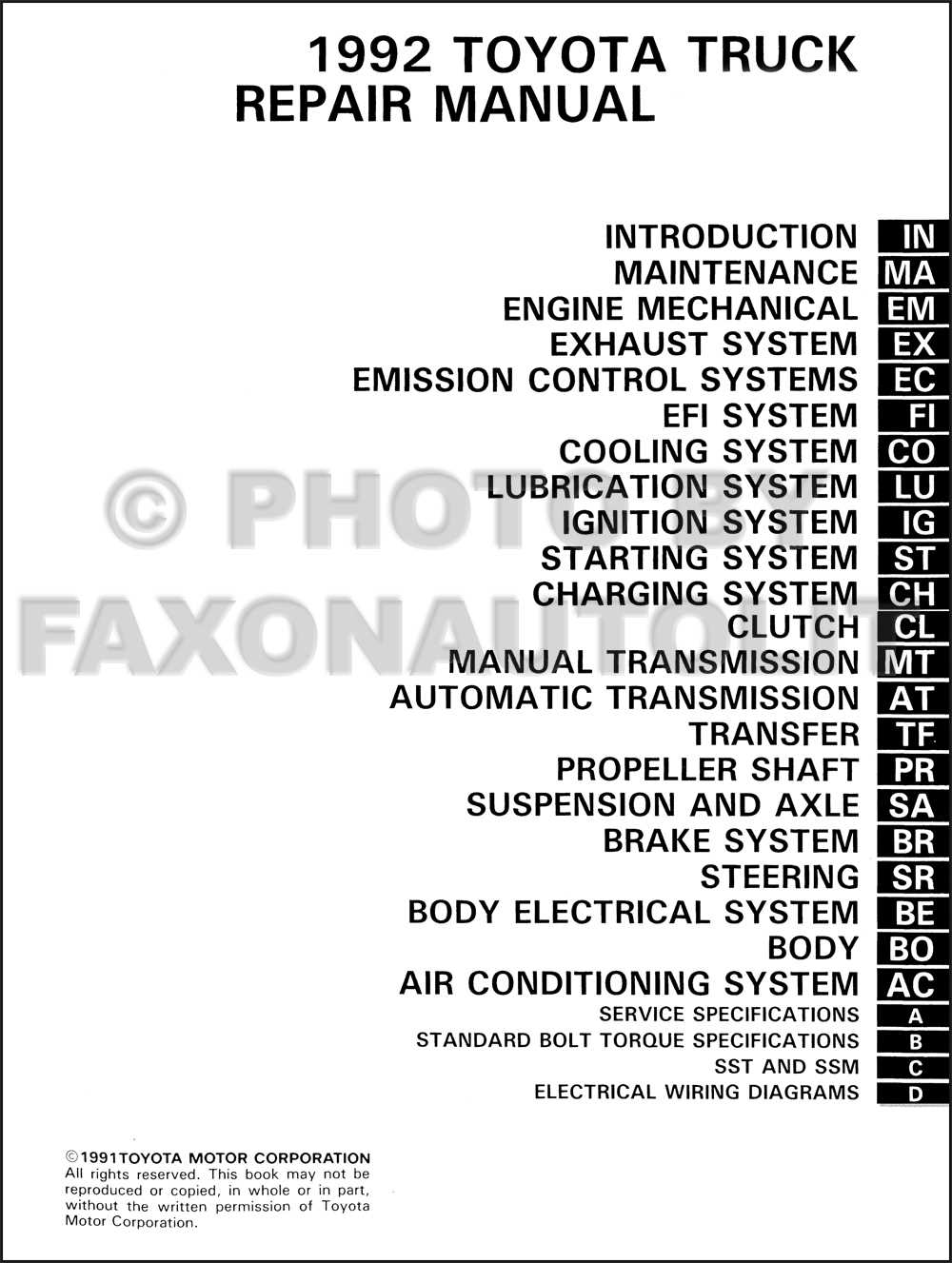

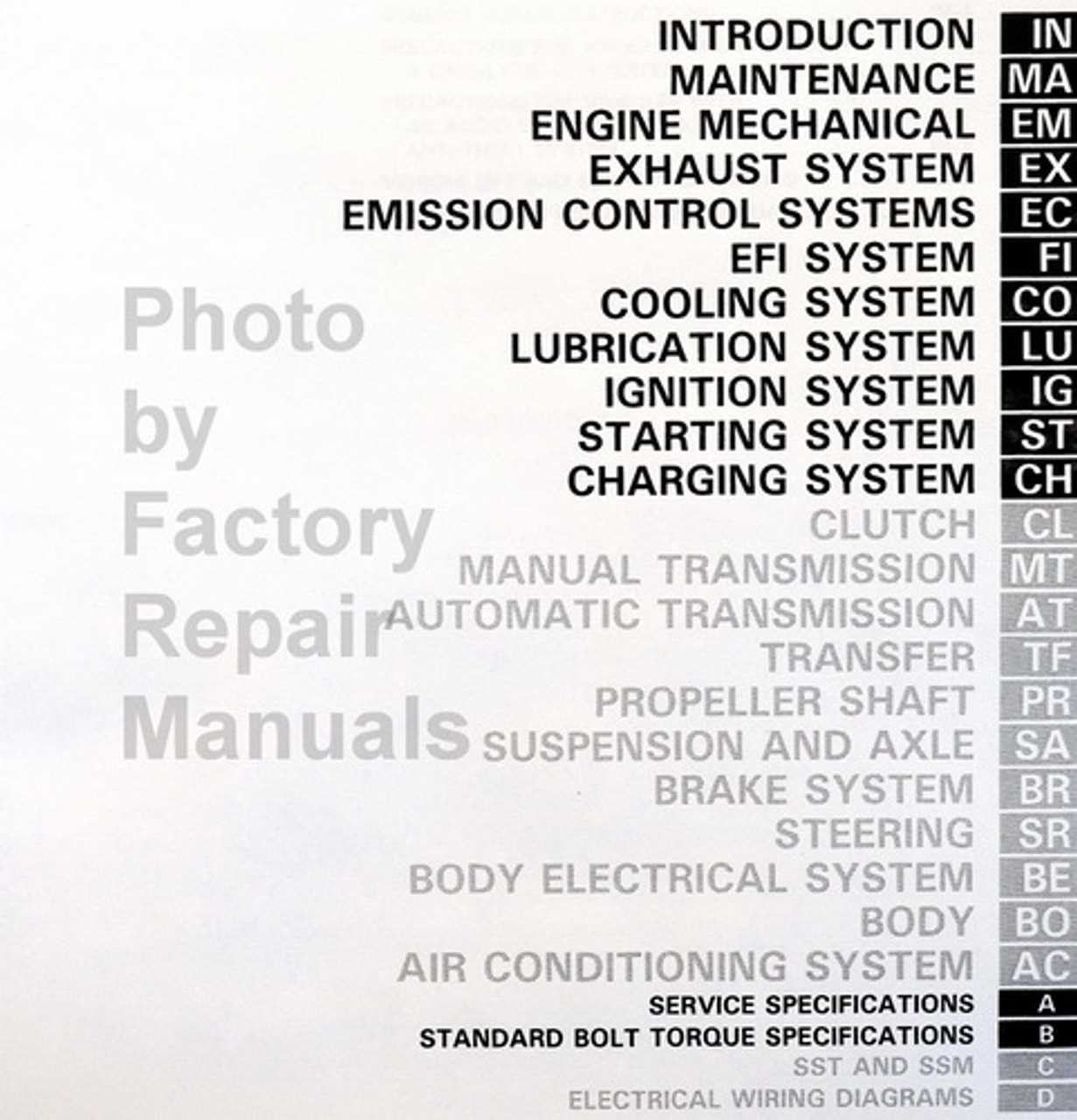

1992 Toyota Truck Repair Guide and Maintenance Tips

Keeping a vehicle in prime condition requires a clear understanding of its components and a proactive approach to care. This guide is designed for enthusiasts and owners looking to understand the essential elements of automobile maintenance, helping ensure long-lasting performance and reliability on the road.

