Briggs and Stratton 276781 Single Cylinder OHV Repair Guide

Understanding the intricacies of engine maintenance is essential for ensuring optimal performance and longevity. This section delves into the various aspects of upkeep, focusing on essential techniques and troubleshooting strategies. With the right knowledge, enthusiasts and professionals alike can effectively address common issues that may arise in their equipment.

By familiarizing oneself with the components and functionality of small engines, users can enhance their skills in diagnosing problems and executing necessary interventions. This guide offers practical insights into the workings of an engine, enabling readers to engage with their machinery confidently. Whether for routine checks or specific challenges, acquiring hands-on knowledge is invaluable.

With clear instructions and detailed explanations, this resource aims to empower users to take charge of their engine care. Understanding each part’s role and how they interact can demystify complex issues, making maintenance a manageable task. Equip yourself with the expertise to prolong the life of your engine and optimize its performance.

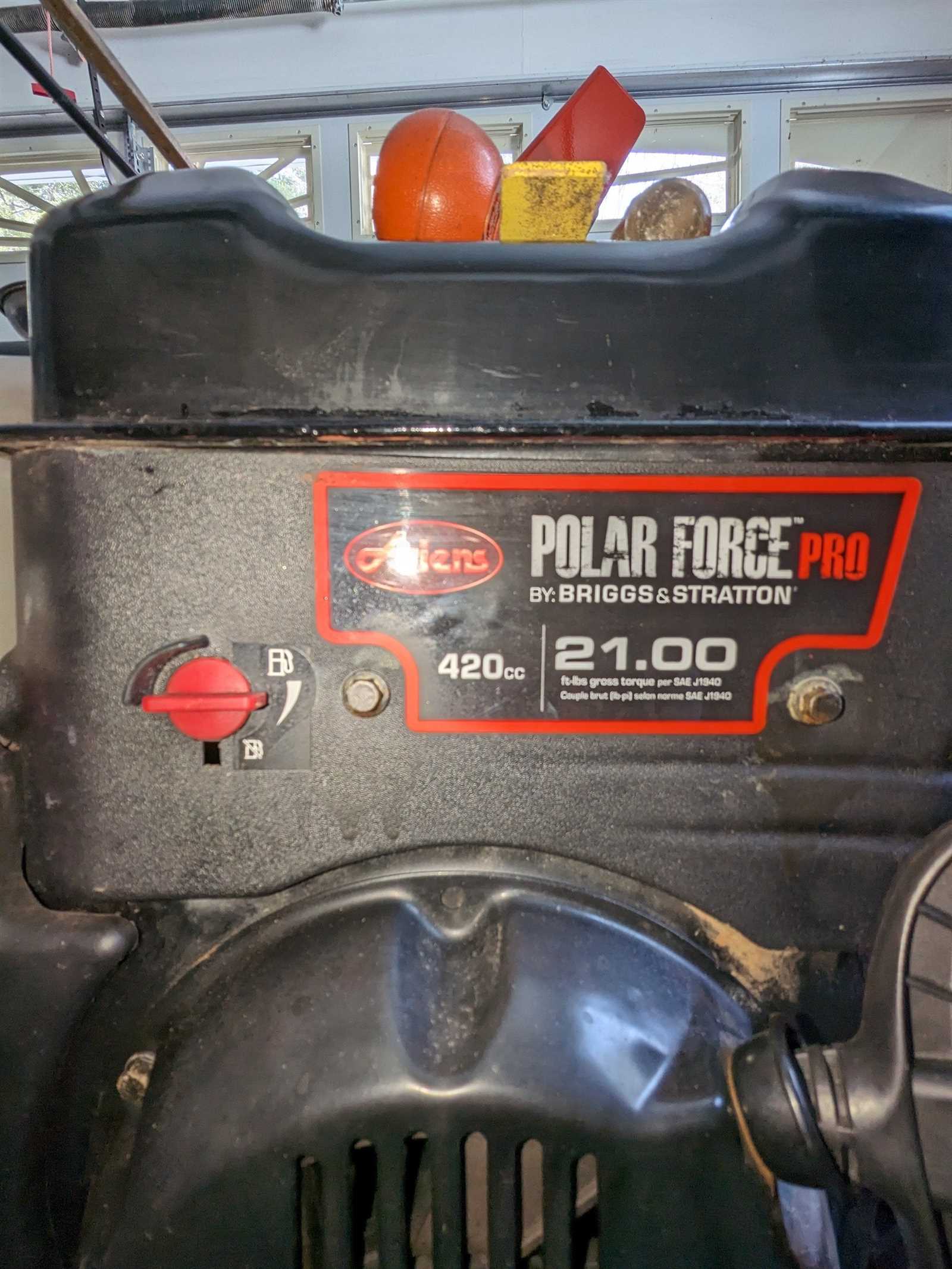

This section will provide an insightful exploration of a renowned power source commonly used in various outdoor equipment. Understanding its fundamental characteristics is essential for effective maintenance and performance optimization. This engine type is recognized for its reliability and efficiency, making it a popular choice among users.

