Comprehensive Guide to John Deere 445 Repair Manual

For enthusiasts and professionals alike, understanding the intricacies of machinery is essential for optimal performance. This section delves into essential guidelines for ensuring longevity and functionality in equipment. Whether you are addressing minor adjustments or more complex issues, having a thorough understanding of your machinery can save time and resources.

Effective maintenance practices not only enhance the efficiency of your machinery but also prevent costly breakdowns. This guide offers insights into common challenges faced by operators and outlines step-by-step solutions that can be applied in various scenarios. Knowledge of these practices empowers users to tackle problems confidently and ensures smooth operation.

Additionally, staying informed about the latest advancements in technology and techniques can significantly impact the care and upkeep of your equipment. By embracing a proactive approach, users can optimize their experience and extend the lifespan of their machinery. This comprehensive resource is designed to provide valuable information and practical advice for all levels of expertise.

Overview of John Deere 445

This section provides a comprehensive look at a well-regarded model known for its reliability and versatility in various agricultural and landscaping tasks. Designed to meet the needs of both professional and amateur users, it combines innovative technology with user-friendly features to enhance performance and efficiency.

Key Features

One of the standout attributes of this model is its robust engine, delivering exceptional power while maintaining fuel efficiency. Additionally, its durable construction ensures longevity, making it a trusted choice for many applications.

| Feature | Description |

|---|---|

| Engine Type | Air-cooled, single-cylinder |

| Horsepower | 20 HP |

| Transmission | Hydrostatic |

| Deck Size | 54 inches |

| Weight | 600 lbs |

Performance and Applications

This model excels in various tasks, from mowing large lawns to handling light-duty garden work. Its maneuverability and ease of use make it suitable for both residential and commercial settings, catering to a wide range of user preferences.

Common Issues with John Deere 445

Owners of this specific model often encounter a range of typical challenges that can affect performance and reliability. Understanding these common problems can help in maintaining optimal functionality and prolonging the lifespan of the equipment.

1. Engine Starting Difficulties: One frequent issue is trouble starting the engine. This can be attributed to various factors, including battery failure, fuel line blockages, or ignition system malfunctions.

2. Overheating: Another common concern is overheating, which may arise from coolant leaks, a malfunctioning thermostat, or a clogged radiator. Monitoring temperature levels is crucial to prevent significant damage.

3. Transmission Problems: Transmission issues often manifest as slipping gears or unresponsiveness. These symptoms may indicate low fluid levels or the need for adjustments to the transmission system.

4. Electrical Failures: Electrical systems can be prone to faults, leading to issues such as malfunctioning lights or faulty gauges. Regular inspection of wiring and connections can help mitigate these problems.

5. Tire Wear: Uneven tire wear can result from improper inflation or alignment issues. Ensuring that tires are correctly inflated and aligned can enhance traction and improve overall performance.

Addressing these common challenges promptly can ensure that the equipment operates efficiently and effectively, reducing downtime and repair costs.

Tools Needed for Repairs

When undertaking maintenance tasks, having the right equipment is essential for efficiency and effectiveness. A well-equipped workspace not only facilitates the process but also ensures safety and precision in every action.

Here are some essential tools to consider:

- Wrenches: A variety of sizes, including adjustable wrenches, are crucial for loosening and tightening bolts.

- Screwdrivers: Both flathead and Phillips types are necessary for handling different screws throughout the equipment.

- Socket Set: A comprehensive socket set allows for easy access to nuts and bolts in tight spaces.

- Pliers: Useful for gripping, bending, and cutting wires or small components.

- Hammer: Essential for driving pins or loosening parts that may be stuck.

- Jack and Stands: Important for lifting equipment safely to access the undercarriage or underside components.

Additional items that may prove useful include:

- Tape Measure: For accurate measurements to ensure proper replacements and adjustments.

- Torque Wrench: Ensures that fasteners are tightened to the manufacturer’s specifications.

- Diagnostic Tools: Such as multimeters or code readers to troubleshoot electrical issues.

- Safety Gear: Including gloves, goggles, and ear protection to maintain safety during maintenance.

Equipping yourself with these tools can significantly enhance the quality and safety of your maintenance activities.

Step-by-Step Maintenance Guide

Proper upkeep of your machinery is essential for optimal performance and longevity. This guide provides a structured approach to maintaining your equipment, ensuring it runs smoothly and efficiently. By following these steps, you can prevent costly repairs and extend the life of your machine.

