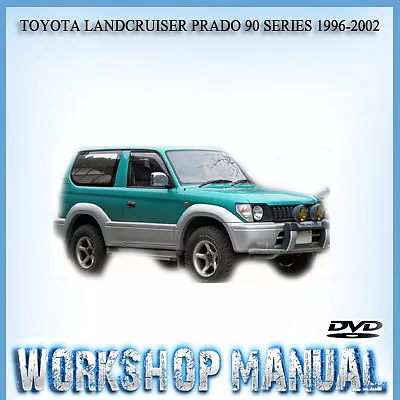

Toyota Land Cruiser Prado 90-95 Series Repair and Service Manual Guide

This section provides an extensive overview of essential procedures and practices necessary for the upkeep and repair of your vehicle. It aims to equip you with the knowledge and skills required to ensure optimal performance and longevity, highlighting common issues and their solutions.

Understanding the intricacies of your automobile is crucial for effective maintenance. This guide encompasses a range of topics, from routine inspections to more complex troubleshooting methods. The focus is on enabling owners to take proactive steps in managing their vehicle’s health, thereby enhancing its reliability and functionality.

In addition to practical tips, the content delves into the specific components that are vital for smooth operation. Familiarizing yourself with these parts can significantly reduce the likelihood of unexpected breakdowns, ensuring that your vehicle remains in excellent condition for years to come.

Toyota Land Cruiser Prado 90-95 Series Repair Guide

This section provides comprehensive instructions for maintaining and fixing your vehicle from the specified era. Understanding the essential procedures and common issues will help enhance your experience and ensure longevity.

Regular maintenance is crucial for optimal performance. Below are some key areas to focus on:

- Engine Maintenance: Regular oil changes and inspections are necessary to keep the engine running smoothly.

- Transmission Care: Monitor fluid levels and check for leaks to maintain proper functionality.

- Braking System: Inspect brake pads and fluid levels periodically to ensure safety.

- Suspension Components: Regularly check for wear and replace any faulty parts to maintain ride quality.

In addition to routine checks, be prepared for specific challenges that may arise:

- Engine overheating due to coolant leaks or thermostat failure.

- Transmission slippage, which may indicate low fluid levels or internal issues.

- Electrical problems, often stemming from faulty wiring or battery issues.

- Suspension noise, which can be a sign of worn-out bushings or shock absorbers.

By following these guidelines, you can effectively manage your vehicle’s upkeep and address any potential concerns. Keeping a proactive approach will ensure a reliable and enjoyable driving experience.

Overview of the Vehicle Features

This section provides a comprehensive look at the characteristics and functionalities of the vehicle, emphasizing its design and performance attributes. Understanding these features is essential for owners and enthusiasts alike, as it highlights the capabilities and advantages that the vehicle offers in various driving conditions.

Design and Comfort

The vehicle boasts a robust design that combines ruggedness with aesthetic appeal. Its spacious interior ensures passenger comfort during long journeys, featuring ergonomic seating and ample cargo space. Advanced climate control systems further enhance the driving experience, providing a pleasant atmosphere regardless of external weather conditions.

Performance and Capability

Equipped with a powerful engine and advanced drivetrain, the vehicle excels in both on-road and off-road scenarios. The all-wheel-drive system offers enhanced traction and stability, making it suitable for challenging terrains. Additionally, the suspension system is designed to absorb shocks effectively, ensuring a smooth ride over rough surfaces. Safety features include advanced braking systems and structural reinforcements that prioritize passenger protection.

Overall, this vehicle stands out as a versatile choice for those seeking reliability and performance in their automotive adventures.

Common Problems and Solutions

This section addresses frequent issues encountered by vehicle owners and provides effective solutions to enhance the overall performance and longevity of their automobiles. Understanding these common challenges can help drivers take proactive measures to maintain their vehicles and avoid costly repairs.

Electrical System Issues

Electrical problems can significantly affect vehicle performance. Here are some common electrical issues:

- Battery failure

- Faulty alternator

- Wiring harness damage

To resolve these issues:

- Regularly check battery connections for corrosion and tightness.

