Comprehensive Guide to Gesipa Taurus 3 Repair

In the realm of equipment functionality, understanding how to effectively maintain and troubleshoot is essential for optimal performance. This section aims to provide detailed insights into the processes involved in preserving and restoring operational integrity of various tools.

By delving into systematic approaches, readers will learn the significance of regular inspections, identifying common issues, and implementing corrective measures. The focus will be on empowering users with knowledge to enhance their familiarity with essential practices.

Moreover, this guide will cover various techniques and methods that can be employed to address frequent complications. Each procedure is outlined clearly to ensure that users can confidently undertake the necessary steps to achieve reliable results.

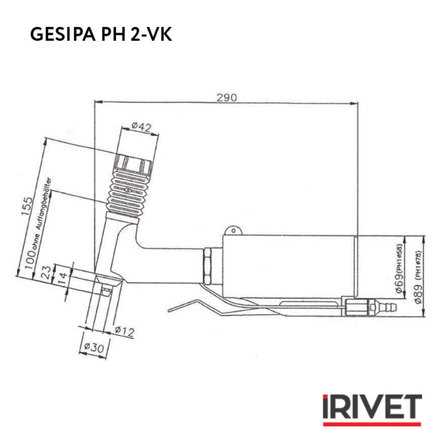

This section aims to provide a comprehensive overview of a specific model within the realm of fastening tools, focusing on its functionalities and key features. By understanding this device, users can better appreciate its applications and potential benefits in various tasks.

Key Features of the Device

This innovative tool boasts several remarkable characteristics that enhance its usability and effectiveness. Below are some of the primary attributes:

| Feature | Description |

|---|---|

| Power Source | Operates efficiently with a reliable energy supply. |

| Ergonomic Design | Crafted for comfortable handling and prolonged use. |

| Versatile Applications | Suitable for a range of fastening tasks across different materials. |

| Durability | Constructed with high-quality components to withstand rigorous use. |

Operational Insights

To maximize performance, users should familiarize themselves with the operating principles of this tool. Understanding how to properly engage and utilize its features can significantly improve efficiency and outcomes in fastening applications.

Common Issues and Troubleshooting Tips

In the realm of industrial fastening equipment, users may encounter a variety of common challenges that can affect performance. Recognizing these issues and knowing how to address them can significantly enhance the efficiency of operations. This section delves into frequent problems and provides practical solutions to restore optimal functionality.

Below is a table summarizing typical complications along with corresponding troubleshooting strategies:

| Issue | Possible Cause | Troubleshooting Steps |

|---|---|---|

| Tool not activating | Insufficient power supply | Check power source and connections |

| Inconsistent fastening | Worn components | Inspect and replace worn parts |

| Excessive noise | Loose fittings | Tighten all connections securely |

| Overheating | Blocked vents | Clear any obstructions from air vents |

By addressing these issues promptly, users can ensure smoother operation and prolong the lifespan of their fastening equipment.

Essential Tools for Effective Repairs

When tackling any maintenance task, having the right instruments at your disposal is crucial for achieving optimal results. A well-equipped toolkit not only enhances efficiency but also ensures precision in every step of the process. Understanding the key items necessary for effective interventions can significantly simplify the journey of troubleshooting and resolving issues.

Basic Hand Tools: A collection of fundamental hand tools forms the backbone of any toolkit. Items such as screwdrivers, pliers, and wrenches are indispensable for manipulating various components with ease. These tools allow for quick adjustments and the ability to access hard-to-reach areas effectively.

Power Tools: Incorporating power tools can elevate the efficiency of your tasks. Electric drills and impact drivers, for example, can expedite fastening and drilling processes. These devices are especially beneficial when dealing with robust materials that require significant effort to modify.

Measurement Devices: Accurate measurements are vital in any task. Utilizing calipers, rulers, and gauges ensures that all components fit seamlessly together. These instruments help maintain precision and prevent errors that could arise from miscalculations.

Safety Equipment: Prioritizing safety is essential during any hands-on endeavor. Protective eyewear, gloves, and ear protection shield you from potential hazards. Investing in safety equipment promotes a secure working environment, allowing for greater focus on the task at hand.

Equipping yourself with these essential tools fosters a smoother workflow and leads to successful outcomes. Each item plays a unique role in facilitating effective interventions and enhancing overall productivity.