| Feature | Description |

|---|---|

| Type | Four-stroke, air-cooled engine |

| Power Output | Typically ranges from 4 to 20 horsepower |

| Fuel Type | Gasoline, with a recommended octane rating of 87 or higher |

| Cooling System | Air-cooled for efficient thermal management |

| Applications | Lawn mowers, generators, and various gardening tools |

Understanding Single Cylinder Engines

Engines with a singular combustion chamber are widely utilized in various applications, ranging from lawn equipment to portable generators. These power sources are renowned for their simplicity and efficiency, making them ideal for both casual users and professionals. The design allows for straightforward maintenance and operation, providing reliable performance in a compact form factor.

The mechanics behind these engines are relatively uncomplicated, facilitating ease of use and servicing. Here, we will explore the fundamental components and functionality that contribute to the effectiveness of these power units.

| Component | Description |

|---|---|

| Crankshaft | Converts linear motion into rotational energy, driving the output shaft. |

| Piston | Moves within the cylinder to compress the air-fuel mixture and transfer energy to the crankshaft. |

| Connecting Rod | Links the piston to the crankshaft, facilitating the conversion of energy. |

| Flywheel | Stores rotational energy and helps maintain engine speed by smoothing out power delivery. |

| Fuel System | Delivers fuel to the combustion chamber, ensuring the correct mixture for efficient operation. |

| Ignition System | Provides the spark necessary to ignite the air-fuel mixture, initiating the combustion process. |

Understanding these key components is crucial for effective troubleshooting and maintenance, ensuring longevity and optimal performance from these essential power sources.

Common Issues with OHV Models

Engines designed with overhead valve technology often face a variety of common challenges that can affect performance and reliability. Understanding these issues can help in diagnosing problems early and ensuring smooth operation.

- Starting Difficulties: One of the frequent complaints is trouble starting the engine. This can be attributed to factors such as fuel system blockages, stale fuel, or faulty ignition components.

- Excessive Smoke: If the engine produces an unusual amount of smoke, it may indicate issues like worn piston rings or valve seals, leading to oil entering the combustion chamber.

- Overheating: Overheating can occur due to insufficient lubrication, clogged cooling fins, or a malfunctioning cooling system, causing the engine to shut down prematurely.

- Unusual Noises: Unwanted sounds, such as knocking or ticking, may signify problems with internal components like lifters or connecting rods, necessitating further inspection.

- Loss of Power: A noticeable decrease in power can result from clogged air filters, fuel delivery issues, or worn-out components, affecting overall engine performance.

Regular maintenance and timely troubleshooting can help address these common issues, prolonging the life of the engine and enhancing its performance. Being aware of these potential problems allows operators to take preventative measures effectively.

Essential Tools for Repair

When undertaking maintenance on outdoor power equipment, having the right set of instruments is crucial for efficiency and effectiveness. Proper tools not only facilitate the job but also ensure safety and precision during the process. This section outlines the indispensable instruments that every technician should have on hand for successful servicing.

| Tool | Purpose |

|---|---|

| Wrench Set | Used for loosening and tightening nuts and bolts, essential for disassembly and assembly tasks. |

| Screwdriver Set | Required for removing and securing screws of various types and sizes. |

| Socket Set | Ideal for accessing hard-to-reach fasteners, providing leverage and torque. |

| Torque Wrench | Ensures fasteners are tightened to the manufacturer’s specifications, preventing damage from over-tightening. |

| Plier Set | Useful for gripping, twisting, and cutting wires, especially in electrical components. |

| Feeler Gauge | Helps measure gaps and clearances between parts, critical for adjusting precision components. |

| Fuel System Cleaner | Used to maintain the fuel system, ensuring optimal performance and longevity. |

Step-by-Step Maintenance Guide

Regular upkeep is essential for ensuring the longevity and optimal performance of your outdoor power equipment. This guide outlines a systematic approach to maintenance tasks that will help you keep your machine running smoothly and efficiently. Following these steps will not only enhance performance but also reduce the likelihood of unexpected breakdowns.