Essential Checks

Begin with a thorough inspection of all key components. Look for any signs of wear or damage, particularly in the engine, belts, and hoses. Ensure that fluids are at appropriate levels and free of contaminants. Regularly changing the oil and filters is crucial for keeping the engine in good condition.

Routine Maintenance Tasks

Establish a schedule for routine tasks such as cleaning air filters, checking tire pressure, and greasing moving parts. These simple actions can greatly enhance performance. Additionally, keeping the exterior clean will help prevent rust and other environmental damage. Always consult your equipment’s specifications for detailed instructions on intervals and procedures.

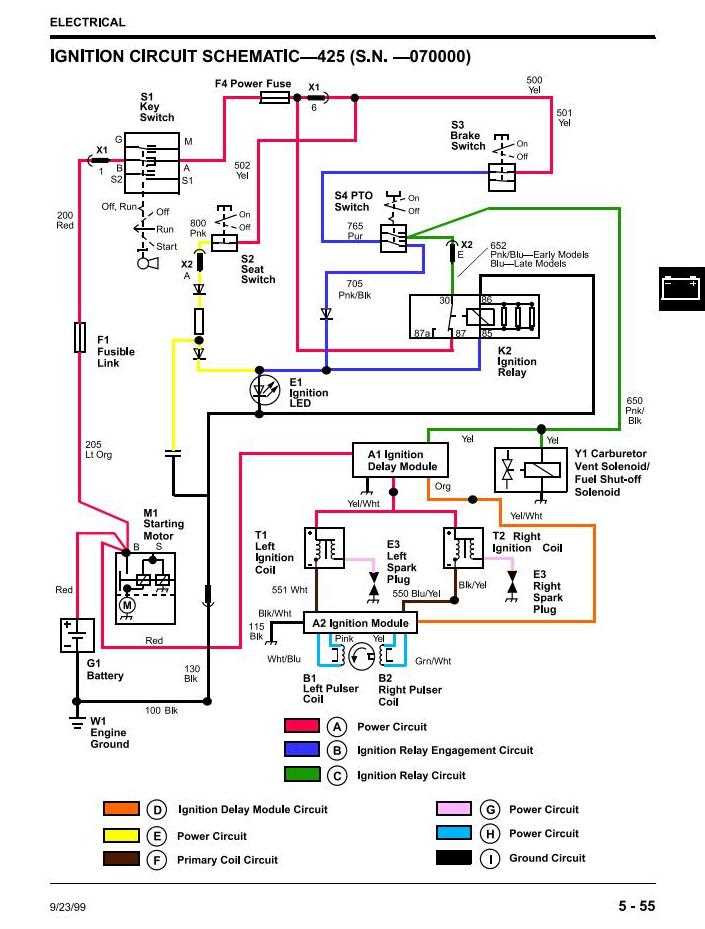

Electrical System Troubleshooting

The efficiency of any machinery heavily relies on its electrical components. Identifying and resolving issues within the electrical system can significantly enhance performance and extend the lifespan of the equipment. This section provides a structured approach to diagnosing common electrical faults.

Understanding Symptoms: The first step in troubleshooting involves recognizing the symptoms of electrical problems. Signs such as inconsistent starting, dim lights, or malfunctioning gauges often indicate underlying issues that require attention.

Safety Precautions: Always prioritize safety when working on electrical systems. Disconnect the power source before performing any checks or repairs to avoid potential hazards. Use insulated tools and wear appropriate personal protective equipment.

Basic Checks: Begin troubleshooting by inspecting the battery connections for corrosion or loose cables. Ensure that all fuses are intact and functioning. A multimeter can be invaluable for testing voltage and continuity throughout the system.

Component Inspection: Pay close attention to critical components such as the starter motor, alternator, and wiring harness. Look for signs of wear, damage, or overheating. Any abnormalities may indicate the need for replacement or repair.

Systematic Testing: Implement a step-by-step testing procedure to isolate the problem. Start with the power source, then move to individual components, checking each for functionality. Document your findings to help pinpoint the exact issue.

Consultation of Resources: Utilizing relevant resources can provide additional insights. Schematics and diagrams can assist in understanding the layout and function of the electrical system, aiding in more efficient troubleshooting.

By following these guidelines, operators can effectively address electrical issues, ensuring their equipment remains in optimal working condition.