- Test the alternator output to ensure it meets specifications.

- Inspect wiring for any signs of wear or damage and replace as necessary.

Suspension and Steering Concerns

The suspension and steering systems are crucial for handling and ride comfort. Common problems include:

- Worn-out shock absorbers

- Misalignment of wheels

- Unusual noises during turns

To address these issues:

- Replace worn shock absorbers to restore ride quality.

- Have the wheel alignment checked and adjusted regularly.

- Identify and replace any worn steering components to eliminate noise.

Engine Maintenance and Servicing Tips

Proper upkeep of the engine is essential for ensuring optimal performance and longevity of any vehicle. Regular maintenance not only helps in identifying potential issues before they escalate but also enhances fuel efficiency and overall reliability. This section provides valuable insights into effective practices that can be employed to keep the engine in prime condition.

Regular Oil Changes

Changing the oil at recommended intervals is one of the most crucial aspects of engine care. Fresh oil lubricates the engine components, reducing friction and preventing wear. It is advisable to consult the manufacturer’s specifications to determine the appropriate oil type and change frequency. Additionally, using high-quality filters will ensure that contaminants are effectively removed, contributing to the engine’s health.

Cooling System Maintenance

The cooling system plays a vital role in preventing the engine from overheating. Regularly checking the coolant levels and inspecting for leaks is essential. Flushing the cooling system periodically helps remove rust and debris, ensuring efficient heat exchange. It is also important to monitor the condition of hoses and the radiator to avoid any potential failures that could lead to severe engine damage.

Transmission Troubleshooting Techniques

Effective troubleshooting of transmission issues is essential for maintaining optimal performance and ensuring longevity. By systematically identifying and addressing potential problems, one can enhance vehicle reliability and prevent costly repairs. This section outlines various techniques for diagnosing transmission-related malfunctions.

Here are some common symptoms that may indicate transmission problems:

- Unusual noises during gear shifting

- Delayed engagement when shifting gears

- Fluid leaks under the vehicle

- Warning lights illuminated on the dashboard

- Slipping gears or unexpected acceleration

To effectively diagnose these issues, consider the following troubleshooting techniques:

- Visual Inspection: Examine the transmission for signs of leakage or damage. Check fluid levels and condition, as low or dirty fluid can lead to performance issues.

- Diagnostic Tools: Utilize scan tools to retrieve error codes from the vehicle’s computer. This information can provide insight into specific malfunctions or system failures.

- Road Test: Conduct a road test to replicate the symptoms. Pay attention to shifts, noises, and any abnormal behavior while driving.

- Fluid Analysis: Analyze the transmission fluid for metal shavings or burnt odors, which can indicate internal damage or wear.

- Electrical Checks: Inspect electrical connections and components related to the transmission, as electronic failures can also contribute to performance issues.

By following these techniques, one can effectively identify and address transmission problems, ensuring that the vehicle operates smoothly and efficiently.

Suspension and Steering Adjustments

This section focuses on the essential modifications and fine-tuning required for the suspension and steering systems of your vehicle. Proper adjustments ensure optimal performance, stability, and safety while driving. Regular maintenance and precise alignments can enhance handling characteristics and prolong the lifespan of components.

To achieve the best results, it’s important to follow specific procedures and utilize the right tools. Below is a table outlining key adjustments, their purposes, and recommended specifications:

| Adjustment | Purpose | Recommended Specification |

|---|---|---|

| Camber Angle | Enhances tire contact with the road | 0° ±0.5° |

| Toe-In | Improves straight-line tracking | 1/16″ to 1/8″ |

| Caster Angle | Stabilizes steering and enhances cornering | 3° ±1° |

| Shock Absorber Settings | Controls ride quality and handling | As per manufacturer specifications |

| Spring Preload | Adjusts ride height and weight distribution | As per manufacturer specifications |

By adhering to these guidelines and regularly checking alignment settings, you can ensure a smoother driving experience and optimal vehicle performance.