In this resource, we’ll delve into the best practices for examining various systems and assemblies, from the engine to the drivetrain. Whether you’re performing routine inspections or tackling specific mechanical challenges, this guide provides insights that simplify each step, aiming to equip you with practical knowledge for effective problem-solving.

Detailed breakdowns of every key process, diagnostic tips, and preventive measures are included to make sure you’re well-prepared for any situation. With the right approach, you can not only enhance the longevity of your vehicle but also gain the confidence to handle a range of technical tasks independently.

1992 Toyota Truck Repair Guide

Addressing maintenance for this classic vehicle involves understanding essential routines and key adjustments. With the right strategies, you can ensure lasting performance and reliability for this model, whether you’re handling routine upkeep or tackling more complex fixes.

Essential Maintenance Tips

Proper upkeep begins with regular checks on the primary systems, including the engine, transmission, and brakes. Performing thorough assessments helps detect potential wear early, preventing costly repairs. Keeping fluid levels balanced, inspecting hoses, and examining belts are core steps to prolonging engine life and maintaining smooth handling on the road.

Key Areas for Inspection

In addition to engine and transmission checks, focus on the electrical system and suspension for signs of deterioration. Regularly examine battery connections, alternator function, and ignition components. Ensuring stable connections and inspecting for corrosion contributes significantly to reliable starts and overall safety. Likewise, a stable suspension is critical for balanced steering and enhanced comfort, so checking shock absorbers and struts can improve driving performance and reduce strain on other components.

Engine Maintenance Essentials

Proper engine care is fundamental to ensure longevity, optimal performance, and fuel efficiency. Regular maintenance reduces the risk of major issues and keeps the engine running smoothly. This section highlights the essential tasks that should be part of every vehicle owner’s routine to keep the engine in prime condition.

- Oil Changes: Timely oil replacements are crucial to prevent excessive wear and maintain smooth engine operation. Use high-quality oil and replace it at recommended intervals.

- Filter Replacements: Air and fuel filters keep contaminants away from the engine. Regularly changing these filters enhances airflow and fuel quality, ensuring better combustion.

- Fluid Levels: Inspect all engine fluids, including coolant and brake fluid, to maintain safe operating temperatures and reliable performance. Top up or replace fluids as necessary.

- Spark Plug Care: Worn spark plugs can lead to poor fuel economy and engine misfires. Replacing them at regular intervals keeps ignition reliable and fuel combustion efficient.

- Belt and Hose Inspection: Check belts and hoses for signs of wear or damage. Damaged belts can lead to engine overheating or alternator failure, so replace them as needed.

Routine inspection and addressing minor issues early on can prevent costly repairs. Making engine maintenance a priority leads to a more dependable and efficient vehicle.

