Suzuki King Quad 300 Comprehensive Repair Guide

When it comes to off-road vehicles, understanding their upkeep is essential for optimal performance and longevity. This guide aims to equip enthusiasts with the necessary knowledge to tackle various maintenance tasks effectively. From routine checks to more intricate repairs, a solid grasp of the inner workings can prevent costly breakdowns and ensure a smoother ride.

In the world of all-terrain vehicles, each component plays a vital role in overall functionality. Familiarity with these elements allows owners to diagnose issues early and implement solutions before they escalate. Whether you’re a novice or an experienced rider, having access to detailed information can empower you to handle maintenance with confidence.

By delving into the specifics of servicing your vehicle, you can enhance its durability and performance. This section will cover critical aspects such as troubleshooting techniques, necessary tools, and step-by-step procedures. Embracing these practices will not only improve your riding experience but also deepen your connection with your machine.

Suzuki King Quad 300 Overview

This section provides a comprehensive insight into a robust all-terrain vehicle designed for both recreational and practical uses. Known for its reliability and versatility, this machine excels in various environments, making it a preferred choice among enthusiasts and professionals alike.

The vehicle features a powerful engine that delivers impressive torque and speed, suitable for navigating challenging terrains. Its ergonomic design ensures comfort during long rides, while the durable construction stands up to rigorous use.

Equipped with advanced suspension systems, it offers enhanced stability and control, allowing for smooth handling over rough landscapes. The combination of power and agility makes this vehicle ideal for tasks such as farming, trail riding, and utility work.

In addition to performance, maintenance is straightforward, ensuring longevity and optimal operation. Regular upkeep and understanding the vehicle’s components are crucial for maximizing its potential.

Overall, this all-terrain vehicle represents a harmonious blend of power, durability, and practicality, appealing to a wide range of users who seek adventure and functionality in their rides.

Common Issues and Troubleshooting Tips

Maintaining a vehicle often involves encountering a range of problems that can arise during its operation. Understanding these common issues and knowing how to address them can significantly enhance your riding experience and prolong the lifespan of your machine. This section provides insights into frequent complications and offers practical solutions for effective troubleshooting.

1. Starting Difficulties: One of the most prevalent issues is trouble with starting the engine. This may be due to a drained battery, faulty ignition system, or fuel delivery problems. Tip: Always check the battery connections and ensure the fuel is fresh. If issues persist, inspecting the spark plug and ignition components can help identify the root cause.

2. Overheating: Overheating can occur due to inadequate coolant levels or a malfunctioning radiator. This can lead to serious damage if not addressed promptly. Tip: Regularly check the coolant reservoir and clean the radiator to ensure proper airflow and cooling efficiency.

3. Unusual Noises: Strange sounds while operating may indicate mechanical issues. These could stem from loose parts or worn-out bearings. Tip: Conduct a thorough inspection of all moving components and tighten or replace any parts as needed to prevent further damage.

4. Handling Problems: If you notice a decrease in handling performance, it may be due to tire pressure or suspension system wear. Tip: Regularly inspect tire inflation levels and the condition of the suspension components to ensure optimal performance.

5. Electrical Failures: Electrical malfunctions can manifest as flickering lights or a non-functional starting system. This may result from blown fuses or faulty wiring. Tip: Check all fuses and inspect the wiring for any signs of wear or damage, replacing components as necessary.

By being aware of these common problems and employing the suggested troubleshooting techniques, you can effectively maintain your vehicle and enjoy a smoother ride.

Maintenance Schedule for King Quad 300

Regular upkeep is essential for optimal performance and longevity of your vehicle. Following a systematic maintenance schedule helps prevent issues and ensures that all components function smoothly. Below is a comprehensive outline for maintaining your all-terrain vehicle.

Daily Checks

- Inspect fluid levels (oil, coolant, and fuel).

- Check tire pressure and overall condition.

- Examine the brakes for proper function.

- Ensure that lights and signals are operational.

Every 50 Hours of Operation

- Change the engine oil and replace the oil filter.

- Inspect and clean the air filter.

- Check the spark plug and replace if necessary.

- Lubricate all moving parts and joints.

Every 100 Hours of Operation

- Replace the fuel filter.

- Inspect the drive belt for wear and tension.

- Check and adjust the throttle cable.

- Inspect suspension components and tighten bolts.

Annual Maintenance

- Flush and replace the coolant.

- Inspect the electrical system, including battery terminals.

- Check all hoses and cables for wear.

- Perform a comprehensive cleaning of the vehicle.

Following this schedule will help ensure that your vehicle remains in peak condition, providing reliability and enjoyment for years to come.

Essential Tools for Repairs

When maintaining and servicing all-terrain vehicles, having the right equipment at hand is crucial for effective troubleshooting and restoration. Each task requires specific instruments that enhance efficiency and ensure safety during the process. This section highlights the must-have tools that every enthusiast should consider for optimal performance and reliability.

Basic Hand Tools

At the foundation of any mechanical work are hand tools. These include wrenches, pliers, screwdrivers, and sockets. A versatile socket set is particularly valuable, as it allows for quick adjustments to various fasteners. Additionally, a quality ratchet will expedite the process of loosening or tightening components. Having a selection of screwdrivers, both flathead and Phillips, ensures that you can tackle different types of screws without hassle.

