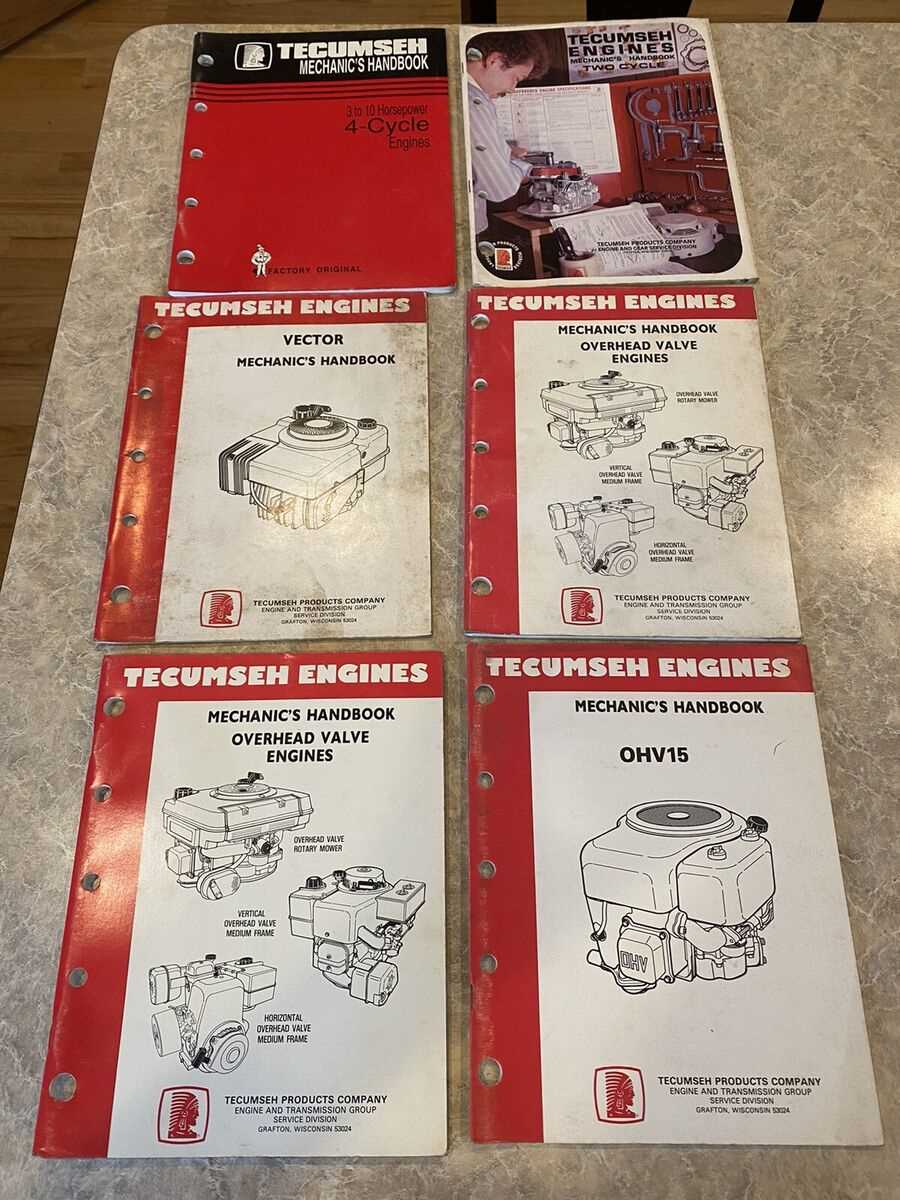

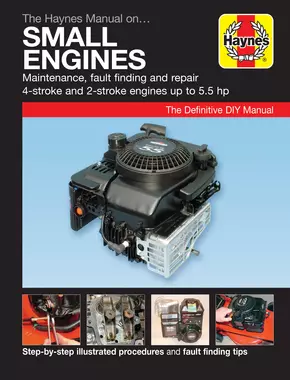

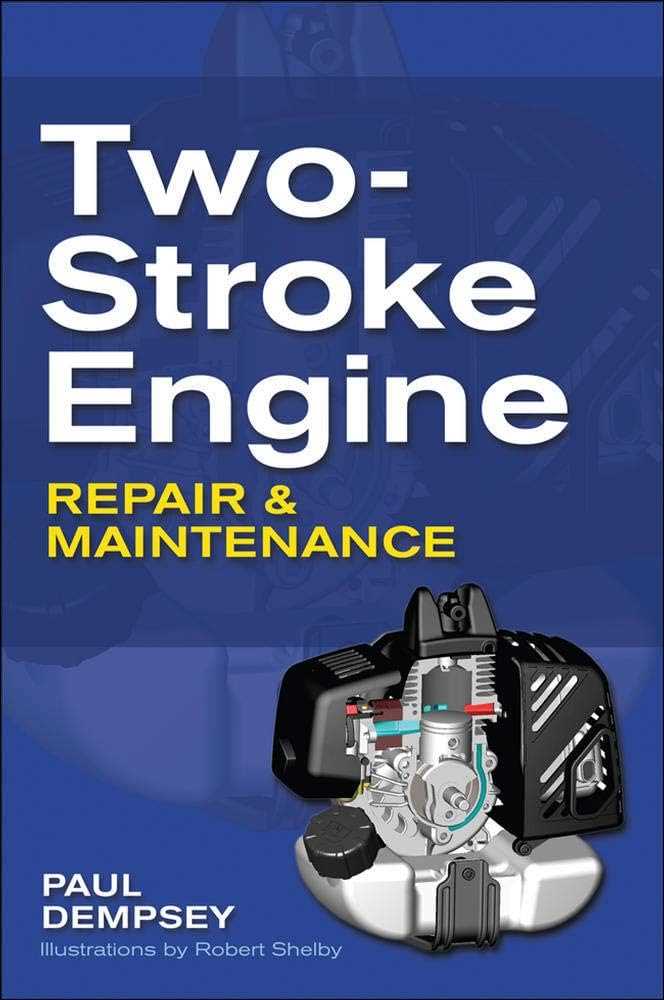

Comprehensive Guide to Repairing 2 Cycle Small Engines

In this section, we explore the essential practices for maintaining and enhancing the functionality of lightweight power units commonly found in various outdoor tools. Understanding the fundamentals of upkeep can significantly improve performance and longevity, ensuring that your equipment operates at its best.

Our focus will be on troubleshooting techniques, part replacement, and preventative measures that anyone can apply. By following these guidelines, users can tackle common issues effectively and keep their machinery in optimal condition.

Whether you are a seasoned operator or a novice, the insights provided here aim to empower you with the knowledge needed to manage and sustain your equipment successfully. Embrace the opportunity to enhance your skills and ensure that your tools remain reliable for years to come.

Understanding frequent complications can significantly enhance the performance and longevity of compact machinery. Many users encounter similar challenges that may stem from various sources, such as improper maintenance or environmental factors. Identifying these recurring problems is essential for ensuring efficient functionality.

| Problem | Description | Possible Causes |

|---|---|---|

| Starting Difficulties | Struggling to initiate operation, often leading to frustration. | Fuel issues, faulty spark plug, or a weak battery. |

| Overheating | Excessive heat buildup can lead to performance drops or failure. | Insufficient cooling, blocked air intake, or low oil levels. |

