Kawasaki Mule 610 Maintenance Guide

In the world of versatile transportation solutions, the importance of understanding the upkeep and troubleshooting of your vehicle cannot be overstated. This section is dedicated to providing essential information that enhances your knowledge and ensures smooth operation.

Equipped with a range of features, these robust vehicles serve various purposes across diverse environments. Familiarizing yourself with the operational nuances will empower you to address common challenges efficiently, prolonging the lifespan of your machine.

By following the guidelines outlined here, you can navigate the intricacies of maintaining your vehicle with confidence. Whether you are a seasoned user or new to this type of machinery, the insights shared will help you maximize performance and minimize downtime.

This section addresses typical challenges encountered with utility vehicles and provides effective resolutions. Understanding these frequent problems can enhance the overall performance and longevity of your vehicle.

Engine Troubles

Issues related to engine performance can hinder functionality. Here are some common symptoms and their solutions:

- Hard starting: Check the battery condition and connections; ensure fuel is reaching the engine.

- Unusual noises: Inspect for loose components and ensure proper lubrication.

- Overheating: Examine the cooling system for leaks and check coolant levels.

Transmission Problems

Transmission issues can significantly affect drivability. Consider the following:

- Slipping gears: Verify fluid levels and inspect for leaks in the transmission system.

- Difficulty shifting: Check the linkage and adjust if necessary; ensure the transmission fluid is clean.

- Unresponsive accelerator: Look for issues in the throttle cable and make adjustments as needed.

Step-by-Step Repair Procedures

This section outlines a systematic approach to addressing issues encountered with the utility vehicle. By following a structured method, users can effectively troubleshoot and resolve common problems, ensuring the longevity and optimal performance of the equipment.

Begin by gathering the necessary tools and materials. A well-organized workspace will facilitate the process, allowing for efficiency and accuracy. Below is a table highlighting essential tools:

| Tool | Purpose |

|---|---|

| Wrench Set | For loosening and tightening fasteners |

| Screwdriver Set | For adjusting screws in various components |

| Multimeter | For checking electrical connections |

| Jack | For lifting the vehicle for better access |

| Cleaning Supplies | For maintaining and preparing surfaces |

Once the workspace is ready, identify the specific issue by performing a thorough inspection. Document any unusual sounds or behaviors, as this information will be crucial for effective troubleshooting. Follow the steps below to proceed:

- Check fluid levels and inspect for leaks.

- Test the battery and electrical systems for proper function.