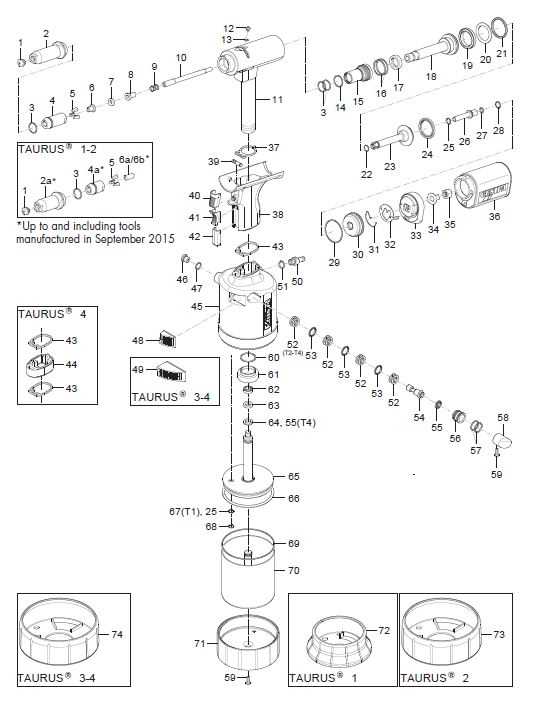

Step-by-Step Disassembly Guide

This section provides a comprehensive procedure for taking apart a specific device, ensuring a methodical approach to each step. Understanding the disassembly process is crucial for maintenance and troubleshooting, allowing for effective handling of components without causing damage.

Required Tools

Before starting, gather the necessary tools to facilitate a smooth disassembly. Having the right equipment on hand will save time and ensure safety during the process.

| Tool | Purpose |

|---|---|

| Screwdriver Set | For removing screws of various sizes |

| Pliers | For gripping and pulling components |

| Wrench | For loosening bolts and nuts |

| Soft Cloth | To protect surfaces and components |

Disassembly Steps

Follow these steps to carefully disassemble the device:

- Ensure the device is unplugged and all safety measures are taken.

- Remove any covers or panels by unscrewing fasteners.

- Detach components systematically, starting from the outer parts and working inwards.

- Label each part as you remove it to aid in reassembly.

- Keep screws and small parts organized to prevent loss.

Reassembling the Device Correctly

Properly reassembling the apparatus is crucial for ensuring its optimal functionality and longevity. Each component plays a vital role, and meticulous attention to detail during the reassembly process can prevent future malfunctions.

Follow these steps for an effective reassembly:

- Begin by organizing all parts. Ensure that screws, springs, and other small components are sorted by type.

- Refer to a visual guide if available. Diagrams or images can be invaluable in illustrating the correct configuration of parts.

- Start with the largest components, gradually moving to smaller ones. This approach helps maintain stability during assembly.

- Pay attention to the orientation of each piece. Misalignment can lead to operational issues.

- Secure all screws and fasteners firmly but avoid overtightening, which can damage threads or components.

Finally, after completing the assembly, conduct a thorough inspection. Ensure that all parts are properly fitted and there are no leftover components. This diligence will help guarantee the effective performance of the device.

Maintenance Practices for Longevity

Ensuring the durability of equipment requires a systematic approach to upkeep. Implementing effective care strategies not only enhances performance but also extends the lifespan of the device. Regular attention to maintenance can prevent potential issues and keep the machinery functioning optimally.

Routine Inspections

Conducting consistent assessments is crucial for identifying wear and tear. Regular checks help in spotting minor problems before they escalate into major repairs. Key aspects to monitor include:

- Mechanical components for signs of fatigue

- Connections for secure fittings

- Lubrication levels for smooth operation

Proper Cleaning Techniques

Keeping the machinery clean is essential for its efficient operation. Accumulated debris can hinder performance and lead to premature deterioration. Utilize appropriate cleaning methods to maintain a pristine environment:

- Use soft brushes for delicate areas

- Employ compressed air to remove dust

- Wipe surfaces with suitable solvents

| Maintenance Activity | Frequency | Notes |

|---|---|---|

| Visual Inspection | Weekly | Look for any visible damages |

| Lubrication | Monthly | Use manufacturer-recommended grease |

| Deep Cleaning | Quarterly | Follow specific cleaning protocols |

Electrical System Overview and Repair

The functionality of a mechanical device heavily relies on its electrical framework. This section delves into the components and workings of the circuitry, ensuring optimal performance and longevity. Understanding the intricacies of this system is crucial for effective troubleshooting and enhancement.

Key Components of the electrical setup include the power source, wiring, and connectors, each playing a vital role in energy distribution. The interaction between these elements ensures that the device operates smoothly. Regular inspection and maintenance of these components can prevent potential issues.

Common Issues that may arise within the electrical network often manifest as inconsistent performance or complete failure. Identifying these problems typically involves a systematic approach, including checking for loose connections, damaged wiring, or malfunctioning parts. Addressing these challenges promptly can restore functionality and prevent further complications.

