Comprehensive Guide to Motorcycle Engine Repair

Understanding the complexities of two-wheeled transportation systems can greatly enhance the longevity and performance of your vehicle. This section delves into the essential practices and methodologies for maintaining the vital components that drive these machines.

With the right knowledge and tools, enthusiasts and owners alike can tackle common challenges, ensuring their rides remain in optimal condition. From troubleshooting issues to conducting routine checks, a proactive approach can prevent minor problems from escalating into major repairs.

Whether you are a seasoned mechanic or a passionate beginner, familiarizing yourself with the intricacies of these systems is key. Embracing this journey not only fosters a deeper appreciation for your ride but also empowers you to take control of its upkeep.

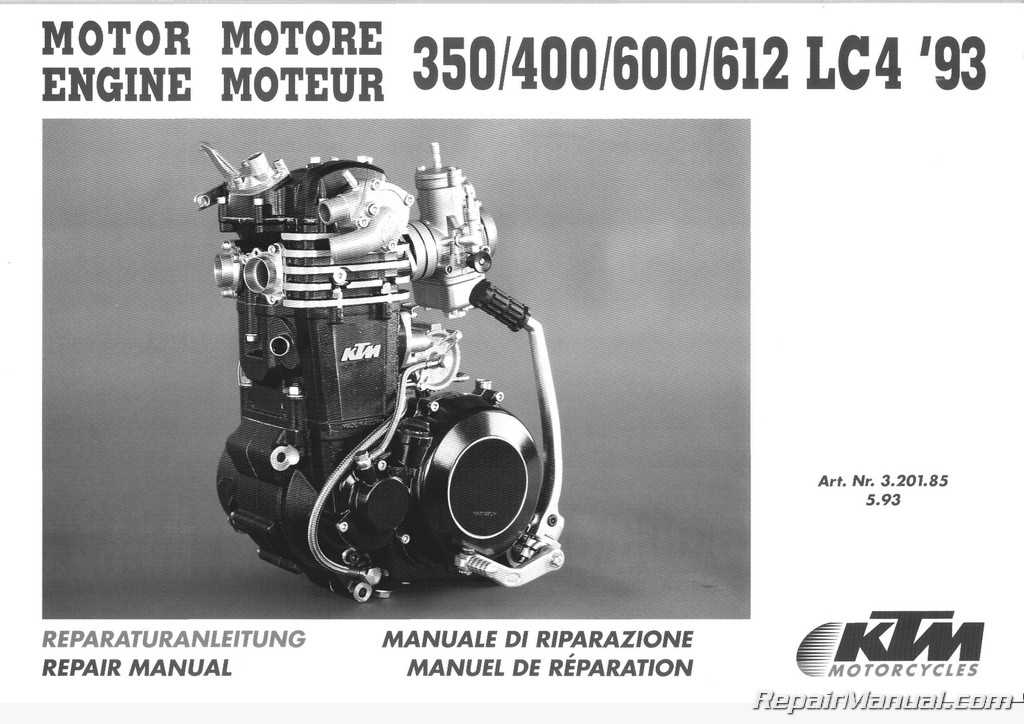

Understanding Motorcycle Engine Components

This section delves into the essential parts that make up a two-wheeled vehicle’s power unit. Each component plays a crucial role in ensuring optimal performance and longevity. Familiarity with these elements not only aids in troubleshooting but also enhances the overall riding experience.

- Block: The main structure housing various internal parts.

- Pistons: Moving components that create power through combustion.

- Cylinders: Enclosures where fuel and air mix for ignition.

- Valves: Mechanisms that regulate airflow in and out of the combustion chamber.

- Crankshaft: Converts linear motion of pistons into rotational motion.

Each of these elements must function harmoniously for the vehicle to operate smoothly. Understanding their interactions can lead to better maintenance practices and enhance the riding experience.

Common Engine Issues and Symptoms

Understanding frequent mechanical problems is essential for maintaining optimal performance. Identifying these issues early can prevent further complications and ensure a smoother ride. Below are some typical challenges along with their associated indicators.

Performance Decline

When the machine exhibits a noticeable decrease in power, it may indicate various underlying issues. Common symptoms include sluggish acceleration and reduced top speed.

