Comprehensive Guide to Repairing SWF Embroidery Machines

In the realm of textile arts, having reliable tools is essential for achieving high-quality results. Understanding how to troubleshoot and maintain these devices can significantly enhance your crafting experience. Whether you’re a novice or a seasoned expert, having a solid foundation in equipment care ensures that your creative projects run smoothly.

Every device has its quirks and potential issues that can arise over time. This section aims to provide valuable insights into common challenges, preventive measures, and solutions to keep your tools functioning optimally. With the right knowledge, you can minimize downtime and maximize productivity, allowing your artistic visions to flourish.

Equipping yourself with essential information about your equipment not only boosts efficiency but also fosters a deeper appreciation for the craft. From understanding components to implementing maintenance routines, mastering these aspects will empower you to tackle any hurdles with confidence. Embrace the journey of exploration and learn how to maintain your indispensable crafting ally.

Overview of SWF Embroidery Machines

This section provides a comprehensive understanding of a specific type of textile crafting equipment renowned for its versatility and advanced features. These devices are designed to facilitate intricate designs and patterns, catering to a wide range of creative applications. They are popular among both hobbyists and professionals, thanks to their user-friendly interfaces and robust performance.

Key Features

One of the standout characteristics of these units is their ability to handle complex designs with precision. With multiple needle capabilities, they allow for diverse thread colors and textures, enhancing the final output. Additionally, built-in software supports customization, enabling users to create unique artworks tailored to their needs.

Applications and Uses

The versatility of this type of equipment makes it suitable for various applications, from fashion design to promotional items. Businesses benefit from the efficiency and quality that these tools provide, ensuring high standards in production. Moreover, they are ideal for personal projects, offering an enjoyable way to explore creativity in textile art.

Common Issues with SWF Models

When operating specialized textile devices, users may encounter various challenges that can affect performance and output quality. Understanding these common difficulties can aid in troubleshooting and enhance the longevity of the equipment.

- Thread Breakage:

This issue can arise due to improper threading, tension settings, or low-quality thread. Regularly checking these elements can minimize disruptions.

- Skipped Stitches:

Skipped stitches can occur if the needle is dull or incorrectly installed. Ensuring that the correct needle type and size are used is crucial.

- Fabric Feeding Problems:

Poor fabric feeding can lead to uneven stitching. This may be caused by incorrect tension or issues with the feed dogs.

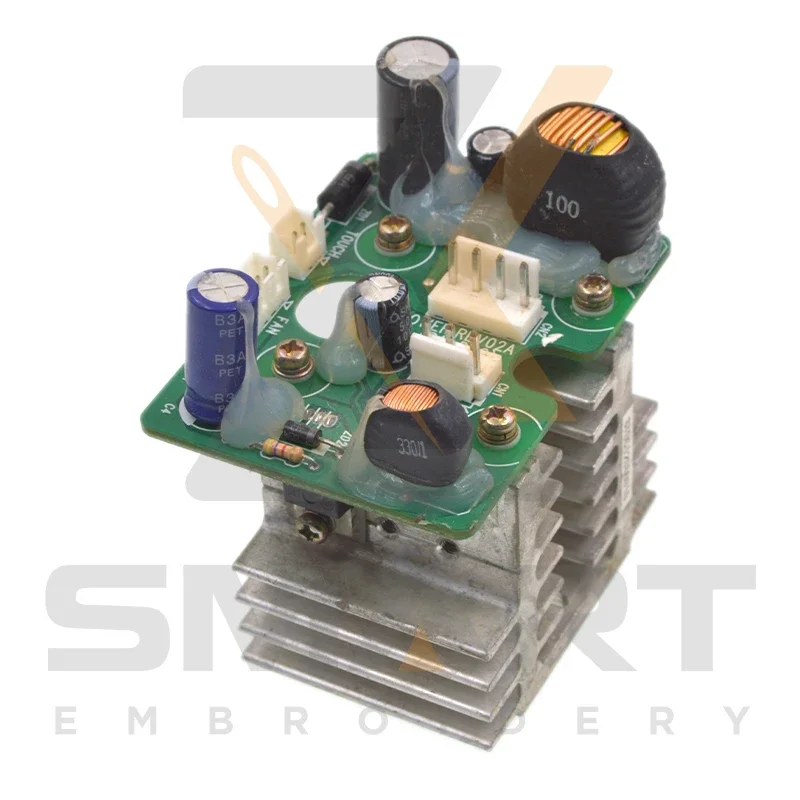

- Electrical Failures:

Electrical components may sometimes malfunction, resulting in the device not powering on or displaying error codes. Regular inspection of connections is advised.

- Software Glitches:

Occasionally, the operating software may exhibit bugs or incompatibilities. Keeping the software updated can help avoid these complications.

Addressing these common issues promptly can significantly enhance performance and ensure a smoother operation. Regular maintenance and attention to detail are key to achieving optimal results.