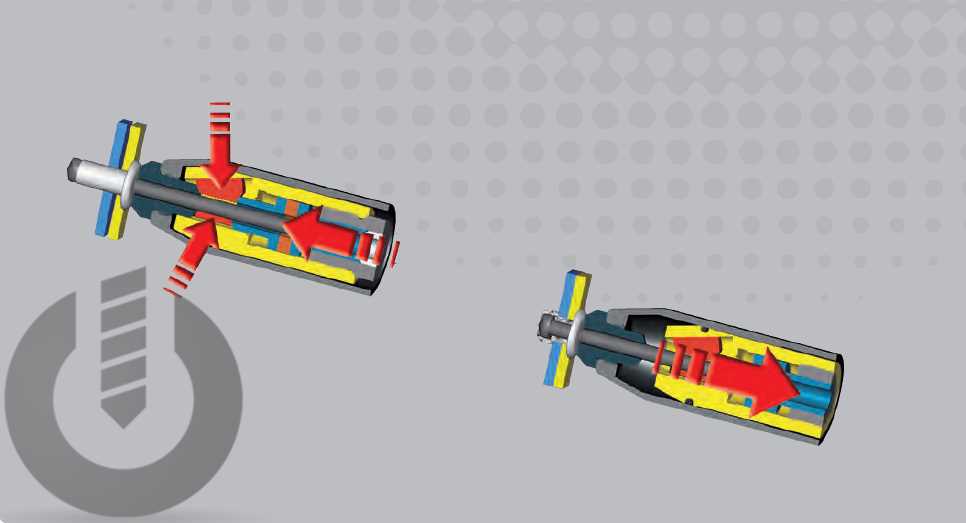

Hydraulic Components and Their Maintenance

Hydraulic systems are crucial for ensuring the efficient operation of various machines. Maintaining these elements is essential for optimal performance and longevity. Regular care not only enhances functionality but also prevents unexpected failures, ensuring a smooth workflow.

Key hydraulic components include pumps, cylinders, valves, and hoses. Each plays a vital role in the overall mechanism, and their proper functioning is interconnected. Regular inspection and maintenance of these parts can significantly reduce wear and tear, prolonging the life of the equipment.

Routine maintenance tasks should focus on checking fluid levels, inspecting for leaks, and ensuring all connections are secure. Replacing worn seals and filters can also enhance the efficiency of the system. A proactive approach to upkeep will minimize downtime and enhance productivity in any operation.

Upgrading Parts for Enhanced Performance

Improving the components of any mechanical device can lead to significant gains in efficiency and functionality. By selecting higher-quality or specialized parts, users can experience enhanced durability, increased power output, and greater precision in operation. This process not only optimizes performance but also extends the lifespan of the equipment.

Choosing Quality Components

Investing in premium materials and expertly engineered elements can make a substantial difference. Durable components are essential for achieving optimal results, as they withstand wear and tear better than standard options. Furthermore, advanced parts often incorporate innovative technologies that elevate overall performance.

Regular Assessments and Upgrades

Conducting routine evaluations allows users to identify areas for improvement. Keeping abreast of the latest advancements in parts technology can inform decisions about potential upgrades. Continuous enhancement ensures that the device operates at peak efficiency, adapting to the evolving demands of its environment.

Safety Precautions During Repair Work

Ensuring a safe environment is paramount when undertaking maintenance tasks on any device. Proper measures can significantly reduce the risk of accidents and injuries, allowing for a more efficient workflow. Understanding the potential hazards and preparing accordingly is essential for any technician.

Before beginning any service, it is crucial to equip oneself with the necessary protective gear. This includes items such as gloves, safety goggles, and masks to guard against debris and hazardous substances. Additionally, working in a well-ventilated area helps to mitigate exposure to harmful fumes.

| Safety Equipment | Description |

|---|---|

| Gloves | Protects hands from sharp edges and chemicals. |

| Safety Goggles | Prevents eye injuries from flying particles. |

| Mask | Reduces inhalation of dust and harmful vapors. |

| Ear Protection | Minimizes noise exposure in loud environments. |

Proper training and knowledge about the equipment being serviced are also vital. Technicians should familiarize themselves with the operational and safety guidelines to effectively identify risks and apply the correct procedures. Regularly updating these skills ensures a higher standard of safety in the workplace.

Frequently Asked Questions About Repairs

This section addresses common inquiries regarding the maintenance and troubleshooting of a specific device. Understanding these aspects can enhance the user experience and ensure longevity in performance.

Common Issues and Solutions

Users often encounter various challenges while operating their devices. Below are some frequently reported problems along with their suggested solutions.

| Issue | Solution |

|---|---|

| Device not powering on | Check the power source and connections. |

| Inconsistent performance | Inspect for blockages and clean as necessary. |

| Noisy operation | Ensure all components are securely fastened. |

Maintenance Tips

Regular upkeep is crucial for optimal functionality. Here are some recommendations to maintain your equipment effectively:

- Perform routine inspections to identify wear and tear.

- Keep the device clean to prevent dust buildup.

- Follow the manufacturer’s guidelines for specific upkeep procedures.