Yamaha F150 Maintenance Guide for Effective Repairs

Understanding the intricacies of keeping a marine engine in peak condition is crucial for ensuring smooth and reliable operation on the water. This guide is designed to provide detailed insights into maintaining and addressing common challenges faced by enthusiasts. It serves as a valuable resource for those looking to deepen their knowledge and enhance the longevity of their equipment.

Whether it’s routine upkeep or addressing specific issues that arise during use, this resource offers a structured approach to diagnosing and resolving various technical problems. From understanding the essential components to mastering the techniques needed for efficient servicing, it provides the necessary information to keep your machinery operating at its best.

The focus here is not just on solving issues but also on preventive care, aiming to extend the lifespan of your equipment and ensure consistent performance. With this practical guide, users can find step-by-step instructions, expert advice, and best practices that make even complex tasks manageable. It’s a vital reference for those who value reliability and want to minimize unexpected setbacks during their maritime adventures.

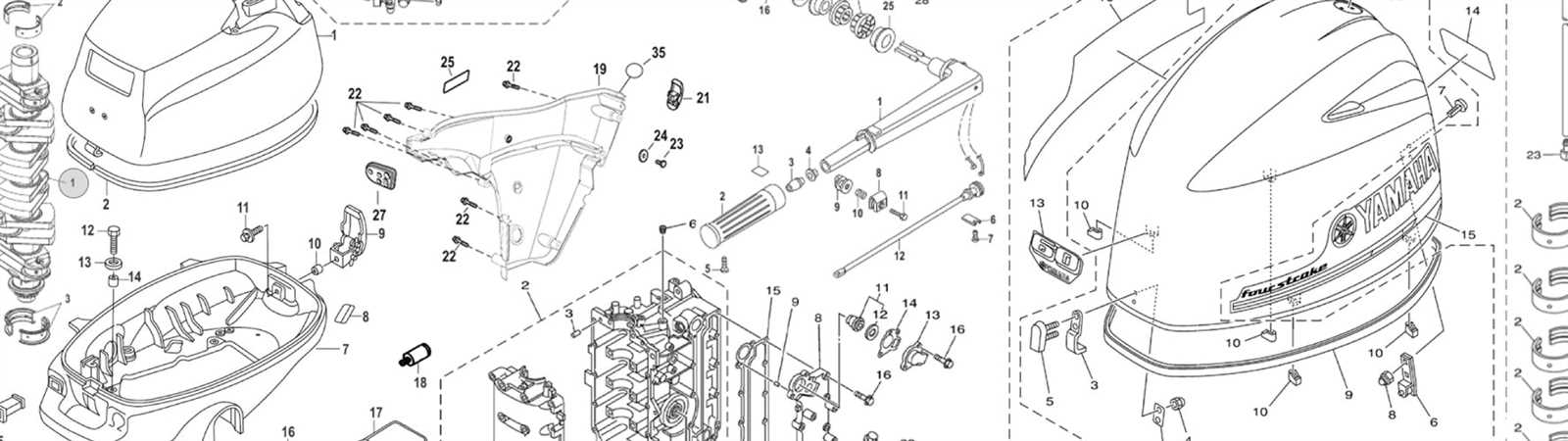

Understanding the Yamaha F150 Engine

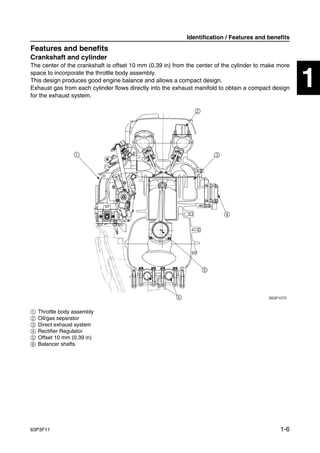

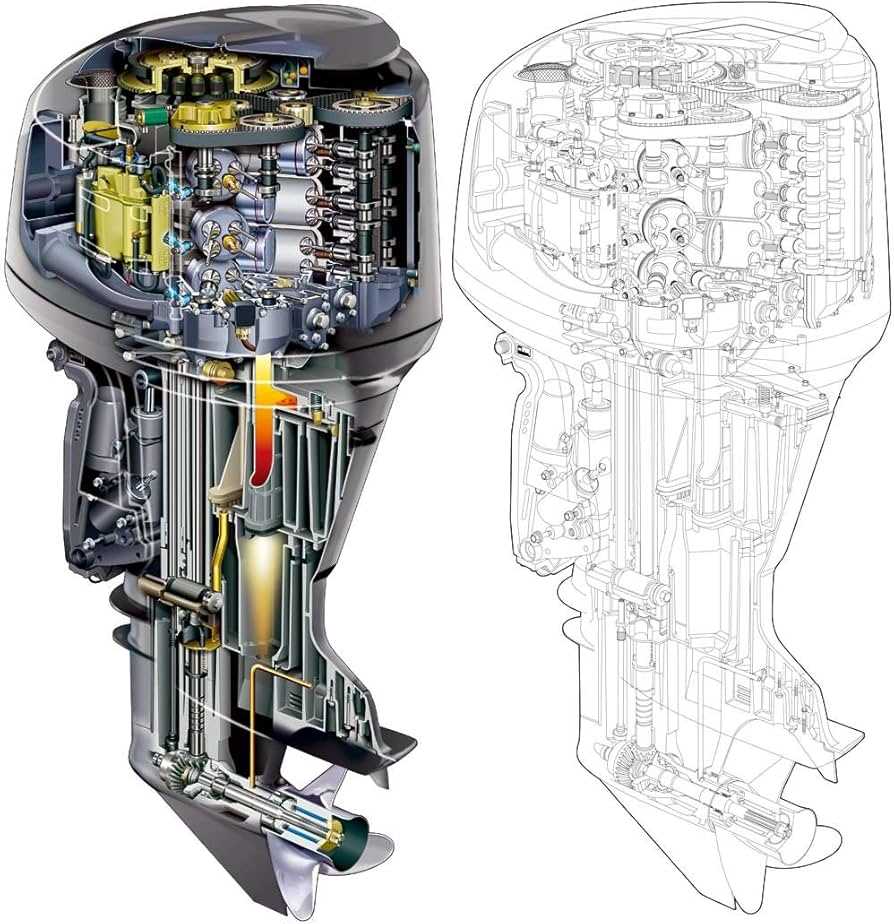

The power unit in question is known for its robust design, providing a reliable solution for various marine applications. Its structure and functionality make it a popular choice among enthusiasts seeking both performance and durability. In this section, we will explore the key elements that contribute to its efficient operation and smooth running.

- Core Design Features: The engine’s layout includes a well-balanced arrangement of internal components, ensuring steady power delivery. The use of advanced materials in construction aids in reducing wear, leading to extended operational life.

- Cooling Mechanism: A sophisticated water-based cooling system maintains optimal temperatures during use, minimizing the risk of overheating. This feature is crucial for maintaining the overall health of the motor and preventing damage from thermal stress.