Essential Tools for Machine Repair

Having the right instruments at hand is crucial for maintaining and troubleshooting your equipment effectively. A well-equipped toolkit not only streamlines the process but also enhances the quality of your work. Understanding which tools are fundamental can save time and prevent potential issues down the line.

Basic Hand Tools

Start with a selection of screwdrivers in various sizes, as they are vital for accessing internal components. A good set of wrenches is also essential for loosening and tightening nuts and bolts. Additionally, pliers come in handy for gripping and manipulating small parts. Always ensure that your tools are of high quality to avoid damage to delicate mechanisms.

Advanced Equipment

For more intricate tasks, consider investing in multimeters to diagnose electrical issues. Lubricants and cleaning solutions are necessary for maintaining optimal performance and longevity. Furthermore, specialized tools like calipers can assist in measuring components accurately, ensuring everything fits perfectly during reassembly.

Step-by-Step Troubleshooting Guide

This section provides a systematic approach to identifying and resolving common issues that may arise during the operation of your device. Following these steps will help you pinpoint problems and implement effective solutions, ensuring optimal performance and longevity.

Begin by checking the power source to confirm that the device is receiving electricity. Ensure that all connections are secure and that the outlet is functional. If the device does not power on, try a different outlet or inspect the power cord for damage.

Next, examine the settings and configurations. Incorrect adjustments can lead to operational failures. Refer to the user interface to verify that all parameters are set correctly for your intended use.

If you encounter errors or malfunctions during operation, consult the error codes displayed on the interface. Each code typically corresponds to a specific issue, providing insight into what may be malfunctioning.

Inspect all moving parts and components for obstructions or wear. Accumulation of debris or lack of lubrication can hinder performance. Clean and maintain these areas regularly to prevent future complications.

Lastly, if issues persist, consider consulting the comprehensive resource guide for more in-depth solutions or reach out to a qualified technician for assistance. Documenting your troubleshooting steps can also be helpful for future reference.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your equipment requires consistent care and attention. Implementing a routine maintenance schedule can significantly extend its lifespan and improve functionality. Here are some essential practices to keep your device in top condition.

Regular Cleaning

Accumulation of dust and debris can hinder performance. Frequently clean the exterior and interior components using appropriate tools. Pay special attention to areas where lint and threads gather, as these can obstruct moving parts and lead to malfunctions.

Proper Lubrication

Regularly lubricate key components to minimize friction and wear. Use high-quality oils recommended for your specific equipment to ensure smooth operation. Avoid over-lubrication, as excess oil can attract dirt and debris, counteracting your maintenance efforts.

Understanding Machine Error Codes

Error codes are essential indicators that provide crucial insights into the operational status of your device. These codes can help identify issues that may arise during use, allowing for quicker diagnosis and resolution. Understanding these signals can significantly enhance the efficiency of your workflow and prolong the lifespan of the equipment.

Common Error Codes and Their Meanings

Familiarizing yourself with typical error codes is vital for effective troubleshooting. Below are some frequently encountered codes and their implications:

- Error Code 01: Indicates a threading issue, often related to improper installation of the thread or a blockage in the path.

- Error Code 02: Signals a sensor malfunction, which may require recalibration or replacement.

- Error Code 03: Suggests a mechanical jam that may need manual intervention to resolve.

- Error Code 04: Points to a power supply problem, potentially necessitating a check of connections.

Tips for Troubleshooting

When faced with an error code, follow these guidelines to efficiently address the issue:

- Refer to the documentation for a comprehensive list of codes and their meanings.

- Inspect the device for any visible issues, such as loose threads or connections.

- Reset the system to see if the error persists after a reboot.

- If the problem remains unresolved, consult a professional technician for further assistance.

By understanding and addressing error codes promptly, you can maintain optimal performance and avoid prolonged downtime.