Diagnostic Equipment

In order to accurately assess issues, diagnostic tools play a significant role. A multimeter is essential for checking electrical systems, while compression testers can evaluate engine performance. These instruments provide insights that are vital for identifying underlying problems, allowing for precise interventions. Investing in these tools not only saves time but also helps prevent further complications down the line.

Step-by-Step Repair Procedures

This section outlines a systematic approach to troubleshooting and fixing common issues encountered in off-road vehicles. By following these organized steps, users can effectively address various mechanical problems and ensure optimal performance.

Initial Assessment

Begin by thoroughly inspecting the vehicle for any visible signs of wear or damage. Check fluid levels, inspect tires for proper inflation, and look for leaks around the engine and transmission. Document any unusual sounds or behaviors that may indicate specific issues.

Systematic Troubleshooting

Once the initial assessment is complete, proceed to troubleshoot specific systems. For electrical issues, utilize a multimeter to test connections and components. For engine performance problems, examine the air and fuel systems, ensuring that filters are clean and free of obstructions. Follow the manufacturer’s guidelines for torque specifications and assembly procedures during reassembly to maintain integrity and safety.

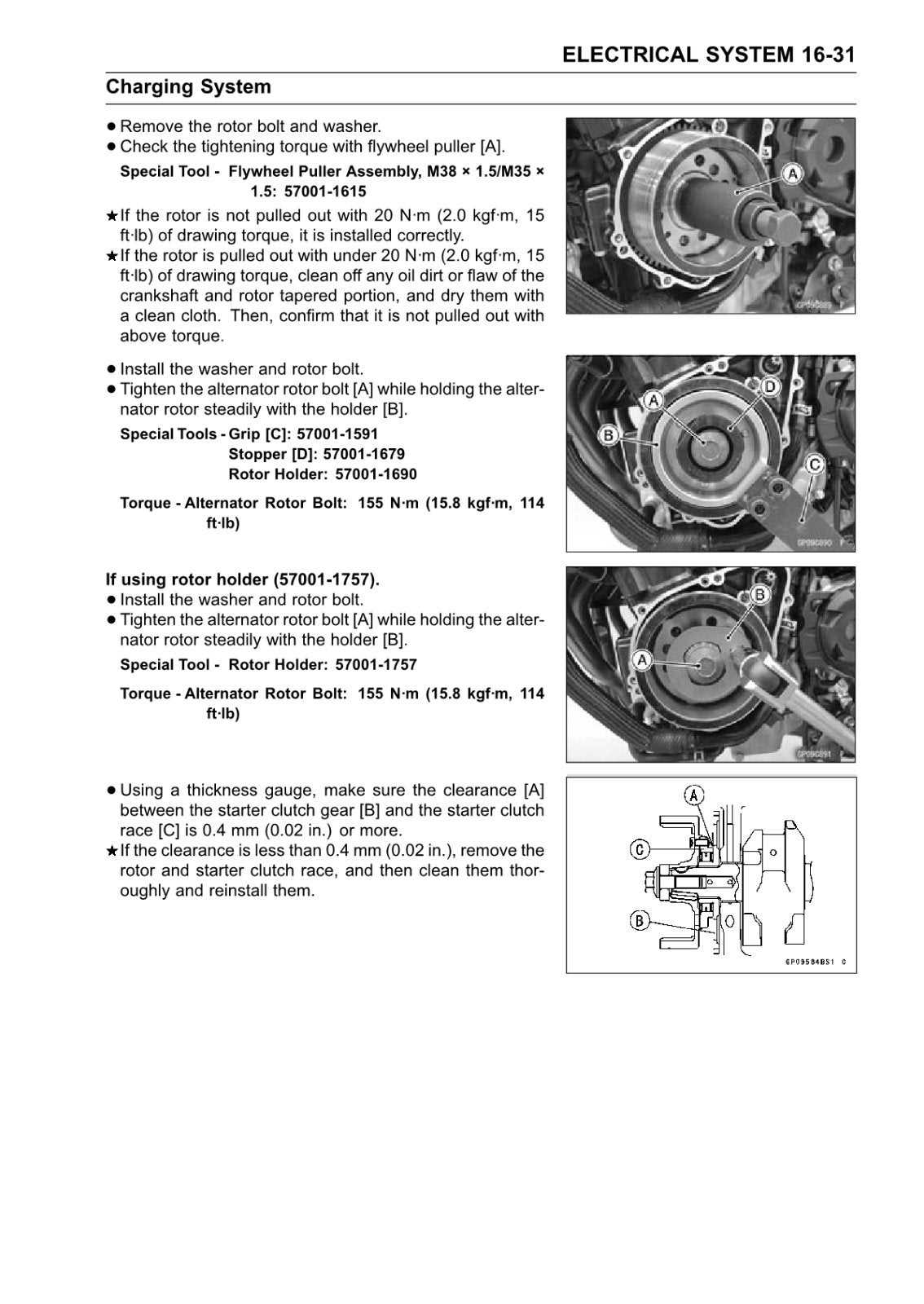

Electrical System Diagnostics

This section focuses on the critical processes involved in troubleshooting and evaluating the performance of electrical components within your vehicle. A comprehensive understanding of the electrical system is essential for identifying malfunctions and ensuring optimal functionality. This guide outlines the necessary steps and tools for effective diagnostics, enabling you to address issues promptly and efficiently.

