Guide to Repairing Haier Dishwashers

In the realm of home appliances, understanding how to address common issues can significantly enhance longevity and efficiency. This section provides essential insights into the intricacies of maintaining and troubleshooting a specific kitchen appliance, ensuring optimal performance over time.

By familiarizing oneself with potential challenges and their solutions, users can navigate minor malfunctions confidently. This guide emphasizes practical techniques and tips that facilitate seamless operation and help prevent unnecessary disruptions.

Whether you’re experiencing a minor hiccup or looking to optimize functionality, this resource serves as a comprehensive companion. Embrace the knowledge contained within to empower your appliance management and ensure it remains a reliable asset in your daily routine.

Understanding Common Dishwasher Issues

Many individuals encounter various challenges with their kitchen appliances, often leading to frustration. Identifying typical problems can assist in troubleshooting and provide a clearer path to resolution.

Some prevalent complications include:

- Inadequate cleaning performance

- Unusual noises during operation

- Water leaks around the unit

- Failure to start or respond

- Residual water after a cycle

Each of these issues may stem from different underlying causes, requiring distinct approaches for resolution. Understanding these factors can enhance maintenance and prolong the lifespan of the appliance.

Below are common scenarios and their potential origins:

- Poor cleaning results: This can occur due to clogged spray arms, incorrect loading, or using inappropriate detergents.

- Strange sounds: Noises may indicate worn-out components, such as bearings or motors, or the presence of foreign objects.

- Leaks: These often arise from damaged door seals, loose connections, or blocked drainage systems.

- Failure to start: Power supply issues or faulty controls may be the culprits.

- Standing water: This could be a result of drain blockages or malfunctioning pumps.

Recognizing these signs early can facilitate timely intervention, ensuring optimal functionality and efficiency.

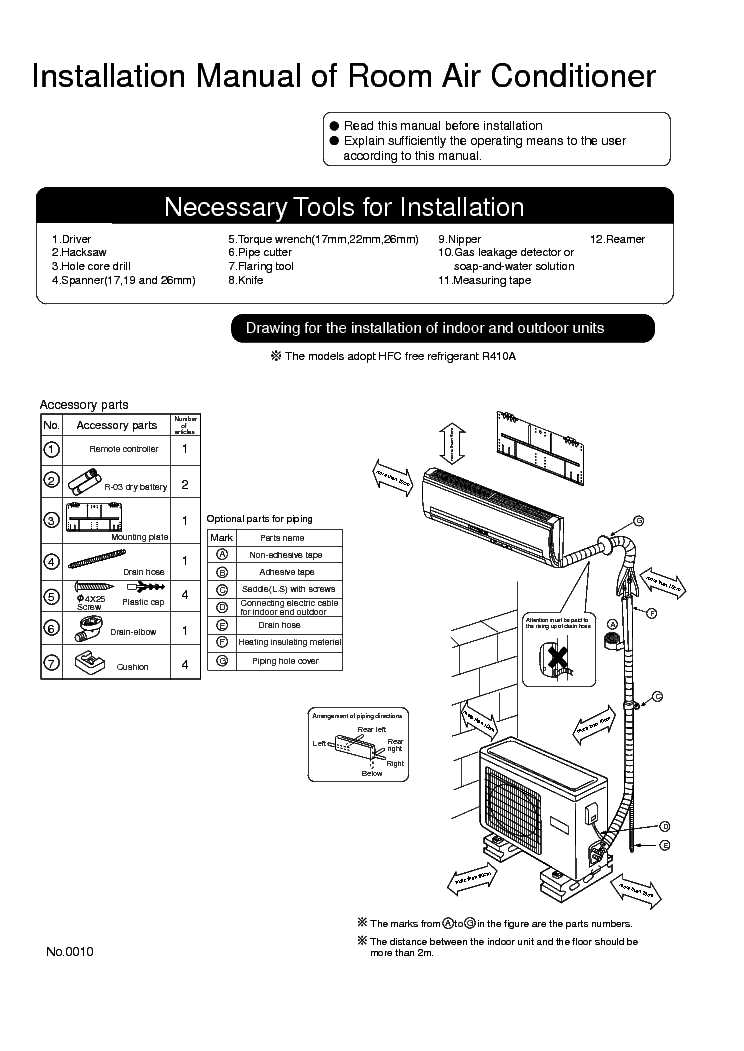

Essential Tools for Repairs

When tackling maintenance tasks around your home appliance, having the right instruments at your disposal is crucial. This section outlines the necessary equipment that will help ensure a smooth and effective process, whether you’re addressing minor issues or more complex challenges.

