Comprehensive Guide to Repairing John Deere LT160

This section serves as an essential resource for those seeking to enhance their understanding of lawn care machinery. With a focus on effective maintenance and troubleshooting techniques, the information provided aims to empower users to maximize the performance and longevity of their equipment.

From detailed procedural steps to practical advice, this guide covers various aspects that are crucial for ensuring optimal functionality. Whether you are facing minor issues or major challenges, the insights shared here will help you navigate through common problems with confidence.

Emphasizing the importance of regular upkeep, this resource highlights best practices that can prevent unnecessary wear and extend the lifespan of your machinery. By following the guidelines and recommendations, users can enjoy a smoother experience and achieve better results in their outdoor endeavors.

Overview of John Deere LT160

This section provides a comprehensive insight into a popular model of lawn care equipment known for its durability and efficiency. Designed to tackle a variety of outdoor tasks, this machine is equipped with features that enhance performance and user comfort.

The device boasts a powerful engine that ensures consistent operation, making it suitable for maintaining medium to large grassy areas. Its ergonomic design facilitates ease of use, allowing operators to maneuver effortlessly while ensuring optimal cutting precision.

Maintenance is straightforward, with accessible components that simplify servicing tasks. Users appreciate the robust construction that withstands the rigors of frequent use, ensuring longevity and reliability in various conditions.

Common Issues with LT160 Models

Many users encounter specific challenges with their garden machinery, often leading to performance issues or operational difficulties. Understanding these common concerns can help in diagnosing problems effectively.

Engine Performance: One frequent issue is related to engine functionality, which may exhibit symptoms such as stalling or difficulty starting. Regular maintenance and inspections are crucial for avoiding such setbacks.

Transmission Troubles: Users may also experience complications with the transmission system. Issues like slipping gears or unresponsive controls can hinder maneuverability, necessitating careful checks of the hydraulic components.

Electrical Failures: Electrical problems, such as faulty wiring or dead batteries, can disrupt operation. Regularly inspecting connections and ensuring battery health are essential practices for reliable performance.