Braking System Inspection Procedures

Ensuring the functionality of the braking system is crucial for vehicle safety and performance. Regular inspections help identify potential issues before they escalate into serious problems. This section outlines essential procedures to thoroughly evaluate the braking components and maintain optimal performance.

1. Visual Inspection: Begin by examining the brake components for any visible signs of wear or damage. Check the brake pads for thickness and ensure there are no cracks or uneven wear patterns. Inspect the rotors for grooves, rust, or warping, which could affect braking efficiency.

2. Fluid Check: Assess the brake fluid level in the reservoir. Low fluid levels can indicate leaks within the system. Also, check the condition of the fluid; it should be clear and free from contaminants. If the fluid appears dark or murky, it may need replacement.

3. Brake Line Examination: Inspect the brake lines for any signs of corrosion or leaks. Look for damp areas around the connections and along the length of the lines. Any signs of deterioration should be addressed promptly to prevent brake failure.

4. Testing Brake Performance: Conduct a road test to evaluate braking performance. Pay attention to any unusual noises, vibrations, or pulling to one side while braking. These symptoms can indicate underlying issues that require further investigation.

5. Professional Assessment: If any irregularities are noted during the inspection, it is advisable to consult a professional technician. They can perform more in-depth diagnostics and repairs, ensuring that the braking system operates safely and effectively.

Electrical System Diagnosis Steps

The process of diagnosing electrical issues in vehicles is crucial for maintaining optimal performance and safety. This section outlines systematic approaches to identifying and resolving common electrical problems. By following these steps, technicians can efficiently pinpoint issues, ensuring effective repairs and reliable operation.

Initial Assessment

Begin by gathering information regarding the symptoms reported by the vehicle owner. This helps in narrowing down potential problems. Follow these steps:

- Ask about specific electrical failures (e.g., lights, ignition).

- Note any unusual behaviors or warning lights on the dashboard.

- Check the vehicle’s history for previous electrical repairs.

Visual Inspection

A thorough visual examination can reveal many issues before diving into technical diagnostics. Consider the following:

- Inspect wiring for damage, wear, or corrosion.

- Examine connectors for secure fits and signs of oxidation.

- Look for blown fuses and replace if necessary.

Testing Components

Once the initial assessment and visual inspection are complete, proceed with testing various electrical components:

- Use a multimeter to measure voltage at key points.

- Test continuity in wiring harnesses and circuits.

- Check the operation of switches and relays.

Document all findings during each step, as this information will be valuable for further analysis or repairs. A structured approach not only aids in diagnosis but also enhances overall service efficiency.

Cooling System Maintenance Practices

Proper upkeep of the cooling system is essential for optimal engine performance and longevity. Regular maintenance helps prevent overheating, which can lead to severe engine damage. By following systematic practices, vehicle owners can ensure their cooling system operates efficiently and effectively, contributing to overall vehicle reliability.

Key Maintenance Tasks

- Regularly check the coolant level and condition.

- Inspect hoses and connections for signs of wear or leaks.

- Flush the cooling system periodically to remove debris and old coolant.

- Examine the radiator for blockages or damage.

- Test the thermostat for proper function.

Recommended Frequency

It is advisable to conduct cooling system inspections at least twice a year or before long trips. Additionally, flushing the system should be performed every two years or as recommended by the manufacturer. Keeping a close eye on the coolant level and condition can prevent potential issues before they escalate.

By implementing these maintenance practices, vehicle owners can prolong the lifespan of their cooling systems, ensuring optimal performance and minimizing the risk of costly repairs.

Fuel System Cleaning Methods

Maintaining the cleanliness of the fuel system is essential for optimal engine performance and efficiency. Over time, fuel injectors and fuel lines can accumulate deposits, leading to decreased fuel flow and performance issues. Implementing effective cleaning techniques can help restore the system’s functionality and prolong the life of the engine.

