Comprehensive Guide to John Deere 8420 Repair Manual

This section aims to provide essential insights and methodologies for the upkeep of advanced agricultural machinery. By adhering to established protocols and guidelines, users can enhance the longevity and efficiency of their equipment.

Understanding the intricate workings of complex machinery is crucial for optimal performance. This guide covers various aspects, from routine checks to troubleshooting techniques, ensuring that operators are well-equipped to handle common challenges.

Whether you are a seasoned professional or a novice, having access to detailed procedures is invaluable. The information presented here will empower users to perform necessary tasks with confidence, ultimately contributing to seamless operation and reduced downtime.

Overview of John Deere 8420

This section provides a comprehensive understanding of a well-known agricultural machine designed for various tasks. Recognized for its efficiency and power, this model is engineered to meet the demands of modern farming practices, offering reliability and advanced features.

Key Features

The equipment is equipped with a robust engine that delivers exceptional performance. Its state-of-the-art technology allows for optimal fuel efficiency while minimizing emissions. Additionally, the ergonomic design ensures operator comfort during extended use.

Applications

Ideal for a wide range of farming operations, this unit excels in tasks such as tilling, planting, and transporting materials. Its versatility makes it a preferred choice among farmers looking to enhance productivity on their land.

Key Features and Specifications

This section highlights the essential characteristics and technical specifications of the agricultural machinery model, focusing on its capabilities and performance metrics. Understanding these features is crucial for operators and technicians to maximize efficiency and ensure optimal functioning.

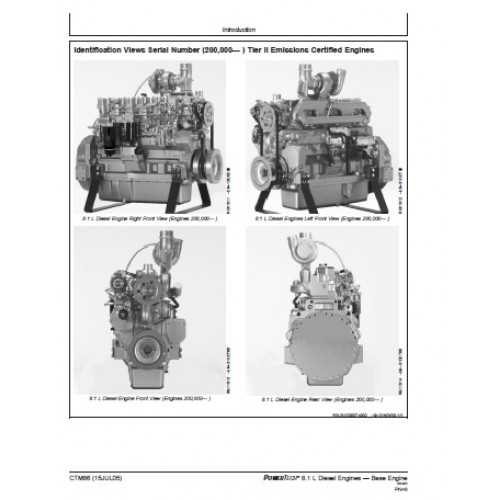

Engine and Performance

- Type: Diesel engine with advanced fuel efficiency.

- Power Output: Robust horsepower suitable for heavy-duty tasks.

- Torque: High torque levels for improved pulling capacity.

Dimensions and Capacity

- Overall Length: Optimized dimensions for maneuverability in various terrains.

- Weight: Significant mass providing stability during operations.

- Fuel Tank Capacity: Ample storage for extended operational periods without refueling.

Maintenance Tips for Optimal Performance

Ensuring the longevity and efficiency of your machinery requires regular upkeep and attention. By adhering to a structured maintenance routine, operators can significantly enhance performance and reduce the likelihood of unexpected breakdowns. The following guidelines will aid in maximizing the functionality and lifespan of your equipment.

| Task | Frequency | Details |

|---|---|---|

| Oil Change | Every 100 hours | Replace engine oil and filter to prevent sludge buildup and maintain engine efficiency. |

| Air Filter Inspection | Every 50 hours | Check and clean the air filter to ensure proper airflow and prevent dust from entering the engine. |

| Tire Pressure Check | Weekly | Monitor tire pressure to ensure optimal traction and prevent uneven wear. |

| Fuel System Cleaning | Every 200 hours | Use a fuel additive to clean injectors and improve combustion efficiency. |

| Hydraulic Fluid Check | Monthly | Inspect hydraulic fluid levels and top off as necessary to ensure smooth operation. |

By following these maintenance recommendations, operators can maintain peak efficiency and reduce the risk of costly repairs. Regular attention to these areas will not only enhance performance but also ensure safe and reliable operation.

Common Issues and Troubleshooting Guide

This section aims to address frequent challenges encountered with specific agricultural machinery, providing insights into identification and resolution. Understanding these common problems can significantly enhance operational efficiency and prolong the lifespan of the equipment.

Engine Performance Problems

One of the primary concerns operators face involves engine functionality. Symptoms may include unusual noises, reduced power output, or difficulty starting. Regular maintenance, such as checking fuel quality and ensuring proper air intake, can mitigate these issues. If problems persist, consulting technical specifications may be necessary.

