Nissan NV200 Maintenance and Repair Guide

Understanding the intricacies of vehicle upkeep is essential for any owner. This section delves into the various aspects of maintaining a specific model, ensuring optimal performance and longevity. Whether you are a seasoned enthusiast or a novice, having access to detailed instructions and insights can significantly enhance your experience.

In this exploration, you will find useful information regarding common issues, preventative measures, and step-by-step guidance on resolving typical challenges. Proper knowledge empowers you to tackle maintenance tasks confidently, ensuring your vehicle operates smoothly and efficiently.

Emphasizing the importance of regular care, this guide aims to equip you with the necessary tools and understanding to address potential concerns effectively. By following these guidelines, you can foster a deeper connection with your vehicle and enhance its reliability.

This section focuses on identifying and resolving common issues related to the braking mechanism. Understanding the symptoms and their causes can aid in ensuring the safety and efficiency of the vehicle.

Common Symptoms and Causes

| Symptom | Possible Cause |

|---|---|

| Squeaking noise when braking | Worn brake pads or insufficient lubrication |

| Spongy brake pedal | Air in the brake lines or low brake fluid level |

| Pulling to one side | Uneven brake pad wear or a stuck caliper |

| Warning light on dashboard | Malfunction in the brake system or low fluid levels |

Troubleshooting Steps

To address these issues, start by inspecting the brake fluid level and checking for any leaks in the system. If necessary, bleed the brake lines to remove any trapped air. Regular maintenance, including replacing worn components, is essential to maintain optimal performance.

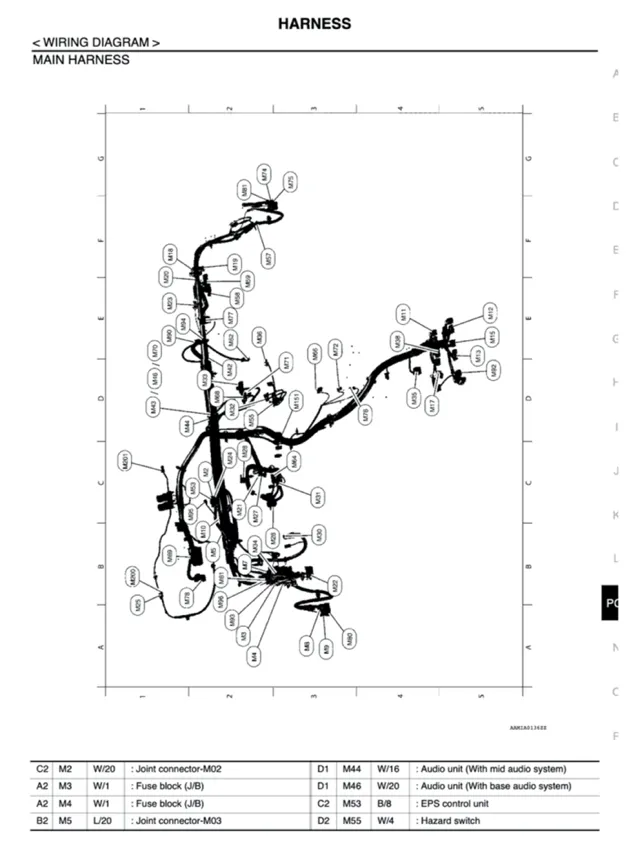

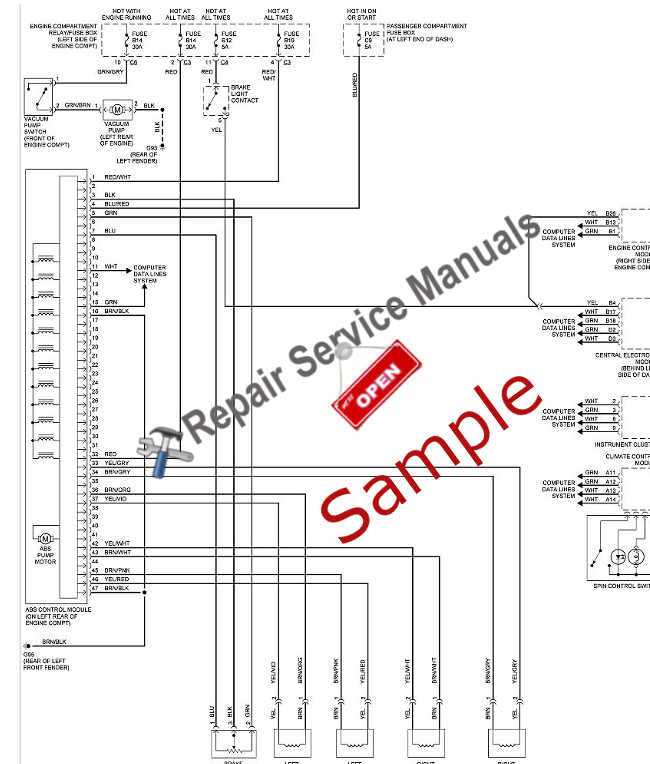

Electrical System Overview

This section provides an insight into the essential components that comprise the electrical framework of the vehicle. Understanding the various elements and their functions is crucial for effective troubleshooting and maintenance.

The electrical framework includes several key components:

- Battery: Serves as the primary power source, storing energy for starting the engine and powering electrical accessories.

- Alternator: Converts mechanical energy into electrical energy, recharging the battery while the engine runs.