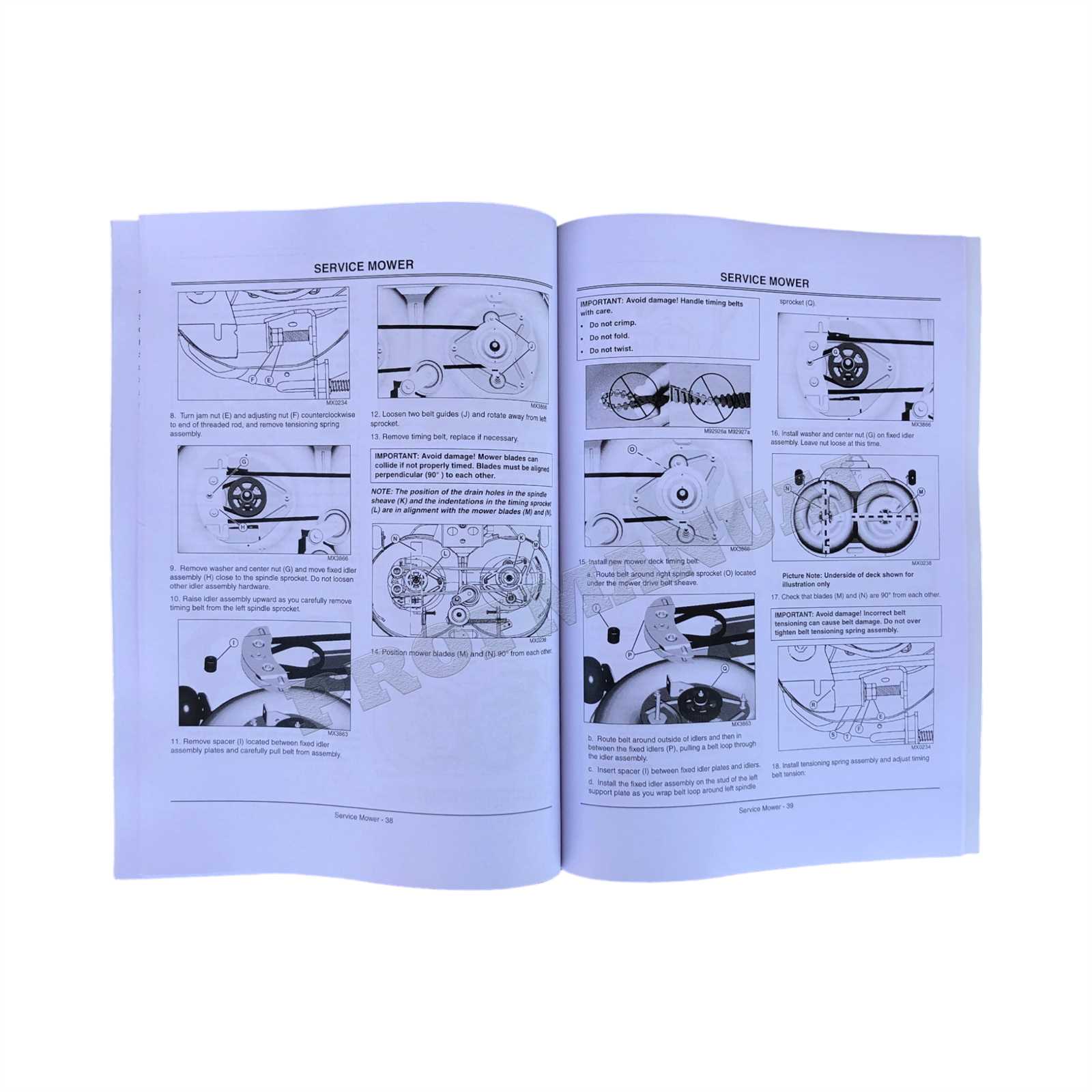

Deck Malfunctions: The cutting deck may present challenges, including uneven cuts or clogs. Ensuring proper blade alignment and cleaning can mitigate these issues significantly.

Maintenance Tips for Longevity

Ensuring the prolonged functionality of outdoor machinery requires consistent care and attention. Regular upkeep not only enhances performance but also significantly extends the lifespan of the equipment. This section provides essential guidance to maintain optimal condition and reliability.

Regular Inspection

Routine checks are crucial for identifying potential issues before they escalate. Focus on the following aspects during inspections:

| Component | Inspection Frequency | Common Issues to Look For |

|---|---|---|

| Engine | Every 50 hours | Oil leaks, unusual noises |

| Belts | Every 25 hours | Cracks, wear, tension |

| Filters | Every 100 hours | Clogs, dirt accumulation |

Routine Cleaning

Maintaining cleanliness is vital for optimal operation. Regularly clean the exterior and components to prevent debris buildup, which can hinder performance. Pay special attention to:

- Air intake areas

- Cooling systems

- Deck and chassis surfaces

Essential Tools for Repair Work

Successful maintenance and troubleshooting require a well-equipped toolkit. Having the right instruments at hand not only streamlines the process but also enhances the efficiency and accuracy of the tasks at hand. This section highlights crucial implements that every technician should consider incorporating into their arsenal.

Wrenches and Sockets: A comprehensive set of wrenches and socket drivers is indispensable for loosening and tightening various fasteners. These tools come in different sizes and styles, making them versatile for a wide range of applications.

Screwdrivers: Both flathead and Phillips screwdrivers are essential for disassembling components. Having a variety of sizes ensures that you can tackle screws of different dimensions without hassle.

Multimeter: This device is vital for diagnosing electrical issues. It allows users to measure voltage, current, and resistance, providing crucial insights into the functioning of electrical systems.

Safety Gear: Personal protective equipment, such as gloves and safety goggles, is paramount to ensure the technician’s safety while performing tasks. Investing in high-quality safety gear cannot be overlooked.

Equipping oneself with these fundamental tools lays the groundwork for effective maintenance work. By ensuring readiness and safety, technicians can perform their duties with confidence and precision.