- Fuel Management: It employs an advanced injection system that precisely controls the fuel-air mixture, contributing to better efficiency and reduced emissions. This system ensures a consistent performance, adapting to varying conditions on the water.

- Durability and Maintenance: The design of this power source emphasizes ease of upkeep, with accessible points for routine checks and servicing. Regular maintenance helps in preserving the engine’s reliability and performance over time.

- Performance Optimization: Various tuning options allow users to tailor the motor’s performance to specific needs, making it versatile for different types of boating activities, from leisure to demanding tasks.

By understanding these aspects, owners can ensure their power unit remains in peak condition, delivering consistent performance season after season.

Common Issues with Yamaha F150

Owners of this popular model may encounter certain recurring challenges that require attention for optimal performance. These issues often relate to maintenance needs or operational aspects, and identifying them early can help ensure smooth functioning and longevity.

| Problem | Possible Causes | Recommended Action |

|---|---|---|

| Engine Hesitation | Clogged fuel injectors or air intake blockage | Inspect injectors, clean or replace as needed |

| Overheating | Insufficient water flow or malfunctioning cooling system | Check water pump and replace worn components |

| Starter Failure | Weak battery or faulty connections | Test battery, secure connections, and replace if necessary |

| Rough Idle | Improper fuel mixture or spark plug issues | Adjust fuel settings and inspect spark plugs |

| Loss of Power | Fuel contamination or exhaust system blockage | Drain fuel tank, clean exhaust passages |

Maintenance Tips for Optimal Performance

Regular upkeep is essential for ensuring longevity and smooth operation of your marine engine. By following simple guidelines, you can minimize wear and tear while maintaining peak efficiency. The key is to stay consistent with routine care and address potential issues before they become significant problems.