Unusual Noises

Uncharacteristic sounds such as knocking, ticking, or grinding can signal serious concerns that require immediate attention. Listening closely to these noises can help pinpoint the source of the problem.

| Issue | Common Symptoms |

|---|---|

| Power Loss | Slow acceleration, difficulty climbing hills |

| Strange Noises | Knocking, grinding, or ticking sounds |

| Excessive Vibrations | Shaking during operation, instability |

| Overheating | High temperature readings, steam |

Tools Needed for Engine Repair

To successfully address issues in a two-wheeled vehicle’s power unit, a range of instruments is essential. Having the right equipment ensures efficient work and enhances the quality of the outcome.

| Tool | Purpose |

|---|---|

| Wrench Set | For tightening and loosening bolts. |

| Screwdriver Set | For driving screws in various sizes. |

| Torque Wrench | To apply precise torque to fasteners. |

| Socket Set | For reaching hard-to-access nuts and bolts. |

| Pliers | For gripping and twisting wires or components. |

Step-by-Step Engine Disassembly Process

Disassembling a power unit requires careful attention and methodical steps to ensure each component is handled properly. This guide outlines the essential stages to follow, promoting an efficient breakdown of the assembly while minimizing potential damage to vital parts.

Preparation and Safety Measures

Before starting the disassembly, ensure that all necessary tools are available and in good condition. Wearing protective gear is crucial to safeguard against any hazards. Organize a clean workspace where each piece can be tracked effectively.

Sequential Component Removal

Begin by loosening and removing the outer casing, followed by systematic detachment of internal components. Keep track of each part and its respective fasteners, as this will simplify reassembly. Take notes or photos during this process to aid in later steps.

Inspecting Engine Parts for Damage

Thorough examination of components is crucial to ensure optimal performance and longevity. Identifying any wear or defects early can prevent more significant issues down the line.

Visual Inspection

Begin with a careful visual assessment of the parts. Look for the following:

- Cracks or fractures

- Signs of excessive wear

- Corrosion or rust

- Loose fittings or connections

Functional Testing

After the visual check, perform functional tests to evaluate the integrity of the components:

- Check for unusual noises during operation.

- Test for any irregular vibrations.

- Monitor temperature variations during use.

Reassembling the Engine Correctly

Proper reassembly of the power unit is crucial for ensuring optimal performance and longevity. This process involves meticulous attention to detail and adherence to specific guidelines.

Follow these steps to achieve a successful reassembly:

- Gather Necessary Tools: Ensure all required tools are available before starting the reassembly.

- Inspect Components: Thoroughly check all parts for wear and damage.

- Clean Surfaces: Clean all mating surfaces to prevent any debris from causing issues.

- Apply Lubricants: Use appropriate lubricants on moving parts to facilitate smooth operation.

- Align Components: Carefully align each part according to the specifications to avoid misfits.

Following these guidelines will help in achieving a seamless reassembly and enhance the overall functionality of the unit.

Engine Lubrication and Maintenance Tips

Proper lubrication and upkeep are essential for ensuring optimal performance and longevity of your vehicle’s power source. Regular attention to these aspects not only enhances efficiency but also minimizes the risk of costly damages.

- Choose the Right Lubricant: Select a high-quality fluid that meets the specifications outlined in the manufacturer’s guidelines.

- Regular Checks: Frequently inspect the lubricant level and quality to ensure it remains effective.

- Change Intervals: Adhere to recommended intervals for fluid changes to prevent buildup of contaminants.

Maintaining appropriate temperatures is crucial for performance. Ensure proper cooling systems are in place to regulate heat effectively.

- Monitor Temperature: Keep an eye on the temperature gauge and address any overheating issues immediately.

- Clean Filters: Regularly clean or replace filters to promote efficient circulation of lubricants.

By following these guidelines, you can significantly enhance the reliability and efficiency of your vehicle’s performance.