Step-by-Step Troubleshooting Guide

This section provides a comprehensive approach to diagnosing common issues that may arise with your equipment. Following a structured process can help identify and resolve problems efficiently, ensuring optimal performance and longevity.

Identify the Symptoms

Begin by observing the behavior of the machine. Look for unusual sounds, erratic movements, or any warning indicators. Document these symptoms, as they will be crucial for diagnosing the issue.

Systematic Checks

Next, conduct a series of systematic checks. Start with the most accessible components and progress to more complex systems. This includes examining fluid levels, electrical connections, and mechanical parts. Ensure that everything is secure and functioning properly. If a specific part is identified as faulty, consider replacing it to restore functionality.

Engine Specifications and Features

This section provides an overview of the essential characteristics and functionalities of the engine used in this lawn care equipment. Understanding these specifications can significantly enhance the user experience and ensure optimal performance during operation.

Performance Attributes

The engine is designed for reliability and efficiency, offering a robust output that caters to various mowing conditions. Its design incorporates advanced engineering principles to maximize power while minimizing fuel consumption. Torque is another crucial aspect, enabling effective handling of challenging terrains.

Maintenance Considerations

Regular upkeep is vital for sustaining the engine’s performance over time. Key features include easy access to components for servicing and a design that supports routine checks without extensive disassembly. Understanding these elements can assist users in maintaining their equipment effectively.

