2001 Hyundai Santa Fe Repair Manual Guide for DIY Maintenance and Repairs

Maintaining a well-functioning vehicle involves regular upkeep and understanding essential procedures to keep it in top condition. This guide provides an in-depth overview of various service techniques and tips for enhancing the longevity and performance of your car. Whether you’re a seasoned driver or a newcomer to auto care, this resource will serve as a valuable reference for keeping your vehicle running smoothly.

From handling common issues to understanding complex systems, each section is designed to clarify the steps involved in efficient and accurate car servicing. Emphasizing preventive care and troubleshooting, this guide enables readers to approach automotive tasks confidently and efficiently. Here, you’ll find guidance on diagnostics, key adjustments, and proactive steps to help you avoid unexpected challenges on the road.

With detailed instructions and expert recommendations, this guide empowers vehicle owners to approach every maintenance task with confidence. Gain insights into crucial processes that can save time, improve safety, and ultimately ensure a smoother driving experience. This is your go-to reference for learning about car care essentials and for enhancing your knowledge of the technical details that keep your vehicle dependable.

Comprehensive Guide to 2001 Hyundai Santa Fe Repairs

In this section, we explore key aspects of maintaining and fixing a widely-known midsize SUV model from the early 2000s. Whether addressing mechanical issues or routine upkeep, this guide aims to provide insights that help ensure the long-term performance and reliability of this vehicle. With a focus on common issues and practical tips, owners can approach troubleshooting with greater confidence and understanding.

Essential Maintenance Tips

Regular upkeep is crucial for extending the lifespan of your vehicle and minimizing unexpected issues. Fluid checks, brake inspections, and timely oil changes play a fundamental role in maintaining optimal performance. Additionally, staying attentive to early warning signs, such as unusual sounds or vibrations, can help prevent minor issues from developing into more significant concerns.

Common Troubleshooting Areas

This SUV model is known for several specific areas that may require extra attention over time. Frequent inspection of the engine components, transmission, and suspension parts can aid in identifying any issues early. Moreover, owners may encounter occasional electrical problems, making it essential to have a clear understanding of the vehicle’s core systems to address these effectively. By following a structured approach to care and addressing known issues promptly, owners can maintain their vehicle’s reliability and performance for years to come.

Essential Tools for Santa Fe Maintenance

Maintaining a vehicle requires specific tools that streamline the process, ensuring efficiency and precision in every task. Having the right equipment on hand not only makes upkeep easier but also enhances the safety and longevity of the vehicle. Here are some essential tools that every car owner should consider for routine maintenance.

Socket and Wrench Set: A comprehensive socket and wrench set is indispensable for reaching and loosening various bolts and nuts across different parts of the vehicle. Choose a set with multiple sizes to cover diverse needs and ensure compatibility with standard fasteners.

Jack and Stands: Safe and stable elevation of the car is crucial when working underneath it. A reliable hydraulic jack, combined with sturdy jack stands, provides the necessary support to safely access components like the exhaust or suspension system.

Torque Wrench: Precision is key when tightening bolts to prevent over-tightening or loose fittings. A torque wrench helps apply the correct force, which is especially important for engine and transmission-related tasks.

Oil Filter Wrench: Changing the oil regularly is fundamental to a vehicle’s upkeep, and an oil filter wrench allows for easy removal and replacement of the filter. Look for a design that provides a solid grip to avoid slipping.

Battery Tester: Monitoring the health of the car’s battery is essential for avoiding unexpected breakdowns. A battery tester enables quick diagnostics, providing insight into the charge level and overall condition of the battery.

Equipping your workspace with these fundamental tools ensures that essential maintenance can be done smoothly, promoting better vehicle performance and extending its service life.