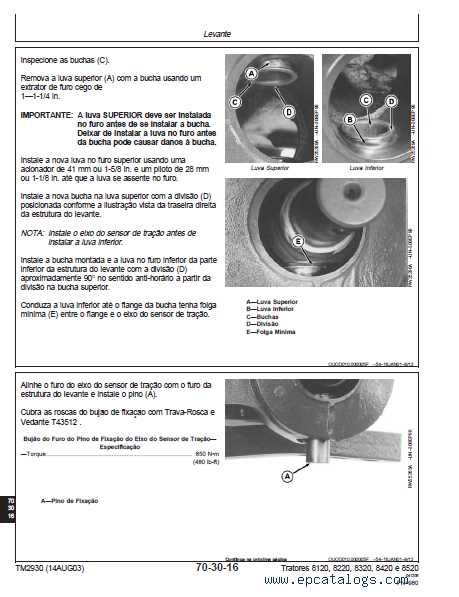

Hydraulic System Failures

Hydraulic malfunctions are another prevalent issue, often indicated by slow or erratic actuator movement. Inspecting fluid levels and examining for leaks are essential first steps. Additionally, ensuring that filters are clean and components are free from damage can help restore optimal performance.

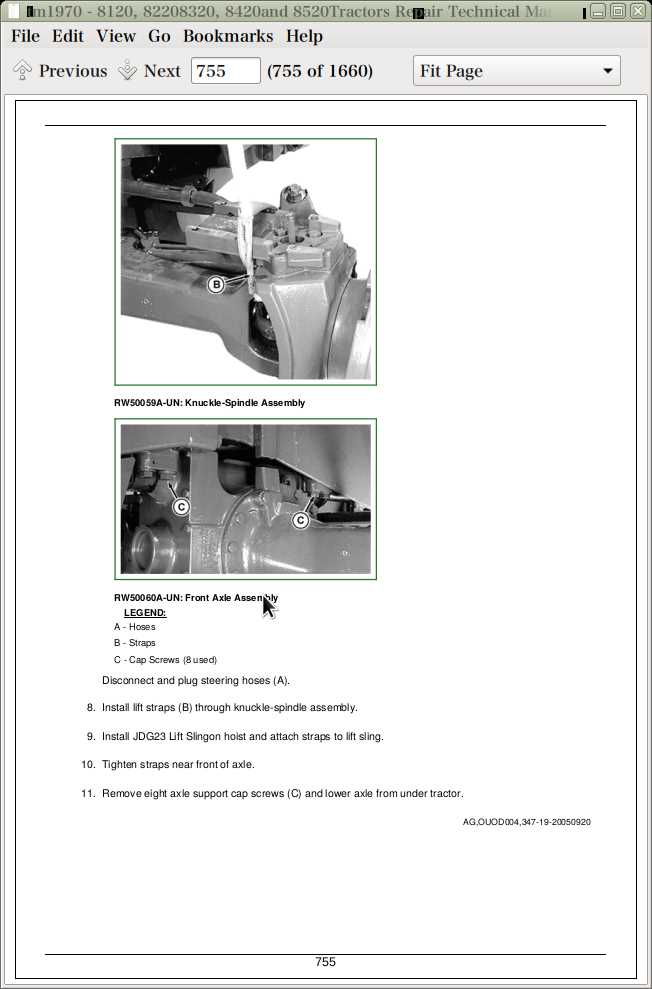

Step-by-Step Repair Procedures

This section provides a comprehensive guide to addressing common issues that may arise in heavy machinery. Following a systematic approach can ensure efficient resolution and optimal performance of the equipment.

Essential Tools and Materials

- Wrenches and sockets

- Screwdrivers

- Diagnostic tools

- Replacement parts

- Lubricants and cleaning agents

Procedure Overview

- Begin by conducting a thorough inspection of the machinery to identify any visible wear or damage.

- Gather all necessary tools and materials before proceeding to disassembly.

- Carefully remove components, following the sequence outlined in the specifications to avoid complications.

- Inspect each part for signs of deterioration and replace any that do not meet operational standards.

- Reassemble components in reverse order, ensuring all connections are secure and properly aligned.

- Perform a final check to confirm that all tools have been removed from the work area.

- Test the equipment to ensure it operates correctly and efficiently.

Essential Tools for Repairs

Effective maintenance requires a selection of indispensable instruments that enhance efficiency and accuracy. Utilizing the right equipment can significantly simplify tasks and ensure quality outcomes.

Wrenches are fundamental for loosening and tightening bolts. A variety of sizes, including adjustable and socket types, will cater to different needs.

Ratchet Sets provide versatility, allowing for quick adjustments in tight spaces. Their design enables rapid engagement and disengagement of fasteners.