Check Fluids and Lubrication

Fluids play a crucial role in keeping the system running smoothly. It’s important to regularly inspect and replace vital fluids like engine oil and coolant. Using the correct type and quantity ensures that the components are well-lubricated and protected from friction.

- Inspect oil levels before every trip to ensure proper lubrication.

- Replace oil and filter every 50-100 hours of use, or as recommended.

- Check coolant levels periodically to prevent overheating during operation.

Inspect and Clean Key Components

Keeping the main parts clean is crucial for preventing buildup that can hinder performance. Focus on areas that are most exposed to elements such as saltwater, dirt, and other debris. Regular cleaning helps to maintain efficiency and prevents premature corrosion.

- Rinse external parts with fresh water after each use to avoid salt buildup.

- Clean the fuel system regularly to prevent clogs and ensure a smooth flow.

- Inspect hoses and connectors for any signs of wear or leakage.

Consistent attention to these details will help you enjoy smooth and reliable performance for years to come.

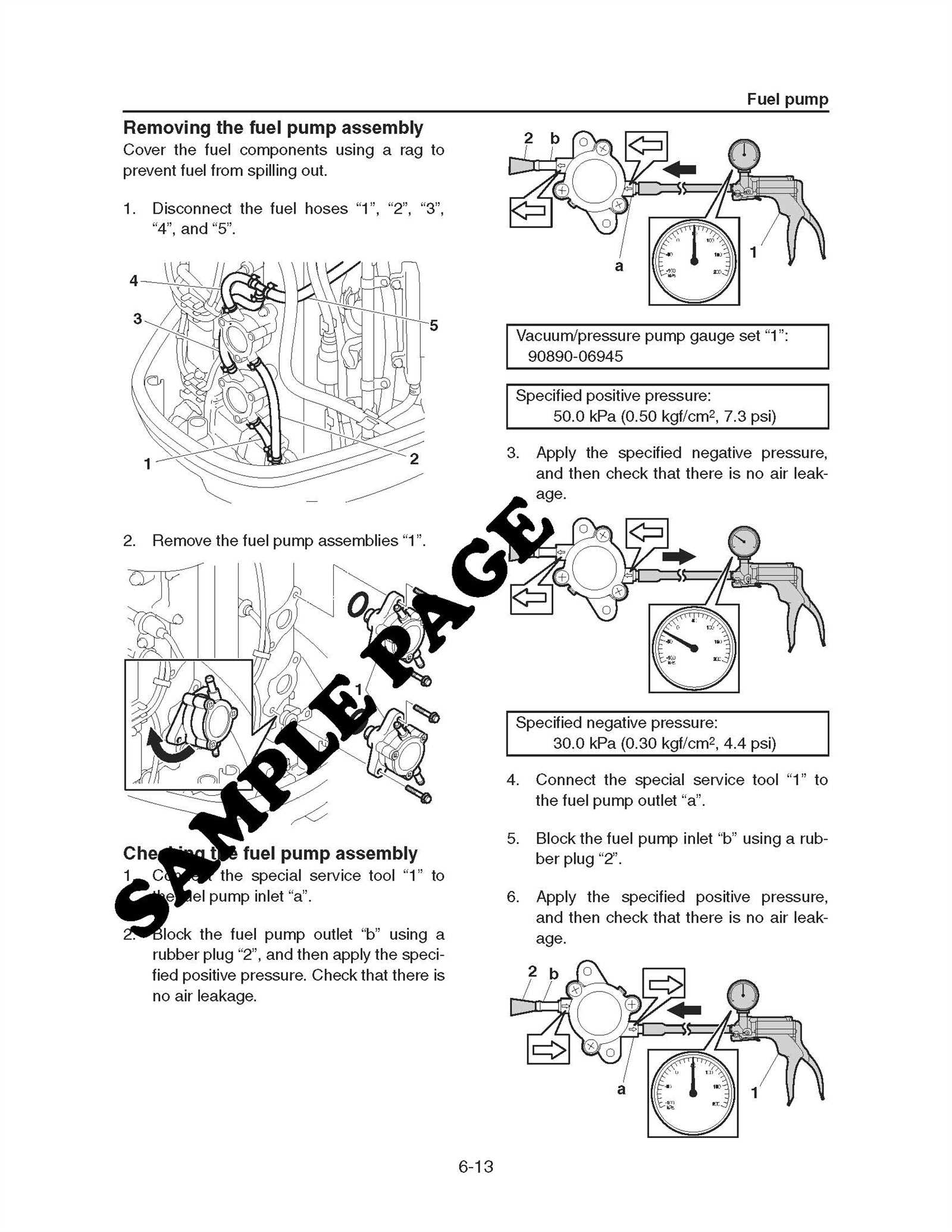

Fuel System Troubleshooting Techniques

Efficient analysis of the engine’s fuel delivery system is essential for maintaining optimal performance. Understanding the common symptoms of issues within this network can assist in identifying underlying concerns that may affect the overall operation. By addressing these challenges systematically, one can prevent more serious complications and ensure a smooth running system.

