Comprehensive Guide to 4T40E Transmission Repair

For those passionate about vehicle maintenance, understanding the inner workings of essential components is key to achieving both performance and longevity. This resource provides in-depth insights and practical approaches to one of the vital systems within many cars, detailing each element’s function and the steps needed to bring it back to optimal operation.

When faced with a challenge, from common wear to specific issues unique to certain setups, knowing the correct process to revitalize the component can save time and cost. This guide covers troubleshooting techniques, component inspection, and practical solutions to common and complex issues, helping enthusiasts and professionals alike enhance both reliability and efficiency.

Whether you are an expert or a newcomer to system restorations, this structured approach provides clear explanations, making it easier to understand how every element should operate. With this knowledge, you can not only improve your system’s functionality but also ensure that each part works seamlessly within the larger framework of the vehicle.

Overview of the 4T40E Transmission

This section provides a comprehensive understanding of one of the widely used automatic units found in many mid-size vehicles, renowned for its reliable structure and functionality. The focus here is on its core design elements, capabilities, and the features that contribute to its performance in various driving conditions.

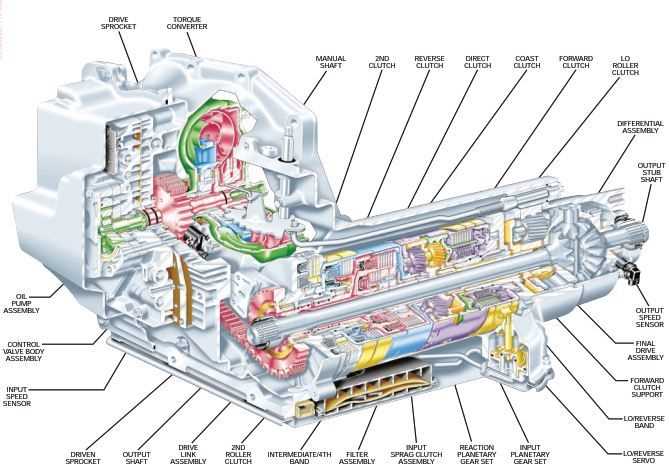

- Design and Build: Built with a compact layout, this unit includes multiple clutches, gears, and hydraulics, organized to maximize space and efficiency.

- Operational Modes: Capable of adapting to diverse driving situations, this model supports smooth gear changes for both urban and highway driving.

- Key Components: The system features integral parts like solenoids, a valve body, and a torque converter, all coordinated to manage power flow effectively.

- Durability Factors: Known for its durability, this model includes reinforced materials designed to handle varying load levels and driving styles.

- Maintenance Needs: Although this unit is designed for longevity, regular inspections are recommended to ensure optimal functionality and early detection of potential issues.

Common Issues and Symptoms

Understanding frequent challenges and recognizable signs of malfunction is essential for effective maintenance and troubleshooting of this system. Identifying early indications helps prevent more significant issues and reduces repair complexity over time.

- Unexpected Shifts: Inconsistent or delayed gear changes can suggest internal disruptions affecting smooth operation.

- Unusual Noises: Whining, grinding, or buzzing sounds often signal wear or damage within moving components.

- Slipping Gears: A tendency to slip out of gear or lose engagement can indicate fluid-related issues or worn parts needing replacement.

- Fluid Leaks: Visible fluid under the vehicle, especially reddish fluid, may point to damaged seals or gaskets, potentially compromising system health.

- Overheating Signs: When excessive heat occurs, it may indicate cooling system inefficiencies or insufficient fluid levels, leading to further wear.

- Erratic Performance: Hesitation or shuddering during acceleration may result from part wear or alignment issues that hinder effective operation.

Recognizing these symptoms promptly enables timely interventions, minimizing risks of prolonged damage and costly repairs.

Essential Tools for Repair

Equipping yourself with the right instruments is the first step to achieving precise and efficient results when working on intricate machinery. Having high-quality tools not only ensures a smoother workflow but also helps to avoid unnecessary delays or complications during the process. Here’s a closer look at the key equipment you’ll want to have on hand for effective and thorough work.

Primary Equipment

A reliable set of wrenches and sockets forms the backbone of any mechanical project. These tools enable secure handling and adjustment of bolts and fasteners, ensuring firm assembly and disassembly. Torque wrenches are especially useful for achieving precise tightness, which is crucial to avoid over-tightening or stripping.

