Comprehensive Guide to 722.6 Transmission Repair Manual

Understanding the intricacies of automotive gear systems is essential for enthusiasts and professionals alike. This section delves into the complexities of a specific type of hydraulic device, focusing on its mechanics, common issues, and effective solutions. Mastering this knowledge can greatly enhance performance and reliability.

By exploring the components and functionalities, readers will gain valuable insights into diagnostics and enhancements. The guide provides a thorough examination of typical failures, along with detailed instructions for addressing these challenges. This information is pivotal for anyone looking to optimize their vehicle’s performance.

Equipped with the right tools and techniques, even the most daunting tasks can become manageable. This resource aims to empower readers, providing them with the confidence to tackle repairs and modifications. With a systematic approach, achieving proficiency in maintaining these crucial systems is within reach.

Understanding 722.6 Transmission Basics

This section delves into the foundational elements of a particular automatic gear system widely utilized in various vehicles. Recognizing how this complex mechanism functions is essential for both enthusiasts and professionals in the automotive field. The operation and characteristics of this assembly play a significant role in vehicle performance and efficiency.

Core Components

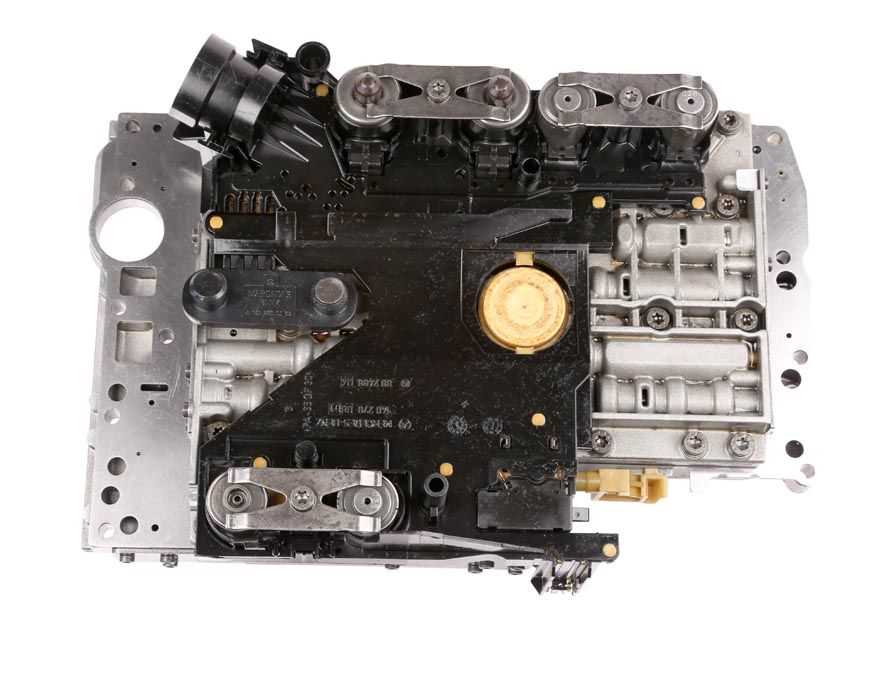

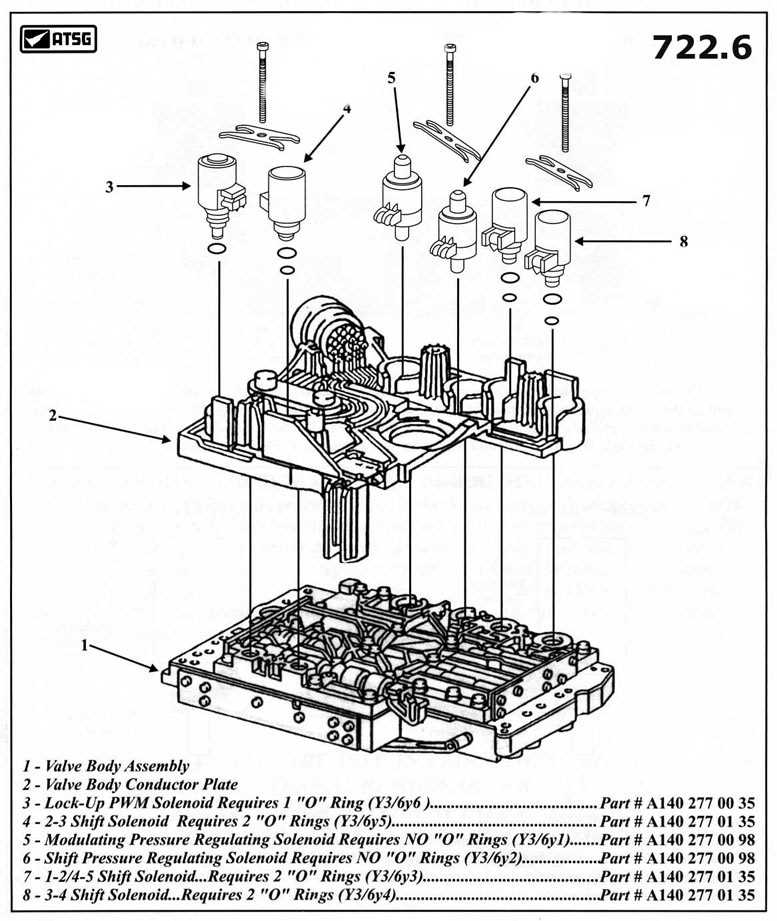

At the heart of this system lies a collection of intricate parts that work seamlessly together. Key elements include hydraulic pumps, clutches, and a sophisticated control unit. Each component has a specific function that contributes to the overall operation, ensuring smooth gear shifts and optimal power delivery.