| Uneven Power Output | Fluctuations in performance can hinder task efficiency. | Fuel contamination, air filter blockage, or ignition system problems. |

| Excessive Vibration | Noticeable shaking during operation may indicate underlying issues. | Loose components, unbalanced parts, or worn bearings. |

Tools Required for Repairs

When it comes to maintaining and fixing various mechanical devices, having the right instruments is crucial for achieving effective results. The following list highlights essential implements that will aid in the process, ensuring that tasks can be completed efficiently and safely.

1. Wrenches: These are vital for loosening and tightening bolts and nuts. A variety of sizes is recommended to accommodate different fasteners.

2. Screwdrivers: A set of both flathead and Phillips screwdrivers will be necessary to handle various screws encountered during maintenance.

3. Pliers: These tools provide grip and leverage, making them useful for holding small components or bending materials as needed.

4. Spark Plug Socket: Specifically designed to remove and install spark plugs, this socket is essential for ignition system adjustments.

5. Multimeter: This device is essential for measuring voltage, current, and resistance, helping diagnose electrical issues effectively.

6. Cleaning Supplies: Brushes, cloths, and appropriate solvents are important for maintaining cleanliness during the process, ensuring that parts function optimally.

Equipped with these tools, you can approach your tasks with confidence, knowing that you have what you need to achieve successful outcomes.

