Yamaha R3 Comprehensive Repair Guide

Ensuring the longevity and performance of your two-wheeled companion involves understanding its intricate systems and components. This section aims to equip you with essential insights and procedures to effectively address common issues that may arise during your riding experience.

Whether you are dealing with mechanical challenges or routine upkeep, having a comprehensive resource can significantly enhance your skills and confidence. By following straightforward instructions and tips, you can foster a deeper connection with your vehicle while maximizing its efficiency and safety on the road.

From troubleshooting minor faults to performing significant service tasks, the following guidelines will empower you to tackle various situations with ease. Embracing the maintenance process not only safeguards your investment but also enriches your overall riding adventure.

Yamaha R3 Maintenance Overview

This section provides an overview of the essential procedures for maintaining the motorcycle, focusing on the key aspects that contribute to its longevity and performance. Proper upkeep ensures that all components function optimally, minimizing the risk of issues that could arise from neglect.

Routine Inspections

Regular checks are vital for identifying potential problems before they escalate. It is advisable to inspect fluid levels, brakes, and tire conditions frequently. By staying proactive, riders can enhance their safety and overall riding experience.

Scheduled Servicing

Adhering to a structured service schedule is crucial for comprehensive care. This includes changing oil, replacing filters, and adjusting the chain. Following manufacturer recommendations will help maintain the vehicle’s efficiency and reliability, ensuring smooth rides for years to come.

Common Issues and Solutions

When it comes to maintaining a two-wheeled vehicle, various challenges may arise that can affect performance and safety. Understanding these common problems and their solutions is essential for any owner to ensure smooth operation and longevity.

1. Engine Performance Problems: One of the frequent issues is a decrease in engine efficiency, which can manifest as rough idling or stalling. This can often be attributed to clogged filters or faulty spark plugs. Regularly replacing these components can significantly enhance performance.

2. Electrical System Failures: Electrical components, such as the battery or wiring, may experience failures over time. Symptoms include flickering lights or difficulty starting the engine. Checking connections and ensuring the battery is charged can often resolve these issues.

3. Brake System Concerns: Ineffective braking can pose serious safety risks. Worn brake pads or low fluid levels are common culprits. Regular inspections and timely replacements of pads and fluid can help maintain optimal braking performance.

4. Tire Wear and Pressure Issues: Maintaining proper tire pressure is crucial for handling and fuel efficiency. Under-inflated tires can lead to increased wear and poor traction. Regularly checking tire pressure and tread depth can prevent these issues from escalating.

By being aware of these potential issues and implementing timely solutions, owners can significantly enhance their riding experience and ensure their vehicle remains in excellent condition.

Tools Required for Repairs

Proper maintenance and restoration of your motorcycle necessitate a range of essential instruments. These tools not only facilitate the process but also ensure accuracy and efficiency when addressing various issues. Familiarity with the required items can significantly simplify your tasks, making it easier to keep your vehicle in optimal condition.

Here are some of the fundamental tools you will need:

- Wrenches: A set of both metric and imperial wrenches is vital for loosening and tightening bolts.

- Screwdrivers: Various sizes of flathead and Phillips screwdrivers are necessary for different types of screws.

- Socket Set: A comprehensive socket set allows for easier access to hard-to-reach bolts.

- Torque Wrench: This tool helps in applying the correct torque to bolts, preventing over-tightening.

- Pliers: Needle-nose and regular pliers are useful for gripping and bending tasks.

Additionally, consider acquiring the following specialized equipment:

- Chain Breaker: Essential for working on the motorcycle chain.

- Stand: A suitable stand will stabilize your bike during maintenance.

- Oil Filter Wrench: This makes oil changes more manageable by assisting in removing the oil filter.

- Cleaning Supplies: A good set of rags, brushes, and cleaners will help keep your machine in top shape.

By equipping yourself with these tools, you’ll be well-prepared to handle various tasks, ensuring your motorcycle remains reliable and efficient on the road.

Step-by-Step Troubleshooting Guide

This section provides a comprehensive approach to identifying and resolving common issues encountered during operation. By following a systematic method, users can effectively diagnose problems, ensuring optimal performance and longevity of the vehicle.

Identifying Symptoms

Begin by observing the behavior of the vehicle. Note any irregular sounds, unusual vibrations, or performance issues. Documenting these symptoms is crucial as it helps narrow down potential causes and leads to more accurate solutions.

Systematic Checks

Next, conduct a series of checks, starting with the basic components such as the battery, fuel system, and electrical connections. Inspecting each part methodically can reveal issues that might not be immediately apparent. Ensure all connections are secure and free from corrosion.

Engine Maintenance Procedures

Proper upkeep of the engine is crucial for optimal performance and longevity. Following systematic procedures not only enhances efficiency but also minimizes the risk of unexpected failures. Regular maintenance tasks should be performed at specified intervals to ensure that the engine operates smoothly.

Essential Maintenance Tasks

- Check and replace the engine oil regularly.