Common Issues and Symptoms

Recognizing typical problems is the first step in diagnosing electrical failures. Symptoms may include dimming lights, erratic instrument readings, or failure to start. It is crucial to observe these indicators carefully, as they often point to underlying electrical faults such as a weak battery, damaged wiring, or malfunctioning relays.

Diagnostic Procedures

Begin the diagnostic process by inspecting all electrical connections for signs of corrosion or looseness. Utilize a multimeter to test voltage levels at various points, ensuring they align with specifications. Additionally, examining fuses and circuit integrity can reveal shorts or breaks that may hinder system performance. Following a systematic approach will aid in isolating the issue and implementing the appropriate corrective measures.

Engine Overhaul Instructions

Overhauling an engine is a meticulous process that requires attention to detail and a solid understanding of mechanical principles. This section provides a comprehensive guide to disassembling, inspecting, and reassembling the engine to ensure optimal performance. Following these steps will help in restoring the engine to its peak condition, enhancing reliability and longevity.

Preparation and Disassembly

Before commencing the overhaul, gather all necessary tools and materials. Start by disconnecting the battery and draining all fluids. Carefully document the position of components as they are removed to facilitate reassembly. Pay close attention to the order of disassembly, and store parts in labeled containers to prevent loss.

Inspection and Reassembly

Once disassembled, inspect all components for wear or damage. Critical areas to check include bearings, seals, and gaskets. Replace any worn parts with high-quality replacements. When reassembling, ensure that all fasteners are torqued to the manufacturer’s specifications. Double-check the alignment of components to avoid future complications.

Suspension and Steering Adjustments

Properly tuning the suspension and steering systems is essential for optimal performance and comfort in any all-terrain vehicle. Adjustments can greatly enhance handling, stability, and ride quality, allowing the operator to navigate various terrains with ease.

Suspension adjustments involve fine-tuning components like shocks and springs to suit the rider’s weight and the type of terrain being traversed. Increasing preload can help with load-bearing when carrying extra weight, while reducing it may improve comfort on softer surfaces. It’s crucial to ensure that the suspension travel is adequate to prevent bottoming out during rough rides.

Steering alignment is equally important, as it affects maneuverability and responsiveness. Regular checks for toe-in and camber angles can prevent uneven tire wear and enhance control. Adjusting these angles ensures that the vehicle tracks straight and true, providing a safer and more enjoyable experience.

Lastly, maintaining the correct tire pressure is vital for both suspension performance and steering precision. Proper inflation not only improves handling but also prolongs tire life, contributing to a smoother ride overall.

Parts Replacement Guide

This section aims to provide essential information for individuals seeking to replace various components of their all-terrain vehicle. Understanding the proper procedures and necessary parts can significantly enhance the longevity and performance of the machine.

When considering part replacement, it is crucial to follow a systematic approach:

- Identify the component that needs replacement.

- Consult the specifications to ensure compatibility.

- Gather the required tools and safety equipment.

Here are some common parts that may require replacement:

- Air Filter: Regular replacement ensures optimal engine performance and efficiency.

- Oil Filter: Changing the oil filter helps maintain clean oil circulation, crucial for engine health.

- Brake Pads: Worn pads can affect stopping power and safety; regular checks are recommended.

- Tires: Inspect for wear and tear; maintaining proper tire pressure is also essential.

- Batteries: A weak battery can lead to starting issues; replace it if performance declines.

To ensure a successful replacement, consider the following steps:

- Disconnect the power source to avoid any electrical hazards.

- Carefully remove the old part using the appropriate tools.

- Install the new component, ensuring it fits securely.

- Reassemble any parts that were removed during the process.

- Reconnect the power source and test the vehicle to confirm proper functionality.

Regular maintenance and timely part replacement can significantly enhance the performance and reliability of your vehicle. Always refer to trusted sources for detailed guidance on specific components and best practices.

Safety Precautions During Repairs

When undertaking maintenance or troubleshooting tasks on an all-terrain vehicle, prioritizing safety is essential. Proper precautions not only protect the individual working on the machine but also ensure the longevity and functionality of the equipment. Awareness of potential hazards and taking the necessary steps can prevent accidents and injuries.

Personal Protective Equipment

Using personal protective gear is crucial when handling machinery. This includes wearing gloves to protect your hands from sharp edges or hazardous substances, safety goggles to shield your eyes from debris, and sturdy footwear to prevent injuries from falling objects. Additionally, consider ear protection if working near loud components.

Workspace Safety

Ensure that your workspace is organized and free from clutter. An orderly environment reduces the risk of trips and falls, which are common hazards during mechanical work. Make sure you have adequate lighting and ventilation, particularly when working with chemicals or fuels. Furthermore, always have a fire extinguisher nearby when dealing with flammable materials.