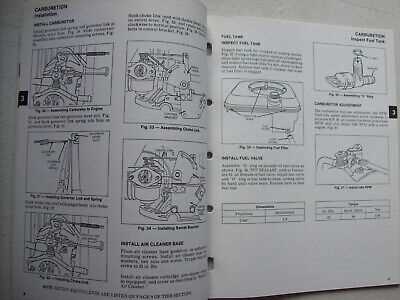

Step-by-Step Maintenance Guide

Proper upkeep of your machinery is essential for optimal performance and longevity. This section will provide a comprehensive approach to maintaining your unit, ensuring it runs smoothly and efficiently. Regular care can prevent potential issues and extend the lifespan of your equipment.

Essential Tools and Materials

- Wrench set

- Screwdrivers

- Oil and fuel

- Cleaning cloths

- Replacement parts

Maintenance Steps

- Begin by inspecting the exterior for any signs of wear or damage.

- Check and clean the air filter to ensure proper airflow.

- Change the oil according to the manufacturer’s recommendations.

- Examine the spark plug and replace it if necessary.

- Ensure all fasteners are tight and secure.

- Test the functionality by starting the unit and listening for unusual noises.

Following these guidelines will help maintain your equipment in peak condition, minimizing the risk of future complications.

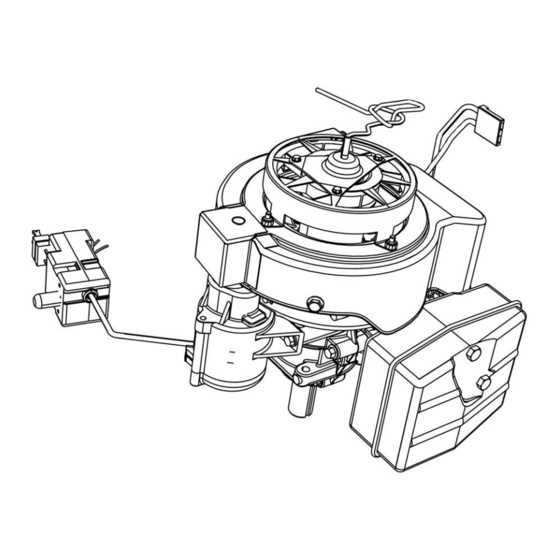

Identifying Engine Components

Understanding the various parts of a motor is essential for effective maintenance and troubleshooting. Each component plays a critical role in the overall function, and recognizing them can enhance the efficiency of the unit. This section will guide you in distinguishing these vital parts, enabling better insight into their operations and potential issues.

Major Parts Overview

The key elements of a motor include the power source, combustion chamber, and transmission system. Each of these areas has specific functions that contribute to the overall performance. By familiarizing yourself with their locations and roles, you will be better equipped to diagnose problems and optimize the functionality of the unit.

Recognizing Additional Features

In addition to the primary components, there are several auxiliary features that enhance performance and control. These may include systems for cooling, lubrication, and ignition. Identifying these additional elements is crucial for comprehensive understanding and effective management of the motor’s operation.

Fuel and Oil Recommendations

Choosing the right types of fluids is essential for maintaining optimal performance and longevity. Proper selection ensures efficient functioning and minimizes the risk of damage. The following guidelines will help you make informed decisions regarding the fluids needed for your equipment.

Recommended Fuels

Utilizing high-quality fuel is crucial for enhancing performance. It is advisable to use a blend that contains a suitable octane rating, ensuring smooth combustion and preventing knocking. Additionally, avoid fuels with high ethanol content, as they can lead to moisture accumulation and potential complications.

Optimal Lubricants

When it comes to lubricants, selecting the appropriate type is vital for reducing friction and wear. Look for products specifically designed for two-stroke applications. These lubricants should provide excellent protection against deposits and help maintain cleanliness within the system. Regularly changing the oil will also contribute to the longevity of the machinery.

Troubleshooting Common Problems

When dealing with various mechanical devices, encountering issues is a common occurrence. Identifying and resolving these complications is essential for maintaining optimal performance. This section provides insights into typical challenges and effective solutions.

Here are some prevalent issues you may encounter:

- Difficulty Starting: If the unit won’t start, check the fuel supply, ignition system, and air filter.

- Inefficient Operation: Poor performance can be attributed to clogged filters or improper fuel mixture.

- Unusual Noises: Unwanted sounds may indicate internal wear or loose components that require attention.

- Excessive Vibration: This can often be resolved by ensuring all parts are securely fastened.

- Fuel Leaks: Inspect for damaged lines or connections that could lead to leakage.

To effectively address these issues, follow these troubleshooting steps:

- Begin with a thorough inspection of all accessible components.

- Consult the operational guidelines for specific advice related to each problem.