Screwdrivers come in various shapes and sizes, ensuring compatibility with a wide range of screws. Both flathead and Phillips types are essential for numerous applications.

Pliers are invaluable for gripping, twisting, and cutting wires. Needle-nose and locking varieties can offer additional leverage and precision.

Torque Wrenches are crucial for applying the correct amount of force when fastening. This ensures components are secured without the risk of damage.

Having a well-rounded toolkit not only streamlines the process but also contributes to longevity and optimal performance of the machinery.

Safety Precautions During Maintenance

Ensuring a safe environment during upkeep procedures is crucial for both personnel and equipment. Adhering to specific guidelines can significantly reduce the risk of accidents and injuries while enhancing the efficiency of the maintenance process.

Personal Protective Equipment

Wearing appropriate personal protective gear is essential. This includes safety goggles, gloves, and sturdy footwear to protect against potential hazards. Additionally, utilizing ear protection in noisy environments helps prevent hearing damage.

Proper Tool Handling

Using tools correctly is vital for safe maintenance practices. Always ensure that tools are in good condition and suitable for the task at hand. Regularly inspect equipment to prevent malfunctions that could lead to accidents.

Understanding the Hydraulic System

The hydraulic system is a vital component in agricultural machinery, playing a crucial role in the operation of various functions. This system utilizes fluid under pressure to transmit power, enabling the equipment to perform tasks efficiently. A comprehensive understanding of this mechanism is essential for optimizing performance and ensuring reliability.

At its core, the hydraulic system consists of several key elements, including pumps, cylinders, and valves. Pumps are responsible for generating the pressure required to move the hydraulic fluid, while cylinders convert this fluid pressure into mechanical force. Valves control the flow and direction of the fluid, allowing for precise operation of attachments and implements.

Regular maintenance and timely inspection of the hydraulic system are necessary to prevent issues such as leaks, pressure drops, and component failures. Understanding the principles of operation and common problems associated with hydraulics will enhance the longevity and effectiveness of the machinery.

Electrical Components and Diagnostics

This section provides an overview of essential electrical elements and their diagnostic procedures, ensuring optimal performance and reliability of the equipment. Understanding these components is crucial for effective troubleshooting and maintenance.

Key Electrical Parts

Various electrical components play a vital role in the functionality of machinery. These include sensors, relays, and controllers, each serving specific purposes in the system. Familiarity with these parts enables users to identify issues quickly and perform necessary repairs.

Diagnostic Techniques

Effective diagnostics involve systematic approaches to pinpoint electrical failures. Utilizing tools such as multimeters and oscilloscopes can aid in analyzing signals and voltages. Regular testing and monitoring of electrical systems enhance reliability and prevent unexpected breakdowns.

Upgrading and Modifying Your Tractor

Enhancing the capabilities and performance of your agricultural vehicle can lead to significant improvements in efficiency and productivity. Whether you are looking to boost horsepower, improve fuel efficiency, or add new functionalities, careful planning and execution are essential for successful modifications.

Performance Enhancements

Increasing the power output of your tractor can be achieved through various means, such as upgrading the engine components or installing performance chips. Additionally, optimizing the air intake and exhaust systems can enhance overall efficiency. Here are some common performance upgrades:

| Upgrade Type | Description |

|---|---|

| Turbocharger | Increases engine power by forcing more air into the combustion chamber. |

| High-Performance Exhaust | Reduces back pressure and enhances engine breathing. |

| ECU Remapping | Adjusts the engine control unit settings for improved power and efficiency. |

Adding New Features

Incorporating additional tools and accessories can further enhance the versatility of your vehicle. Consider options such as GPS guidance systems, precision farming technology, or advanced hydraulic systems. These modifications can provide better control and data insights during operations.

Resources for Further Learning

For those seeking to deepen their understanding of agricultural machinery maintenance and troubleshooting, a variety of educational materials are available. These resources encompass books, online courses, and forums where enthusiasts and professionals share their expertise.

Books and Publications: Numerous guides and literature focus on the principles of machinery operation, maintenance techniques, and troubleshooting methods. These texts often provide detailed illustrations and step-by-step procedures, making them invaluable for hands-on learners.

Online Courses: Various platforms offer structured learning experiences tailored to machinery operation and upkeep. These courses often include video tutorials, quizzes, and community support, allowing participants to learn at their own pace.

Discussion Forums: Engaging with online communities can provide insights into common issues and innovative solutions. These platforms enable users to exchange knowledge, seek advice, and share experiences related to machinery management.

Utilizing these resources can significantly enhance one’s proficiency in machinery care and support long-term operational efficiency.