VW Transmission Repair Guide

The efficient functioning of a vehicle relies heavily on its intricate components, which work in harmony to deliver a smooth driving experience. Among these, the system that governs the transfer of power from the engine to the wheels plays a crucial role. Understanding how to maintain this essential mechanism is vital for any car owner looking to ensure longevity and optimal performance.

In this section, we will delve into the various aspects involved in the upkeep of this critical assembly. By familiarizing yourself with the underlying principles and practices, you can better appreciate the nuances of how to keep your vehicle operating at its best.

From recognizing potential issues to implementing preventive measures, having a solid grasp of this subject will empower you to take informed actions. This knowledge not only enhances your driving experience but also contributes to the overall reliability of your automobile.

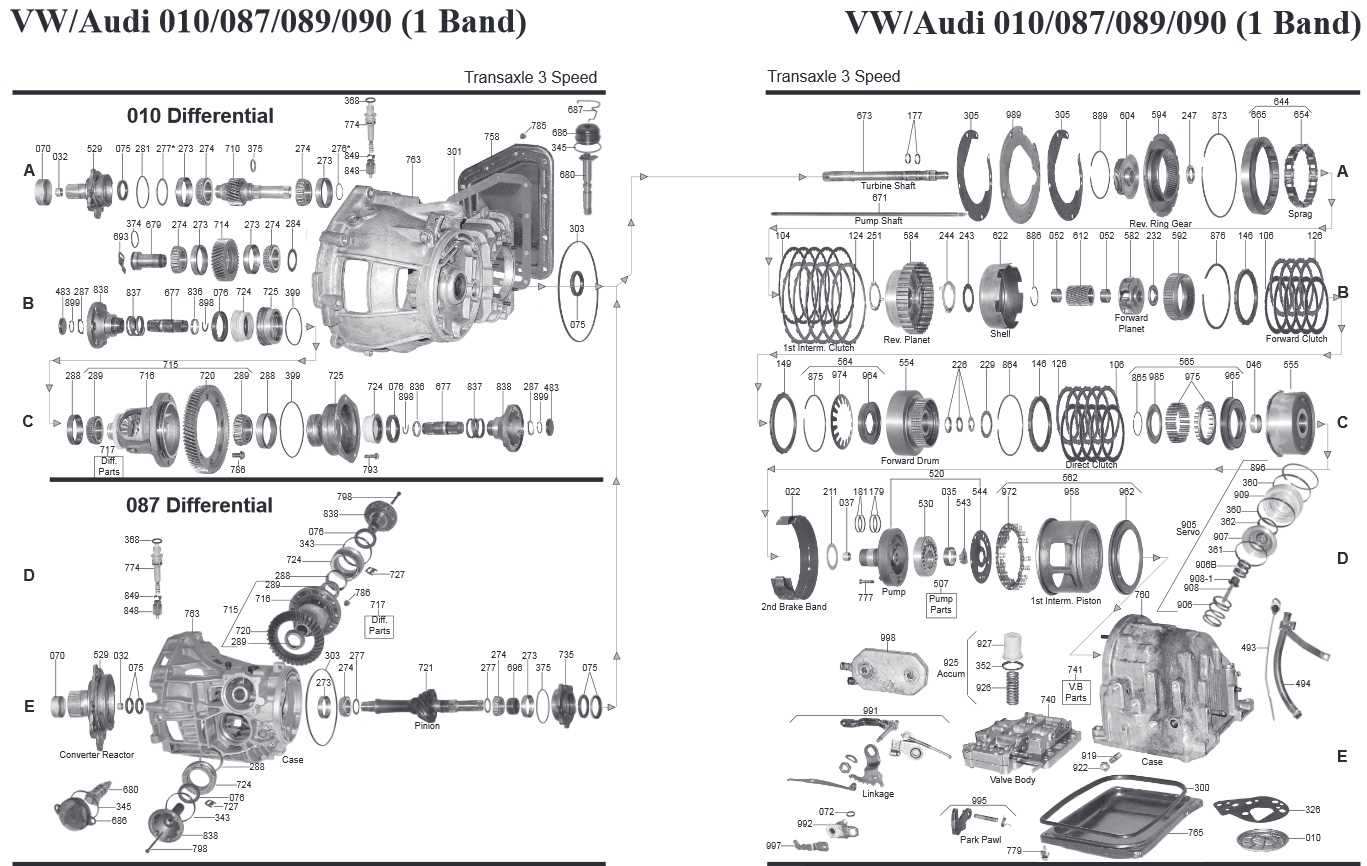

VW Transmission Basics Explained

This section delves into the fundamental principles behind the systems that facilitate gear shifting in VW vehicles. Understanding these concepts is essential for anyone looking to gain insight into how power is transferred from the engine to the wheels, ensuring optimal performance and driving experience.

Key Components

- Gear Sets: Different configurations that allow for varying levels of torque and speed.

- Clutches: Mechanisms that engage and disengage the engine from the drive system.

- Fluid Systems: Essential for lubrication and cooling, maintaining proper function.

Operational Mechanisms

- Power is generated by the engine.

- The clutch engages to transfer power.

- Gear sets are selected based on driving conditions.

- The system adapts to maintain efficiency.

Common Transmission Issues and Solutions

Understanding the typical challenges encountered in vehicle power transfer systems is essential for effective maintenance and troubleshooting. These complications can stem from various factors, including wear and tear, fluid deficiencies, or mechanical failures, leading to performance issues that affect drivability.

Signs of Trouble

Common indicators of issues include slipping gears, delayed engagement, and unusual noises during operation. Drivers may also notice warning lights on the dashboard, signaling the need for further investigation. Addressing these symptoms promptly can prevent more severe damage.

Effective Solutions

Addressing the identified problems often involves several steps. Regular fluid changes can help maintain optimal performance and prevent overheating. Additionally, inspecting components for wear and ensuring proper alignment can mitigate issues. In some cases, replacing faulty parts may be necessary to restore functionality.