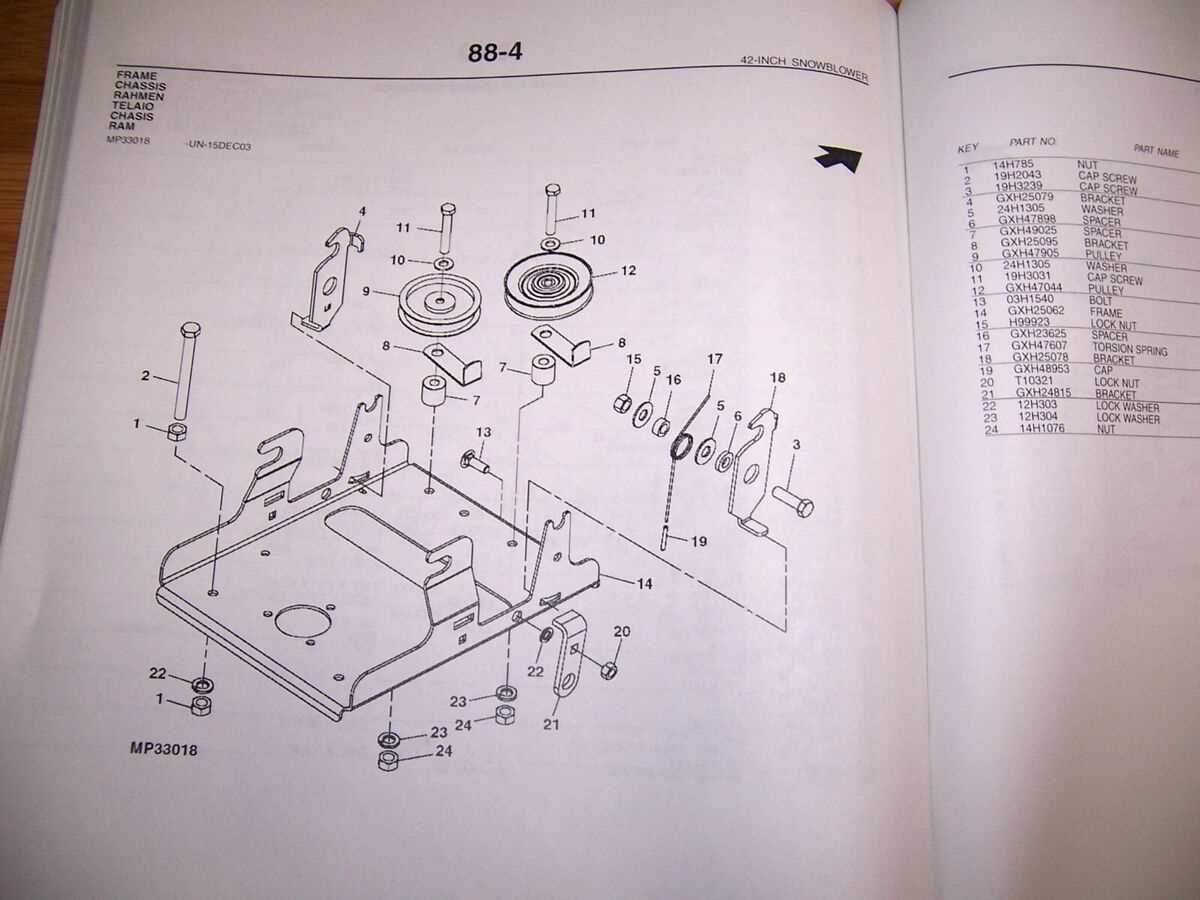

Replacing Components: A Practical Guide

Maintaining the longevity and efficiency of machinery often requires the replacement of various parts. This process ensures optimal performance and minimizes potential downtime. Understanding the steps involved in component substitution is essential for both novice and experienced operators.

Identifying Components for Replacement

Before initiating the replacement process, it is crucial to accurately identify which components need attention. Regular inspections can help determine wear and tear, allowing for proactive measures.

Steps for Component Substitution

Once the necessary parts are identified, follow these systematic steps to ensure a smooth replacement:

| Step | Description |

|---|---|

| 1 | Gather all required tools and new components. |

| 2 | Power down the equipment to prevent accidents. |

| 3 | Remove the old component, taking care to document any connections. |

| 4 | Install the new part, ensuring all connections are secure. |

| 5 | Test the equipment to confirm functionality. |

By following these guidelines, users can effectively manage the replacement of components, ensuring continued operation and reliability.