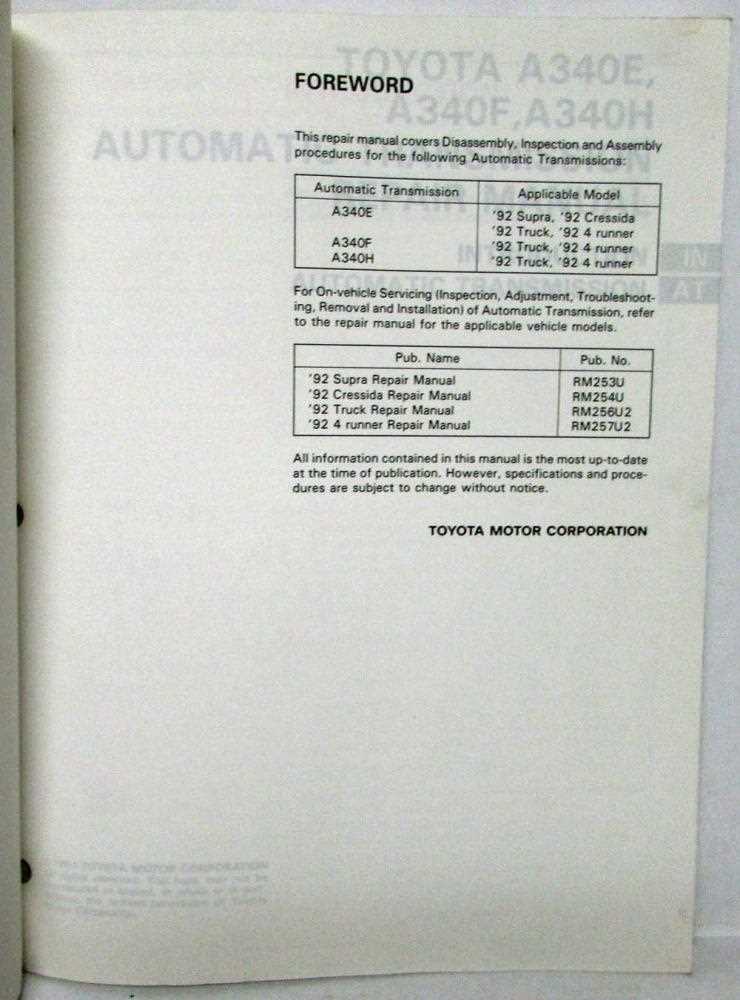

Transmission System Inspection Tips

Regular inspection of the transmission system is essential for maintaining smooth gear shifts and prolonging the system’s lifespan. Understanding key points of inspection can help identify potential issues early and avoid costly repairs. This guide offers practical steps for assessing the system’s core components effectively and ensuring long-term performance.

Fluid Level and Condition

Begin by checking the transmission fluid level, as this is crucial for proper lubrication and cooling. Ensure the fluid is within the recommended range and inspect its color and odor. Fresh fluid should have a clear red or amber tint, without a burnt smell. Replace or top up the fluid as needed to maintain optimal performance and prevent internal wear.

Inspecting Linkages and Connections

Another important step involves examining the shift linkages and connections. Loose or misaligned components can disrupt gear shifting, leading to transmission issues. Carefully check each connection point and linkage, adjusting or tightening as necessary to maintain smooth operation. This can enhance gear engagement and reduce unnecessary strain on the transmission system.

By following these inspection tips, drivers can help sustain their vehicle’s reliability and performance, making each journey smoother and more efficient.

Brake System Troubleshooting Techniques

Understanding effective techniques for diagnosing brake system issues is crucial for maintaining vehicle safety. Identifying the root causes of brake problems ensures that the necessary adjustments or replacements are accurately applied, restoring proper function and performance.

Common Brake System Issues: Brake systems can develop various issues over time, from unusual noises to decreased stopping power. Common warning signs include squealing or grinding sounds, inconsistent pedal feel, or a noticeable decrease in braking efficiency. Recognizing these indicators early can prevent more extensive damage.

Step-by-Step Diagnostic Process: To diagnose brake problems, begin with a visual inspection of key components such as the brake pads, rotors, and calipers. Examine for wear, warping, or any signs of fluid leaks. Testing brake response and pedal pressure can further reveal underlying issues. Utilizing these methods systematically helps in identifying specific areas in need of attention.

Tools and Tips for Accurate Troubleshooting: Employing the right tools, including a brake bleeder and torque wrench, enhances accuracy in troubleshooting. Keeping the brake fluid at optimal levels, regularly inspecting for air in brake lines, and ensuring all connections are secure are essential for maintaining a fully functional brake system.

Electrical System Repair Overview

The vehicle’s electrical system is integral to its overall functionality, supplying power to key components and enabling reliable performance. This section offers a concise guide for maintaining and troubleshooting various parts of the system to ensure optimal vehicle operation.