Operational Principles

The functioning of this gear system is based on a combination of hydraulic principles and electronic controls. Fluid dynamics allow for the transfer of power between different gears, while electronic signals regulate the timing and application of clutches. This synergy is crucial for achieving the desired driving experience, whether in everyday commuting or high-performance scenarios.

Common Issues with 722.6 Transmissions

The performance of automatic gear systems can be influenced by a variety of factors, leading to several typical challenges that drivers may encounter. Recognizing these issues early can help maintain optimal functioning and prevent more severe complications down the line.

| Issue | Description | Symptoms |

|---|---|---|

| Fluid Leaks | Leakage of hydraulic fluid can occur due to worn seals or gaskets. | Low fluid levels, visible puddles under the vehicle. |

| Slipping | The system may struggle to engage gears properly, leading to unexpected RPM fluctuations. | Engine revs without corresponding vehicle acceleration. |

| Overheating | Excessive heat buildup can result from prolonged use or inadequate cooling. | Warning lights on the dashboard, burning smells. |

| Delayed Engagement | There may be a noticeable delay when shifting from park to drive or reverse. | Hesitation before the vehicle moves when accelerating. |

| Rough Shifting | Shifts may feel harsh or jarring, indicating potential internal wear. | Abnormal noises during gear changes, sudden jolts. |

Awareness of these common problems can empower vehicle owners to take proactive measures, ensuring longevity and reliability in their driving experience.

Tools Required for Repairs

Performing maintenance on complex machinery necessitates a range of specialized instruments and equipment. Understanding the specific tools needed is essential for achieving effective outcomes and ensuring that every component functions optimally. This section outlines the key tools that will facilitate the process, enhancing both efficiency and safety.

Essential Hand Tools

Basic hand tools are the foundation of any maintenance task. Wrenches, sockets, and screwdrivers are crucial for disassembling parts and securing components. Additionally, having a reliable torque wrench is vital to apply the correct force when fastening elements, preventing damage or failure.

Advanced Diagnostic Equipment

Beyond standard hand tools, advanced diagnostic equipment plays a significant role in identifying issues accurately. Scan tools allow technicians to retrieve fault codes and monitor system performance, while pressure gauges are essential for assessing fluid dynamics. Investing in oscilloscopes can further enhance the diagnostic process, providing detailed insights into electrical signals.

Step-by-Step Repair Process

This section outlines a systematic approach to addressing issues with your vehicle’s gear shifting system. By following these steps carefully, you can ensure a thorough examination and resolution of common problems, enhancing the overall functionality of the unit.

Preparation Phase

- Gather necessary tools and equipment.

- Ensure the workspace is clean and well-lit.

- Review safety precautions to prevent accidents.

- Consult the specific guidelines for your model to familiarize yourself with components.

Disassembly and Inspection

- Begin by removing the outer casing carefully.

- Inspect all internal components for wear and damage.

- Take note of any broken parts that need replacing.

- Clean all accessible areas to remove debris and grime.

- Document your findings for reference during reassembly.

Following these stages will set the groundwork for effective maintenance and enhance the longevity of your vehicle’s shifting mechanism.

Importance of Regular Maintenance

Consistent upkeep of vehicle components is crucial for ensuring optimal performance and longevity. Neglecting this aspect can lead to significant issues that compromise not only the functionality but also the safety of the vehicle. Regular inspections and timely interventions help in identifying potential problems before they escalate, ultimately saving time and resources.

Adhering to a maintenance schedule fosters the efficiency of the machinery, enhancing fuel economy and reducing wear on critical parts. This proactive approach can also improve overall driving experience, making it smoother and more reliable. Additionally, regular checks contribute to better resale value, as well-maintained vehicles attract more buyers and command higher prices.

In summary, routine care is an investment in the vehicle’s future, minimizing unexpected breakdowns and extending its operational life. By prioritizing this essential practice, owners can ensure their vehicle remains in peak condition, ready to perform when needed.

Diagnosing Transmission Problems

Identifying issues within the shifting mechanism of a vehicle is crucial for maintaining optimal performance. A systematic approach can help pinpoint the root cause of irregularities, allowing for effective solutions. Understanding the symptoms and conducting thorough checks is key to ensuring the longevity of the vehicle’s components.