Supporting Tools for Accuracy

Beyond the basics, items like diagnostic scanners and voltage meters offer essential support for detailed assessments and adjustments. These tools allow for accurate troubleshooting, which helps pinpoint areas needing attention and ensures all components function harmoniously. Quality measuring instruments can significantly improve the accuracy of any complex repair.

These essential tools, when used effectively, create a solid foundation for tackling complex mechanical tasks with confidence and precision.

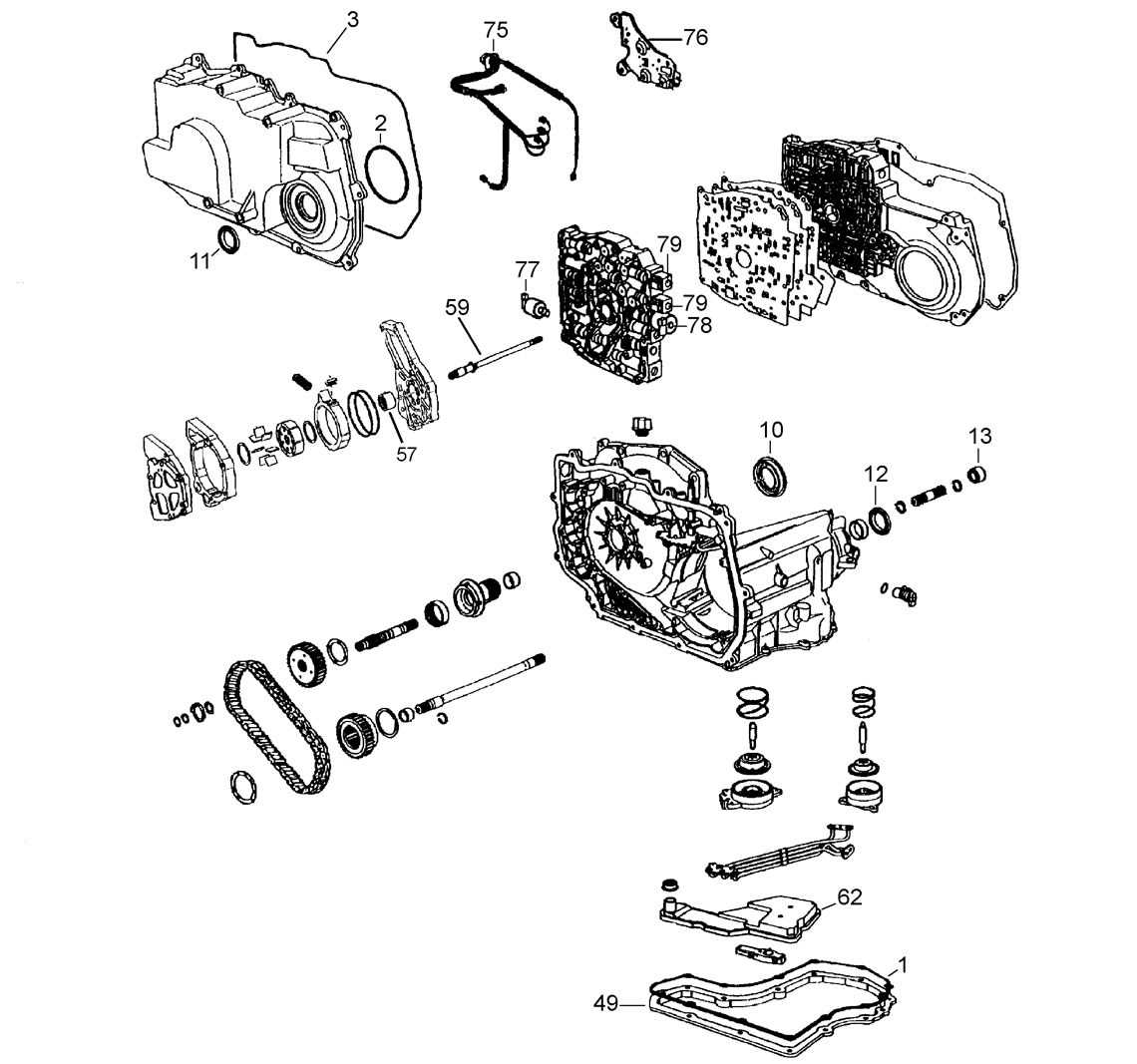

Step-by-Step Disassembly Guide

In this section, we’ll explore a systematic approach to carefully dismantling each component, ensuring each part is separated in an organized manner. This guide aims to help you maintain clarity and prevent errors during reassembly.

