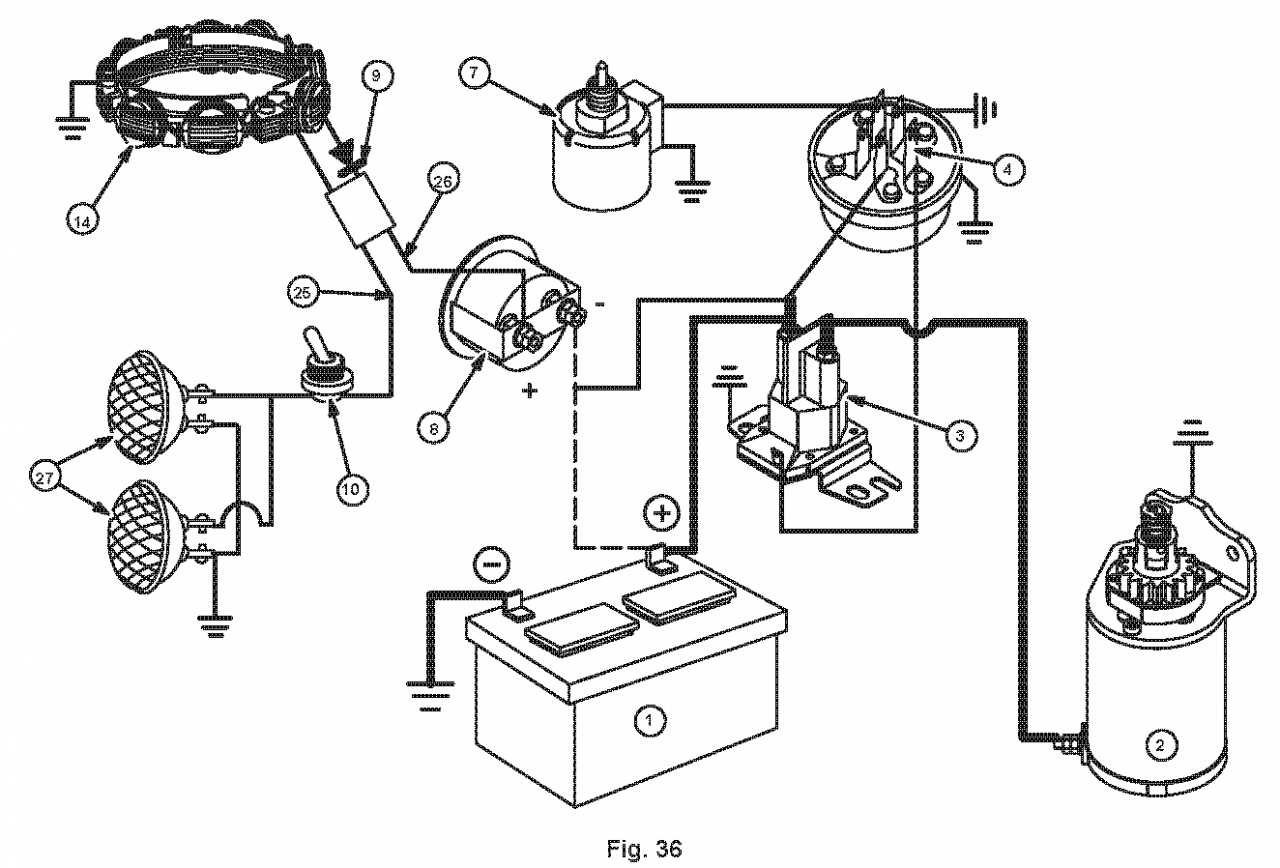

Reassembling the Engine Correctly

Putting the power unit back together requires careful attention to detail and a methodical approach. Following the proper sequence ensures that all components fit together seamlessly, leading to optimal performance.

Before starting the reassembly process, gather all necessary tools and components. Ensure that everything is clean and free from debris.

- Verify that all parts are present and in good condition.

- Review any notes or diagrams taken during disassembly to guide the process.

- Utilize a clean workspace to keep everything organized.

Begin with the base assembly and proceed through each component systematically. Here are some steps to follow:

- Align the base components securely.

- Attach the crankshaft and ensure it rotates freely.

- Install the various covers, ensuring all seals are properly seated.

- Reconnect the fuel and air systems, checking for any obstructions.

- Finalise with electrical connections, ensuring they are secure and insulated.

Once the assembly is complete, conduct a thorough inspection. Check for any loose parts or misalignments before attempting to start the unit.

Testing Engine Performance Post-Repair

After completing maintenance on the power unit, evaluating its functionality is crucial to ensure optimal operation. This assessment allows you to confirm that all adjustments have been successful and that the unit runs smoothly. Proper testing will help identify any remaining issues and guarantee reliability in future use.

Initial Startup Check

Begin by starting the unit in a controlled environment. Listen for unusual noises and observe the vibration levels. A stable and quiet operation indicates a well-functioning system. Allow the unit to warm up and monitor its idle performance, ensuring it maintains a consistent speed without stalling.

Performance Under Load

Once the initial checks are complete, test the unit under load conditions. Engage the operating mechanism and observe how the power unit responds to increased demand. Ensure it accelerates smoothly without hesitation. Take note of any fluctuations in performance, as these may signal underlying issues that need addressing.

Safety Precautions During Repairs

When undertaking maintenance tasks, it is essential to prioritize safety to prevent accidents and injuries. Following certain guidelines can help create a secure working environment and ensure that the process goes smoothly.

Essential Safety Guidelines

- Always wear protective gear, including gloves and goggles, to shield yourself from debris and chemicals.

- Work in a well-ventilated area to avoid inhaling harmful fumes.

- Disconnect the power source before starting any work to prevent unintended activation.

- Keep a fire extinguisher nearby in case of emergencies.

Proper Tool Usage

- Ensure that all tools are in good condition and appropriate for the task.

- Use tools as intended; improper usage can lead to accidents.

- Store tools safely when not in use to avoid tripping hazards.

Adhering to these safety measures will significantly reduce the risk of injury and make the maintenance process more efficient.

Resources for Further Assistance

When tackling mechanical challenges, having access to reliable resources can make all the difference. Whether you are looking for guidance on specific issues or general maintenance tips, numerous platforms offer valuable information to help you succeed.

Online Forums and Communities

Engaging with fellow enthusiasts through online forums can provide insights and practical solutions. These communities often share personal experiences, troubleshooting advice, and can point you toward effective methods for resolving problems. Participating in discussions can also lead to valuable connections with seasoned experts.

Instructional Videos and Tutorials

Visual learners may benefit from video tutorials available on various platforms. These resources typically demonstrate step-by-step processes, allowing you to see techniques in action. By following along with these guides, you can enhance your understanding and improve your skills effectively.