Start by inspecting the flow pathways and ensuring that each component is functioning as expected. Look for signs of blockages or wear that might disrupt the circulation. If issues persist, assess the fuel pressure to verify if it falls within the recommended range. Low pressure could indicate a clogged filter or a failing pump, while excessive pressure may signal regulator problems.

Additionally, pay attention to irregularities in consumption rates, as sudden changes can be indicative of leaks or faulty injectors. By isolating these variables one by one, pinpointing the root cause becomes more manageable. Proper diagnostics require patience and a methodical approach, but a thorough check can prevent unnecessary replacements and ensure long-term reliability.

Guide to Diagnosing Electrical Problems

Understanding how to identify and address issues within an electrical system is crucial for maintaining performance and reliability. This section outlines a systematic approach for tracing malfunctions, ensuring a thorough and efficient process to locate and resolve faults.

Before starting any analysis, it is important to ensure that all connections are secure and free of corrosion. A visual inspection can often reveal loose wires or terminals. Once the preliminary checks are completed, proceed with the following steps to diagnose potential issues:

| Step | Description | ||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1. Check the Battery | Measure voltage levels with a multimeter. A healthy power source should maintain a stable voltage. If the readings are low, recharge or replace as needed. | ||||||||||||||||||||||

| 2. Inspect Fuses | Examine the condition of all fuses in the circuit. A blown fuse may indicate a short circuit or an overloaded system. Replace damaged fuses and test again. | ||||||||||||||||||||||

| 3. Analyze Wiring Integrity | Use a continuity tester to verify the integrity of wiring. This helps to find any breaks or faulty wires that could disrupt the flow of current. | ||||||||||||||||||||||

| 4. Test Components Individually | Disconnect and test individual components like switches, relays, and sensors. This helps to isolate the problem and determine which part requires attention. | ||||||||||||||||||||||

| 5. Inspect Ground Connections | Check all

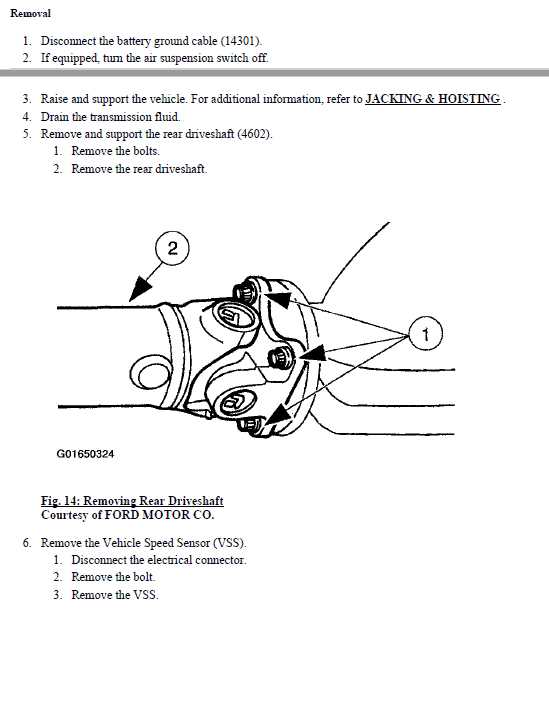

Replacing the Water Pump Correctly

Ensuring optimal performance of your vessel’s engine requires regular maintenance, particularly the effective functioning of the water circulation system. A faulty water pump can lead to overheating and potential engine damage. This section provides a clear and concise guide to properly replace this essential component, ensuring smooth operation and longevity. Gathering Necessary Tools and ComponentsBefore beginning the replacement process, it’s vital to have all necessary tools and components on hand. You’ll typically need a socket set, a torque wrench, a screwdriver, and a new pump. Additionally, gather any required gaskets or seals to prevent leaks after installation. Having everything prepared in advance will streamline the procedure and minimize downtime. Step-by-Step Replacement Process

Start by draining the cooling system to prevent spills. Next, remove the cover and detach the old pump carefully. It’s essential to inspect the mounting area for any debris or corrosion that may affect the new installation. After placing the new pump, ensure all connections are secure and torqued to the manufacturer’s specifications. Finally, refill the cooling system and run the engine to check for leaks, ensuring the pump operates efficiently. Steps for Tuning the Carburetor

Tuning the fuel delivery system is essential for optimal engine performance. Proper adjustments can enhance efficiency, improve throttle response, and ensure smooth operation. The following guidelines will help you achieve the desired settings.

