Toro Timemaster Repair Guide

Ensuring the longevity and optimal performance of your lawn care apparatus requires a thorough understanding of its components and functionality. This section aims to provide essential insights and troubleshooting techniques that can enhance the efficiency of your machinery. Proper maintenance not only extends the life of the equipment but also guarantees a pristine lawn with minimal effort.

Throughout this guide, you will discover practical tips and detailed instructions tailored to address common issues faced by users. Emphasizing the importance of regular upkeep, we will explore various methods to keep your device in top condition. From adjusting settings to cleaning and lubrication, these guidelines are designed to empower you with the knowledge necessary for successful maintenance.

By familiarizing yourself with the key elements of your lawn care tools, you will be better equipped to identify potential problems before they escalate. With diligence and attention to detail, you can ensure that your equipment operates smoothly, allowing you to enjoy the benefits of a well-manicured yard.

Many individuals encounter various challenges when utilizing lawn care equipment. Understanding these common problems can help in diagnosing and resolving issues more effectively, leading to a smoother operation and improved performance.

Frequent Problems

Users often report several recurring difficulties, which can stem from different factors such as maintenance neglect, incorrect usage, or manufacturing flaws. Addressing these problems promptly can prevent more significant complications.

| Issue | Description | Possible Solutions |

|---|---|---|

| Starting Difficulties | Inability to start the equipment, often caused by fuel issues or electrical problems. | Check fuel levels, inspect the battery and connections, and clean the spark plug. |

| Uneven Cutting | Grass may not be cut evenly, leading to an unkempt appearance. | Ensure blades are sharp and properly adjusted for height. |

| Overheating | Equipment may overheat during operation, resulting in shutdowns. | Allow for proper ventilation, clean air filters, and check oil levels regularly. |

Conclusion

By familiarizing oneself with these common challenges, users can take proactive measures to maintain their lawn equipment, ensuring it operates efficiently and effectively throughout the season.

Essential Tools for Repairing

Having the right set of instruments is crucial for maintaining and restoring equipment effectively. A well-equipped toolkit can significantly streamline the process, ensuring that you can tackle various tasks with ease and efficiency.

Among the most important items are wrenches and screwdrivers, which allow for loosening and tightening various components. Additionally, pliers come in handy for gripping and manipulating small parts, while socket sets provide versatility for a range of fasteners. Multimeters are also essential for diagnosing electrical issues, ensuring that all systems function correctly.

Moreover, having a workbench equipped with proper lighting enhances visibility and organization. Safety gear, such as gloves and goggles, is also vital to protect oneself during any maintenance tasks. Lastly, investing in lubricants and cleaning supplies can help prolong the lifespan of your equipment by maintaining optimal performance.

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to ensuring the longevity and optimal performance of your lawn care equipment. Regular upkeep is essential to prevent mechanical issues and enhance efficiency. Following this guide will help you keep your machine in excellent condition, ensuring it operates smoothly throughout the season.

1. Cleaning: Begin by removing any grass clippings, dirt, and debris from the exterior and undercarriage. A clean surface prevents rust and maintains performance. Use a brush or compressed air for thorough cleaning.

2. Checking the Blades: Inspect the cutting blades for sharpness and damage. Dull or damaged blades can hinder cutting efficiency. Sharpen or replace them as necessary to ensure a clean cut.

3. Inspecting the Engine: Regularly check the engine oil level and quality. Change the oil according to the manufacturer’s recommendations to prevent engine wear and tear.

4. Air Filter Maintenance: Examine the air filter for dirt and debris. A clean air filter is crucial for optimal engine performance. Replace it if it appears clogged or damaged.

5. Fuel System Care: Ensure the fuel is fresh and free of contaminants. Old or contaminated fuel can lead to engine problems. Consider using a fuel stabilizer to prolong the life of your fuel.

6. Tire Inspection: Check tire pressure and condition. Properly inflated tires improve traction and maneuverability. Replace any tires that show signs of excessive wear.

7. Battery Maintenance: For battery-powered models, regularly check the battery’s charge level and terminals. Clean any corrosion and ensure secure connections to maintain optimal performance.

By adhering to this maintenance guide, you can significantly enhance the performance and lifespan of your equipment, ensuring it serves you well for years to come.

Diagnosing Engine Problems

Identifying issues with the engine is crucial for ensuring optimal performance and longevity of your equipment. Recognizing symptoms early can prevent more severe complications down the line. Various signs may indicate underlying problems that require careful investigation.

Start by listening for unusual noises while the engine is running. Sounds such as knocking, rattling, or hissing can be indicators of mechanical issues. Additionally, pay attention to any vibrations that seem out of the ordinary, as these can signify misalignment or worn components.

Next, observe the performance during operation. If the engine struggles to start or loses power while in use, it may be time to check the fuel system, spark plugs, or air filters. A noticeable decrease in efficiency can often point to issues that need immediate attention.

Finally, keep an eye on emissions from the exhaust. Smoke in various colors–blue, black, or white–can indicate specific problems. Blue smoke typically suggests oil consumption, while black smoke often indicates a rich fuel mixture. White smoke can be a sign of coolant entering the combustion chamber.