- Fuses: Protect electrical circuits by preventing overloads and short circuits, ensuring safety and functionality.

- Wiring Harness: A collection of wires that connects various electrical components, allowing for communication and power distribution.

- Control Modules: Electronic units that manage and regulate various systems within the vehicle, enhancing performance and efficiency.

Regular inspection and understanding of these elements can prevent potential issues and enhance the overall reliability of the vehicle.

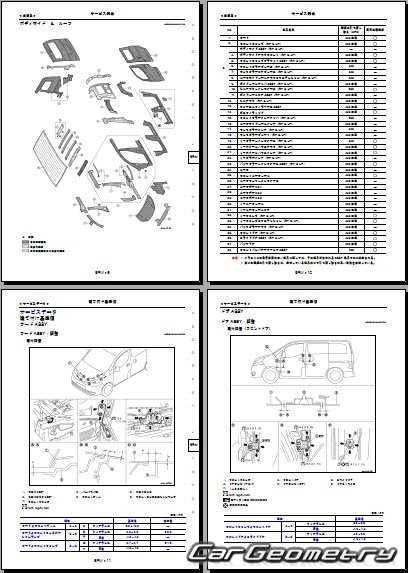

Body and Interior Repairs

The maintenance and restoration of the exterior and cabin components are essential for preserving the vehicle’s overall appearance and functionality. This section addresses various aspects of maintaining the structure and interior features, ensuring a comfortable and safe driving experience.

Exterior Assessment: Regular inspections of the outer surface are crucial for identifying any damages or wear. Scratches, dents, and corrosion should be promptly addressed to prevent further deterioration.

Interior Comfort: The cabin’s aesthetics and functionality greatly impact the user experience. Replacing worn upholstery, ensuring proper operation of control elements, and maintaining cleanliness are vital for enhancing comfort.

Restoration Techniques: Various methods can be employed for restoring both the body and interior. These may include painting, panel replacement, or upholstery cleaning. Utilizing the right tools and materials ensures high-quality results.

Maintaining the vehicle’s body and interior not only improves its appearance but also contributes to its longevity. Regular care and timely repairs play a significant role in sustaining its value over time.

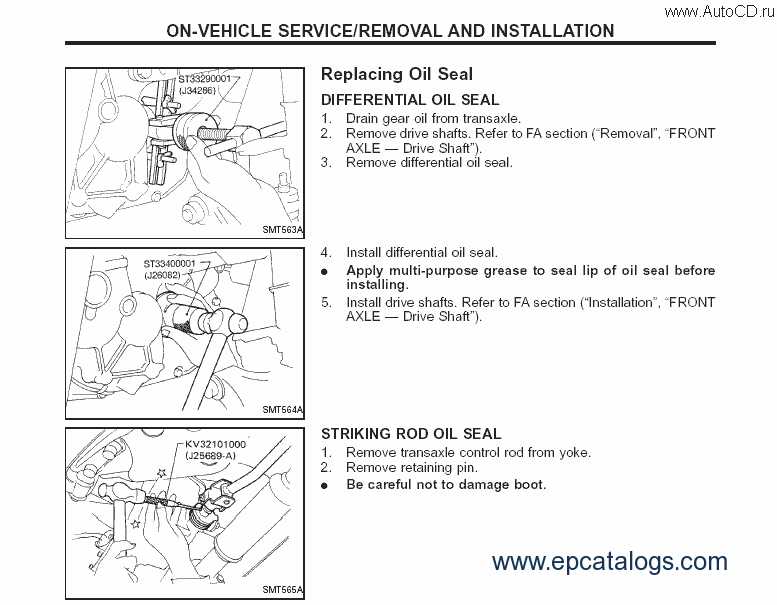

Fluid Checks and Replacements

Regular maintenance of essential liquids in your vehicle is crucial for optimal performance and longevity. Ensuring that all fluids are at appropriate levels and in good condition helps prevent potential issues and promotes smooth operation.

Types of Fluids to Monitor

Key liquids to inspect include engine oil, coolant, transmission fluid, brake fluid, and power steering fluid. Each plays a vital role in the functionality of various systems within the vehicle. Routine checks will help identify any necessary replacements or top-ups.

Steps for Checking and Replacing Fluids

To check fluid levels, use the dipstick for oil and the designated reservoir indicators for other liquids. If levels are low or if any fluid appears discolored or contaminated, a replacement is advised. Follow manufacturer guidelines for draining and refilling, ensuring the correct type of fluid is used to maintain system integrity.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance tasks is essential for preventing accidents and injuries. Adhering to specific guidelines not only protects the individual working on the vehicle but also safeguards the surrounding environment. Awareness of potential hazards and the implementation of preventive measures are key components in promoting a secure workspace.

First and foremost, it is crucial to wear appropriate personal protective equipment (PPE), such as gloves, goggles, and masks. This gear minimizes exposure to harmful substances and protects against physical injuries. Additionally, maintaining a clean and organized workspace helps to reduce the risk of accidents caused by clutter or misplaced tools.

Moreover, always ensure proper ventilation in the work area to prevent the accumulation of toxic fumes. When dealing with fluids or chemicals, handle them with care, following the manufacturer’s instructions for use and disposal. If necessary, consult safety data sheets for guidance on hazardous materials.

Lastly, having a comprehensive understanding of the tools and equipment being utilized is vital. Familiarity with their operation and potential risks can significantly enhance safety. When in doubt, seek assistance or consult relevant resources to ensure correct procedures are followed.