Preparation and Safety Precautions

Before beginning the breakdown process, ensure you have adequate tools and a clean workspace. Lay out trays or containers to store individual components safely, and label each one if necessary. Safety should always come first; wear protective gloves and safety glasses to prevent injuries.

Initial Component Removal

Start by loosening any visible bolts, securing brackets, and covers. Use a precision approach for each step, as parts can be delicate and may require specific tools for proper removal. Keep track of smaller components like screws, springs, and clips, placing them in clearly labeled sections.

Next, gradually disassemble the larger structural elements, carefully noting their alignment and orientation. Documenting each step with photos or notes is highly recommended to assist in accurate reassembly.

Continue through each section, systematically detaching parts one at a time. Remember, patience and methodical work are key to preventing damage and ensuring a smooth reassembly process.

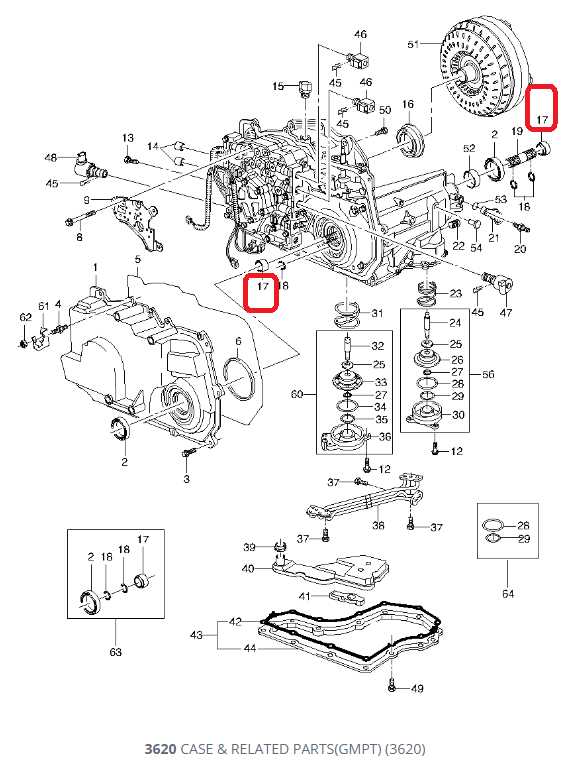

Inspecting Internal Components

Thorough examination of inner parts is essential for ensuring smooth functionality and detecting wear that could impact the system’s performance. Careful inspection allows for the identification of issues that may go unnoticed during routine checks, helping to maintain reliability over time.

The following table highlights critical internal areas and common issues to look out for:

| Component | Common Issues | Inspection Notes |

|---|---|---|

| Clutch Plates | Wear, warping, excessive heat marks | Check for smooth surfaces and even thickness across all plates. |

| Valve Body | Blockages, leakage, erosion | Ensure passages are clear and check for signs of fluid seepage. |

| Seals and Gaskets | Cracks, hardening, deterioration | Look for flexibility and check for any visible damage that could lead to leaks. |

| Pump Assembly | Scoring, reduced flow rate | Inspect the pump housing and gears for wear marks that could affect pressure. |

| Planetary Gear Set | Broken teeth, excessive play, misalignment | Examine each gear for chipped or worn teeth, and