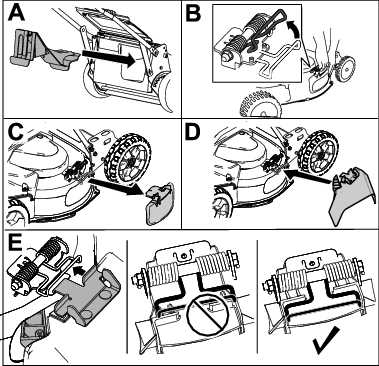

Replacing Blades and Cables

Maintaining the sharpness of the cutting edges and ensuring the cables are in good condition are vital for optimal performance. This section provides guidance on how to effectively change the blades and cables of your equipment, enhancing its longevity and efficiency.

Steps for Replacing Blades

To ensure safe and efficient operation, follow these steps when replacing the blades:

- Disconnect the power source to prevent accidental activation.

- Use appropriate tools to remove the existing blades carefully.

- Inspect the blade holder for any signs of damage or wear.

- Install the new blades securely, ensuring they are properly aligned.

- Reconnect the power source and perform a test run to verify functionality.

Steps for Replacing Cables

Replacing worn or damaged cables is crucial for safe operation. Here’s how to do it:

- Identify the cables that need replacement and assess their condition.

- Carefully detach the old cables, taking note of their connections.

- Install the new cables, ensuring they are routed correctly.

- Secure all connections tightly to avoid any malfunctions.

- Test the equipment to confirm that all functions operate smoothly.

Cleaning and Lubricating Components

Regular maintenance is essential for ensuring the longevity and optimal performance of your equipment. This involves not only cleaning but also properly lubricating various parts to minimize wear and tear. Keeping components free of debris and adequately oiled helps maintain efficiency and prevents unnecessary breakdowns.

Here are some key steps to effectively clean and lubricate the important parts:

-

Cleaning:

- Disconnect the power source to ensure safety during maintenance.

- Remove any grass clippings, dirt, or debris from the exterior surfaces using a brush or compressed air.

- Clean the blades and any cutting surfaces thoroughly to maintain cutting performance.

- Inspect the air filter and clean or replace it if necessary to promote efficient operation.

-

Lubrication:

- Use the recommended lubricant for specific components, such as bearings and pivot points.

- Apply lubricant sparingly to avoid attracting dirt and grime.

- Check the owner’s guidelines for any specific lubrication points and intervals.

- Ensure that excess lubricant is wiped away to prevent buildup that could hinder performance.

By following these maintenance practices, you can ensure that your equipment remains in peak condition, allowing for efficient and effective operation throughout its lifespan.

Electrical System Troubleshooting

Diagnosing issues within the electrical framework of a lawn maintenance machine is essential for ensuring optimal performance. Understanding how to identify and address common electrical problems can save time and enhance the longevity of the equipment. This section will explore typical faults, their causes, and effective solutions.

Common Electrical Issues

Among the prevalent electrical challenges, battery failure is often a primary concern. Signs of a malfunctioning battery may include dimming lights or the machine failing to start. Another frequent issue is faulty wiring, which can lead to intermittent power loss or erratic behavior of electrical components.

Troubleshooting Steps

To begin troubleshooting, first inspect the battery connections for corrosion and ensure they are secure. If the battery appears fine, move on to check the wiring for any signs of damage or wear. Using a multimeter can help measure voltage levels throughout the system to identify weak points. If necessary, consult the device’s specifications to ensure all components are functioning within normal parameters.

Regular maintenance and prompt attention to electrical problems can significantly extend the lifespan of your equipment. Always follow safety precautions when handling electrical components.

Parts Replacement Procedures

This section outlines the essential steps for effectively substituting components in your equipment. Understanding the process of part replacement is crucial for maintaining optimal performance and extending the lifespan of your device.

Step 1: Begin by gathering the necessary tools and replacement parts. Ensure that you have everything on hand before starting the procedure to avoid interruptions.

Step 2: Carefully disconnect the power source to prevent any accidents. Safety should always be the top priority when working with mechanical devices.

Step 3: Identify the part that needs to be replaced. Consult the specifications to ensure you are handling the correct component, and follow the recommended guidelines for removal.

Step 4: Remove the defective part by following the outlined steps in the specifications. Be gentle to avoid damaging surrounding components.

Step 5: Install the new part securely, ensuring that it is properly aligned and fitted. Double-check your work to confirm that everything is in place.

Step 6: Reconnect the power source and test the device to ensure that the replacement was successful. Observe its operation to confirm that it is functioning as intended.

By following these procedures meticulously, you can ensure a smooth replacement process, leading to enhanced functionality and durability of your equipment.