Basic Tools

- Screwdrivers (flathead and Phillips)

- Pliers (needle-nose and standard)

- Wrenches (adjustable and socket)

- Flashlight or work light

- Multimeter for electrical diagnostics

Specialized Instruments

- Spray lubricant for hinges and moving parts

- Replacement parts specific to your model

- Soft cloths for cleaning

- Measuring tape for precision

- Safety goggles and gloves for protection

By assembling this collection of tools, you’ll be well-equipped to handle various challenges effectively, ensuring longevity and optimal performance of your home appliance.

Troubleshooting Water Drain Problems

Effective management of liquid removal is crucial for the optimal functioning of any cleaning appliance. When issues arise in this area, it can lead to inefficient operation and potential damage. This section aims to identify common challenges and provide guidance on how to resolve them.

Identifying Common Issues

One of the first steps in addressing drainage problems is to recognize signs that indicate a malfunction. These may include standing water at the bottom, unusual noises during the draining cycle, or error messages on the control panel. Understanding these symptoms can help in pinpointing the root cause.

Steps for Resolution

Begin by checking the drainage hose for any kinks or clogs that could impede water flow. Ensure that the connection to the sink drain is secure and not blocked. Additionally, inspect the filter for debris accumulation, which can hinder performance. Regular maintenance of these components can prevent recurring issues and extend the lifespan of the appliance.

Identifying Electrical Failures

Detecting issues within electrical systems is crucial for ensuring optimal functionality. Various symptoms may indicate underlying problems, ranging from intermittent operation to complete failure. Understanding these signs can aid in diagnosing the root cause of malfunctions.

Common indicators include unusual noises, inconsistent performance, and unexpected error messages. Each of these manifestations may point to specific electrical anomalies, such as short circuits, component failures, or wiring issues. Addressing these concerns promptly can prevent further complications and extend the lifespan of the unit.

To begin the troubleshooting process, it is essential to inspect the power source and connections. Verify that the appliance is receiving adequate voltage and check for any visible signs of damage or wear on cables. This initial examination can often reveal straightforward solutions to complex problems.

Regular maintenance and monitoring can significantly reduce the likelihood of electrical failures. Keeping an eye on usage patterns and responding swiftly to any irregularities will help maintain the device’s efficiency and reliability.

Cleaning the Filter Effectively

Maintaining the cleanliness of the filtration system is essential for optimal performance and longevity. Regularly addressing this component ensures efficient operation and helps prevent undesirable odors or blockages.

Step-by-step Process: Begin by carefully removing the filter from its designated location. Rinse it under warm water to eliminate loose debris and buildup. For more stubborn residues, a soft brush or sponge can be employed, ensuring not to damage the filter’s surface.

Tip: Soaking the filter in a mixture of warm water and a mild detergent for a few minutes can enhance the cleaning process. After thorough rinsing, allow the filter to air dry completely before reinstalling it to avoid trapping moisture.

By regularly following these steps, you will contribute to the overall efficiency and functionality of the appliance, promoting a cleaner and fresher environment.

Examining the Spray Arm Function

The spray arm is a crucial component that plays a vital role in the cleaning process of kitchenware. Its primary purpose is to distribute water evenly throughout the interior, ensuring that every item receives adequate coverage. Understanding how this mechanism operates can significantly impact overall performance and efficiency.

During operation, the arm rotates and emits streams of water, which helps to dislodge food particles and debris from surfaces. The effectiveness of this system can be influenced by several factors, including water pressure, blockages, and the condition of the spray arm itself. Regular maintenance is essential to ensure optimal functionality.

Common issues may include uneven water distribution, which can lead to spots or residues on dishes. This can often be traced back to obstructions in the spray arm’s nozzles or a malfunctioning rotation mechanism. Identifying these problems early can help maintain the unit’s efficiency and extend its lifespan.

In summary, the performance of the spray arm is fundamental to achieving clean kitchenware. Understanding its function and potential issues can aid in maintaining peak efficiency and ensuring satisfactory results.