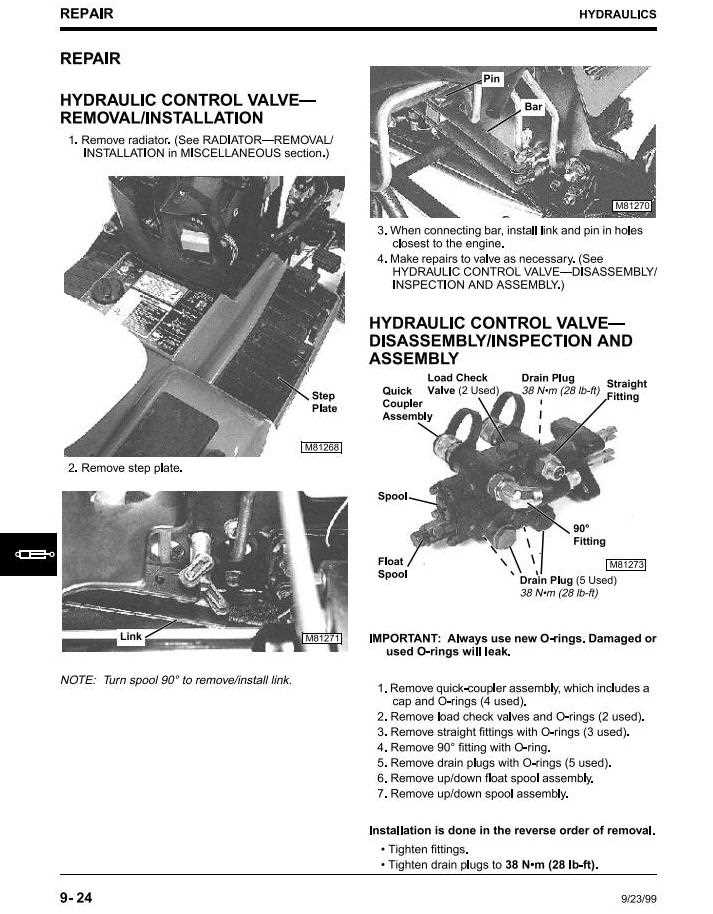

Hydraulic System Diagnostics

Effective troubleshooting of hydraulic systems is crucial for maintaining optimal performance and reliability. A systematic approach allows operators to identify issues accurately, ensuring efficient operation and preventing costly downtime. This section focuses on essential diagnostic techniques and common symptoms associated with hydraulic malfunctions.

Common Symptoms of Hydraulic Issues

Operators may encounter various indicators signaling potential problems within the hydraulic system. These include unusual noises, erratic movement of components, and inconsistent pressure readings. Fluid leaks are another critical sign, as they can significantly affect system efficiency. Understanding these symptoms is the first step toward effective diagnosis.

Diagnostic Techniques

To assess the hydraulic system, start with a thorough visual inspection. Check for leaks, damaged hoses, and worn-out seals. Next, utilize pressure gauges to measure the system’s performance. Comparing actual pressure readings against specifications will help identify discrepancies. Additionally, analyzing fluid condition and cleanliness can provide insights into potential contamination or degradation issues.

Engine Repair Techniques

Effective engine maintenance is crucial for ensuring optimal performance and longevity of machinery. This section outlines various methods and strategies that can be employed to address common issues, enhance efficiency, and extend the life of the power unit. By utilizing appropriate techniques, operators can achieve significant improvements in functionality.

Diagnosing Issues: The first step in addressing engine concerns is accurate diagnosis. Utilizing tools such as compression gauges and multimeters can help identify problems. Pay attention to unusual sounds, smoke, or changes in performance, as these can signal underlying issues.

Component Inspection: Regular examination of critical components is essential. This includes checking for wear and tear on belts, gaskets, and hoses. Inspecting fuel lines and filters ensures a clean fuel supply, while examining the cooling system helps prevent overheating.

Routine Maintenance: Implementing a consistent maintenance schedule can prevent many common problems. Regular oil changes, air filter replacements, and coolant checks are fundamental practices that contribute to smooth operation.

Repair Techniques: When addressing specific issues, techniques such as resealing leaks, replacing worn parts, and adjusting timing can restore performance. Utilizing high-quality replacement components is vital to ensure compatibility and durability.

Testing and Calibration: After performing repairs, thorough testing is necessary. This may involve checking engine output, adjusting settings, and ensuring all systems function correctly. Proper calibration can significantly enhance performance and reliability.

Documentation: Keeping detailed records of maintenance and repairs is beneficial. This information aids in tracking performance trends and can be invaluable for future troubleshooting efforts.