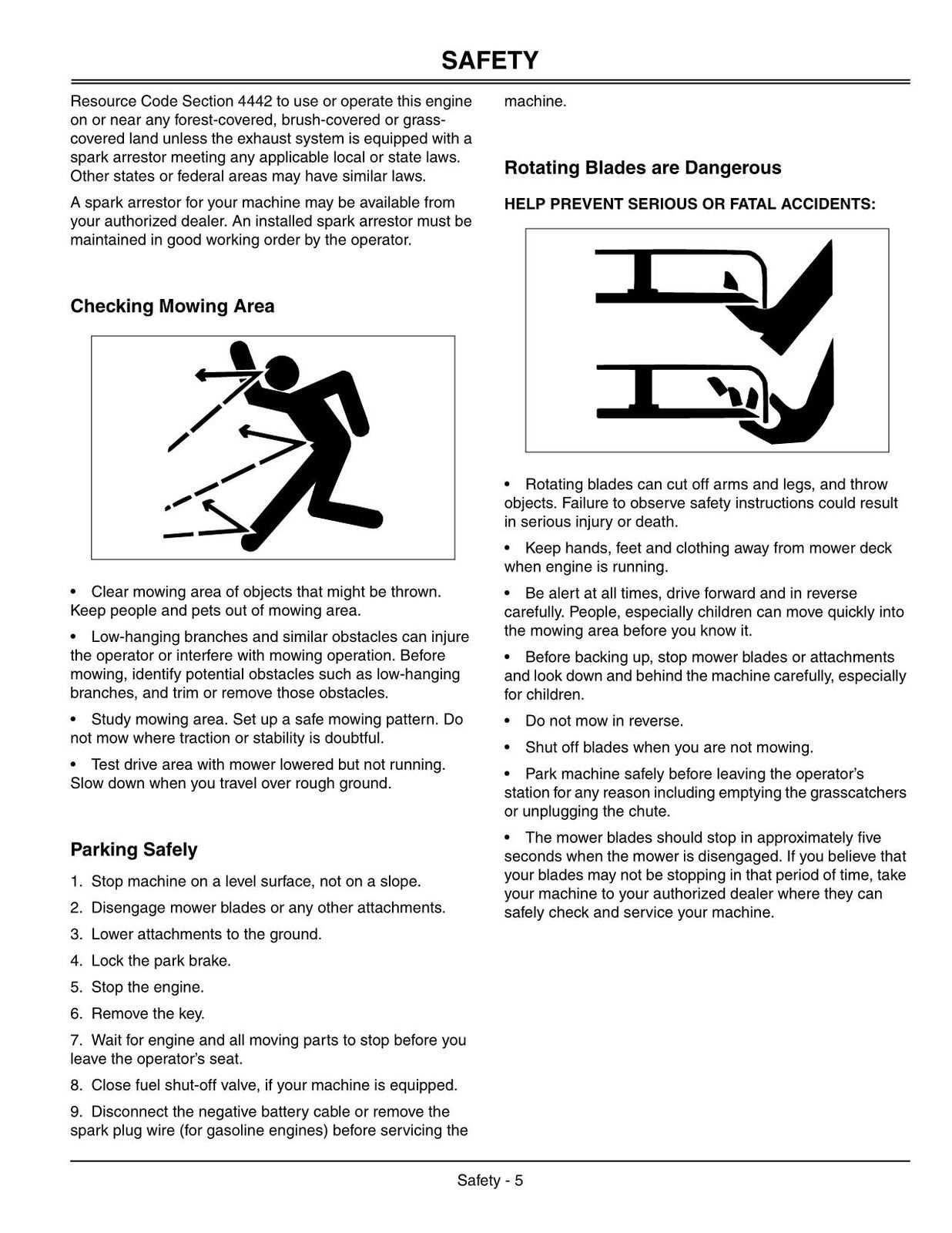

Safety Precautions During Repairs

When undertaking maintenance tasks on machinery, it is crucial to prioritize safety to prevent accidents and injuries. Proper precautions ensure that both the operator and the equipment remain unharmed during the servicing process. Understanding and implementing safety measures can greatly enhance the efficiency and effectiveness of maintenance activities.

Essential Safety Gear

Wearing appropriate protective equipment is vital for safeguarding oneself while working on machinery. The following table outlines the essential gear that should be utilized:

| Safety Equipment | Purpose |

|---|---|

| Safety Goggles | Protects eyes from debris and chemicals |

| Gloves | Prevents cuts and protects hands from hazardous materials |

| Steel-Toed Boots | Provides foot protection from heavy objects |

| Ear Protection | Reduces exposure to loud noise |

Work Area Considerations

Maintaining a clean and organized workspace is essential to minimize hazards. Ensure that the area is well-lit and free from clutter to reduce the risk of slips, trips, and falls. Additionally, keep all tools and equipment in designated places to avoid accidental injuries during the servicing process.

How to Change Oil Effectively

Regular maintenance is essential for optimal performance and longevity of your equipment. One of the most crucial tasks is the oil change, which ensures that the engine operates smoothly and efficiently. Understanding the proper steps to perform this task can prevent costly repairs and enhance the machine’s reliability.

Gather Necessary Tools and Supplies

Before starting, ensure you have all required tools and materials at hand. This includes a suitable oil filter, the correct type and amount of lubricant, a wrench, an oil pan, and a funnel. Having everything prepared will streamline the process and minimize mess.

Steps for an Effective Oil Change

Begin by warming up the engine slightly, as warm oil drains more easily. Next, position the oil pan under the drain plug and remove the plug, allowing the old lubricant to flow out completely. Once drained, replace the drain plug and tighten it securely. Remove the old filter and install the new one, making sure it’s properly seated. Finally, refill the engine with fresh oil, checking the level with the dipstick to ensure it is within the recommended range.

By following these steps diligently, you can maintain your equipment’s performance and extend its operational life.