Regular Maintenance is crucial in prolonging the lifespan of power transfer systems. Adhering to a consistent service schedule can help detect potential problems early and ensure the vehicle operates smoothly.

Step-by-Step Repair Procedures

This section outlines a systematic approach to address common issues encountered in the vehicle’s drivetrain system. Following these structured steps will enhance the likelihood of effectively resolving problems while ensuring safety and efficiency throughout the process.

Preparation and Tools Required

Before commencing the task, gather all necessary tools and equipment. Proper preparation is key to a smooth workflow. Ensure that the workspace is clean and well-organized.

| Tools | Purpose |

|---|---|

| Socket Set | To remove and install bolts and nuts. |

| Torque Wrench | To apply the correct torque when fastening components. |

| Fluid Pump | To efficiently fill or replace fluids. |

| Diagnostic Scanner | To identify fault codes and monitor system performance. |

Step-by-Step Procedure

Once the tools are prepared, follow these steps to address issues:

- Begin by safely lifting the vehicle using a hydraulic jack and securing it with jack stands.

- Disconnect the battery to ensure safety during the process.

- Remove any components obstructing access to the targeted area.

- Inspect all parts for wear or damage, noting any abnormalities.

- Replace or adjust components as necessary based on the findings.

- Reassemble all parts, ensuring all connections are secure.

- Reconnect the battery and conduct a system check using the diagnostic scanner.

Essential Tools for Transmission Repair

When tackling the intricate mechanisms of automotive gear systems, having the right equipment is crucial. Proper tools not only facilitate efficiency but also ensure that the intricate components are handled with care. Here is a look at the essential items needed for servicing these complex assemblies.

| Tool | Description |

|---|---|

| Socket Set | A comprehensive set that allows for easy access to fasteners in tight spaces. |

| Torque Wrench | Ensures that bolts are tightened to manufacturer specifications, preventing damage. |

| Pliers | Various types, including needle-nose and locking pliers, useful for gripping and manipulating small parts. |

| Screwdriver Set | A range of sizes and types to handle different screws encountered during disassembly. |

| Fluid Pump | Used for transferring and managing lubricants essential for smooth operation. |

| Seal Puller | A specialized tool designed to remove seals without causing damage to surrounding areas. |

Diagnosing Transmission Problems Effectively

Identifying issues within a vehicle’s drive system is crucial for maintaining optimal performance. A systematic approach can help pinpoint the source of complications, allowing for timely solutions. Understanding symptoms, utilizing the right tools, and following a structured process are key elements in this endeavor.