Transmission Maintenance Tips

Proper upkeep of the transmission system is crucial for ensuring optimal performance and longevity of any machinery. Regular maintenance can prevent costly repairs and enhance the efficiency of the equipment. This section outlines essential practices for maintaining the transmission system effectively.

| Tip | Description |

|---|---|

| Fluid Checks | Regularly inspect the transmission fluid levels and quality. Ensure that the fluid is clean and at the appropriate level to facilitate smooth operation. |

| Filter Replacement | Replace the transmission filter according to the manufacturer’s recommendations. A clean filter helps to remove contaminants that can cause damage. |

| Inspect Seals and Gaskets | Regularly examine seals and gaskets for any signs of wear or leaks. Promptly address any issues to prevent fluid loss and maintain performance. |

| Cooler Maintenance | Ensure that the transmission cooler is free of debris and functioning correctly. This helps to regulate temperature and prevent overheating. |

| Routine Testing | Conduct routine diagnostic tests to check for any irregularities in performance. Early detection of issues can save time and resources in the long run. |

Parts Replacement Process

Replacing components in machinery is a crucial aspect of maintenance that ensures optimal performance and longevity. This process involves careful planning, the right tools, and knowledge of the specific parts involved. Properly executing each step can prevent further issues and enhance the efficiency of the equipment.

The following table outlines the general steps involved in the parts replacement procedure:

| Step | Description |

|---|---|

| 1 | Identify the faulty component by conducting a thorough inspection. |

| 2 | Gather the necessary tools and replacement parts needed for the job. |

| 3 | Disconnect power sources and ensure safety measures are in place. |

| 4 | Carefully remove the defective part, noting how it is connected. |

| 5 | Install the new component, ensuring it is secure and correctly positioned. |

| 6 | Reconnect power and test the machinery to confirm proper functionality. |

Following this systematic approach will help in achieving successful replacements, ultimately enhancing the overall performance of the equipment.

Using the Repair Manual Effectively

Utilizing a comprehensive guide can significantly enhance the maintenance and troubleshooting process for machinery. By understanding how to navigate and interpret the information provided, users can ensure optimal performance and longevity of their equipment.

Here are some strategies for making the most of your guide:

- Familiarize Yourself with the Structure: Start by understanding the layout of the document. Look for sections dedicated to common issues, parts lists, and maintenance schedules.

- Utilize the Index: The index can be an invaluable tool. It allows you to quickly locate specific topics or components, saving time and effort during the diagnostic process.

- Follow Step-by-Step Instructions: When performing repairs or maintenance, adhere strictly to the outlined procedures. Each step is designed to ensure safety and effectiveness.

- Refer to Diagrams and Illustrations: Visual aids can greatly enhance your understanding. Make sure to consult diagrams for a clearer view of assembly and disassembly.

- Take Notes: While working, jot down important observations or modifications. This can help in future maintenance tasks and improve efficiency.

By implementing these approaches, you can maximize the benefits of your guide, leading to more successful and efficient equipment upkeep.

Safety Precautions During Repairs

Ensuring safety while performing maintenance tasks is crucial for preventing accidents and injuries. Proper awareness and adherence to safety guidelines can create a secure environment, enabling efficient work without unnecessary risks. Before beginning any maintenance procedure, it is essential to recognize potential hazards and take appropriate measures to mitigate them.

Personal Protective Equipment

Utilizing personal protective equipment (PPE) is a fundamental aspect of maintaining safety standards. Essential gear includes safety goggles to protect the eyes from debris, gloves to shield the hands from sharp objects and chemicals, and steel-toed boots for foot protection. Additionally, wearing hearing protection is advisable when working with loud machinery to prevent hearing loss over time.

Work Area Safety

Maintaining a tidy and organized workspace significantly reduces the risk of accidents. Ensure that tools and equipment are stored properly and that any spills are cleaned promptly. Furthermore, adequate lighting is vital for visibility, allowing for precise work and minimizing the chance of mishaps. Always be aware of your surroundings and the potential for equipment movement during maintenance tasks.

Finding OEM Parts for John Deere

Locating original equipment manufacturer components is essential for maintaining the performance and longevity of your machinery. These parts are specifically designed to fit and function perfectly with your equipment, ensuring optimal operation and reliability.

To effectively source these components, consider the following steps:

- Identify the specific part number you need. This information can usually be found in the product documentation or on the existing part itself.

- Visit official websites of manufacturers to access their catalogs and online stores.

- Check with local dealers who specialize in agricultural or industrial equipment for availability.

- Explore reputable online marketplaces that focus on OEM parts.

Additionally, joining online forums and communities can provide valuable insights and recommendations from other users who have successfully sourced parts. Engaging with these groups can also help you discover alternative sources or aftermarket options if needed.

Always ensure that you are purchasing from reliable sources to avoid counterfeit products, which can lead to performance issues and potential damage to your machinery.