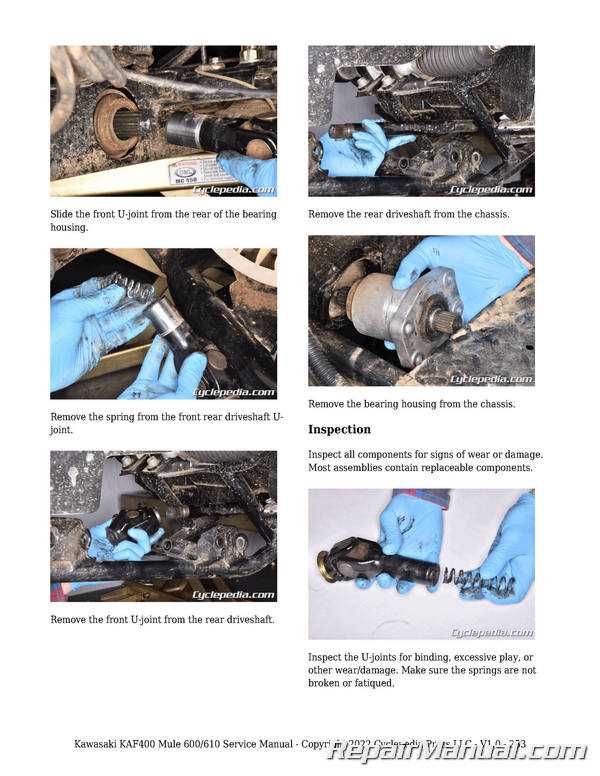

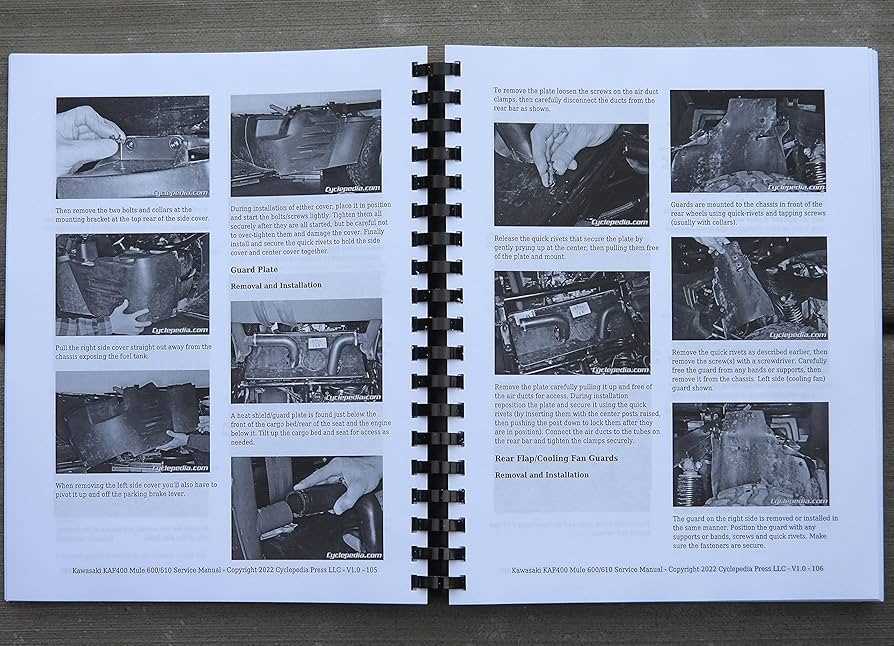

- Examine the drivetrain components for wear or damage.

- Adjust or replace any faulty parts as necessary.

- Perform a final inspection to ensure everything is secure and functioning correctly.

By adhering to this structured procedure, users can confidently address various issues, promoting safe and efficient operation of the vehicle.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance tasks is crucial for protecting both the individual performing the work and the equipment itself. Awareness of potential hazards and adherence to safety guidelines can significantly reduce the risk of accidents.

Before starting any maintenance activities, consider the following precautions:

- Always wear appropriate personal protective equipment, such as gloves, goggles, and sturdy footwear.

- Work in a well-ventilated area to prevent the accumulation of harmful fumes.

- Ensure that the engine is turned off and cooled down before beginning any procedures.

- Disconnect the battery to prevent accidental electrical discharge.

- Keep a fire extinguisher nearby in case of emergency situations.

By following these safety measures, you can create a secure working environment that minimizes risks and promotes effective maintenance.

Maintenance Schedule for Longevity

Ensuring the durability of your vehicle requires a consistent and well-structured maintenance plan. Regular upkeep not only enhances performance but also extends the lifespan of the machinery. Adhering to a scheduled routine helps in identifying potential issues before they escalate, promoting reliability in operation.

Here are essential maintenance tasks to consider:

- Regular Inspections: Conduct thorough checks of all systems, including brakes, engine, and electrical components.

- Fluid Levels: Regularly monitor and replace engine oil, coolant, and transmission fluid as needed.

- Filter Changes: Replace air and fuel filters at specified intervals to ensure optimal performance.

- Tire Care: Check tire pressure and tread depth frequently, rotating tires as recommended.

- Battery Maintenance: Inspect battery terminals for corrosion and ensure secure connections.

Following a comprehensive maintenance schedule will significantly contribute to the longevity and efficiency of your equipment, allowing for a smooth and enjoyable experience over time.

Parts Replacement Guidelines

Maintaining optimal performance of your vehicle involves timely and efficient component substitutions. Understanding the process and adhering to specific practices ensures longevity and reliability.

Assessment of Needs: Regularly inspect all parts for wear and tear. Identifying signs of damage early can prevent larger issues and enhance safety. Focus on areas that experience high stress or exposure to harsh conditions.

Selection of Quality Components: Always opt for high-quality substitutes that meet or exceed manufacturer specifications. Utilizing reliable parts contributes to the overall functionality and durability of the system.

Installation Procedures: Follow detailed installation protocols meticulously. Proper fitting and alignment are crucial for effective operation. Consider seeking assistance from professionals if unsure about the process.

Post-Replacement Checks: After replacing any parts, conduct thorough tests to ensure everything operates smoothly. Address any irregularities immediately to maintain performance and safety.