Dealing with Unusual Noises

When your kitchen appliance starts producing unexpected sounds, it can be a cause for concern. Identifying and addressing these noises early can prevent more significant issues down the line. Here’s a guide to understanding common disturbances and how to handle them effectively.

Here are some common unusual noises you might encounter:

- Banging or Clanking: This could indicate loose parts or items obstructing the mechanism.

- Hissing: Often a sign of a water issue, such as a leak or a malfunctioning valve.

- Buzzing: This may suggest electrical problems or that the motor is struggling.

- Grinding: Typically points to debris caught in the machinery or worn-out components.

To troubleshoot these sounds, follow these steps:

- Turn off the unit and disconnect it from the power source for safety.

- Inspect the interior for any foreign objects that might be causing noise.

- Check for any loose or damaged parts that may need tightening or replacement.

- If the issue persists, consult a professional technician for a thorough examination.

By paying attention to these indicators, you can maintain the efficiency of your appliance and address potential problems before they escalate.

Fixing Door Seal Issues

Ensuring an effective closure is crucial for maintaining the efficiency of your appliance. When the sealing mechanism is compromised, it can lead to leaks and diminished performance. This section outlines the common problems associated with sealing and offers solutions for restoring proper function.

| Issue | Possible Cause | Solution |

|---|---|---|

| Water leakage | Worn or damaged seal | Inspect the seal for cracks or tears and replace it if necessary. |

| Door not closing properly | Debris or obstructions | Clean the edges of the door and the frame to ensure a tight fit. |

| Seal not adhering | Old or degraded adhesive | Remove the old sealant and apply a new adhesive to secure the seal. |

Regular maintenance of the sealing components will help prolong the life of your appliance and improve its efficiency. Make sure to perform checks periodically to catch any issues early.

Replacing Faulty Components

When appliances encounter issues, identifying and substituting malfunctioning parts can restore functionality and enhance performance. This process involves a systematic approach to ensure that every defective element is addressed, ultimately extending the lifespan of the unit.

Before initiating the replacement process, it is essential to gather the necessary tools and components. A well-organized workspace facilitates a smoother workflow. Below is a table outlining common components that may require replacement, along with their typical symptoms of failure:

| Component | Symptoms of Failure |

|---|---|

| Motor | Unusual noises, failure to start |

| Heating Element | Insufficient heating, water remaining cold |

| Control Board | Erratic behavior, failure to respond |

| Water Inlet Valve | Leakage, failure to fill |

Identifying the defective part is the first step, followed by sourcing a compatible replacement. Proper installation is crucial to ensure optimal performance and prevent further complications. Always consult the specifications and guidelines to achieve the best results.

Performing Regular Maintenance Checks

Routine inspections are essential for ensuring the longevity and optimal performance of your kitchen appliance. By implementing a consistent maintenance schedule, you can identify potential issues early and enhance the efficiency of the unit.

Key Areas to Inspect

- Filter System: Regularly clean and check for blockages to ensure proper water flow.

- Hoses and Connections: Examine for leaks or wear to prevent water damage.

- Exterior Surface: Wipe down to remove stains and prevent corrosion.

Steps for Effective Maintenance

- Disconnect the unit from power before starting any inspection.

- Remove and clean the filter, ensuring no debris is left behind.

- Check all hoses and connections for tightness and integrity.

- Inspect the door seals for any signs of wear or damage.

- Reconnect the appliance and run a short cycle to ensure everything functions correctly.

Upgrading Your Dishwasher Parts

Enhancing the components of your cleaning appliance can significantly improve its performance and longevity. This section explores the advantages of upgrading various elements, providing insights into what options are available and how they can benefit your household tasks.

Benefits of Component Upgrades

Upgrading specific parts can lead to improved efficiency, reduced noise levels, and enhanced cleaning capabilities. High-quality components often outperform standard parts, resulting in better energy consumption and longer service life.

Common Parts to Consider

| Component | Description | Advantages |

|---|---|---|

| Spray Arm | Responsible for distributing water during cycles. | Improved coverage and cleaning efficiency. |

| Filter | Helps trap food particles and debris. | Enhanced filtration for cleaner results. |

| Heating Element | Heats water to the desired temperature. | Faster heating times and better sanitization. |

| Control Board | Manages the operation of the appliance. | More reliable and efficient operation. |