Complete Guide to Repairing the Pfaff 1222 Sewing Machine

For enthusiasts and professionals alike, a well-functioning stitching device is essential for achieving high-quality results in textile projects. Over time, these intricate machines may require attention to ensure optimal performance. Understanding how to troubleshoot and maintain your equipment is vital for both longevity and efficiency.

The intricacies of these devices can sometimes lead to common issues that users encounter during operation. Familiarizing oneself with the various components and mechanisms not only aids in resolving problems but also enhances the overall sewing experience. Regular upkeep, including cleaning and adjustments, plays a crucial role in preventing malfunctions.

In this guide, we will delve into practical steps and insights to help you navigate through the intricacies of your sewing apparatus. By following these tips, you can confidently tackle challenges and keep your machine in peak condition, ensuring that it continues to serve you well for years to come.

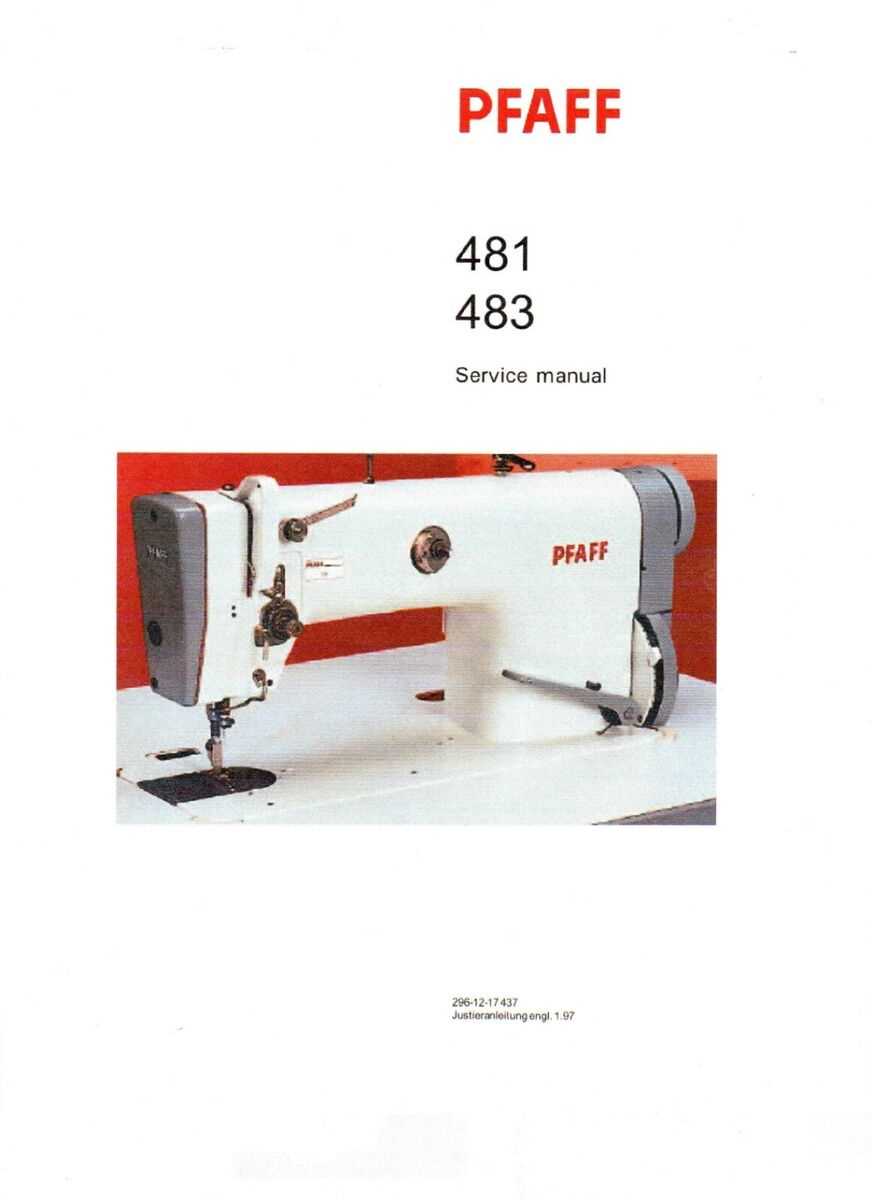

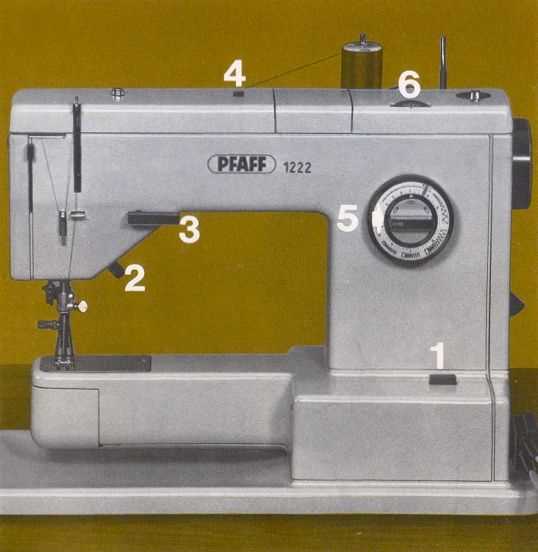

Understanding the Pfaff 1222 Model

This section delves into the intricacies of a renowned sewing machine, highlighting its features, functionalities, and the unique attributes that set it apart in the world of textile crafting. This model is celebrated for its reliability and versatility, making it a favored choice among both amateur and professional users.

One of the most notable aspects of this sewing device is its robust construction, which ensures longevity and consistent performance. The machine’s intuitive design simplifies the sewing process, allowing users to navigate various projects with ease. Its advanced stitch options cater to a wide range of sewing techniques, enhancing creativity and efficiency.

Additionally, the ergonomic layout of controls promotes user-friendly operation, while the attention to detail in engineering minimizes potential issues. Understanding the operational mechanics of this device can empower users to maximize its potential and maintain its excellent performance over time.

Overall, this model embodies a blend of innovation and tradition, making it a vital tool for anyone passionate about sewing and crafting. Exploring its features can lead to greater appreciation and more successful sewing endeavors.

Common Issues with the Pfaff 1222

Every sewing machine can encounter certain challenges during its lifespan, affecting performance and user experience. Understanding these frequent problems can help enthusiasts maintain their devices more effectively and prolong their functionality.

Thread Jamming: One of the most prevalent concerns is thread jamming, often caused by improper threading or incorrect tension settings. This can lead to frustrating interruptions during sewing projects.