1. Routine Checks and Cleaning

Begin by inspecting the machine for any visible signs of wear or damage. Clean the exterior thoroughly, removing dirt and debris that can accumulate over time. Pay special attention to the air filter, as a clean filter promotes better airflow and engine performance. Replace it if it appears clogged or dirty.

2. Fluid Maintenance

Checking and changing fluids is crucial for optimal operation. Start with the oil; ensure it’s at the appropriate level and free of contaminants. If it looks dark or gritty, perform an oil change. Additionally, inspect the fuel; old or contaminated fuel can cause performance issues. Drain any stale fuel and refill with fresh, clean gasoline.

Remember: Proper maintenance not only extends the life of your equipment but also ensures safety during operation. Regular attention to these details will result in a more reliable and efficient machine.

Replacing Engine Components

Maintaining optimal performance in any small engine requires periodic replacement of its various parts. Over time, components may wear out due to prolonged use or environmental factors, leading to diminished efficiency. This section focuses on the essential steps and considerations involved in swapping out crucial engine elements to ensure smooth operation and longevity.

Identification of Components

Before initiating the replacement process, it’s vital to identify the components that require attention. Common parts include the piston, valves, and gaskets, which can significantly affect the engine’s functionality. Regular inspections can help detect signs of wear, such as unusual noises, leaks, or decreased power output.

Tools and Preparation

Gathering the necessary tools is crucial for a successful replacement. Standard equipment may include wrenches, screwdrivers, and pliers. Additionally, having a clean workspace and proper lighting will facilitate the process and help prevent the loss of small parts.

Removal of Old Components

Once the problematic parts have been identified, the next step involves removing them carefully. Follow the specific guidelines for each component, ensuring that all fasteners are loosened appropriately. Take note of the order of disassembly, as this will aid in the reinstallation of new parts.

Installation of New Parts

After removing the old components, it’s time to install the new ones. Ensure that all parts are compatible and of high quality. Align the new components correctly and secure them in place according to the manufacturer’s specifications. Double-check connections and fittings to avoid future issues.

Testing and Final Checks

After installation, conducting a thorough test is essential. Start the engine and observe its performance, listening for any irregular sounds. Additionally, check for leaks and ensure all parts are functioning as expected. Performing these final checks will help confirm that the replacement was successful and that the engine is ready for continued use.

Tuning and Adjusting the Engine

Regular tuning and precise adjustments are essential to maintaining optimal engine performance. Adjustments can help improve efficiency, reduce fuel consumption, and ensure smooth operation under various conditions. This section provides key steps and considerations for refining the setup, aiming to maximize functionality and reliability over time.

Begin by inspecting essential components such as the carburetor and ignition system. Clean and adjust the carburetor to maintain a balanced air-fuel mixture, which is crucial for effective combustion. Adjusting idle speed and checking fuel lines for any blockages can also contribute to improved responsiveness.

Next, verify spark plug condition and gap, as this influences ignition timing and fuel combustion. A well-maintained spark plug ensures consistent power output and minimizes the risk of misfiring. Additionally, examine the air filter and replace it if needed to prevent airflow restrictions, which can impact power and fuel efficiency.

Finally, consider valve adjustments if applicable, as well-set valves allow for better compression and smoother engine cycles. Test the adjustments by starting the engine and listening for any irregular sounds, indicating further fine-tuning may be needed. Consistent maintenance and tuning efforts contribute significantly to the longevity and efficiency of the engine.

Safety Precautions During Repairs

Ensuring safety is crucial when working on mechanical systems. Observing proper safety guidelines can prevent accidents and make the process smoother. This section covers key precautions to keep in mind for a safe and efficient experience.

Personal Protective Equipment

- Eye protection: Always wear safety glasses to shield your eyes from potential debris and sharp particles.

- Gloves: Use gloves to protect your hands from sharp edges and hot surfaces.

- Hearing protection: In noisy environments, ear protection can prevent hearing damage.

Preparing the Work Area

- Ensure adequate ventilation, especially if working in enclosed spaces.

- Keep tools and materials organized to avoid tripping hazards and ensure quick access.

- Maintain proper lighting to avoid mistakes and ensure visibility of small parts.

- Disconnect Power: Before beginning, disconnect any power source to prevent accidental starts.

- Secure the System: Stabilize components before handling to prevent unexpected movements.

- Handle Parts Cautiously: Avoid contact with hot surfaces and sharp edges, and allow parts to cool if recently in use.