Main Components of the Electrical System

Understanding the primary elements of the electrical system is essential before beginning any maintenance. These components play a crucial role in delivering power and facilitating connectivity throughout the vehicle.

- Battery: The primary source of energy, responsible for powering essential functions.

- Alternator: Maintains battery charge and supplies current to electrical systems while the engine is running.

- Starter Motor: Engages the engine for ignition.

- Fuse Box: Houses fuses that protect various circuits from overloads.

Common Electrical System Issues

Electrical issues may arise over time due to wear, environmental exposure, or other factors. Recognizing these common issues can help in addressing them effectively.

- Dim or Flickering Lights: Often caused by a weak battery or faulty connections.

- Slow Engine Start: Potentially due to a worn starter motor or reduced battery power.

Cooling System Maintenance Guide

Proper upkeep of the cooling system is crucial for optimal engine performance and longevity. This section focuses on essential practices that help maintain an efficient cooling system, preventing overheating and ensuring that your vehicle operates smoothly under various conditions.

Regular Inspections

Routine checks of the cooling components can help identify potential issues before they escalate. Inspect the radiator, hoses, and water pump for any signs of wear, leaks, or damage. Additionally, verify that the coolant levels are adequate and that the fluid is clean. Regular maintenance is vital to avoid costly repairs and extend the lifespan of the engine.

Coolant Replacement

Over time, coolant can become contaminated or lose its effectiveness. It is important to replace the coolant at recommended intervals to maintain its protective properties. Flushing the system ensures that old fluid is removed, and fresh coolant is introduced, enhancing the cooling system’s performance and preventing corrosion within the engine components.

Fuel System Repair Procedures

The fuel system is a crucial component of any vehicle, ensuring the proper delivery of fuel to the engine for optimal performance. Addressing issues within this system is essential for maintaining efficiency and reliability. This section outlines the necessary steps and techniques for diagnosing and fixing common problems related to fuel delivery and management.

Diagnosis of Fuel System Issues: Begin by identifying symptoms such as poor engine performance, difficulty starting, or unusual fuel consumption. Utilizing diagnostic tools can help pinpoint issues with the fuel pump, filters, or injectors. A thorough inspection of fuel lines for leaks or blockages is also recommended.

Fuel Filter Replacement: Regularly changing the fuel filter is vital for maintaining clean fuel flow. To replace the filter, relieve the fuel pressure, disconnect the negative battery terminal, and carefully remove the old filter. Install the new filter in the correct orientation and reconnect the fuel lines, ensuring all connections are secure.

Fuel Pump Testing: To check the functionality of the fuel pump, listen for its operation when the ignition is turned on. If no sound is heard, further testing may be required. This includes checking electrical connections, fuses, and voltage supply to the pump. If necessary, replace the pump following manufacturer specifications.

Injector Cleaning: Over time, fuel injectors can become clogged, affecting engine performance. Cleaning can be done using specialized cleaning solutions or by removing the injectors for ultrasonic cleaning. Ensure all components are reinstalled properly to prevent leaks.

Following these procedures can help maintain the fuel system’s integrity, enhancing the vehicle’s overall functionality and longevity.

Suspension and Steering Adjustments

Properly tuning the suspension and steering components is crucial for achieving optimal vehicle handling and comfort. This section delves into the various adjustments that can enhance the performance and longevity of these systems.

Key aspects to consider include:

- Alignment: Ensuring the wheels are properly aligned can improve steering responsiveness and tire wear.

- Ride Height: Adjusting the height of the suspension can affect vehicle stability and comfort.

- Shock Absorbers: Evaluating and replacing worn shock absorbers can enhance ride quality and control.

- Sway Bars: Adjusting or replacing sway bars can reduce body roll during cornering.

To effectively implement these adjustments, follow these general guidelines:

- Inspect all components for wear and damage before making adjustments.