Uneven Stitch Quality: Users may notice inconsistent stitch quality, which can be attributed to dull needles, incorrect stitch length settings, or the type of fabric being used. Regularly replacing needles and adjusting settings can help mitigate this issue.

Bobbin Issues: Problems with the bobbin, such as misalignment or improper winding, can lead to complications in stitching. Ensuring that the bobbin is correctly installed and wound can resolve many related concerns.

Noise During Operation: Excessive noise can signal mechanical wear or insufficient lubrication. Regular maintenance, including oiling moving parts, can reduce operational noise and improve overall performance.

Electrical Malfunctions: Occasionally, electrical components may fail, leading to issues such as unresponsive controls or inconsistent power. Troubleshooting these problems often requires careful inspection of wiring and connections.

By being aware of these common issues, users can take proactive steps to maintain their machines, ensuring smooth and enjoyable sewing experiences.

Essential Tools for Repairs

When tackling any machine maintenance task, having the right set of instruments is crucial for achieving optimal results. These tools not only facilitate the process but also enhance precision and efficiency. A well-equipped toolkit can make all the difference in ensuring smooth operation and longevity of the device.

Basic Hand Tools: A collection of hand tools forms the foundation of any maintenance endeavor. Essential items include screwdrivers, pliers, and wrenches, which allow for easy adjustments and replacements. It’s important to have a variety of sizes to accommodate different components.

Specialized Equipment: Depending on the complexity of the task, certain specialized tools may be necessary. This can include stitch gauges for measuring tensions or electronic testers for assessing functionality. Investing in quality equipment can significantly simplify the troubleshooting process.

Lubricants and Cleaners: Maintaining the internal workings is essential for preventing wear and tear. Appropriate lubricants reduce friction, while specialized cleaners help maintain optimal performance by removing dust and debris. Always choose products that are compatible with the specific machinery.

Organizational Supplies: Keeping your workspace tidy is vital for an efficient workflow. Utilizing containers, labels, and tool organizers helps to easily access necessary items, minimizing downtime during projects. A well-structured setup can lead to a more productive experience.

By assembling a comprehensive toolkit that includes these essential instruments, any user can confidently approach maintenance tasks. Proper preparation not only streamlines the process but also ensures that the equipment remains in peak condition for years to come.

Step-by-Step Troubleshooting Guide

This section provides a systematic approach to diagnosing common issues encountered with sewing machines. By following a structured method, users can identify problems and implement effective solutions, ensuring smooth operation and optimal performance.