Understanding Common Engine Issues

Engines are complex systems that require consistent attention to perform optimally. Over time, various factors can impact their efficiency, leading to issues that range from minor inconveniences to serious mechanical problems. Recognizing early symptoms and understanding frequent engine complications can help maintain performance and prevent costly repairs.

| Issue | Possible Cause | Solution |

|---|---|---|

| Overheating | Low coolant levels or faulty thermostat | Check coolant system; replace thermostat if needed |

| Rough Idling | Dirty fuel injectors or spark plugs | Clean or replace injectors and spark plugs |

| Power Loss | Faulty air filters or fuel delivery issues | Inspect and replace air filter; check fuel pump |

| Knocking Sounds | Incorrect fuel grade or worn bearings | Use correct fuel; inspect and replace bearings |

| Excessive Exhaust Smoke | Oil leaks or worn piston rings | Check for leaks; repair or replace piston rings |

Addressing these common issues promptly can extend engine life and ensure reliable performance. Regular maintenance and attention to warning signs play a crucial role in preventing these complications and sustaining vehicle health.

Transmission Troubleshooting for Hyundai Santa Fe

Transmission issues can significantly impact the performance and longevity of your vehicle. Understanding common signs and diagnostic methods can help identify underlying problems early, potentially preventing costly repairs. This section provides an overview of typical transmission problems and the steps to troubleshoot them, ensuring smoother operation and reliable performance on the road.

| Problem | Possible Cause | Suggested Solution |

|---|---|---|

| Delayed or Slipping Shifts | Low fluid levels or worn clutch components | Check transmission fluid levels and refill as necessary. Inspect for leaks or worn parts. |

| Grinding or Shaking | Internal mechanical damage or fluid contamination | Examine fluid condition. If it appears discolored or has metal particles, consider a fluid change or professional inspection. |

| Unusual Noises | Worn bearings, gears, or insufficient lubrication | Investigate for abnormal sounds, particularly when shifting gears. Lubricate or replace faulty components as needed. |

| Warning Light Activation | Faulty sensors or transmission overheating | Scan for diagnostic codes using an OBD-II tool to pinpoint the exact issue. Resolve as per recommended steps. |

Replacing the Timing Belt Correctly

The timing belt plays a crucial role in maintaining the engine’s synchronization, ensuring that internal components move in harmony. Over time, this belt can wear out, and its replacement becomes essential to prevent major engine issues. Proper timing belt replacement requires specific steps to achieve optimal alignment and function.

Preparation: Before starting, gather all necessary tools and a compatible replacement belt. Ensure the engine is completely cool to avoid potential hazards. Disconnect the battery to prevent accidental starts during the process.

Removing the Old Belt: Start by removing any components blocking access to the belt, such as covers and belts from auxiliary systems. Carefully mark the positions of the timing components, as these must remain in precise alignment when the new belt is installed.

Installing the New Belt: Position the new belt onto the pulleys, ensuring each mark aligns with its counterpart on the engine. Tighten any tensioners to the specified level, allowing the belt to sit firmly but not overly tight. Check that all components are secure before reassembling surrounding parts.

Final Check: Once everything is back in place, rotate the engine manually a few times to ensure proper alignment. Reconnect the battery and start the engine, listening for any unusual noises and verifying that the belt operates smoothly.

How to Fix Electrical Problems

Addressing issues related to the electrical system in your vehicle can be daunting, but with the right approach, it becomes manageable. Understanding how the various components interact is crucial for diagnosing and resolving faults effectively.

Start by examining the battery, as it is the heart of the electrical system. Ensure that the terminals are clean and securely connected. If the battery is weak or dead, consider replacing it with a new one. Next, check the fuses to identify any that may have blown. Replacing a faulty fuse can often restore functionality to inoperative systems.

Another important aspect is the wiring. Inspect the cables for any signs of damage, such as fraying or corrosion. Damaged wires can lead to intermittent issues or complete failures. If necessary, replace any damaged wiring to ensure a stable connection.

Additionally, the alternator plays a vital role in maintaining the electrical system’s health. Test the alternator output to confirm it is charging the battery adequately. If it is not functioning properly, consider replacing it to prevent future electrical complications.

Finally, if problems persist, utilizing a multimeter can help diagnose more complex issues. This tool allows you to measure voltage, current, and resistance, providing valuable insights into the health of the electrical system. By following these steps, you can effectively troubleshoot and rectify electrical challenges in your vehicle.

DIY Brake System Repairs

Maintaining the braking system is crucial for vehicle safety and performance. With some basic tools and knowledge, you can address common issues yourself, saving time and money. This section outlines essential tasks you can undertake to ensure your braking components are functioning optimally.