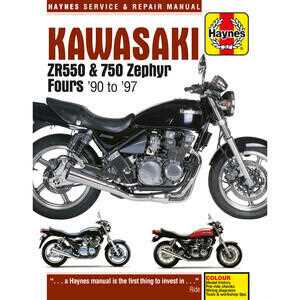

Tuning Your Engine for Optimal Performance

Achieving peak functionality in your vehicle requires meticulous adjustments that enhance overall responsiveness and efficiency. Fine-tuning involves various techniques aimed at improving power output and ensuring a smooth ride. Understanding the fundamentals of this process can lead to significant improvements in performance.

Essential Modifications to Consider

Start by evaluating components such as the intake system and exhaust flow. Upgrading these areas can drastically influence airflow, allowing the machine to breathe better. Additionally, consider adjustments to the fuel delivery system to ensure the correct mixture for combustion, which is vital for maximizing power.

Importance of Regular Maintenance

Regular upkeep is crucial for maintaining optimal performance. Clean filters, timely oil changes, and proper lubrication contribute to a well-functioning system. Monitoring wear and tear on parts can prevent potential issues, ensuring your setup remains in peak condition.

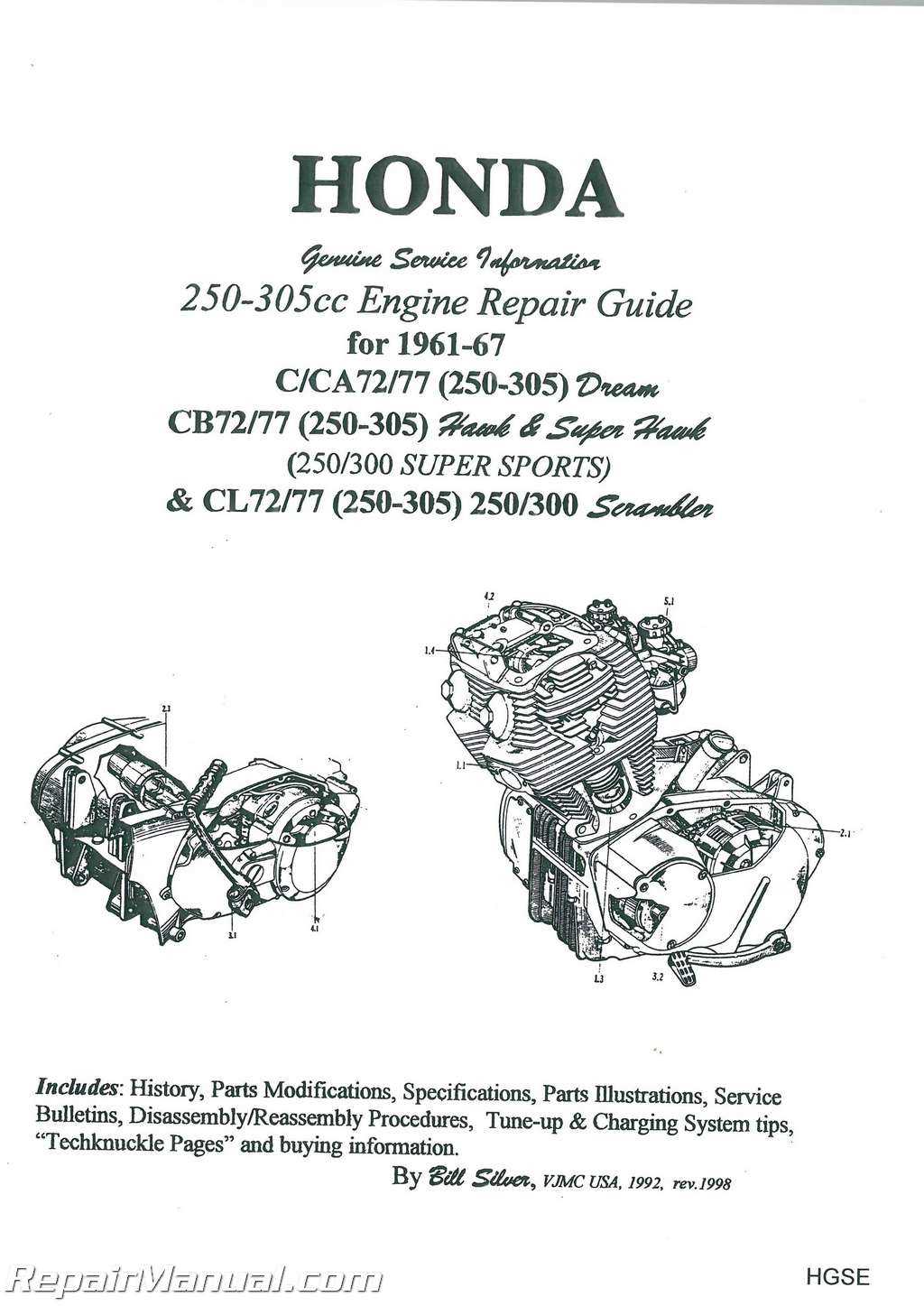

Replacing Worn Engine Components

When maintaining performance, it is crucial to address the deterioration of internal parts promptly. Over time, components can become less effective, leading to a decline in overall functionality. Recognizing the signs of wear and understanding the steps for replacement can significantly enhance the longevity and efficiency of the machine.

The following table outlines common components that may require attention and their corresponding signs of wear:

| Component | Signs of Wear |

|---|---|

| Pistons | Low compression, unusual noise |

| Rings | Excessive oil consumption, smoke from exhaust |

| Bearings | Vibration, knocking sounds |

| Gaskets | Leaks, engine overheating |

Addressing these issues promptly can prevent further damage and ensure optimal performance. Regular inspections and timely replacements are key to maintaining a reliable and efficient system.

Diagnosing Electrical Problems in Engines

Identifying issues within the electrical systems of vehicles requires a systematic approach and keen attention to detail. Understanding the various components and their interactions can aid in pinpointing malfunctions effectively.

To begin the diagnosis, consider the following common signs of electrical faults:

- Unresponsive ignition system

- Fluctuating power levels

- Electrical components malfunctioning intermittently

- Inconsistent lighting or signaling

Once symptoms are recognized, proceed with these diagnostic steps:

- Visual Inspection: Check wiring, connections, and components for signs of wear, corrosion, or damage.

- Multimeter Testing: Use a multimeter to measure voltage, resistance, and continuity in circuits.

- Battery Check: Ensure the battery is fully charged and terminals are clean and secure.

- Component Functionality: Test individual parts such as relays, fuses, and switches to confirm they operate correctly.

By following these steps and utilizing appropriate tools, one can effectively diagnose and address electrical issues, ensuring optimal performance and reliability.

Advanced Techniques for Engine Repairs

In the realm of mechanical troubleshooting, mastering complex methods can significantly enhance the efficiency of vehicle maintenance. This section explores innovative strategies that can elevate the quality of work, ensuring optimal performance and longevity of the internal components.

Precision Diagnostics

Utilizing sophisticated diagnostic tools is crucial in identifying underlying issues. Advanced sensors and software applications allow for real-time analysis, providing insights that traditional methods may overlook. This precision aids in pinpointing exact malfunctions, leading to more effective resolutions.

Component Upgrades

Incorporating high-performance parts can greatly improve functionality. By replacing standard components with upgraded alternatives, enthusiasts can enhance power output and fuel efficiency. It’s essential to ensure compatibility and quality during this process to achieve the best results.

| Technique | Description | Benefits |

|---|---|---|

| Diagnostics | Utilizing advanced tools for issue identification. | Increased accuracy in troubleshooting. |

| Upgrading Components | Replacing standard parts with high-performance options. | Enhanced power and efficiency. |

| Preventive Maintenance | Regular checks and updates to avoid future problems. | Prolonged lifespan and reliability. |

Safety Precautions During Engine Work

Engaging in mechanical tasks requires a thorough understanding of safety measures to prevent accidents and injuries. Proper preparation and awareness can significantly enhance the experience and ensure a secure working environment.

Personal Protective Equipment

Always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and sturdy footwear. This gear is essential to shield against potential hazards like sharp objects and hot surfaces.

Workspace Organization

Maintain a clean and organized workspace to minimize risks. Ensure tools and materials are within reach, and avoid clutter to prevent tripping or mishandling items. Prioritize safety by keeping emergency equipment readily accessible.