By following these guidelines, you can ensure a safer environment, minimize the risk of injury, and protect the integr

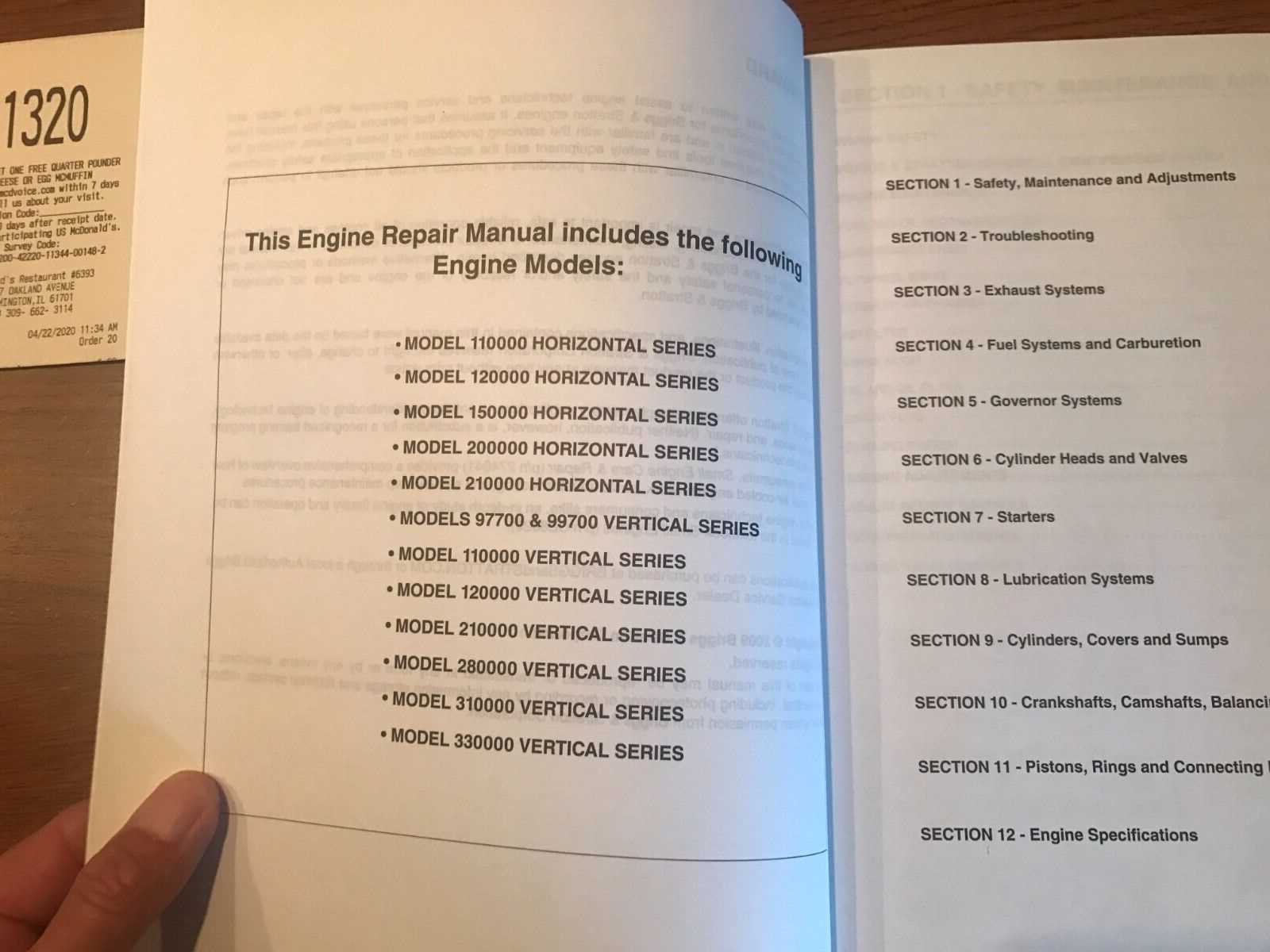

Identifying Engine Specifications

Understanding engine attributes is essential for efficient maintenance and optimal performance. This section provides a detailed overview of how to recognize key features that define the functionality and compatibility of your engine model.

Key Features Overview

To begin, identifying the main parameters like displacement, bore, and stroke measurements is crucial. These elements often determine the power output and compatibility with various components, impacting the engine’s performance in different applications. Additionally, noting the type and arrangement of essential parts contributes to effective troubleshooting and maintenance.

Technical Specification Table

The table below highlights typical specifications to look for, including measurements and capacity limits that characterize most engine types of this category. Confirming these values helps in selecting the correct replacement parts and adjusting settings as needed.

| Specification | Description |

|---|---|

| Displacement | Volume capacity of the engine’s combustion chamber, influencing overall power output. |

| Bore and Stroke | Internal dimensions that determine piston movement, affecting torque and efficiency. |

| Compression Ratio | Ratio indicating the level of compression, impacting fuel efficiency and power. |

| Fuel Capacity | Total volume for fuel storage, necessary for determining run time between refuels. |

| Oil Type and Capacity | Recommended lubricant and volume needed for optimal engine lubrication. |

Referencing these specifications ensures that your engine operates within the intended parameters, maximizing both performance and longevity.