Troubleshooting Electrical Problems

Addressing issues within the electrical system is crucial for maintaining optimal performance and functionality of your vehicle. Understanding common symptoms and their underlying causes can aid in effective diagnosis and resolution of these problems.

Common Symptoms

Identifying specific indicators can help pinpoint electrical faults:

- Unresponsive ignition or starting difficulties

- Dim or flickering lights

- Erratic behavior of gauges and indicators

- Failure of accessories or electronic components

Diagnostic Steps

Follow these steps to systematically troubleshoot electrical issues:

- Inspect the battery connections for corrosion or looseness.

- Check fuses for continuity and replace any that are blown.

- Test the voltage output from the battery.

- Examine wiring for signs of wear, damage, or shorts.

By methodically following these guidelines, you can effectively identify and rectify electrical issues, ensuring reliable operation of your vehicle.

Engine Care and Upkeep

Maintaining optimal performance of your power unit is essential for longevity and efficiency. Regular attention to essential components ensures smooth operation and prevents unexpected issues that may arise from neglect. This section outlines key practices to enhance the durability of the engine.

Regular Maintenance Tasks

Routine checks and services play a crucial role in engine upkeep. Below is a table summarizing essential maintenance tasks:

| Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 100 hours | Replace engine oil to ensure proper lubrication. |

| Air Filter Inspection | Every 50 hours | Check and clean or replace the air filter as needed. |

| Coolant Level Check | Before each use | Ensure coolant is at the proper level to prevent overheating. |

Signs of Trouble

Being aware of potential issues can help mitigate serious problems. Look out for unusual sounds, performance drops, or fluid leaks, as these can indicate underlying complications that need immediate attention.

Transmission Service and Adjustments

Proper maintenance of the transmission system is essential for ensuring optimal performance and longevity of your vehicle. This section focuses on the necessary procedures and adjustments required to keep the transmission functioning smoothly.

Routine Inspection

Regular checks are crucial to identify any potential issues early on. Inspect fluid levels, look for leaks, and examine the condition of the fluid. A clean and adequately filled system helps maintain efficiency.

Adjustment Procedures

Making precise adjustments to the transmission settings can significantly enhance performance. Follow the manufacturer’s guidelines for proper alignment and tension settings to ensure a smooth driving experience.

Conclusion

Adhering to these service recommendations will not only improve functionality but also extend the lifespan of the transmission components. Regular maintenance is key to a reliable and efficient vehicle.

Cleaning and Care Tips

Maintaining your utility vehicle is essential for optimal performance and longevity. Regular cleaning and proper care help to ensure that all components function effectively, reducing wear and enhancing overall reliability. This section provides valuable insights into keeping your machine in top condition.

Regular Cleaning Routine

Establishing a consistent cleaning routine is crucial. Here are some recommended steps:

- Wash the exterior with mild soap and water to remove dirt and grime.

- Inspect and clean the wheels and tires to maintain traction.

- Ensure that the undercarriage is free from mud and debris.

Maintenance of Internal Components

Pay attention to the internal components to avoid mechanical issues:

| Component | Care Tips |

|---|---|

| Engine | Check oil levels regularly and replace as needed. |

| Filters | Inspect air and fuel filters and replace when dirty. |

| Batteries | Clean terminals and check connections for corrosion. |

Upgrading Performance Components

Enhancing the capabilities of your utility vehicle involves selecting and installing superior components that optimize its efficiency and overall functionality. By focusing on key areas such as the engine, suspension, and transmission, you can significantly improve performance and responsiveness.

Engine Modifications

Investing in engine upgrades can lead to noticeable improvements in power output and torque. Consider the following options:

- High-Performance Air Filters: These allow for better airflow, enhancing combustion efficiency.

- Performance Exhaust Systems: Upgrading the exhaust can reduce back pressure, leading to better engine performance.

- ECU Tuning: Modifying the engine control unit can optimize fuel delivery and ignition timing.

Suspension Enhancements

Improving the suspension system contributes to better handling and stability. Key upgrades include:

- Upgraded Shocks: High-quality shocks can provide improved dampening and comfort.

- Stiffer Springs: These can enhance the vehicle’s handling characteristics and load-carrying capacity.

- Adjustable Sway Bars: These allow for fine-tuning of the vehicle’s balance during turns.