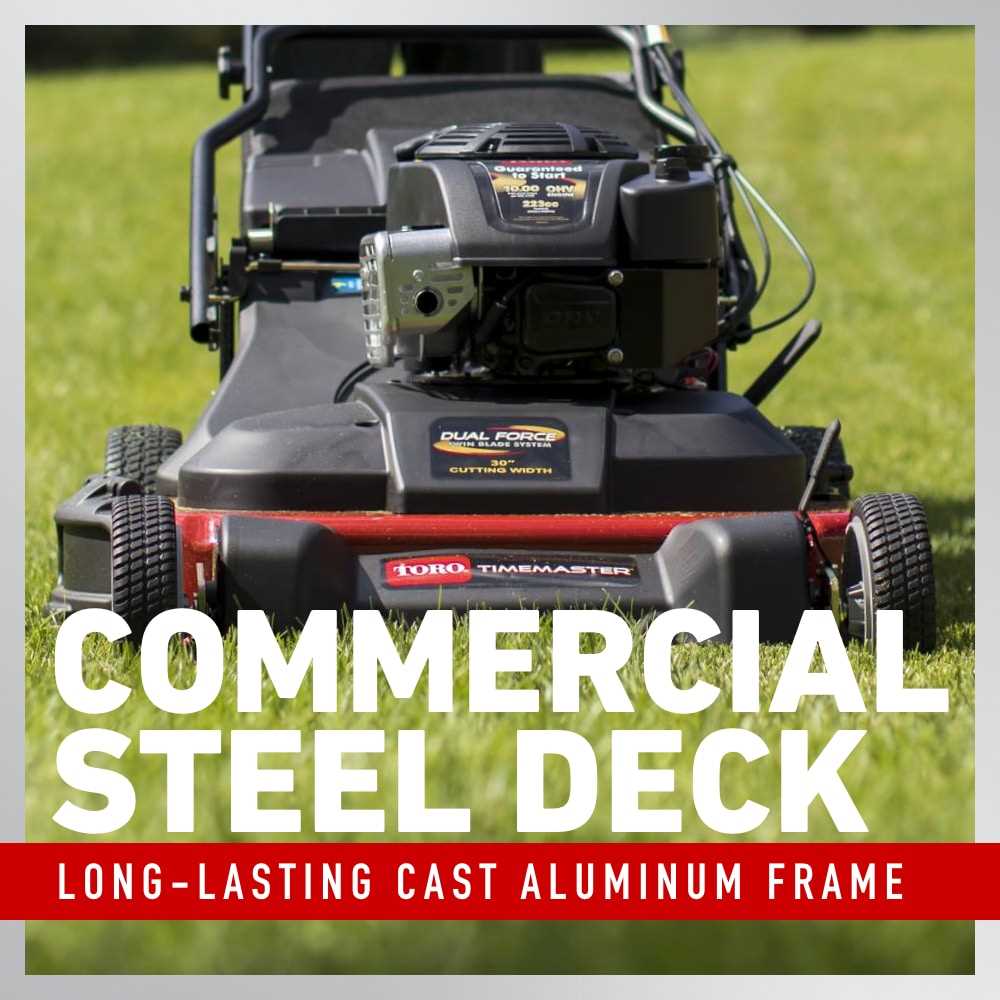

Upgrading Your Toro Timemaster

Enhancing the performance and functionality of your lawn maintenance equipment can significantly improve its efficiency and longevity. By focusing on specific upgrades, users can transform their machines to better meet their gardening needs and preferences. This section outlines various modifications that can elevate your mowing experience.

Performance Enhancements

Boosting the power and efficiency of your equipment often involves replacing or upgrading specific components. Consider the following options:

| Component | Upgrade Option | Benefits |

|---|---|---|

| Engine | Higher RPM Model | Increased cutting power and speed |

| Blades | Sharp, High-Performance Blades | Cleaner cuts and improved grass health |

| Wheels | Larger, Traction-Focused Tires | Better grip on uneven terrain |

Convenience Features

Incorporating additional features can enhance user experience and make lawn care more enjoyable. Here are some suggestions:

| Feature | Upgrade Option | Benefits |

|---|---|---|

| Handle | Adjustable Ergonomic Handle | Improved comfort during use |

| Grass Collector | High-Capacity Bag | Less frequent emptying and increased efficiency |

| Starter | Electric Start System | Effortless starting and reduced strain |

Storing Your Mower Safely

Proper storage of your lawn care equipment is crucial for maintaining its performance and extending its lifespan. Whether you’re preparing for the off-season or just a short break, ensuring that your machine is stored correctly can prevent damage and ensure it’s ready for use when needed.

Choosing the Right Location

Find a clean, dry, and well-ventilated area for storage. Avoid damp or humid environments, as moisture can lead to rust and corrosion. A dedicated shed or garage is ideal, but ensure that the space is free from clutter to prevent any accidental damage.

Preparing Your Equipment for Storage

Before putting your machine away, perform essential maintenance tasks. Drain the fuel to prevent stale gasoline from causing starting issues. Clean the blades and the underside of the deck to remove grass clippings and debris. Additionally, consider applying a light coat of oil to metal parts to provide protection against rust.

By taking these precautions, you can ensure your lawn maintenance equipment remains in excellent condition and is ready for action when the time comes.