- Inspect the air filter and clean or replace as needed.

- Monitor the coolant level and top up as necessary.

- Examine the spark plugs for wear and replace if necessary.

- Ensure all hoses and belts are in good condition.

Lubrication and Cleaning

Keeping the engine components well-lubricated is vital for reducing friction and wear. Additionally, a clean engine prevents debris accumulation, which can hinder performance. Implement the following steps:

- Use high-quality oil recommended for your engine type.

- Regularly clean external parts to remove dirt and grime.

- Lubricate moving parts according to the manufacturer’s guidelines.

Electrical System Diagnostics

The electrical system plays a crucial role in the overall functionality of the vehicle. Proper diagnostics are essential to ensure that all components are operating efficiently. This section will provide an overview of key diagnostic practices, helping to identify potential issues within the electrical framework.

Understanding Electrical Components

To effectively diagnose electrical problems, one must have a solid understanding of the various components involved. This includes the battery, wiring, fuses, and connectors. Each element must be examined for signs of wear, corrosion, or damage that could hinder performance.

Diagnostic Techniques

Utilizing the right diagnostic techniques is vital for accurate assessments. Start with visual inspections, checking for loose connections or frayed wires. Following this, employing a multimeter can help measure voltage, current, and resistance. By carefully analyzing these readings, one can pinpoint issues and determine the necessary corrective actions.

Suspension and Brake Adjustments

The performance of a motorcycle greatly relies on the proper setup of its suspension and braking system. These components play a crucial role in ensuring stability, handling, and safety while riding. Adjustments can enhance comfort and responsiveness, allowing the rider to maintain control under various conditions. It is essential to understand the key aspects involved in tuning these systems for optimal performance.

Suspension Setup

Adjusting the suspension involves modifying preload, compression, and rebound settings to suit the rider’s weight and riding style. Proper setup can significantly improve cornering stability and overall ride comfort. It is advisable to follow the manufacturer’s guidelines and consider personal preferences when making adjustments.

Brake System Tuning

Brake adjustments are vital for achieving effective stopping power. Ensuring that the brake pads, fluid levels, and calipers are correctly positioned can enhance performance. Regular maintenance checks and adjustments are necessary to ensure responsiveness and safety.

| Adjustment Type | Description | Recommended Frequency |

|---|---|---|

| Preload | Adjusts the initial tension on the suspension springs. | Every 2000 miles |

| Compression | Controls how quickly the suspension compresses. | Every 2000 miles |

| Rebound | Regulates the speed at which the suspension returns to its original position. | Every 2000 miles |

| Brake Pad Inspection | Checks for wear and replaces as necessary. | Every 1000 miles |

| Fluid Level Check | Ensures proper brake fluid levels for effective braking. | Every 1000 miles |

Regular Service Intervals Explained

Understanding maintenance schedules is crucial for optimal performance and longevity of your vehicle. Consistent servicing not only ensures that your machine operates efficiently but also helps identify potential issues before they escalate into major problems.

Importance of Regular Maintenance

Adhering to a maintenance schedule provides several benefits:

- Enhances overall performance

- Improves fuel efficiency

- Extends the lifespan of components

- Increases safety on the road

Typical Service Intervals

Here are common service intervals to consider for regular upkeep:

- Every 1,000 miles: Inspect and change the oil, check fluid levels, and examine the brakes.

- Every 3,000 miles: Replace the air filter and check tire pressure and condition.

- Every 6,000 miles: Inspect the chain, adjust the suspension, and check the battery.

- Annually: Perform a comprehensive inspection and replace any worn parts.

Following these intervals can help maintain peak performance and prevent unforeseen issues, ensuring a smoother and safer ride.

Parts Replacement Guidelines

Replacing components in a vehicle is essential for maintaining optimal performance and safety. Following proper procedures ensures that new parts function correctly and contribute to the longevity of the system.

Here are key considerations for successful component substitution:

- Identify the Part: Ensure you know the specific part number and specifications to avoid compatibility issues.

- Use Quality Components: Always opt for high-quality replacements to ensure reliability and performance.

- Follow Manufacturer Recommendations: Adhere to suggested guidelines for installation and specifications.

- Inspect Surrounding Areas: Examine adjacent components for wear or damage during the replacement process.

- Document the Process: Keep records of what parts were replaced and when, for future reference.

Additionally, it is advisable to follow a systematic approach:

- Gather Tools: Assemble the necessary tools before starting the replacement to streamline the process.

- Ensure Safety: Always take precautions, such as disconnecting the battery and using protective gear.