- Utilize appropriate tools and follow manufacturer specifications for precise measurements.

- Test drive the vehicle after adjustments to ensure improvements in handling and comfort.

- Regular maintenance checks will help maintain optimal performance over time.

By regularly assessing and fine-tuning these systems, one can ensure a safer and more enjoyable driving experience.

Exhaust System Checks and Fixes

Maintaining optimal performance of the exhaust system is crucial for the overall functionality of any vehicle. Regular inspections help identify potential issues such as leaks, blockages, or corrosion that can negatively impact engine efficiency and emissions. Proper diagnostics can enhance performance and prolong the lifespan of various components.

Begin by examining the exhaust pipes for visible signs of rust or damage. Any holes or cracks can lead to leaks, which not only affects performance but also poses safety hazards. Ensure all connections are secure and inspect the hangers that support the system, as these can wear over time and lead to misalignment.

Next, check the muffler for any unusual sounds or vibrations. A malfunctioning muffler can cause increased noise levels and may indicate underlying problems. Additionally, inspecting the catalytic converter is essential, as its failure can lead to increased emissions and decreased engine efficiency. If any blockage is suspected, consider using a professional cleaning service or replacing the component if necessary.

Lastly, ensure that all seals and gaskets are in good condition. Replacing worn or damaged seals can prevent exhaust leaks and enhance overall performance. Regular maintenance and prompt repairs are key to keeping the exhaust system functioning efficiently.

Interior Features Maintenance Tips

Proper care of the interior components can significantly enhance the overall experience and longevity of your vehicle. Regular attention to these features not only maintains their appearance but also ensures optimal functionality.

Begin with the upholstery by vacuuming regularly to remove dirt and debris. For stains, use a suitable cleaner that matches the fabric type, applying it gently to avoid damage. Protecting the seats with covers can also prevent wear and tear.

Keep the dashboard and control panels clean by using a microfiber cloth and an appropriate cleaning solution. Avoid harsh chemicals that can cause fading or cracking. Additionally, consider using UV protectants to shield surfaces from sun damage.

Ensure that all electronic components are functioning correctly by checking connections and performing updates as necessary. Regularly inspect the sound system and navigation features for any performance issues and address them promptly.

Lastly, maintain a pleasant atmosphere inside the vehicle by regularly changing cabin air filters and using air fresheners as needed. This will help create a comfortable and inviting environment for all occupants.

Exterior Care and Preservation

Maintaining the outer surface of your vehicle is essential for ensuring its longevity and aesthetic appeal. Proper care can prevent damage from environmental factors and enhance the overall value. This section outlines effective strategies to protect and preserve the exterior, ensuring it remains in optimal condition.

Regular Cleaning

Frequent washing is crucial to remove dirt, grime, and contaminants that can lead to corrosion and dullness. Follow these steps for effective cleaning:

- Use a gentle automotive soap and soft sponge to wash the surface.

- Rinse thoroughly to eliminate soap residues.

- Dry with a microfiber cloth to prevent water spots.

Protective Coatings

Applying protective products can shield the finish from UV rays and pollutants. Consider the following options:

- Waxing every three months to provide a barrier against environmental damage.

- Using sealants for longer-lasting protection, ideally every six months.

- Applying ceramic coatings for enhanced durability and shine.

Preventive Care for Longevity

Maintaining a vehicle in optimal condition is essential for ensuring its durability and performance over time. Regular attention to various components can significantly reduce the likelihood of unexpected breakdowns and costly repairs.

Routine inspections are vital for identifying potential issues before they escalate. Checking fluid levels, tire pressure, and brake functionality on a consistent basis can help in preserving overall functionality. Additionally, changing fluids at recommended intervals ensures that engine and transmission components operate smoothly.

Another important aspect is to monitor wear and tear on essential parts such as belts, hoses, and batteries. Replacing these components proactively can prevent inconvenient failures. Lastly, investing in regular professional evaluations not only enhances safety but also extends the lifespan of the vehicle.