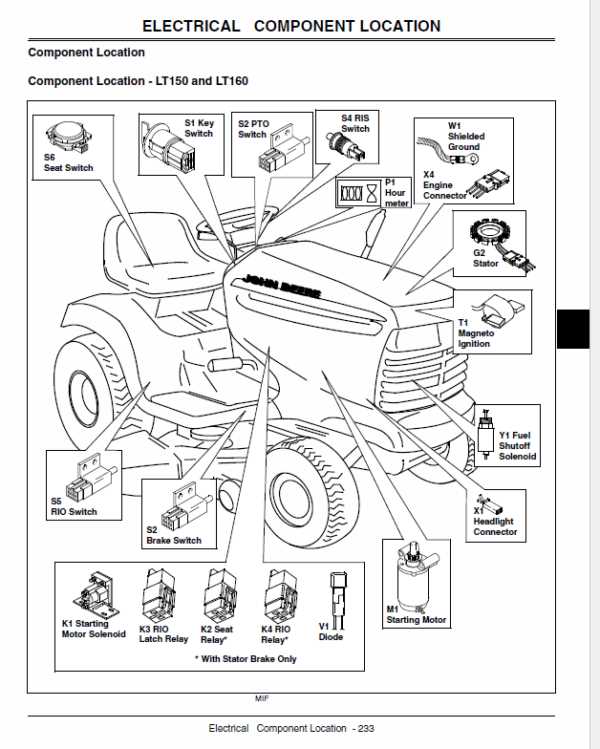

Understanding the Electrical System

The electrical framework of a machinery unit plays a crucial role in its overall functionality and performance. It encompasses various components that work together to ensure efficient operation and reliability. Familiarity with this system is essential for effective troubleshooting and maintenance.

This system typically includes the following key elements:

- Power Source: The origin of electrical energy, often from a battery or alternator.

- Wiring Harness: A network of wires that connects different electrical components, allowing them to communicate and function together.

- Control Modules: Electronic units that manage various functions, responding to input signals to regulate operations.

- Sensors: Devices that monitor specific parameters and provide data to the control modules for adjustments.

- Actuators: Components that convert electrical signals into mechanical motion, executing commands from the control system.

Understanding how these elements interact can enhance troubleshooting skills and lead to more effective maintenance practices. Regular inspections and diagnostics are recommended to identify potential issues before they escalate.

Recommended Replacement Parts

When maintaining outdoor machinery, choosing the right components is essential for ensuring optimal performance and longevity. Below are suggested replacement items that can enhance the functionality of your equipment.

| Part Name | Description | Recommended Brand |

|---|---|---|

| Air Filter | Helps keep the engine clean by filtering out dirt and debris. | Premium Brand A |

| Oil Filter | Essential for maintaining engine health by trapping contaminants in the oil. | Trustworthy Brand B |

| Spark Plug | Ensures reliable ignition and efficient engine operation. | Reliable Brand C |

| Belt | Transmits power from the engine to various components. | Durable Brand D |

| Battery | Powers electrical systems and starts the engine. | Trusted Brand E |

Customer Feedback and Repair Experiences

This section delves into the insights and testimonials provided by users regarding their experiences with maintenance and service procedures. By sharing individual accounts, potential owners can gain a clearer understanding of the common challenges and successful solutions encountered during upkeep.

Many users highlight the importance of having access to comprehensive support and resources, emphasizing that detailed documentation can significantly enhance the overall experience. Positive feedback often centers around effective troubleshooting techniques that simplify complex tasks, enabling users to tackle issues with confidence.

Additionally, some participants note the value of community forums, where sharing personal stories and tips can lead to innovative approaches for resolving problems. The exchange of information among peers not only fosters a sense of camaraderie but also provides practical insights that can prove beneficial for those navigating similar situations.

Where to Find Replacement Manuals

Locating alternative guides for equipment maintenance can be essential for ensuring optimal performance and longevity. Various resources are available for individuals seeking comprehensive documentation to assist in the upkeep of their machinery.

Online Resources

- Manufacturer’s Website: Official websites often provide downloadable versions or purchase options for replacement guides.

- Online Marketplaces: Websites like eBay or Amazon frequently list new and used copies of instructional literature.

- Specialized Forums: Community forums dedicated to specific equipment can be invaluable for obtaining copies shared by other users.

Local Options

- Dealerships: Authorized dealers typically stock printed versions and can assist with specific inquiries regarding documentation.

- Libraries: Local libraries may have technical books or can assist in accessing manuals through interlibrary loans.

- Repair Shops: Local service centers might offer printed guides or can direct you to where you can obtain them.