Repair Guide for 1977 Evinrude 85 HP Engine

When it comes to maintaining a powerful watercraft engine, understanding its components and functionality is essential. This guide offers valuable insights into the upkeep of high-performance marine engines, ensuring optimal operation and longevity. Enthusiasts and operators alike can benefit from a thorough exploration of effective techniques and strategies tailored for peak performance.

In this section, we will delve into various aspects of engine care, covering topics such as troubleshooting common issues, performing routine checks, and implementing solutions to enhance efficiency. By following these guidelines, users can develop a deeper appreciation for the mechanics involved, ultimately leading to a smoother boating experience.

Equipped with the right knowledge and tools, individuals can tackle challenges that arise during operation. Whether addressing minor adjustments or more complex tasks, having a solid foundation in engine management ensures readiness for any situation on the water.

Understanding the 1977 Evinrude 85 HP

This section provides insights into a specific model of outboard engines, focusing on its features and functionalities. A comprehensive grasp of its components and performance can enhance the overall experience for users and enthusiasts alike.

Key Features

- Powerful performance suitable for various watercraft.

- Durable construction ensuring longevity and reliability.

- Efficient fuel consumption for extended trips on the water.

Common Applications

- Ideal for recreational boating and fishing.

- Compatible with a range of small to medium-sized vessels.

- Used frequently in both fresh and saltwater environments.

Understanding the characteristics of this engine can help users make informed decisions about maintenance and operation, leading to a more enjoyable boating experience.

Common Issues with Evinrude Outboards

Outboard motors can encounter a variety of challenges that may affect their performance and reliability. Understanding these frequent problems can help users maintain optimal functionality and prolong the lifespan of their equipment. Recognizing the signs of issues early can lead to timely interventions and smoother operation on the water.

Fuel System Complications

One prevalent concern involves complications within the fuel system. Blockages or contamination in the fuel lines can disrupt the flow of gasoline, leading to inadequate power output. Regular inspection of fuel filters and lines is essential to prevent such issues. Additionally, stale fuel can cause starting difficulties and poor engine performance, making it crucial to use fresh fuel for optimal results.

Electrical System Failures

Another common area of trouble lies in the electrical system. Issues such as corroded connections or faulty wiring can hinder the ignition process, resulting in starting failures or inconsistent power. Routine checks of the battery and wiring harness are advisable to ensure reliable operation. Furthermore, ensuring connections are clean and secure can significantly enhance performance.

Essential Tools for Repairs

Having the right equipment is crucial for maintaining and fixing various marine engines. Proper tools not only enhance efficiency but also ensure quality outcomes during any servicing task. A well-equipped toolbox can make a significant difference in the repair process.

Basic Hand Tools are fundamental for any maintenance activity. Items such as wrenches, screwdrivers, and pliers are indispensable for performing various adjustments and replacements. Having a variety of sizes ensures versatility for different components.

Specialized Equipment might also be necessary, depending on the complexity of the job. Tools like compression testers and spark plug gauges allow for accurate diagnostics, helping to identify issues effectively. Investing in high-quality specialized tools can lead to better long-term performance.

Safety Gear should never be overlooked. Items like gloves, goggles, and ear protection safeguard the user from potential hazards during maintenance tasks. Prioritizing safety ensures a secure working environment and minimizes the risk of injury.

Overall, a well-chosen selection of tools not only streamlines the maintenance process but also contributes to the longevity and performance of marine engines. Careful preparation and organization can significantly enhance the effectiveness of any servicing endeavor.

Step-by-Step Troubleshooting Guide

This section provides a comprehensive approach to diagnosing issues with your outboard motor. Following a systematic method will help identify the root causes of performance problems, ensuring that your equipment runs smoothly and efficiently.

| Issue | Possible Causes | Recommended Actions |

|---|---|---|

| Engine Won’t Start | Dead battery, faulty ignition, or clogged fuel line | Check battery connections, inspect ignition components, and clean the fuel line. |

| Poor Acceleration | Dirty carburetor, wrong propeller size, or air intake blockage | Clean the carburetor, ensure the propeller is appropriate, and clear any obstructions. |

| Overheating | Low coolant levels, blocked water intake, or faulty thermostat | Check coolant levels, clear debris from the water intake, and test the thermostat. |

| Unusual Noises | Loose components, damaged bearings, or misaligned parts | Inspect all fittings, replace damaged bearings, and realign any misaligned parts. |

Engine Maintenance Tips and Tricks

Regular upkeep of your outboard motor is essential for optimal performance and longevity. By following a few straightforward practices, you can ensure that your engine runs smoothly and efficiently.

1. Regular Oil Changes: Changing the oil at recommended intervals helps maintain lubrication and reduces wear on internal components. Always use the correct type of oil for your engine.

2. Inspect Fuel System: Regularly check the fuel lines, filters, and connections for any signs of wear or leaks. Clean or replace components as necessary to prevent performance issues.

3. Check Spark Plugs: Inspect spark plugs for carbon buildup or damage. Replacing worn plugs can significantly improve engine starting and efficiency.