Common Symptoms to Watch For

Drivers may notice various signs indicating potential faults. These can include unusual noises, difficulty in gear engagement, or erratic behavior while changing speeds. Paying attention to these indicators can provide valuable insights into underlying issues.

Utilizing Diagnostic Tools

Employing specialized diagnostic equipment is essential in the assessment process. Tools such as scan devices can read error codes, while pressure gauges may help evaluate fluid dynamics. Combining these methods with a thorough visual inspection often leads to a clearer understanding of the situation.

In conclusion, addressing concerns within a vehicle’s drive system demands a comprehensive strategy. By recognizing symptoms and effectively utilizing diagnostic tools, one can significantly enhance the likelihood of accurate identification and resolution of issues.

Transmission Fluid Maintenance Guidelines

Proper upkeep of fluid levels is essential for optimal performance and longevity of the vehicle’s gear-shifting system. Regular monitoring and replacement of this vital lubricant help ensure smooth operation and prevent potential issues that could arise from neglect.

Start by checking the fluid level regularly, ideally every few thousand miles. This can be done using the dipstick, which provides an easy way to gauge whether the levels are within the recommended range. If the fluid appears dark or has a burnt smell, it’s a clear indication that it needs to be replaced.

When it comes to replacing the lubricant, consult the manufacturer’s specifications for the correct type and capacity. It is generally advisable to perform this service every 30,000 to 60,000 miles, though this can vary based on driving habits and conditions.

During fluid changes, it is also beneficial to clean the filter, if applicable, to ensure that any debris is removed and does not interfere with the system’s functionality. Regular maintenance of this kind can significantly enhance the reliability and efficiency of the gear-shifting mechanism.

Upgrading VW Transmission Components

Enhancing the functionality of your vehicle’s drivetrain can significantly improve performance and driving experience. By focusing on key elements, enthusiasts can achieve better power delivery, efficiency, and overall responsiveness. This section explores various upgrades that can elevate your VW’s performance through improved componentry.

Enhanced Gear Sets

Upgrading gear sets allows for optimized ratios that can enhance acceleration and top speed. By selecting gear combinations tailored to your driving style, you can maximize the efficiency of power transfer from the engine to the wheels. Consider options that offer lightweight materials for reduced inertia, contributing to quicker shifts and improved performance.

Improved Clutch Systems

A high-performance clutch system can dramatically affect your vehicle’s capability to handle increased power. Upgrading to a more robust setup can provide better engagement and disengagement, allowing for smoother transitions. Look for options that feature higher torque ratings and enhanced durability, ensuring that your system can withstand rigorous driving conditions.

Identifying Gear Slipping Symptoms

Recognizing the signs of gear disengagement is crucial for maintaining optimal vehicle performance. Symptoms can manifest in various ways, indicating potential issues within the system that require attention.

Common Indicators

- Unusual Noises: Hearing grinding or clunking sounds while shifting may suggest a problem.

- Difficulty Shifting: Struggling to engage gears can point to underlying complications.

- Engine RPM Fluctuations: Noticeable variations in engine speed without corresponding acceleration are a red flag.

- Unexpected Changes in Speed: Experiencing sudden drops in speed without any throttle adjustment can signal a malfunction.

Additional Observations

- Check for warning lights on the dashboard, as these can indicate system faults.

- Monitor for fluid leaks underneath the vehicle, which may suggest internal issues.

- Pay attention to the overall responsiveness of the vehicle during acceleration.

Transmission Replacement Considerations

When facing the need to replace a vehicle’s power transfer system, several factors must be evaluated to ensure a smooth transition and optimal performance. The process involves understanding various elements that can influence the overall experience, from cost and compatibility to potential upgrades and long-term maintenance.

Cost Factors

The expenses associated with this process can vary widely based on several components. It is essential to account for both parts and labor, as well as any additional services that may be required. Researching prices for different options, including new, used, or refurbished units, can significantly affect your budget.