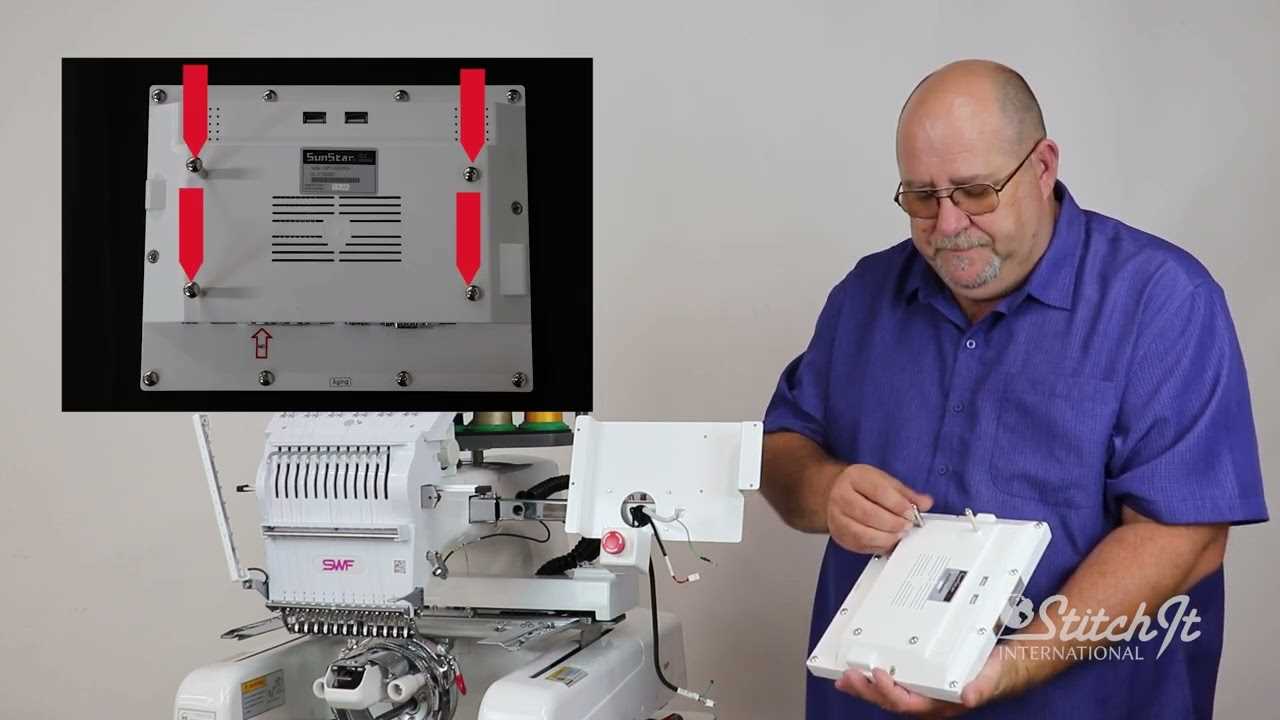

Replacing Parts on SWF Machines

Maintaining optimal performance in specialized equipment often requires the replacement of certain components. Understanding the process of substituting worn-out or malfunctioning parts is crucial for ensuring longevity and efficiency. This section provides insights into the steps and considerations necessary for effective component swaps.

Before initiating the replacement process, it is vital to identify the specific part that requires attention. Familiarity with the equipment’s assembly and common failure points can streamline this identification. Consulting available documentation or support resources may provide additional guidance on common issues and compatible alternatives.

Once the defective component has been located, the next step involves acquiring the appropriate replacement. Utilizing genuine parts is recommended to guarantee compatibility and performance. Always verify that the new component matches the specifications of the original to avoid complications during installation.

When preparing for the replacement, ensure that the equipment is powered down and disconnected from any power source. This precaution not only enhances safety but also prevents accidental damage to other components. Using the correct tools for the job will facilitate a smooth transition and minimize the risk of errors.

After the old part has been removed, carefully install the new one, following any manufacturer guidelines or instructional materials. Secure it properly to avoid future issues, and double-check connections to ensure everything is in order. Once installation is complete, reconnect the power and conduct a test to confirm that the equipment is functioning as expected.

Regular maintenance and timely replacements can significantly extend the lifespan of the equipment. By following these procedures, operators can maintain high performance and reduce the likelihood of future breakdowns.

Calibration and Setup Procedures

This section outlines essential steps for ensuring optimal performance of your device. Proper alignment and configuration are crucial for achieving precise results and maintaining longevity.

Follow these steps for effective calibration:

- Initial Assessment:

- Inspect all components for wear and tear.

- Ensure that the workspace is clean and free from obstructions.

- Positioning:

- Place the unit on a stable surface.

- Verify that all attachments are securely fastened.

- Calibration Settings:

- Access the configuration menu.

- Adjust parameters according to the manufacturer’s specifications.

- Testing:

- Run a test sequence to evaluate performance.

- Monitor for any discrepancies or unusual sounds.

- Final Adjustments:

- Make necessary tweaks based on test results.

- Document all settings for future reference.

By following these calibration and setup procedures, you can enhance the functionality and efficiency of your apparatus, ensuring reliable outcomes for various tasks.

When to Seek Professional Help

Understanding when to call in an expert can save time and prevent further complications. Certain signs indicate that a skilled technician is necessary to address issues effectively and efficiently. Recognizing these moments is crucial for maintaining optimal performance and longevity.

Signs That Indicate Professional Assistance is Needed

- Persistent malfunction despite troubleshooting efforts

- Unusual noises or vibrations during operation

- Frequent errors that disrupt functionality

- Physical damage or wear that affects performance

- Inability to achieve desired results, such as consistent quality

Benefits of Seeking Expertise

- Access to specialized knowledge and experience

- Potentially lower long-term costs by preventing further damage

- Faster resolution of complex issues

- Improved performance and reliability of the device

In cases where problems persist or worsen, reaching out to a professional is often the best course of action. Their expertise can ensure that your equipment operates smoothly and effectively, minimizing downtime and maximizing output.