- Inspecting Brake Pads: Regularly checking the thickness of your brake pads can prevent uneven wear and potential damage to other components.

- Replacing Brake Fluid: Old or contaminated fluid can compromise braking efficiency. Flushing and replacing it can restore optimal performance.

- Bleeding the Brakes: Air trapped in the brake lines can lead to a spongy pedal feel. Bleeding the system removes air bubbles, ensuring a firm response.

By addressing these tasks, you not only enhance the vehicle’s safety but also extend the lifespan of the braking system.

Steps for Basic Brake Pad Replacement

- Gather necessary tools: a jack, lug wrench, socket set, and new brake pads.

- Lift the vehicle and remove the wheels.

- Unbolt the caliper and slide it off the rotor.

- Replace the old pads with new ones, ensuring they fit snugly.

- Reattach the caliper, secure it in place, and reinstall the wheels.

- Lower the vehicle and pump the brakes to ensure proper engagement.

Following these guidelines can help you effectively maintain your vehicle’s stopping power, enhancing both safety and driving experience.

Cooling System Inspection and Repair

The cooling system is a vital component that maintains optimal engine temperature, preventing overheating and ensuring efficient performance. Regular checks and maintenance are essential to identify potential issues early, which can save time and resources in the long run.

Common Signs of Cooling System Issues

It is crucial to recognize the indicators of a malfunctioning cooling system. Some common symptoms include:

| Symptom | Possible Cause |

|---|---|

| Overheating Engine | Low coolant levels, faulty thermostat, or a broken water pump |

| Coolant Leaks | Deteriorated hoses, loose clamps, or a cracked radiator |

| Unusual Engine Noise | Air trapped in the cooling system or a failing water pump |

Inspection and Maintenance Steps

To ensure the cooling system functions correctly, follow these inspection and maintenance steps:

- Check coolant levels and top up as needed.

- Inspect hoses and connections for wear and leaks.

- Examine the radiator for debris and obstructions.

- Test the thermostat to ensure it opens and closes correctly.

- Flush the cooling system at regular intervals to remove sediment and rust.

