Comprehensive Guide to John Deere 6200 Repair Manual

In the world of agricultural machinery, understanding the intricacies of your equipment is crucial for optimal performance. This guide aims to provide valuable insights into the upkeep and troubleshooting of a specific tractor model, ensuring that operators can maximize efficiency and longevity.

With a wealth of information on common issues, this resource offers step-by-step solutions and preventative measures. Emphasizing practical knowledge, it serves as a comprehensive reference for both seasoned professionals and novice users alike, fostering confidence in handling mechanical challenges.

By delving into the specifics of care and maintenance, this guide empowers users to tackle potential malfunctions proactively. From regular inspections to detailed troubleshooting techniques, it lays the groundwork for a deeper understanding of your machinery’s operational needs, ultimately leading to improved productivity.

Understanding John Deere 6200 Features

This section delves into the distinctive attributes and functionalities of a well-regarded agricultural machine, highlighting its efficiency and user-friendly design. A comprehensive understanding of these elements can significantly enhance the operational experience and maintenance practices.

Key Attributes

- Powerful Engine: Equipped with a robust power unit that ensures optimal performance in various farming tasks.

- Hydraulic System: Features an advanced hydraulic mechanism that facilitates seamless attachment and operation of implements.

- Cab Comfort: Designed with ergonomic seating and controls for enhanced operator comfort during extended hours of use.

Functional Capabilities

- Versatility: Suitable for a range of applications, from tilling to hauling, making it a valuable asset for diverse farming needs.

- Fuel Efficiency: Engineered to minimize fuel consumption, allowing for cost-effective operation without sacrificing power.

- Durability: Constructed with high-quality materials that ensure longevity and resilience in demanding environments.

Common Issues with John Deere 6200

When it comes to agricultural machinery, certain recurring problems can arise that may hinder performance and efficiency. Understanding these common challenges is crucial for maintaining optimal functionality and ensuring longevity.

Here are some frequent concerns faced by operators:

- Engine Performance: Many users report issues such as poor starting, stalling, or reduced power output. These can often stem from fuel system problems or air filter blockages.

- Hydraulic System Failures: Leaks or loss of pressure in the hydraulic system can lead to a decrease in lifting capability, affecting overall operation.

- Electrical Problems: Electrical failures, including faulty wiring or malfunctioning sensors, can disrupt various functions, making troubleshooting essential.

- Transmission Issues: Operators may experience slipping or difficulty shifting gears, often linked to fluid levels or mechanical wear.

By identifying these prevalent issues early, users can implement effective strategies to address them, minimizing downtime and maintaining productivity.

Maintenance Tips for Your Tractor

Regular upkeep is essential for ensuring the longevity and efficiency of your agricultural machinery. Proper care not only enhances performance but also minimizes the risk of unexpected breakdowns. Here are some key practices to consider for optimal operation.

1. Check Fluid Levels

Regularly inspect the levels of essential fluids such as engine oil, coolant, and hydraulic fluid. Maintaining appropriate levels helps prevent overheating and mechanical failure. Always use the recommended types of fluids for your equipment.

2. Clean the Air Filter

A clean air filter is crucial for optimal engine performance. Inspect and clean or replace the air filter periodically to ensure efficient airflow. This practice helps prevent dust and debris from entering the engine, prolonging its lifespan.

3. Inspect Tires

Ensure that your tires are properly inflated and show no signs of excessive wear. Regularly check for any punctures or damage that could affect performance. Adequate tire maintenance contributes to better traction and fuel efficiency.

4. Grease Moving Parts

Regular lubrication of moving components minimizes friction and wear. Use the appropriate grease for various parts, such as bearings and joints, as specified in your equipment guidelines. This will enhance overall functionality and reduce the risk of breakdowns.

5. Schedule Routine Inspections

Establish a routine for thorough inspections of your machinery. Regular checks allow you to identify potential issues before they become major problems. Keep a log of all maintenance activities to track performance and service history.

By incorporating these maintenance strategies into your routine, you can help ensure that your agricultural machinery operates smoothly and efficiently for years to come.

How to Access Repair Manuals

Finding the right guidance for equipment maintenance can greatly enhance the longevity and performance of your machinery. Accessing detailed documentation is essential for troubleshooting, performing routine check-ups, or addressing complex issues. This section will provide insights into effective methods for obtaining essential resources.

Online Resources

The internet offers a plethora of platforms where you can find comprehensive documentation. Websites dedicated to agricultural machinery often host digital copies of various guides. Utilizing search engines to look for specific models can yield valuable results, including downloadable PDFs and user forums where enthusiasts share their insights and experiences.

Local Dealers and Workshops

Another reliable avenue is reaching out to authorized dealers or service centers. These establishments often have access to the most up-to-date literature and can provide hard copies or direct you to official sources. Additionally, they may offer consultation services to help with specific issues, ensuring that your machinery operates smoothly.