4. Cooling System Maintenance: Ensure the cooling system is functioning properly by checking the water intake and monitoring the temperature. Clean any debris that might block water flow.

5. Battery Care: Keep the battery terminals clean and ensure a secure connection. Regularly test the battery to prevent starting issues.

By integrating these tips into your maintenance routine, you can enhance the performance and lifespan of your engine.

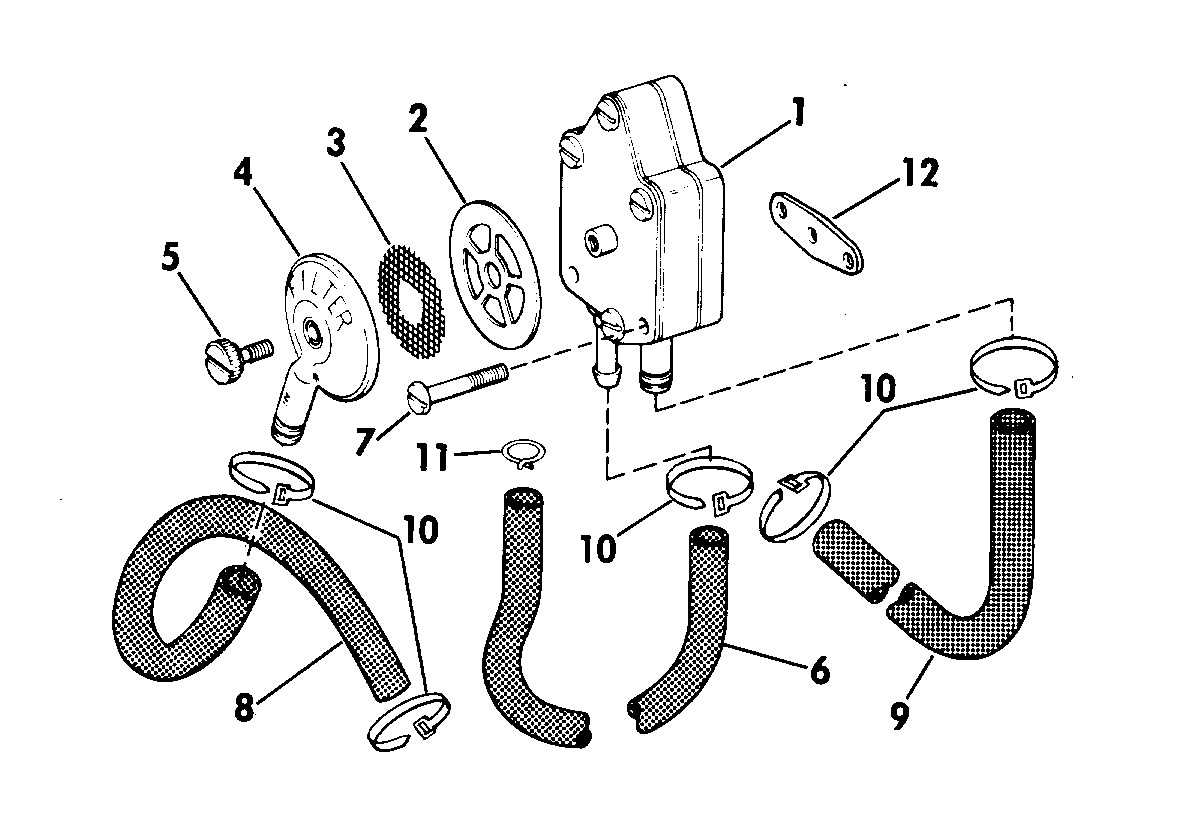

Fuel System Inspection Procedures

The examination of the fuel system is essential for ensuring optimal performance and longevity of the engine. Proper assessment helps identify potential issues that may affect fuel delivery and efficiency. Regular inspections are crucial for maintaining reliability and preventing costly repairs.

Start the inspection by checking the fuel lines for any signs of wear, leaks, or damage. Ensure that connections are secure and that there are no blockages present. Follow these steps for a thorough evaluation:

| Step | Description |

|---|---|

| 1 | Visually inspect fuel lines for cracks or deterioration. |

| 2 | Check all fittings and connections for tightness. |

| 3 | Examine the fuel filter for clogging and replace if necessary. |

| 4 | Inspect the fuel pump operation and ensure proper pressure levels. |

| 5 | Verify that the fuel tank is clean and free of contaminants. |

By following these procedures, the integrity of the fuel system can be upheld, contributing to the overall efficiency and functionality of the engine.

Electrical Components and Diagnostics

This section delves into the essential elements that form the electrical system of a marine engine, focusing on their roles and diagnostic procedures. Understanding these components is crucial for maintaining optimal performance and ensuring reliability on the water.

Key Electrical Elements

Key elements of the electrical system include the battery, ignition system, and wiring harness. The battery provides the necessary power for starting the engine and powering various electrical accessories. The ignition system, which consists of components such as the coils and spark plugs, is responsible for igniting the fuel-air mixture, ensuring smooth operation. The wiring harness connects these elements, facilitating efficient power distribution and signal transmission throughout the engine.