- Test any suspected faulty parts, replacing them as necessary.

- Keep a maintenance log to track any recurring issues and solutions implemented.

By following these guidelines, you can enhance the longevity and efficiency of your device.

Rebuilding Engine Basics

Reconstructing a power unit involves understanding its core components and the systematic approach needed for successful assembly. This process can enhance performance and extend the lifespan of the machinery, making it a valuable skill for enthusiasts and professionals alike.

Essential Components

- Cylinder block

- Piston assembly

- Cylinder head

- Crankshaft

- Fuel system

Steps for Reassembly

- Clean all parts thoroughly.

- Inspect each component for wear and damage.

- Replace any faulty parts.

- Follow the manufacturer’s specifications for torque settings.

- Ensure proper alignment during assembly.

Safety Precautions During Repair

Ensuring safety while conducting maintenance tasks is crucial for preventing accidents and injuries. Adopting the right measures can significantly minimize risks associated with working on mechanical devices.

General Guidelines

Before commencing any work, it is essential to familiarize oneself with the equipment and its components. Proper attire, including gloves and goggles, should be worn to protect against potential hazards. Furthermore, maintaining a clean and organized workspace aids in reducing the likelihood of accidents.

Handling Tools and Materials

Using tools correctly is vital for safe operations. Always inspect tools before use to ensure they are in good condition. Store hazardous materials securely and follow manufacturer instructions for their use.

| Precaution | Description |

|---|---|

| Wear Protective Gear | Use gloves and safety goggles to safeguard against injuries. |

| Work in a Well-Lit Area | Ensure adequate lighting to avoid mistakes and accidents. |

| Keep Workspace Organized | A tidy area reduces the risk of tripping or misplacing tools. |

| Inspect Tools Regularly | Check tools for damage or wear before each use to prevent malfunctions. |

When to Seek Professional Help

Understanding the limits of your knowledge and skills is crucial when dealing with mechanical issues. While many problems can be addressed with basic troubleshooting and adjustments, there are situations that require the expertise of a trained technician. Recognizing these instances can save time, resources, and prevent further complications.

Complex Issues Beyond Your Expertise

When faced with intricate malfunctions or symptoms that persist despite your efforts, it may be time to consult a professional. Issues involving advanced components or diagnostics often necessitate specialized knowledge and tools. Attempting to resolve these without proper training can lead to costly mistakes or additional damage.

Safety Concerns

Always prioritize safety. If you encounter situations that pose a risk to your well-being, such as leaks, unusual noises, or other hazardous conditions, seeking assistance is advisable. Professionals are equipped to handle dangerous scenarios safely and effectively, ensuring peace of mind while addressing the problem.

Maintaining Optimal Performance

Ensuring peak functionality of your equipment requires consistent care and attention. Regular upkeep not only enhances efficiency but also prolongs the lifespan of the machinery. By following a systematic approach, you can keep your apparatus running smoothly and effectively.

Key Maintenance Practices

- Regular Inspection: Periodically check for wear and tear on components.

- Clean Air Filters: Ensure that filters are free from debris to maintain airflow.

- Monitor Fuel Quality: Use fresh fuel to avoid issues related to stale or contaminated gasoline.

- Check Lubrication: Keep all moving parts adequately lubricated to reduce friction and prevent overheating.

Seasonal Considerations

- Before Winter: Store equipment in a dry place and consider using stabilizers in fuel.

- During Summer: Ensure that cooling systems are functioning properly to prevent overheating.

- Routine Usage: Use the machinery regularly to keep parts from seizing and to maintain functionality.

Long-Term Care Tips for Engines

Ensuring the longevity of your machinery involves a series of proactive measures that enhance performance and reliability. Consistent maintenance not only prevents potential issues but also contributes to optimal functionality over time.

Regular inspection is essential. Checking components for wear and tear allows you to identify problems before they escalate. Pay close attention to parts that experience high levels of friction or heat.

Keeping the internal mechanisms clean is crucial. Accumulation of debris can hinder efficiency, so routine cleaning will help maintain smooth operation. Additionally, using high-quality lubricants can significantly reduce friction and prolong the life of moving parts.

Monitor fuel quality, as it directly impacts performance. Using clean, fresh fuel minimizes the risk of clogging and other complications. Regularly changing filters is also recommended to ensure a steady flow of fuel to the system.

Finally, store your equipment properly when not in use. Protecting it from harsh weather conditions and extreme temperatures can prevent damage and keep it in peak condition. Following these guidelines will ensure your machinery remains effective for many years.