Essential Tools for Repairs

When it comes to maintaining agricultural machinery, having the right instruments at your disposal can significantly enhance efficiency and effectiveness. A well-equipped toolkit not only simplifies the process but also ensures that tasks are completed safely and accurately. Understanding which tools are necessary for various maintenance tasks is crucial for any operator or technician.

Wrenches are fundamental for loosening and tightening bolts and nuts. An assortment of sizes will accommodate different components, allowing for versatile use. Screwdrivers also play a vital role, as they are needed to access and secure various panels and mechanisms. A set with both flat and Phillips heads is recommended for comprehensive coverage.

Additionally, pliers are indispensable for gripping, twisting, and cutting wires or other materials. For more complex operations, having a socket set can save time and effort, as it allows for quick changes between sizes and types. Torque wrenches are essential for applying precise force, ensuring components are fastened correctly without risk of damage.

Lastly, safety gear should never be overlooked. Items like gloves, goggles, and ear protection ensure that maintenance work is performed without risking personal injury. Investing in quality tools and protective equipment lays the groundwork for successful upkeep and longevity of your machinery.

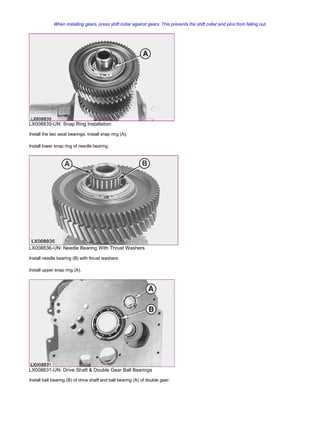

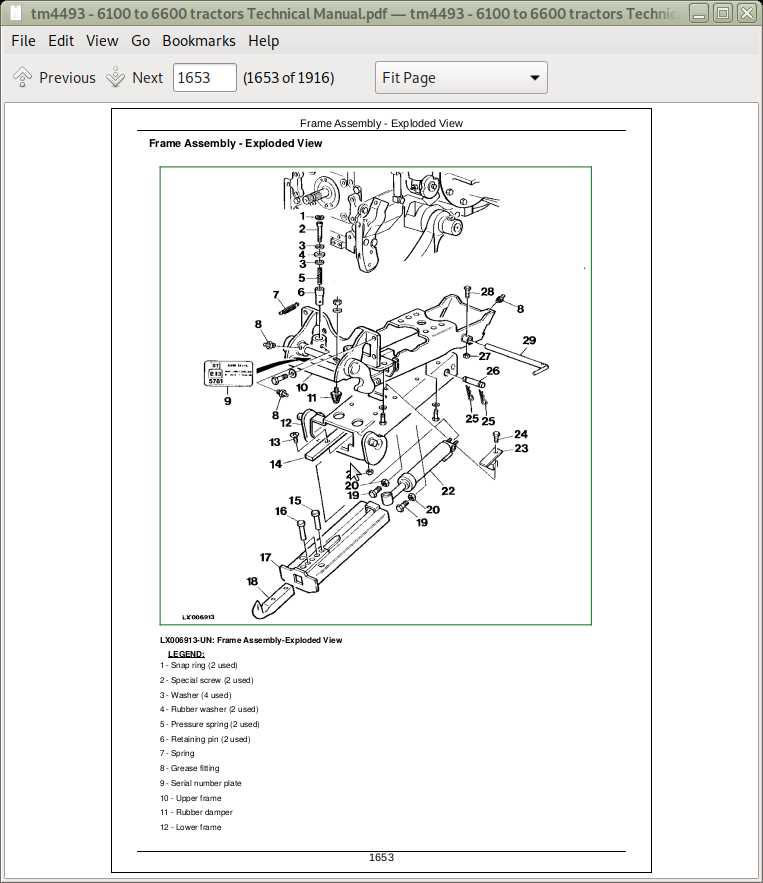

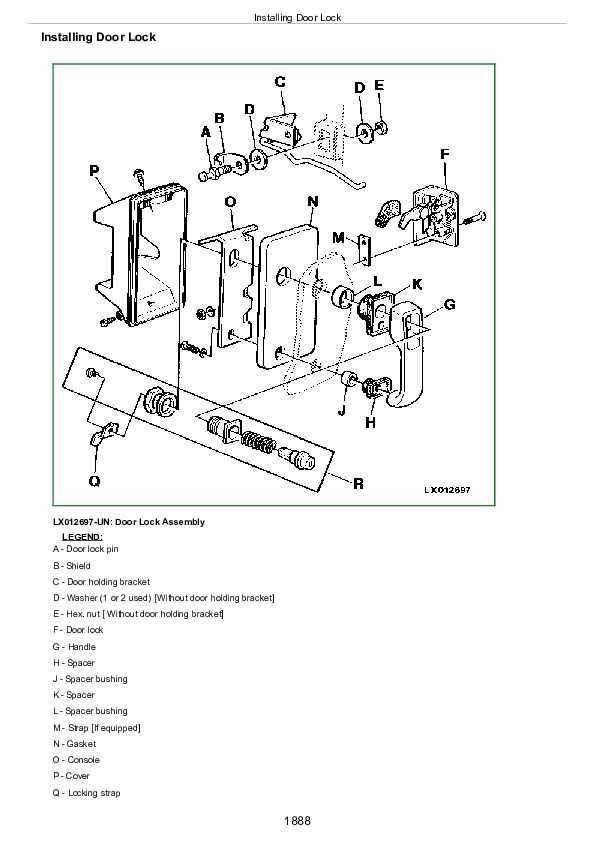

Step-by-Step Repair Procedures

This section provides a comprehensive guide to addressing common issues encountered during maintenance. Following a systematic approach ensures efficiency and effectiveness, allowing you to restore equipment to optimal working condition.

Preparation

- Gather all necessary tools and equipment.

- Review the specific issue to determine the best approach.

- Ensure a clean and organized workspace.

Diagnostic Steps

- Conduct a visual inspection for any obvious signs of wear or damage.

- Check fluid levels and inspect for leaks.

- Test all electrical components to confirm functionality.

- Document any findings for reference during the repair process.

Following these procedures will facilitate a smoother restoration process and enhance the longevity of your machinery.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance tasks is paramount to prevent accidents and injuries. Proper precautions not only protect the individual performing the work but also safeguard the machinery and surrounding environment. By adhering to specific guidelines, one can minimize risks and enhance overall efficiency.

Wear Appropriate Personal Protective Equipment (PPE): Always don suitable gear, such as gloves, goggles, and hard hats, to shield against potential hazards. This equipment is essential for protecting against cuts, falling objects, and harmful substances.

Disconnect Power Sources: Before beginning any service, it is crucial to disconnect power sources to eliminate the risk of unintended activation. This includes turning off engines and removing batteries to ensure a safe working environment.

Use Proper Tools and Equipment: Utilizing the correct tools is vital for both efficiency and safety. Make sure tools are well-maintained and appropriate for the task at hand, as improper equipment can lead to accidents.