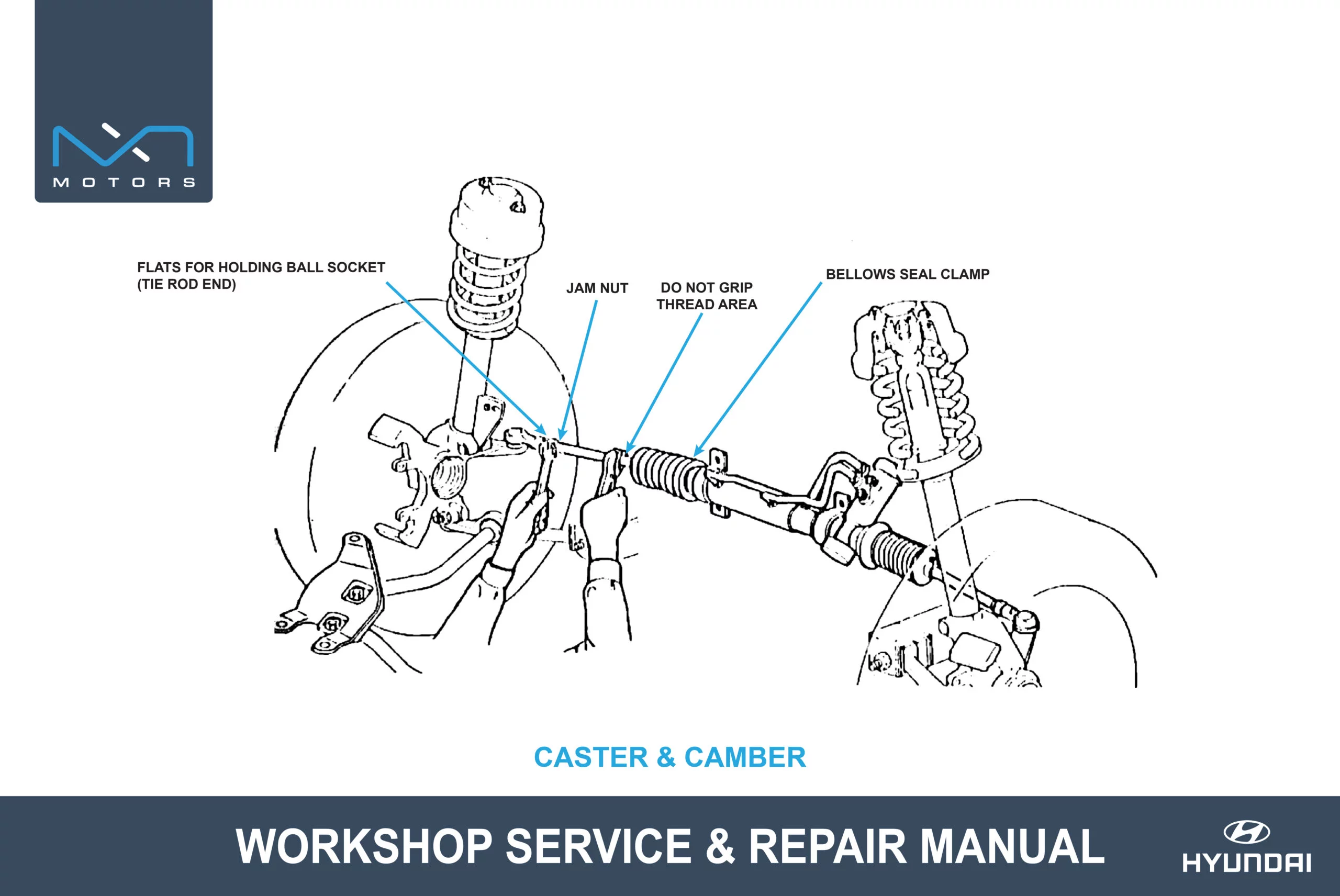

Suspension Check and Replacement Tips

Maintaining a vehicle’s suspension system is crucial for ensuring a smooth ride and overall safety. Regular inspection can help identify issues early, preventing costly repairs down the line. This section provides insights into checking and replacing various components of the suspension system effectively.

Key Components to Inspect

When examining the suspension, focus on the following elements:

| Component | Signs of Wear |

|---|---|

| Shock Absorbers | Leaking fluid, excessive bouncing |

| Control Arms | Cracks, rust, loose connections |

| Springs | Visible damage, sagging |

| Ball Joints | Clunking noise, excessive play |

Replacement Procedure

For component replacement, follow these steps to ensure proper installation:

- Gather necessary tools and parts.

- Lift the vehicle securely and remove the wheel.

- Disconnect the old component from its mountings.

- Install the new part, ensuring all bolts are tightened to manufacturer specifications.

- Reattach the wheel and lower the vehicle.

Fuel System Maintenance and Cleaning

The proper upkeep of the fuel system is essential for optimal vehicle performance and longevity. Regular maintenance not only enhances efficiency but also helps prevent costly repairs in the long run. This section outlines the key practices for maintaining and cleaning the fuel system effectively.

- Routine Inspections: Regularly check fuel lines and connections for any signs of wear or leaks. Look for cracks, fraying, or corrosion that could compromise the system’s integrity.

- Fuel Filter Replacement: Replace the fuel filter at recommended intervals to ensure that contaminants do not enter the fuel system. A clogged filter can lead to reduced engine performance.

- Fuel Injector Cleaning: Clean fuel injectors periodically to remove deposits that can hinder their function. Consider using a specialized cleaning solution or have them professionally serviced.

- Check Fuel Quality: Always use high-quality fuel to minimize the buildup of deposits. Poor-quality fuel can contain impurities that affect the entire system.

- Preventive Measures: Add fuel system cleaners to the tank as part of regular maintenance. These additives help dissolve carbon deposits and keep the injectors clean.

By following these maintenance practices, vehicle owners can ensure their fuel system operates efficiently, leading to better fuel economy and performance. Regular attention to these areas will help maintain the overall health of the vehicle.