Mechanical Cleaning involves the physical removal of deposits from various components within the fuel system. This can be achieved through the use of specialized tools designed to clean injectors and fuel rails. Disassembling the components allows for thorough inspection and cleaning, ensuring that any obstructions are removed.

Chemical Cleaning methods utilize specific cleaning agents that dissolve carbon deposits and contaminants. These products are introduced into the fuel system either through the fuel tank or directly into the intake manifold. It is crucial to select high-quality cleaning solutions that are compatible with the engine to avoid potential damage.

Ultrasonic Cleaning is a highly effective method for cleaning fuel injectors. This process uses ultrasonic waves to agitate a cleaning solution, which removes deposits from injectors without disassembly. It ensures a thorough cleaning and is particularly beneficial for restoring the precision of injector spray patterns.

Fuel Additives are another option for maintaining cleanliness within the fuel system. Regular use of additives can help to prevent buildup and maintain optimal fuel flow. These products are formulated to keep injectors clean and enhance fuel quality, contributing to better overall engine performance.

Bodywork and Interior Repairs

This section focuses on the essential aspects of maintaining and restoring the exterior and interior components of a vehicle. Proper care and attention can enhance the overall aesthetics and functionality, ensuring longevity and comfort for occupants.

Exterior Maintenance

Maintaining the outer shell of a vehicle involves regular inspections and prompt repairs. Common issues include dents, scratches, and rust formation. To address these, it’s crucial to assess the extent of damage and determine the appropriate repair methods. For minor dents, techniques such as paintless dent removal can be effective, while more significant damages may require panel replacement. Regular washing and waxing not only preserve the paint finish but also protect against environmental elements.

Interior Restoration

The interior of a vehicle plays a vital role in passenger comfort and overall driving experience. Over time, upholstery can wear out, and surfaces may become stained or damaged. Restoring these elements involves cleaning, reupholstering, or replacing worn components. Utilizing high-quality materials for repairs ensures durability. Additionally, maintaining proper care of electronic components and fixtures is essential for a fully functional and enjoyable environment.

In summary, a comprehensive approach to both exterior and interior maintenance can significantly enhance the lifespan and value of a vehicle. Regular upkeep not only addresses immediate concerns but also contributes to a more enjoyable driving experience.

Regular Maintenance Schedule Recommendations

Consistent upkeep is vital for ensuring optimal performance and longevity of your vehicle. Adhering to a structured maintenance plan not only enhances reliability but also minimizes the risk of unexpected breakdowns. Below are essential recommendations for a regular maintenance schedule.

- Engine Oil Change: Every 5,000 to 7,500 miles, depending on driving conditions.

- Air Filter Replacement: Check every 15,000 miles and replace as necessary.

- Brake Inspection: Inspect brakes at least twice a year to ensure safety.

- Tire Rotation: Rotate tires every 6,000 to 8,000 miles to promote even wear.

- Fluid Levels Check: Regularly check and top off fluids, including coolant, transmission fluid, and brake fluid.

Following these guidelines can help maintain your vehicle’s efficiency and prevent costly repairs. It’s advisable to consult a professional for specific needs based on driving habits and environmental factors.

Tools Required for Efficient Repairs

When undertaking maintenance tasks on vehicles, having the right set of tools is essential for achieving optimal results. A well-equipped toolkit not only streamlines the repair process but also enhances safety and effectiveness. Below are key instruments that every mechanic should consider for efficient work.

Essential Hand Tools

Basic hand tools form the backbone of any maintenance endeavor. A good assortment of wrenches, ratchets, and screwdrivers is necessary to tackle a variety of tasks. Additionally, having a quality socket set can greatly facilitate work on hard-to-reach bolts and nuts.

Specialized Equipment

Beyond hand tools, certain specialized equipment can significantly improve the repair experience. For instance, a reliable jack and jack stands are crucial for safely lifting the vehicle during service. Furthermore, an OBD-II scanner can provide valuable diagnostic information, helping to identify issues quickly and accurately.