Regular maintenance of the fuel system can lead to better engine longevity and performance. Following these steps can ensure that your engine runs smoothly and efficiently. Yamaha F150 Cooling System Repairs

The effectiveness of the cooling apparatus is vital for maintaining optimal performance and longevity of marine engines. Addressing any issues that may arise within this system ensures that the engine operates efficiently and prevents potential damage from overheating. Regular maintenance and prompt attention to problems can significantly enhance reliability on the water. Common Issues in the Cooling MechanismSeveral factors can lead to malfunctions within the cooling mechanism. These may include blockages, leaks, or wear and tear of components. Identifying these issues early can save both time and resources. Below are some prevalent complications associated with this system:

Maintenance Tips for the Cooling System

Proper upkeep is essential for ensuring the cooling system functions optimally. Here are some suggestions to consider:

Proper Lubrication for Longevity

Ensuring adequate lubrication is essential for extending the lifespan and optimal performance of marine engines. Regular application of the appropriate lubricants not only minimizes friction but also protects vital components from wear and corrosion. This practice is crucial in maintaining the overall health of the machinery, allowing it to operate smoothly under various conditions. Types of Lubricants

Different lubricants serve specific purposes within the engine. Synthetic oils are often preferred for their superior performance in extreme temperatures and conditions, providing excellent protection against breakdown. Mineral oils, while more traditional, can still be effective but may require more frequent changes. Choosing the right type is vital for ensuring proper functionality. Application Techniques

Proper application techniques are equally important. Regularly check the lubricant levels and replace them as needed, ensuring that the correct amount is applied to each designated area. Using a manual pump or appropriate tools can help in distributing the lubricant evenly, preventing any potential dry spots that could lead to damage over time. Identifying Exhaust System IssuesProper functioning of the exhaust system is crucial for optimal engine performance and efficiency. Recognizing the signs of malfunction can prevent more severe damage and costly repairs. Various indicators can suggest problems within this vital component, warranting careful inspection and attention. Common Symptoms of Exhaust Problems

Several symptoms can point to exhaust system issues. An unusual increase in engine noise is often the first noticeable sign, indicating potential leaks or cracks. Additionally, a decrease in fuel efficiency may occur, as the engine struggles to expel exhaust gases effectively. If the vehicle emits excessive smoke or a strong odor, these are clear warnings that should not be ignored. Inspection Techniques

To assess the condition of the exhaust system, a visual inspection is essential. Look for any visible damage, such as rust, holes, or loose connections. Listening for abnormal sounds while the engine is running can also provide valuable insights. Utilizing diagnostic tools can further aid in pinpointing specific issues within the system, ensuring a thorough evaluation. Prompt attention to these symptoms can enhance performance and extend the lifespan of the engine. Addressing problems early can save both time and resources in the long run. Cleaning the Air Intake System

The air intake mechanism plays a crucial role in maintaining optimal performance by ensuring that the engine receives clean air for combustion. Regular maintenance of this system is essential to prevent dirt and debris from affecting engine efficiency and longevity. This section outlines the steps and considerations for effectively cleaning the air intake pathway. Before starting the cleaning process, gather the necessary tools and materials to ensure a smooth workflow. Proper preparation will help avoid any complications during the maintenance. Below is a list of recommended items:

Begin the cleaning process by carefully disconnecting the air intake assembly from the engine. Make sure to take note of any connections and positioning for easy reassembly. Once detached, use compressed air to clear out any loose particles from the intake manifold and throttle body. Follow this by applying the cleaning solvent with a soft brush, ensuring to target any areas with noticeable buildup. Wipe down all components with a clean cloth to remove residue and prevent contamination. After the cleaning is complete, reattach the air intake assembly securely, ensuring all connections are properly fitted. This maintenance not only enhances engine performance but also contributes to fuel efficiency and overall reliability. |