Step-by-Step Oil Change Guide

Changing the engine lubricant is a fundamental maintenance task that enhances vehicle performance and longevity. This process ensures that the engine operates smoothly and efficiently by removing dirt and contaminants that accumulate over time.

Step 1: Gather all necessary supplies, including new lubricant, an oil filter, a wrench, an oil catch pan, and a funnel. Make sure to select the correct type and quantity of lubricant suitable for your vehicle’s engine.

Step 2: Start by parking the vehicle on a level surface and turning off the engine. Allow it to cool for a few minutes to ensure safety while working. Then, raise the front of the vehicle using jack stands for easier access to the undercarriage.

Step 3: Locate the oil drain plug underneath the engine. Position the oil catch pan beneath the plug and remove it using a wrench. Allow the old lubricant to completely drain into the pan.

Step 4: While the oil is draining, proceed to replace the oil filter. Locate the filter, and using an oil filter wrench, carefully remove it. Before installing the new filter, apply a small amount of new lubricant to the rubber gasket of the filter to ensure a proper seal.

Step 5: Install the new oil filter by twisting it into place until it is snug. Do not overtighten, as this can cause damage.

Step 6: Once the old lubricant has fully drained and the filter is replaced, reattach the drain plug securely. Use a wrench to tighten it appropriately, ensuring there are no leaks.

Step 7: Using a funnel, pour the new lubricant into the engine through the oil filler cap. Refer to the owner’s specifications for the correct amount of oil needed.

Step 8: After filling, replace the oil filler cap and start the engine. Allow it to run for a few moments and check for any leaks around the oil filter and drain plug.

Step 9: Finally, check the oil level using the dipstick. Add more lubricant if necessary, ensuring it remains within the recommended range.

Completing these steps will help maintain optimal engine performance and extend the life of your vehicle. Regular oil changes are crucial for preventing engine wear and ensuring a smooth driving experience.

Identifying Exhaust System Problems

The exhaust system plays a crucial role in the overall performance of a vehicle, and recognizing issues early can prevent further damage. A malfunctioning exhaust can lead to decreased fuel efficiency, increased emissions, and potential engine problems. Understanding the signs of exhaust system failures is essential for maintaining vehicle health.

Common Symptoms of Exhaust Issues

Several indicators may suggest a problem within the exhaust system. Observing these symptoms can help in early detection and resolution:

| Symptom | Description |

|---|---|

| Unusual Noises | Rattling, hissing, or loud exhaust sounds may indicate loose or damaged components. |

| Decreased Fuel Efficiency | A noticeable drop in miles per gallon may result from exhaust leaks affecting engine performance. |

| Strong Odors | Excessive fumes inside the cabin can be a sign of exhaust leaks, posing health risks. |

| Check Engine Light | An illuminated dashboard warning may suggest exhaust system failures, prompting a diagnostic check. |

Steps for Diagnosis

To accurately assess exhaust system issues, follow these diagnostic steps:

- Visually inspect the entire exhaust system for visible signs of damage, rust, or loose fittings.

- Listen for any unusual sounds while the engine is running, particularly during acceleration.

- Monitor fuel consumption patterns to identify any drastic changes.

- Utilize an OBD-II scanner to check for trouble codes associated with the exhaust system.

Preventative Care for Optimal Performance

Maintaining your vehicle through regular upkeep is essential for ensuring its longevity and efficiency. Proactive measures not only enhance functionality but also minimize the risk of costly repairs. By adhering to a consistent maintenance schedule, you can enjoy a smoother driving experience and extend the life of your automobile.

Routine inspections and servicing play a pivotal role in preventing unexpected breakdowns. Here are some key areas to focus on:

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Oil Change | Every 5,000 miles | Reduces engine wear and improves efficiency |

| Tire Rotation | Every 6,000 miles | Ensures even wear and extends tire life |

| Brake Inspection | Every 10,000 miles | Enhances safety and performance |

| Fluid Levels Check | Monthly | Prevents overheating and ensures smooth operation |

| Battery Inspection | Every 6 months | Avoids starting issues and enhances reliability |

By committing to these preventative care measures, you can ensure that your vehicle remains in optimal condition, providing a reliable and enjoyable driving experience for years to come.