Step 1: Identify the Issue

Begin by observing the machine during operation. Listen for unusual sounds and watch for any irregularities in stitching. Common concerns may include skipped stitches, thread jams, or inconsistent tension.

Step 2: Check the Basics

Ensure the machine is properly plugged in and powered on. Verify that the foot pedal is functioning and that the machine is set to the correct settings for the fabric and type of stitch being used.

Step 3: Inspect the Threading

Examine the threading of both the upper and lower threads. Incorrect threading can lead to various problems. Rethread the machine according to the manufacturer’s guidelines, ensuring that the thread paths are followed accurately.

Step 4: Examine the Needle

A damaged or dull needle can cause issues such as skipped stitches or fabric damage. Replace the needle if it appears bent or worn. Ensure the needle is inserted correctly and suitable for the fabric type.

Step 5: Adjust the Tension

Tension settings significantly impact stitching quality. Test different tension settings to find the optimal configuration for the fabric being used. Remember that different fabrics may require adjustments.

Step 6: Clean the Machine

Dirt and lint buildup can hinder performance. Regularly clean the bobbin area, feed dogs, and surrounding parts. Use a brush and compressed air to remove debris, ensuring the machine operates smoothly.

Step 7: Consult the Documentation

If problems persist, refer to the provided documentation for troubleshooting tips specific to your model. This can offer insights into less common issues and their resolutions.

Step 8: Seek Professional Help

If all else fails, consider contacting a qualified technician. They possess the expertise to diagnose and fix complex issues that may not be easily resolved through basic troubleshooting.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the enduring performance of your sewing equipment. By following a few simple practices, you can enhance its lifespan and maintain optimal functionality. Consistent care not only prevents potential issues but also promotes a smoother sewing experience.

Routine Cleaning

Keeping your machine free from dust and debris is crucial. Follow these steps for effective cleaning:

- Disconnect the power before cleaning.

- Use a soft brush to remove lint from the bobbin area and feed dogs.

- Wipe down exterior surfaces with a damp cloth.

- Clean the needle and presser foot to ensure precise stitching.

Lubrication Practices

Proper lubrication is vital for smooth operation. Consider the following tips:

- Consult the manufacturer’s guidelines for lubrication intervals.

- Use high-quality sewing machine oil for optimal performance.

- Apply oil sparingly to designated points, avoiding excess.

- Check for any signs of wear or damage during lubrication.

By implementing these maintenance strategies, you can help ensure that your sewing machine remains a reliable companion for years to come.

Replacing the Sewing Machine Needle

Changing the needle in a sewing device is a crucial maintenance task that ensures optimal performance and high-quality stitching. A dull or damaged needle can lead to fabric snags, skipped stitches, and an overall frustrating sewing experience. Regularly replacing the needle will not only enhance your project results but also prolong the life of your machine.

To effectively swap out the needle, follow these straightforward steps:

| Step | Action |

|---|---|

| 1 | Turn off the machine and unplug it for safety. |

| 2 | Remove the presser foot to gain better access to the needle. |

| 3 | Loosen the needle clamp screw using a screwdriver or your fingers. |

| 4 | Carefully pull the old needle down and out of the holder. |

| 5 | Insert the new needle with the flat side facing the back of the machine. |

| 6 | Tighten the needle clamp screw securely. |

| 7 | Reattach the presser foot and ensure it is locked in place. |

| 8 | Plug the machine back in and power it on to test the new needle. |

Always remember to select the appropriate needle type for your fabric to achieve the best results. Regular maintenance, including needle replacement, will help keep your sewing projects running smoothly.

Cleaning the Pfaff 1222 Effectively

Maintaining your sewing machine in optimal condition is essential for ensuring its longevity and performance. Regular cleaning helps prevent dust and lint buildup, which can lead to mechanical issues and affect the quality of your stitching. This guide will provide effective techniques for keeping your machine spotless and running smoothly.

Begin by gathering your supplies: a soft brush, lint cloth, and a vacuum attachment. These tools will help you remove debris from hard-to-reach areas without damaging sensitive components.

Start with the exterior: Wipe down the outer casing with a damp cloth to remove any surface dust and dirt. Ensure that you avoid using abrasive materials, as they can scratch the finish.

Next, focus on the internal parts: Carefully open the access panels to reach the bobbin case and feed dogs. Use the soft brush to gently remove lint from these areas. A small vacuum attachment can also be beneficial for sucking up stubborn debris.

Pay special attention to the needle and presser foot: Replace the needle regularly and keep the presser foot clean to ensure smooth operation. Wipe these components with a lint-free cloth to eliminate any buildup.