Common Symptoms to Watch For

Drivers should be attentive to various indicators that may suggest underlying complications. These can include unusual noises, delayed engagement, or slipping while changing gears. Additionally, warning lights on the dashboard should never be ignored, as they can signal serious concerns that require immediate attention.

Steps for Effective Diagnosis

To accurately assess the condition of the shifting system, start with a visual inspection. Look for signs of leaks, damaged components, or worn-out seals. Following this, conduct a fluid check to ensure the lubricant is at the appropriate level and in good condition. Lastly, utilizing diagnostic tools can provide valuable insights, revealing error codes that guide further investigation.

By staying vigilant and following these steps, vehicle owners can address potential issues promptly, ultimately prolonging the life of their automotive system.

Replacing Transmission Fluids

Regularly changing the fluid within your vehicle’s gearbox is essential for maintaining optimal performance and longevity. Over time, these fluids can degrade, losing their effectiveness and leading to potential issues with shifting and overall functionality. Understanding the process and importance of fluid replacement can help ensure your vehicle operates smoothly.

To begin, it’s crucial to gather the necessary tools and materials, including a suitable container for the old fluid, a funnel, and the recommended replacement fluid. Ensure that the vehicle is parked on a level surface and the engine is turned off. Safety gear, such as gloves and goggles, should also be worn during this process.

Next, locate the fill and drain plugs on the unit. Remove the drain plug to allow the old fluid to escape completely into the container. Once drained, replace the drain plug securely before proceeding to refill with fresh fluid through the fill plug. It’s important to add the appropriate amount as specified by the manufacturer to avoid overfilling or underfilling, both of which can cause complications.

After replacing the fluid, start the engine and allow it to reach normal operating temperature. This ensures that the new fluid circulates properly. Finally, check the fluid level once more to confirm it’s at the correct level, adjusting as necessary. This maintenance task, when performed regularly, contributes significantly to the reliability and efficiency of your vehicle.

Upgrading Components for Performance

Enhancing the efficiency and responsiveness of a vehicle’s power delivery system can significantly improve overall performance. By focusing on key components and implementing strategic upgrades, enthusiasts can achieve better acceleration, smoother shifts, and greater reliability. This section will explore various modifications that can elevate performance levels.

| Component | Description | Benefits |

|---|---|---|

| High-Performance Torque Converter | Increases stall speed for improved acceleration | Enhanced responsiveness and quicker launches |

| Stronger Clutches | Upgraded friction materials for better grip | Greater durability and reduced slippage |

| Improved Valve Body | Optimizes fluid flow and shift patterns | Faster shifts and improved drivability |

| Performance Oil Cooler | Maintains lower operating temperatures | Extended component lifespan and consistent performance |

| ECU Tuning | Adjusts parameters for enhanced performance | Increased power output and improved efficiency |

Investing in these upgrades not only elevates performance but also ensures a more enjoyable driving experience. Each component plays a crucial role in the overall functionality and responsiveness, making careful selection and installation essential for achieving desired results.

Professional vs. DIY Repairs

When it comes to addressing complex mechanical issues, car owners often face a pivotal choice: to enlist the help of seasoned specialists or to tackle the job themselves. Each approach has its own set of advantages and challenges, and understanding these can significantly influence the outcome of the endeavor.

Professional services bring a wealth of experience and specialized tools to the table. Technicians are trained to diagnose and resolve intricate problems efficiently, often ensuring higher reliability and longevity of the work performed. This option can also provide peace of mind, knowing that the job has been handled by an expert.

On the other hand, DIY enthusiasts may find immense satisfaction in taking matters into their own hands. With access to online resources and community forums, many individuals are empowered to learn and develop their skills. This approach can be cost-effective and fulfilling, allowing for a deeper understanding of the vehicle.

Ultimately, the decision hinges on factors such as budget, time constraints, and personal expertise. Weighing the pros and cons of each route can help vehicle owners make informed choices tailored to their specific situations.

Cost Analysis of Repair Options

When faced with mechanical issues in a vehicle, it is essential to evaluate the various approaches to restoration in order to make an informed decision. Understanding the financial implications of each choice can significantly influence the overall outcome, both in terms of immediate expenses and long-term reliability. This analysis will explore the cost factors associated with different solutions, ranging from minor adjustments to complete overhauls.

Comparative Costs of Solutions

Choosing between a quick fix and a comprehensive overhaul can be challenging. Quick fixes typically require less initial investment but may lead to recurrent problems and additional expenses over time. In contrast, a thorough overhaul might entail a higher upfront cost but could enhance the longevity and performance of the vehicle, ultimately saving money in the long run. Evaluating the initial outlay against potential future costs is crucial.

Hidden Costs and Considerations

In addition to the obvious expenses, it’s vital to consider hidden costs that may arise during the process. These can include labor charges, the price of parts, and potential downtime. Assessing these factors will provide a clearer picture of the total investment required. Moreover, consulting with experienced professionals can reveal insights into the most cost-effective strategies tailored to specific circumstances.