Work in a Well-Ventilated Area: Ensure that the workspace is adequately ventilated to avoid exposure to toxic fumes and maintain air quality. This is especially important when working with chemicals or during tasks that generate dust.

Keep the Workspace Organized: A tidy work area can prevent trips and falls. Ensure that all tools and materials are stored properly and that the floor is free from obstructions.

Be Aware of Surroundings: Always stay alert to your environment and the activities of others. Awareness can help you anticipate potential dangers and react appropriately.

By following these essential safety measures, individuals can greatly reduce the likelihood of accidents and create a more productive atmosphere during maintenance tasks.

When to Seek Professional Help

Recognizing the right moment to consult an expert can be crucial in maintaining optimal performance and longevity of your machinery. While some tasks may seem manageable, others require specialized knowledge to prevent further complications.

Signs That Indicate a Need for Expertise

Look for warning signals such as persistent unusual noises, irregular operation, or frequent breakdowns. If basic troubleshooting does not yield results, it may be time to call in a professional.

Benefits of Professional Assistance

Enlisting the help of a specialist ensures that complex issues are diagnosed accurately and resolved effectively. Their experience can ultimately save time and resources, providing peace of mind and reliability.

Parts and Accessories for 6200

When maintaining and enhancing the performance of agricultural machinery, selecting the right components and supplementary items is crucial. These elements not only ensure the equipment operates smoothly but also contribute to its longevity and efficiency. This section will provide insights into essential parts and useful accessories that can elevate the functionality of your machinery.

| Part/Accessory | Description | Benefits |

|---|---|---|

| Fuel Filters | Devices that remove contaminants from fuel. | Improves engine performance and fuel efficiency. |

| Air Filters | Filters that clean incoming air for combustion. | Enhances engine life and reduces emissions. |

| Hydraulic Hoses | Flexible tubes that transport hydraulic fluid. | Ensures optimal hydraulic system operation. |

| Belts and Chains | Components that transmit power within the machine. | Improves efficiency and reduces wear on machinery. |

| Seat Cushions | Comfort-enhancing accessories for operator seats. | Improves operator comfort and reduces fatigue. |

| LED Work Lights | High-efficiency lighting for nighttime operation. | Increases visibility and safety during work hours. |

FAQs About John Deere 6200 Repairs

This section addresses common inquiries regarding maintenance and troubleshooting for the specified agricultural machine. Understanding these aspects can enhance the longevity and efficiency of your equipment.

Common Issues

- What are typical problems that may arise with this model?

- How can I identify if my machine needs attention?

- What are the signs of wear and tear that I should watch for?

Maintenance Tips

- How often should I perform routine checks?

- What are the essential components that require regular maintenance?

- Are there specific lubricants or fluids recommended for optimal performance?

By addressing these frequently asked questions, operators can ensure their machinery remains in peak condition, reducing downtime and enhancing productivity.