Finally, perform a routine oiling: Check your machine’s guidelines for the recommended oiling points. Use only the specified lubricant to avoid any potential damage. A well-lubricated machine operates more efficiently and reduces wear and tear.

By following these steps, you will maintain the cleanliness and efficiency of your sewing machine, enhancing its performance and ensuring it serves you well for years to come.

Adjusting Tension Settings Correctly

Achieving the perfect stitch quality is crucial for any sewing project, and one of the key factors in this process is the proper adjustment of thread tension. Incorrect settings can lead to a variety of issues, including loose stitches, puckering, or thread breakage. Understanding how to fine-tune these settings will help you produce clean, professional-looking results.

Understanding Thread Tension

Thread tension refers to the amount of pull applied to the thread as it moves through the machine. Each project may require different tension levels depending on the fabric type, thickness, and the stitching technique used. It is essential to strike a balance that allows the top and bobbin threads to interlock properly, resulting in a smooth and even stitch.

Steps to Adjust Tension

To begin adjusting tension, start by selecting a test piece of the same fabric you plan to use for your project. Set the initial tension according to the manufacturer’s recommendations. If you notice issues such as uneven stitching, gradually adjust the top tension dial in small increments, either tightening or loosening as needed. Always test your adjustments by sewing a few lines on your test fabric, and observe the stitch formation. Continue this process until you achieve the desired outcome.

Rewiring the Pfaff 1222 Safely

When dealing with vintage sewing machines, ensuring safe electrical connections is crucial for optimal performance and longevity. This section will guide you through the process of reconfiguring the electrical wiring, focusing on safety measures and best practices to avoid potential hazards.

Essential Safety Precautions

Before starting any electrical work, it’s important to take necessary precautions to protect both yourself and the machine. Here are some key steps to follow:

| Step | Action |

|---|---|

| 1 | Unplug the device from the power source. |

| 2 | Use insulated tools to prevent electric shock. |

| 3 | Work in a dry environment to reduce risk. |

| 4 | Wear protective eyewear and gloves. |

Steps for Rewiring

Once safety measures are in place, you can proceed with the wiring adjustments. Follow these steps carefully:

First, remove the casing to access the internal components. Identify the wires that need replacing, taking note of their original positions. It can be helpful to take photos for reference. Then, carefully detach the old wires, ensuring that you do not damage any surrounding parts.

Next, select high-quality replacement wires that are compatible with the machine’s specifications. Attach the new wires following the original configuration, making sure all connections are secure. Finally, reassemble the casing and perform a test run to confirm everything is functioning correctly.

Finding Replacement Parts Online

Locating components for your sewing machine can be a straightforward task with the right approach. The online marketplace offers a plethora of options, making it easier for enthusiasts and professionals alike to source the necessary items. Understanding where to look and how to navigate these resources will streamline the process.

Where to Search

- Specialized Websites: Many platforms focus exclusively on sewing equipment and accessories, providing a wide selection of parts.

- Online Marketplaces: Large e-commerce sites often have dedicated sections for sewing machinery, where you can find both new and used components.

- Manufacturer’s Sites: Official websites may offer direct sales of replacement items, ensuring compatibility and quality.

- Forums and Communities: Engaging with fellow sewing enthusiasts online can yield valuable leads on where to find specific parts.

Tips for Successful Shopping

- Check Compatibility: Always verify that the part matches your machine model to avoid any issues.

- Read Reviews: Look for feedback from previous buyers to assess the quality and reliability of the seller.

- Compare Prices: Explore different sources to find the best deal available for your needed components.

- Shipping Policies: Be mindful of shipping costs and delivery times, especially if you need the parts urgently.

Resources for Further Assistance

When seeking help with your sewing machine, a variety of resources are available to provide guidance and support. Whether you’re a novice or an experienced user, these tools can enhance your understanding and troubleshooting skills, ensuring your device operates smoothly and efficiently.

Online Communities and Forums

Engaging with online communities can be incredibly beneficial. Platforms such as sewing forums and social media groups allow you to connect with fellow enthusiasts who can share their insights and experiences. Here, you can ask questions, exchange tips, and even find tutorials that cover specific issues or techniques.

Instructional Videos and Tutorials

Many users find visual aids to be extremely helpful. Websites like YouTube host a plethora of instructional videos that demonstrate various functions and maintenance tasks. These tutorials can provide step-by-step guidance, making it easier to understand complex procedures. Additionally, many manufacturers offer video resources on their official websites, which can be valuable for specific models.

Utilizing these resources can empower you to effectively manage and enhance your sewing experience, ensuring that you get the most out of your equipment.