Compatibility and Upgrades

Ensuring that the selected system matches the vehicle’s specifications is crucial. Compatibility extends beyond mere dimensions; factors such as technology and functionality play a significant role. Moreover, considering enhancements or upgrades during the replacement can lead to improved performance and efficiency.

| Consideration | Details |

|---|---|

| Budget | Estimate total costs including parts, labor, and additional services. |

| Compatibility | Ensure the new unit aligns with vehicle specifications. |

| Upgrades | Evaluate potential performance enhancements during replacement. |

| Warranty | Check warranty options for parts and installation services. |

Preventive Measures for Longevity

Ensuring the extended lifespan of your vehicle’s vital components requires a proactive approach. Implementing regular maintenance routines and adopting mindful driving habits can significantly reduce wear and tear. By addressing potential issues before they escalate, you can enhance overall performance and reliability.

Regular Maintenance Checks

Conducting routine inspections is essential for identifying early signs of wear. Regular fluid changes, filter replacements, and system flushes are crucial steps in maintaining optimal function. Adhering to the manufacturer’s recommended service schedule helps prevent unforeseen complications.

Mindful Driving Practices

Adopting careful driving techniques contributes to the longevity of critical components. Avoiding sudden accelerations and harsh braking can minimize stress on various systems. Additionally, maintaining steady speeds and allowing your vehicle to warm up before driving can further enhance durability.

Understanding Transmission Types in VW

Volkswagen vehicles are equipped with various systems for managing power delivery to the wheels. These systems can significantly affect driving dynamics, fuel efficiency, and overall performance. This section explores the primary configurations found in VW models, highlighting their unique characteristics and benefits.

Common Types of Power Management Systems

- Manual Systems: These allow the driver to select gears manually, offering a more engaging driving experience.

- Automatic Systems: Designed for ease of use, these systems shift gears automatically based on driving conditions.

- Dual-Clutch Systems: A hybrid of manual and automatic, these utilize two clutches for seamless gear changes, improving performance.

Choosing the Right System

Selecting the appropriate power management configuration depends on personal driving preferences and vehicle usage. Consider the following factors:

- Driving Style: Enthusiasts may prefer manual systems for enhanced control.

- Convenience: Automatic systems are ideal for urban commuting.

- Performance Needs: Dual-clutch options often offer the best acceleration and efficiency.

Costs Associated with Transmission Repair

The expenses involved in addressing issues related to vehicle gear systems can vary significantly based on several factors. Understanding these costs is crucial for effective budgeting and decision-making when facing such mechanical challenges.

Factors influencing the overall price include the specific nature of the malfunction, the type of vehicle, and the complexity of the required solutions. Basic diagnostics may incur minimal fees, while extensive work can lead to substantial expenditures.

Parts Replacement: Often, components must be replaced due to wear or damage. The cost of these parts can range widely, particularly if specialized or high-performance items are needed.

Labor Costs: Skilled technicians usually charge an hourly rate, which can add up quickly. The more intricate the work, the longer it may take, leading to increased labor expenses.

Overall Budgeting: Setting aside a financial cushion for potential gear system issues can help mitigate unexpected costs. Regular maintenance and inspections may also prevent larger expenses down the road.

FAQs About VW Transmission Repairs

This section addresses common inquiries regarding the maintenance and troubleshooting of VW gear systems. Understanding these aspects can help owners make informed decisions about their vehicles.

| Question | Answer |

|---|---|

| What are the signs of issues with my vehicle’s gear system? | Common indicators include unusual noises, difficulty shifting gears, or fluid leaks. |

| How often should I check the fluid levels? | It’s advisable to inspect fluid levels regularly, ideally during routine maintenance intervals. |

| Can I fix minor problems myself? | Some minor issues can be addressed at home, but more complex problems typically require professional assistance. |

| What is the average cost for professional assistance? | The costs can vary significantly depending on the specific issue and the model of the vehicle. |

| How can I prolong the lifespan of my gear system? | Regular maintenance, including fluid changes and inspections, can significantly extend its durability. |