Diagnostic Techniques

Effective diagnostics begin with visual inspections, checking for loose connections, corrosion, or damaged wires. Utilizing a multimeter can help assess voltage levels and continuity, identifying potential issues within the system. Additionally, observing engine performance during operation can provide insights into electrical component functionality, guiding necessary interventions for optimal performance.

Propeller and Gearbox Maintenance

Proper upkeep of the propulsion system is crucial for ensuring optimal performance and longevity. Regular attention to the propeller and gearbox can prevent issues that may hinder functionality and safety during operation.

Start by examining the propeller for any signs of damage, such as dents or cracks. A compromised propeller can significantly impact efficiency and lead to further complications within the gearbox. Ensure the propeller is securely attached and that all components are free of corrosion.

Next, focus on the gearbox, which plays a vital role in transmitting power. Regularly check the oil levels and quality, replacing it as necessary to maintain lubrication and prevent wear. It’s essential to inspect seals and gaskets for any leaks that could indicate a need for replacement.

| Maintenance Task | Frequency |

|---|---|

| Inspect Propeller | Every outing |

| Check Gearbox Oil | Monthly |

| Replace Worn Components | As needed |

| Clean Propeller and Gearbox | After each use |

By adhering to these maintenance guidelines, operators can enhance the reliability and performance of their vessels, ensuring a smoother and safer experience on the water.

Seasonal Storage Guidelines for Outboards

Proper seasonal storage of outboard motors is crucial for maintaining performance and longevity. Implementing effective techniques during storage can prevent damage caused by environmental factors and ensure that the engine is ready for use when the season returns.

Preparation Steps Before Storage

- Thoroughly clean the exterior and interior components to remove any dirt, salt, or debris.

- Drain all fluids, including fuel and oil, to avoid contamination and deterioration.

- Inspect and replace any worn or damaged parts to ensure optimal functionality.

- Lubricate moving parts to prevent rust and corrosion during the storage period.

Storage Environment Considerations

- Store the motor in a cool, dry place to minimize exposure to humidity and temperature fluctuations.

- Use a protective cover to shield against dust and debris while in storage.

- Consider placing the motor in an upright position to facilitate drainage and prevent leaks.

Following these guidelines will help maintain the integrity of your outboard motor, ensuring it remains in excellent condition for the next boating season.

Upgrades for Enhanced Performance

Improving the functionality of your outboard engine can significantly elevate your boating experience. Various enhancements can lead to better speed, fuel efficiency, and overall reliability. Below are several effective modifications that can optimize performance.

- Propeller Replacement: Upgrading to a high-performance propeller can improve acceleration and top speed, providing a more efficient thrust.

- Ignition System Upgrade: Installing an advanced ignition system can enhance combustion efficiency, resulting in smoother operation and improved power output.

- Fuel System Enhancements: Utilizing higher-quality fuel injectors or carburetors can ensure better fuel atomization, leading to improved engine responsiveness.

- Exhaust Modifications: Modifying the exhaust system can reduce back pressure, allowing for better exhaust flow and increased horsepower.

- Weight Reduction: Removing unnecessary accessories or replacing heavy components with lightweight alternatives can improve speed and maneuverability.

Implementing these upgrades can lead to noticeable improvements in performance, ensuring a more enjoyable and efficient boating experience.

Finding Replacement Parts Easily

Locating suitable components for your outboard engine can seem challenging, but there are numerous resources available to simplify the process. Whether you’re dealing with a minor issue or a major overhaul, knowing where to look can save you time and effort.

Start by checking online retailers that specialize in marine parts. These platforms often have extensive catalogs, allowing you to search by model or part number. Additionally, visiting local marine supply stores can provide immediate assistance, as knowledgeable staff can guide you to the right items.

Another effective strategy is to connect with online forums or communities dedicated to boating enthusiasts. Members frequently share their experiences and recommendations on sourcing components, which can lead you to reliable suppliers.

Don’t forget to consider second-hand options. Auctions, classified ads, and specialty shops may offer used parts at a fraction of the cost. Just ensure that these components are in good condition before making a purchase.

By utilizing these methods, you can easily find the necessary items to keep your engine in optimal working condition. Remember to keep a list of essential parts for future reference, which can expedite the replacement process when needed.

Safety Precautions While Repairing

Ensuring personal safety during maintenance tasks is crucial. Adhering to proper guidelines can prevent accidents and promote a secure working environment. It is essential to be aware of potential hazards and take necessary measures to mitigate risks while handling equipment.

Protective Gear

Always wear appropriate protective gear, including gloves, goggles, and masks. This equipment helps shield against harmful substances and reduces the likelihood of injury from sharp tools or moving parts. Prioritize your safety by ensuring that your gear fits properly and is in good condition.

Work Area Organization

Maintain a clean and organized workspace to minimize the risk of accidents. Keep tools and materials in designated areas, and ensure that walkways are free of obstructions. Good organization allows for better focus and reduces distractions, leading to more efficient work practices.