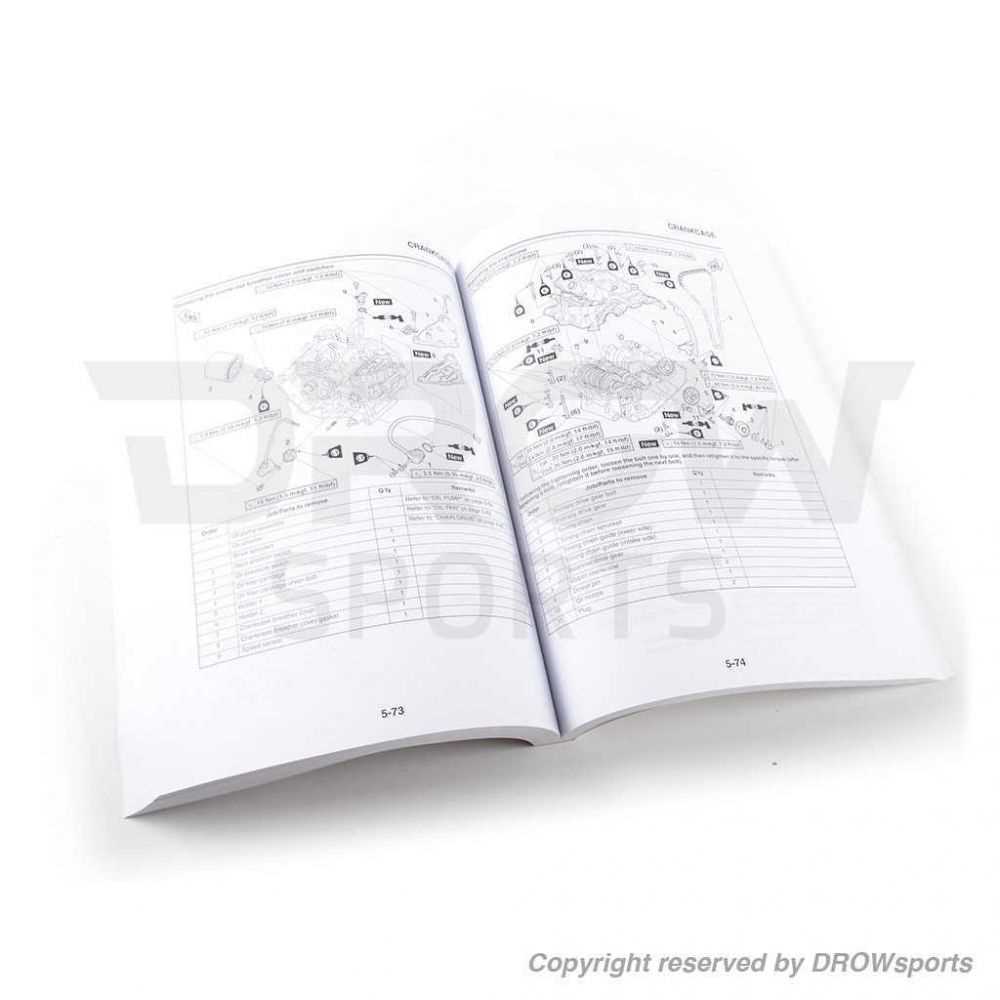

- Consult Technical Resources: Refer to instructional documents or guides specific to the components being replaced.

- Test After Replacement: After installation, check the functionality to ensure everything operates correctly.

Adhering to these guidelines will enhance the effectiveness of component replacements and contribute to overall vehicle health.

Upgrading Yamaha R3 Components

Enhancing the performance of your motorcycle can significantly improve your riding experience. Focusing on key elements can lead to better handling, increased power, and overall efficiency. This section will explore various upgrades that can transform your ride.

Key Areas for Improvement

- Suspension: Upgrading the suspension can provide improved stability and comfort on different terrains.

- Exhaust System: A high-performance exhaust can increase horsepower and improve sound.

- Brakes: Better braking components ensure safety and responsiveness during rides.

- Air Intake: Enhancing the air intake system can improve engine efficiency and throttle response.

Choosing the Right Components

- Research reputable brands that offer quality products.

- Consider compatibility with your existing setup.

- Evaluate your riding style to determine the best upgrades.

- Seek recommendations from experienced riders and forums.

Investing in the right components can elevate your motorcycle’s performance and provide a more enjoyable riding experience. Always ensure that modifications are carried out correctly to maximize benefits.

Safety Tips During Repairs

When working on mechanical tasks, prioritizing safety is essential to ensure a secure environment. Adhering to proper protocols can prevent accidents and injuries, allowing for a smoother workflow and effective outcomes.

Wear Appropriate Gear: Always equip yourself with protective clothing, gloves, and goggles. This attire safeguards against potential hazards, such as sharp edges or harmful substances.

Organize Your Workspace: A clutter-free area minimizes distractions and the risk of mishaps. Ensure all tools are within reach and that the surroundings are clear of unnecessary items.

Understand the Equipment: Familiarize yourself with the machinery or components you are working on. Knowing the functions and specifications helps in avoiding mistakes and promotes efficiency.

Follow Guidelines: Stick to established procedures and instructions. Deviating from recommended practices can lead to unforeseen complications.

Take Breaks: Working for extended periods can cause fatigue, increasing the likelihood of errors. Regular breaks refresh your focus and maintain high standards of safety.