Rebuilding Techniques for Durability

Ensuring longevity and reliability in automotive systems requires a thorough understanding of effective reconstruction methods. When undertaking a rebuild, attention to detail and the application of specific techniques can significantly enhance the overall performance and lifespan of the unit. Quality Components: Utilizing high-grade parts is essential. Opting for superior materials not only improves functionality but also minimizes the risk of premature wear. Carefully selecting components that meet or exceed manufacturer specifications is a vital step in the process. Precision Assembly: Achieving exact tolerances during reassembly is crucial. Any deviation can lead to inefficiencies and potential failures. Using calibrated tools to ensure each piece fits perfectly contributes to a smoother operation and enhances the durability of the entire system. Thorough Cleaning: Before beginning the assembly, it is imperative to clean all components meticulously. Removing old lubricants, debris, and contaminants prevents any obstructions that could interfere with performance. A clean environment is fundamental to a successful reconstruction. Proper Lubrication: Adequate lubrication during assembly cannot be overstated. Ensuring that all moving parts are well-greased reduces friction and heat buildup, which are detrimental to longevity. Using the recommended lubricants helps maintain optimal operation. Testing and Calibration: After completing the assembly, conducting thorough tests is necessary to confirm that everything functions as intended. Fine-tuning adjustments and calibrating the system ensures peak performance and addresses any potential issues before putting it back into service. By following these techniques, one can significantly enhance the reliability and durability of the rebuilt automotive system, ultimately leading to greater satisfaction and reduced maintenance costs over time. Cleaning and Preparing PartsMaintaining optimal performance of components is crucial for ensuring longevity and reliability. Before reassembly, it is essential to thoroughly clean and prepare each piece to prevent contamination and enhance functionality. This process not only improves the efficiency of the overall system but also minimizes the risk of future issues. Importance of Proper CleaningEffective cleansing removes grime, dirt, and old lubricants that can hinder performance. Using appropriate solvents and tools is vital to ensure that no residues remain. Attention to detail during this phase is crucial; even small particles can lead to significant complications later on. Steps for PreparationAfter cleaning, inspect each item carefully for any signs of wear or damage. Replacing worn parts at this stage can save time and effort in the long run. Lubrication should also be applied where necessary to facilitate smooth operation once everything is reassembled. Proper preparation lays the groundwork for a successful rebuild. Assembly Instructions for ReinstallationReassembling the powertrain component is a critical process that requires careful attention to detail and adherence to specific guidelines. Ensuring that all parts are correctly positioned and secured will enhance performance and longevity. This section outlines essential steps to follow for a successful reinstallation. Preparation StepsBefore commencing the reinstallation, gather all necessary tools and components. Inspect each part for wear or damage, replacing any that do not meet the required standards. Ensure the workspace is clean and organized to facilitate a smooth assembly process. Reinstallation Procedure

Begin by aligning the main housing with the engine block, ensuring that all mating surfaces are clean. Carefully insert any necessary seals or gaskets to prevent fluid leaks. Utilize the correct torque specifications for all fasteners, as this is crucial for the integrity of the assembly. Gradually tighten the bolts in a crisscross pattern to maintain even pressure, and recheck all connections to confirm they are secure. After the initial assembly, perform a thorough inspection of the entire setup. Ensure that all components are correctly installed and that no tools or debris remain in the vicinity. Finally, connect the necessary electrical and hydraulic lines, verifying their integrity before completing the reinstallation process. Testing for Optimal PerformanceEnsuring the smooth operation of your vehicle’s drivetrain system requires careful evaluation and testing of its components. Identifying any issues early on can prevent more severe problems down the line. By conducting thorough assessments, you can ensure that everything is functioning efficiently, thus enhancing your vehicle’s overall performance. Visual InspectionBegin by performing a comprehensive visual examination of the assembly. Look for any signs of wear or damage, such as fluid leaks, cracks, or corrosion. Inspect the connections and seals to ensure they are secure and intact. Addressing any visible concerns at this stage can significantly improve the efficiency of the system. Fluid Quality Assessment

Next, check the quality and level of the fluid. Contaminated or low fluid can lead to inadequate lubrication and increased friction, causing wear on internal components. Use a dipstick to assess the color and consistency; fresh fluid should appear clean and reddish in hue. If the fluid is dark or has a burnt smell, it may be time for a change. Maintenance Tips for LongevityTo ensure the enduring performance of your vehicle’s essential components, regular upkeep and attention to detail are crucial. By adopting a proactive approach to maintenance, you can significantly enhance the lifespan and efficiency of your automotive system. 1. Regular Fluid Checks: Ensure that all vital fluids are at optimal levels. This includes hydraulic fluid, which plays a critical role in the smooth operation of various mechanisms. Regularly inspect for leaks and top up as necessary. 2. Routine Inspections: Conduct periodic assessments of critical parts. Look for signs of wear and tear, and address any issues before they escalate into major problems. This practice helps maintain overall functionality. 3. Heat Management: Excessive heat can be detrimental. Ensure that cooling systems are functioning properly to avoid overheating. Installing a high-quality cooler can also aid in managing temperatures effectively. 4. Optimal Driving Habits: Gentle acceleration and deceleration can minimize stress on components. Avoid sudden stops and starts, as they can contribute to unnecessary strain and wear. 5. Professional Servicing: Engage with a qualified technician for regular maintenance checks. Their expertise can identify potential issues early and provide recommendations tailored to your vehicle’s needs. 6. Quality Components: When replacements are necessary, opt for high-quality parts that meet or exceed manufacturer specifications. This can greatly influence performance and longevity. By implementing these maintenance tips, you can significantly contribute to the longevity and reliability of your vehicle’s intricate systems, ensuring a smoother driving experience. |