Fuel System Troubleshooting Tips

The fuel system is crucial for engine performance, and diagnosing issues within this system can prevent larger problems. Understanding common symptoms and their causes helps in identifying the correct adjustments or replacements needed.

| Issue | Possible Cause | Solution |

|---|---|---|

| Engine Fails to Start | Clogged fuel lines, contaminated fuel, or improper fuel mix | Inspect and clean fuel lines, drain old fuel, and refill with fresh fuel |

| Engine Runs Unevenly | Blocked fuel filter, air leaks, or faulty fuel pump | Replace the fuel filter, check for air leaks, and inspect the fuel pump for damage |

| Poor Fuel Efficiency | Incorrect carburetor settings or low-quality fuel | Adjust carburetor settings and switch to high-grade fuel |

| Fuel Leaks | Loose fuel line connections or damaged gaskets | Tighten connections and replace any worn gaskets |

Regular maintenance of the fuel system components, such as the fuel filter and fuel lines, along with using high-quality fuel, extends the lifespan of the engine and enhances its reliability.

Electrical System Diagnostics

In the process of maintaining engine functionality, understanding and troubleshooting the electrical system is essential. This section covers effective methods for identifying and addressing common electrical issues, ensuring optimal performance and reliability.

Basic Checks and Inspection

Begin diagnostics by checking all visible connections, inspecting wires for wear or damage, and ensuring that no corrosion is present. It’s crucial to examine the battery condition, as a weak or dead battery can be a primary cause of electrical problems. A multimeter can help verify if the battery and connections are supplying the correct voltage. Clean contacts as necessary to ensure consistent current flow.

Testing the Ignition and Charging Components

The ignition and charging systems are vital to engine performance. Start by testing the ignition coil, ensuring it produces the correct spark. A weak or inconsistent spark can signal issues with the coil or associated connections. For charging system diagnostics, confirm that the alternator is generating adequate power to recharge the battery. Replacing faulty components or tightening loose wires may resolve many performance issues.

Note: Regular diagnostics and maintenance of the electrical system not only prevent unexpected malfunctions but also extend the lifespan of the equipment, ensuring a stable and reliable operation for years to come.

Common Replacement Parts Explained

Maintaining a well-functioning engine relies on understanding the essential components that often require replacement over time. Familiarity with these parts can streamline upkeep, ensuring smooth operation and longevity. This section provides insights into the main elements that frequently need attention, offering clarity on their roles and when they may need to be refreshed.

Air Filter

The air filter plays a crucial role in keeping debris and particles out of the engine, allowing it to breathe freely. Over time, dirt accumulation can hinder airflow, leading to reduced efficiency. Replacing the air filter periodically helps maintain optimal performance and extends the engine’s operational life.

Fuel System Components

Parts like the fuel filter and carburetor are central to a healthy fuel system. The fuel filter traps impurities, protecting other elements from contamination, while the carburetor manages the mix of fuel and air. Cleaning or replacing these components ensures a steady flow and consistent power, making them essential for routine checks.

Other significant parts include the spark plug, which ignites the fuel mixture, and the gasket, which seals various sections of the engine, preventing leaks. Regular inspection and timely replacement of these parts contribute to sustained, efficient operation, reducing the likelihood of more complex

Resources for Further Assistance

If you’re seeking additional support for maintenance tasks or component analysis, there are numerous sources of guidance and technical advice. These resources offer detailed explanations, step-by-step instructions, and troubleshooting tips to help enhance your understanding and capability.

Technical Documentation and Guides

Many online platforms provide technical documents, guides, and user communities that cater to a range of mechanical configurations. These sources can be invaluable for finding specific instructions, exploring various approaches, and gaining insight from experienced users.

Community Support and Forums

Joining a community or forum related to engine and machine maintenance offers an excellent way to find answers, ask questions, and learn from others who have faced similar challenges. Enthusiasts and professionals alike share tips, solutions, and modifications that can simplify many tasks.

| Resource Type | Description | Access |

|---|---|---|

| Online Libraries | Collections of technical documents, instructional materials, and comprehensive service guides. | Free or subscription-based |

| Video Tutorials | Visual demonstrations of essential maintenance techniques, part replacement, and performance optimization. | Public platforms |

| Expert Forums |